Anti-corrosion high-toughness lead storage battery plastic shell

A lead-acid battery, high toughness technology, applied in the direction of lead-acid batteries, battery components, circuits, etc., can solve the problems of lead-acid batteries not being resistant to corrosion, mechanical properties decline, etc., to achieve high curing efficiency, short curing time, and uniform structure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

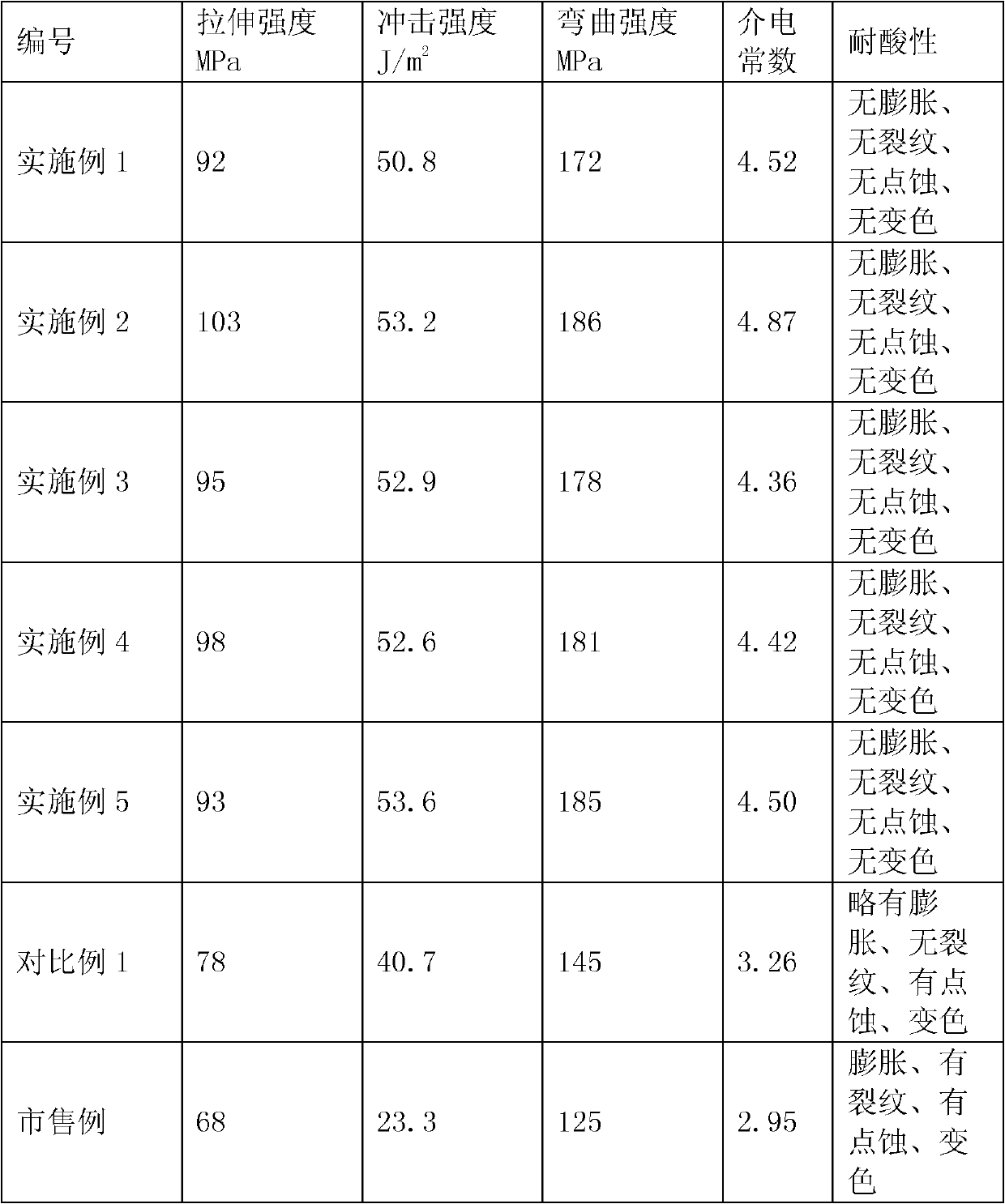

Examples

Embodiment 1

[0045] An anti-corrosion and high-toughness plastic case for lead storage batteries, which is composed of an organic-inorganic composite board inside the plastic case and a plastic case coated on the outside of the organic-inorganic composite board. The surface of the organic-inorganic composite board is also coated with a layer containing Fluorine coating.

[0046] The plastic casing includes the following components in parts by weight: 80 parts of ABS resin, 10 parts of toughened glass fiber with organic resin, 3 parts of chlorinated polyethylene, aluminum hydroxide and tetrabromobisphenol A with a mass ratio of 4:5 10 parts of the composition, 1 part of the composition with a mass ratio of antimony trioxide and lanthanum oxide of 5:1, 1 part of calcium carbonate and 0.1 part of stearic acid amide.

[0047] The preparation method of organic resin toughened glass fiber is as follows:

[0048] (1) Pore-making: Soak the glass filaments in 0.01mol / L hydrofluoric acid and 0.1mol...

Embodiment 2

[0062] An anti-corrosion and high-toughness plastic case for lead storage batteries, which is composed of an organic-inorganic composite board inside the plastic case and a plastic case coated on the outside of the organic-inorganic composite board. The surface of the organic-inorganic composite board is also coated with a layer containing Fluorine coating.

[0063] The plastic casing includes the following components in parts by weight: 100 parts of ABS resin, 25 parts of toughened glass fiber with organic resin, 10 parts of chlorinated polyethylene, a combination of aluminum hydroxide and tetrabromobisphenol A with a mass ratio of 4:10 15 parts of compound, 5 parts of antimony trioxide and lanthanum oxide composition with a mass ratio of 10:1, 3 parts of sepiolite and 0.5 part of ethylene bisstearamide.

[0064] The preparation method of organic resin toughened glass fiber is as follows:

[0065] (1) Pore-making: Soak glass filaments in 0.05mol / L hydrofluoric acid and 0.15m...

Embodiment 3

[0079] An anti-corrosion and high-toughness plastic case for lead storage batteries, which is composed of an organic-inorganic composite board inside the plastic case and a plastic case coated on the outside of the organic-inorganic composite board. The surface of the organic-inorganic composite board is also coated with a layer containing Fluorine coating.

[0080] The plastic case includes the following components in parts by weight: 85 parts of ABS resin, 15 parts of toughened glass fiber with organic resin, 5 parts of chlorinated polyethylene, a combination of aluminum hydroxide and tetrabromobisphenol A with a mass ratio of 4:6 12 parts of compound, 3 parts of antimony trioxide and lanthanum oxide composition with a mass ratio of 6:1, 2 parts of quartz powder and 0.3 parts of ethylene bis stearic acid amide.

[0081] The preparation method of organic resin toughened glass fiber is as follows:

[0082] (1) Pore-making: Soak the glass filaments in 0.03mol / L hydrofluoric ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com