Preparation method of nano ZnO/graphene composite material

A composite material, graphene technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low yield and long reaction time, and achieve high yield and short reaction time. , The effect of uniform and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

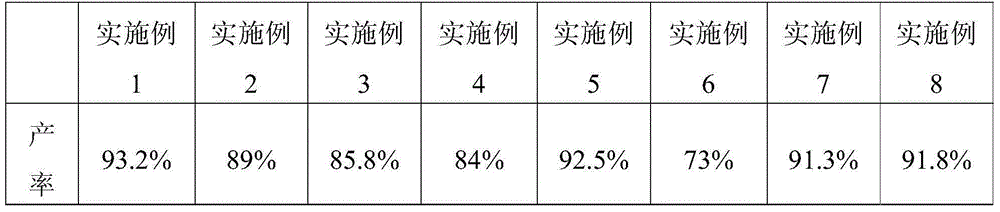

Examples

Embodiment 1

[0023] 10 mL of nano-ZnO solution with a concentration of 1 mg / mL was uniformly mixed with 10 mL of CRGO (chemically reduced graphene oxide solution) with a concentration of 0.1 mg / mL. Then the mixed solution was put into an ultrasonic instrument, and the ultrasonic reaction was performed for 2 hours under the conditions of a frequency of 40KHz and a power of 150W. After the reaction, the product is centrifuged and washed to obtain a nanometer ZnO-graphene composite material.

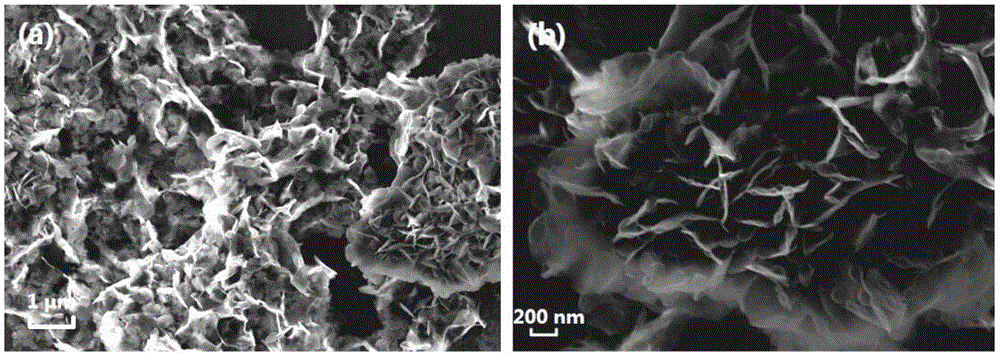

[0024] The obtained nanometer ZnO-graphene composite material is carried out scanning electron microscope, and its result is as follows figure 1 As shown, it is found that the composite material forms a three-dimensional microporous shape, and the nano-ZnO particles are coated inside the graphene, forming a shape similar to a pea pod.

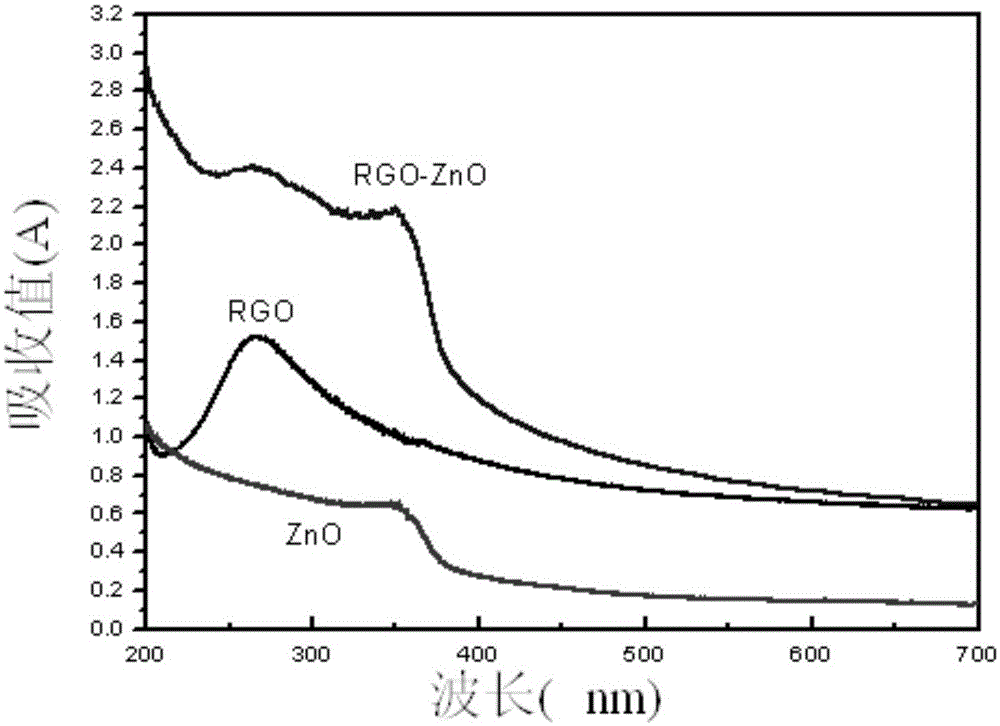

[0025] The composite material was characterized by ultraviolet-visible light absorption spectrum, and the results were as follows: figure 2 As shown, it is found that...

Embodiment 2

[0027] Mix 10 mL of nano-ZnO solution with a concentration of 5 mg / mL with 10 mL of CRGO with a concentration of 1 mg / mL. Then the mixture was put into an ultrasonic instrument, and the ultrasonic reaction was performed for 1 hour under the conditions of a frequency of 40KHz and a power of 200W. After the reaction, the product is centrifuged and washed to obtain a composite material.

Embodiment 3

[0029] Mix 10 mL of 0.02 mg / mL nano-ZnO particle solution with 10 mL of 0.01 mg / mL CRGO evenly. Then the mixed solution was put into an ultrasonic instrument, and the ultrasonic reaction was performed for 4 hours under the condition of a frequency of 40KHz and a power of 40W. After the reaction, the product is centrifuged and washed to obtain a composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com