Zirconium diboride and short carbon fiber modified thermal shock resistant and ablation resistant SiBCN ceramic material and preparation method thereof

A technology of short carbon fiber and ceramic materials, which is applied in the field of SiBCN ceramic materials and its preparation, can solve the problems of poor thermal shock resistance and ablation resistance, and achieve the effects of improved thermal shock resistance, extended crack propagation path, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

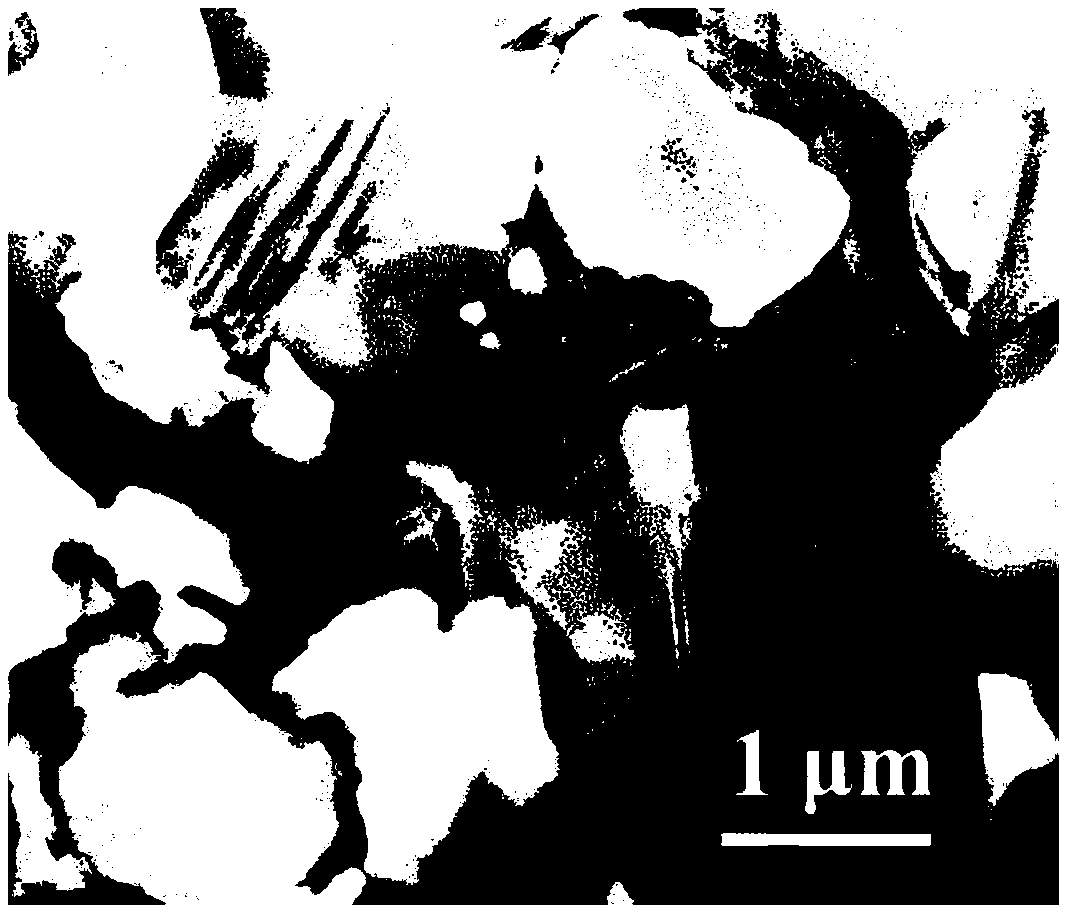

[0033] Specific embodiment 1: The thermal shock-resistant and ablation-resistant SiBCN ceramic material modified by zirconium diboride and short carbon fiber in this embodiment is composed of SiBCN, short carbon fiber and ZrB 2 Composite; the volume fraction of short carbon fibers in the thermal shock-resistant and ablation-resistant SiBCN ceramic material is 5-10vol%, ZrB 2 The mass fraction is 10-30 wt%, and the balance is SiBCN.

[0034] The principles and beneficial effects of this embodiment are:

[0035] 1. The thermal shock-resistant and ablation-resistant SiBCN ceramic material modified by zirconium diboride and short carbon fibers in this embodiment has excellent mechanical properties, thermal shock resistance and ablation resistance. Among them, the mechanical properties of materials can be developed through different structures and C f (short carbon fiber) is introduced to design, and its main strengthening mechanism is through the developed BN(C) sheet and short ...

specific Embodiment approach 2

[0038] Embodiment 2: This embodiment is different from Embodiment 1 in that: the length of the short carbon fibers is 1-2 mm; the diameter is 5-8 μm. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0039] Specific embodiment three: The preparation method of the thermal shock-resistant and ablation-resistant SiBCN ceramic material modified by zirconium diboride and short carbon fiber in this embodiment is carried out according to the following steps:

[0040] Step 1: Add silicon powder, graphite powder, hexagonal boron nitride powder and zirconium diboride powder into a high-energy ball mill, and conduct ball milling under the protection of argon to obtain nano-SiBCN-ZrB 2 powder;

[0041] The mol ratio of silicon powder, graphite powder and hexagonal boron nitride powder described in step one is 4: (5~7): (1~3), the total mass of silicon powder, graphite powder and hexagonal boron nitride powder and diboron The mass ratio of zirconium powder is: 1:(0.1~0.3);

[0042] Step 2: Nano-SiBCN-ZrB 2 The powder is mixed with short carbon fibers, placed in absolute ethanol for ultrasonic dispersion for 15-30 minutes, and then ball milled to obtain ceramic slurry;

[0043] Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com