Patents

Literature

62results about How to "Widen the temperature range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot rolled steel plate for punch process and method of manufacturing the same

InactiveCN101293321ALow phase transition pointReduce nucleation rateTemperature control deviceSheet steelPunching

The invention belongs to the technical field of metal materials and preparation thereof, in particular to a hot-roll steel plate used for punching processing and a preparation method thereof. The invention is that boron alloy is added in the refining process of a low carbon-aluminum piping steel; the mol ratio of boron and nitrogen in a steel liquid is 0.81 to 1.10; the content of the nitrogen in the steel during the continuous casting process is not higher than 60ppm; the temperature for a casting blank to enter a soaking furnace is 900 to 949 DEG C; rough rolling is carried out after the soaking furnace is heated to the temperature of 1050 to 1099 DEG C; the temperature of a low-carbon steel plate containing boron or tape reel is lower by 40 to 60 DEG C than the transformation temperature of a traditional low-carbon steel austenite without boron to a ferrite in the refining process; after final rolling, a plate belt is cooled to the temperature of 560 to 650 DEG C at the speed of 5 to 20 DEG C / s; the temperature of a steel belt is 540 to 630 DEG C when coiling. The hot-roll steel plate used for punching processing manufactured by the method can ensure that the yielding strength of a product is lower than 260MPa, the anti-tension intensity is lower than 370MPa and the extension rate is higher than 45 percent.

Owner:CENT IRON & STEEL RES INST +1

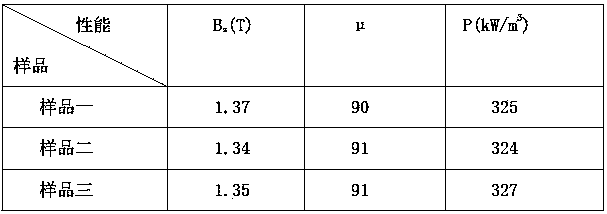

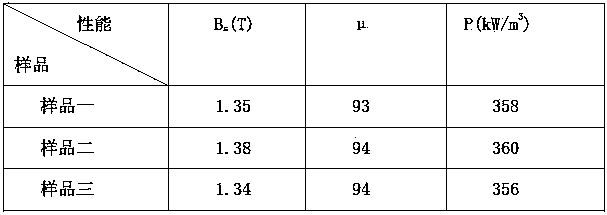

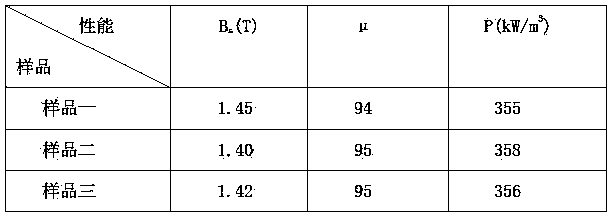

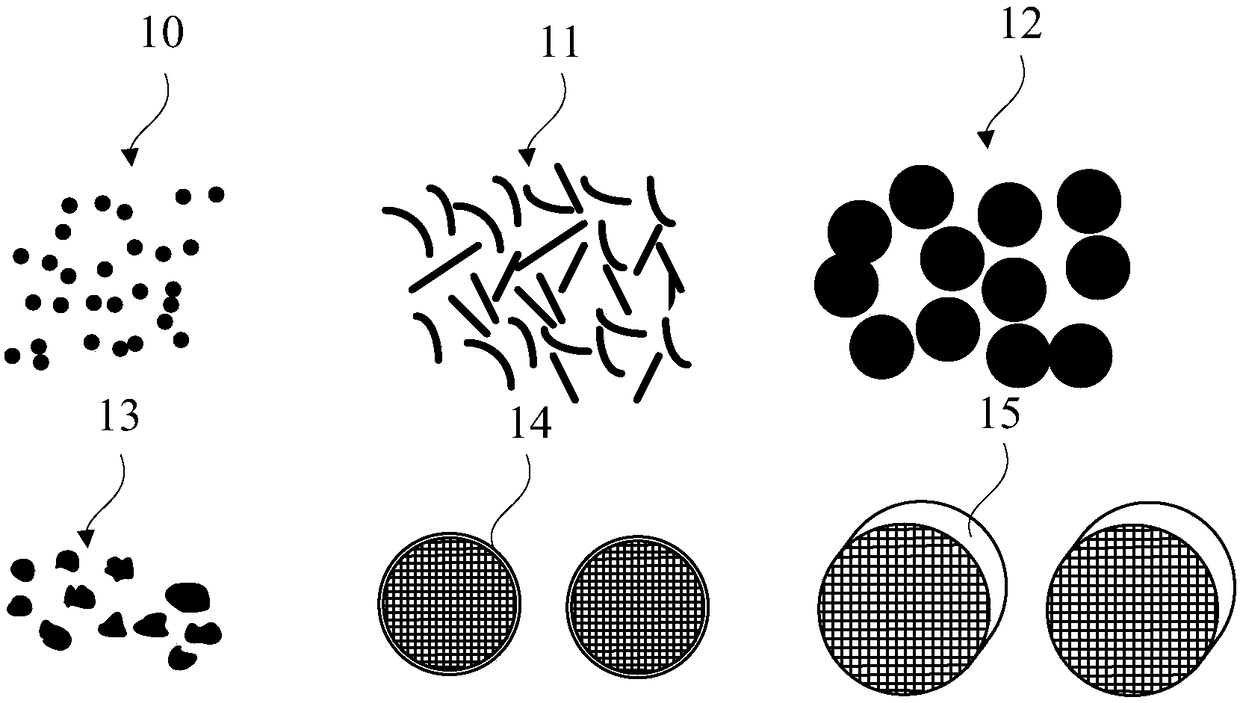

High saturation magnetic induction intensity iron-based amorphous soft magnetic composite material and manufacturing method thereof

InactiveCN104036904AHigh saturation magnetic inductionImprove self-fluxingMagnetic materialsCompression moldingElectron

The invention discloses a high saturation magnetic induction intensity iron-based amorphous soft magnetic composite material and a manufacturing method of the composite material. The atomic ratio expression of the alloy composition forming the amorphous soft magnetic composite material is Fe100-a-b-c-dREaMbPcSd, wherein 0<a<=8, 10<=b<=25, 0<c<=10, 0<d<=0.5, RE is one or a mixture selected from Y, La, Eu, Gd, Dy, Ho, Er, Tm, Yb and Lu, and M is one or a mixture selected from C, Si and B. The manufacturing method of the iron-based amorphous soft magnetic composite material includes the technical steps of alloy smelting, atomizing and pulverizing, insulating cladding, compression molding and heat treating. The iron-based amorphous soft magnetic composite material prepared through the method is high in saturation magnetic induction intensity and can be applied to electronic devices high in power and frequency.

Owner:ZHEJIANG UNIV

Supercritical fluid foaming method for polypropylene material

The invention discloses a supercritical fluid foaming method for a polypropylene material. The method comprises the following steps: (1) heating the polypropylene material to a foaming temperature ina mold cavity; (2) injecting a supercritical fluid into the mold cavity, and keeping the supercritical state for at least 5 min; (3) slowly releasing pressure in the mold cavity to reduce the pressurein the mold cavity to 0-90% of original pressure; (4) re-injecting a supercritical fluid into the mold cavity, and keeping the supercritical state for at least 5 min; and (5) repeating the step (3) and the step (4) at least twice, and quickly releasing the pressure in the mold cavity. The supercritical fluid foaming method for the polypropylene material provided by the invention shortens the saturation time, improves the production efficiency, widens the foaming temperature interval, and reduces the product rejection rate.

Owner:EAST CHINA UNIV OF SCI & TECH

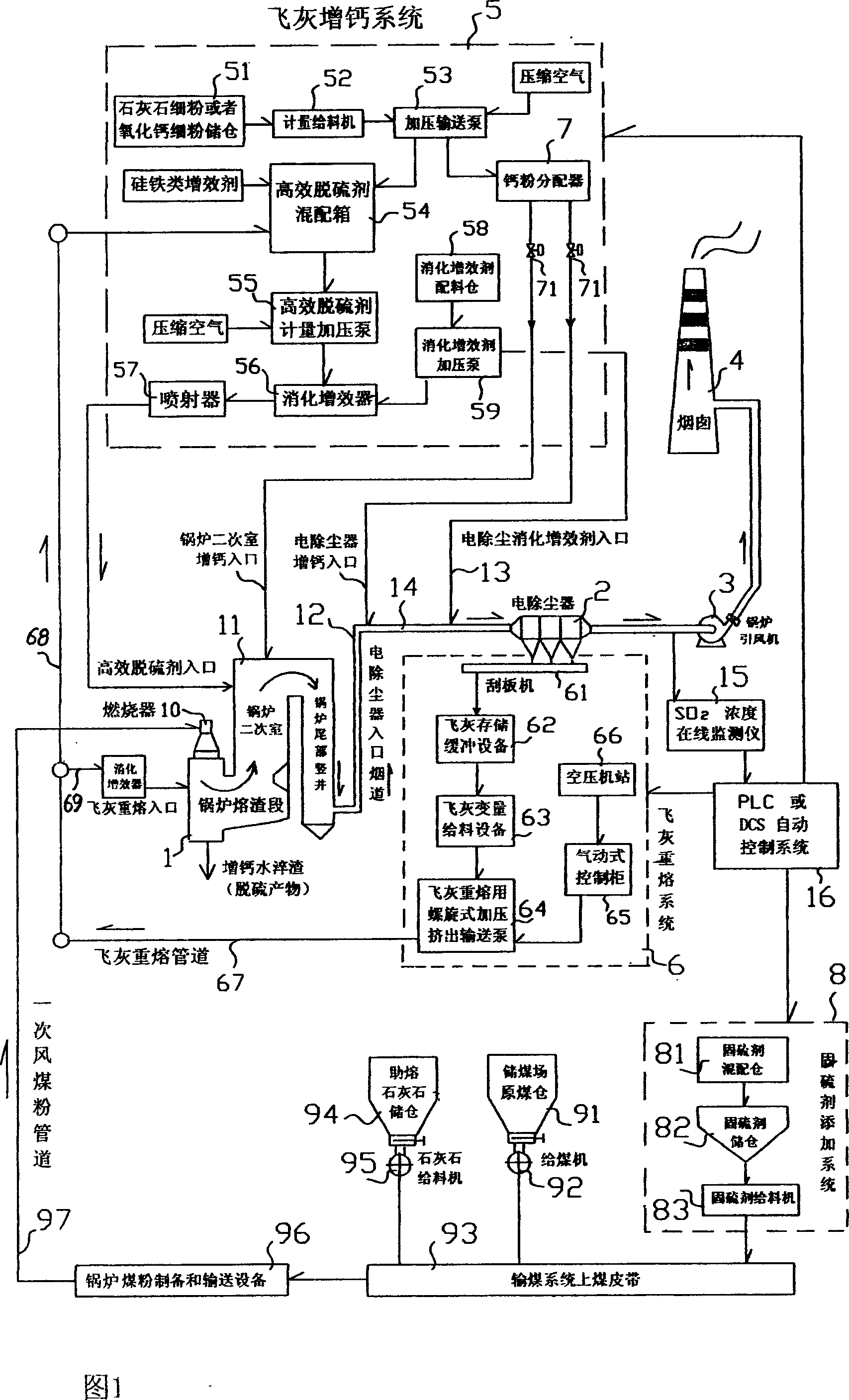

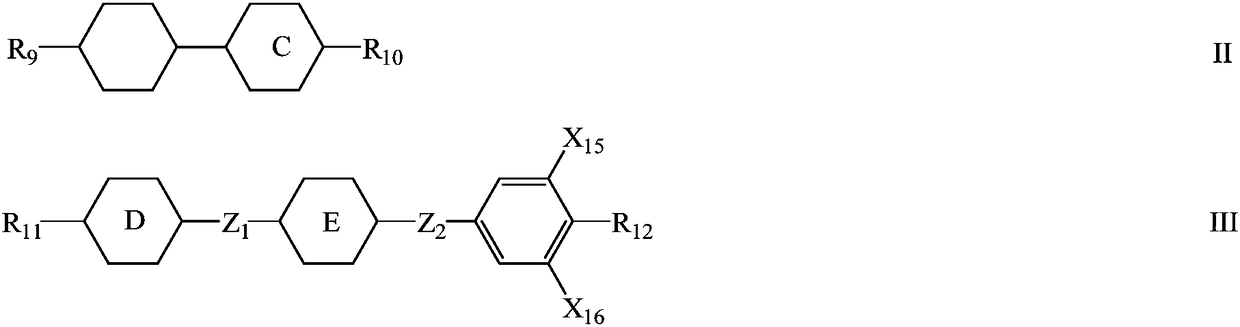

Method and system for increasing calsium and remelting flyash in boiler and high temperature desulfurizing in boiler

InactiveCN101069805AAvoid fire accidentsImprove desulfurization effectLighting and heating apparatusDispersed particle separationCombustorIncreased calcium

The present invention provides a boiler fly ash calcium-increasing remelting-intrafurnace desulfurizing method and its system. Said method includes the following steps: (1), making the fly ash discharged by boiler be passed through remelting system, then making collection, pressurization and distribution; (2), making the fly ash having need of increasing calcium undergo the process of calcium-increasing treatment; and (3),spraying the calcium-increased fly ash into the furnace cavity to make secondary combustion, remelting and desulfurization. Said system includes boiler coal-feeding belt system, powder-making system, combustor, boiler, dust-remover, boiler blower and stack, etc. Said system also includes a fly ash calcium-increasing system connected with boiler and a fly ash remelting system connected with dust-remover, and the fly ash remelting system is connected with said fly ash calcium-increasing system.

Owner:殷大众

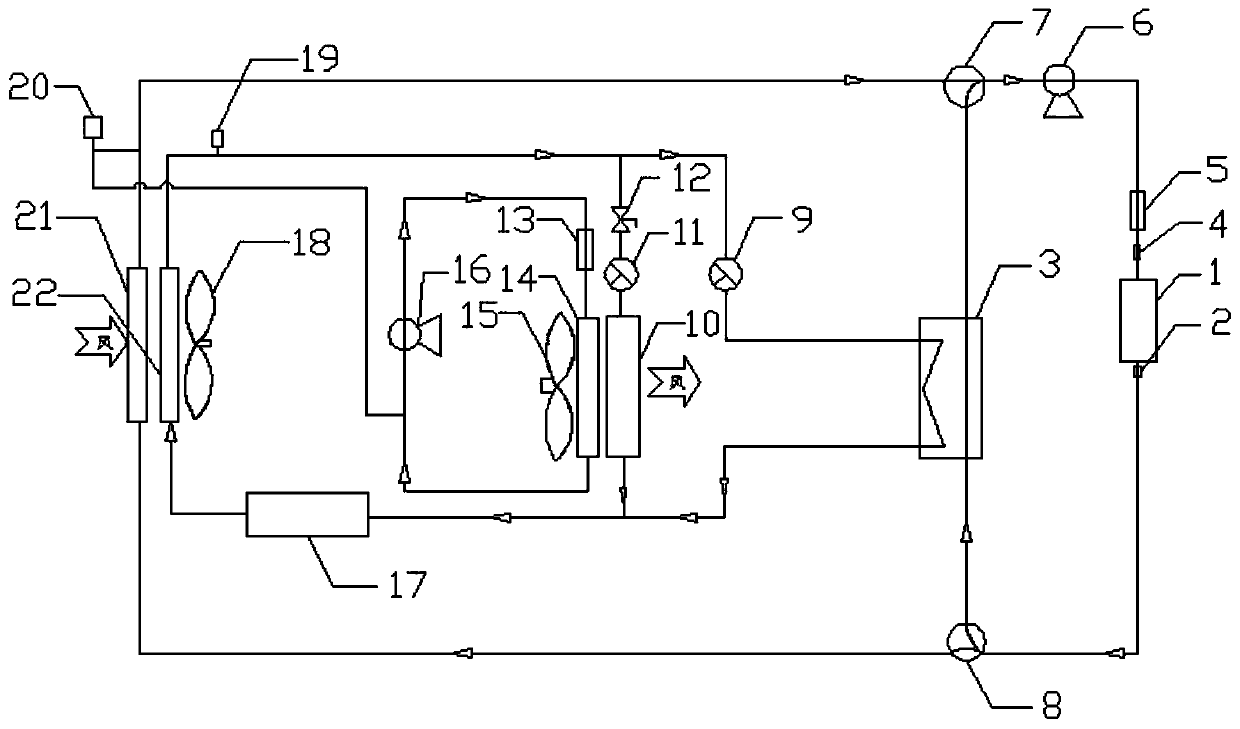

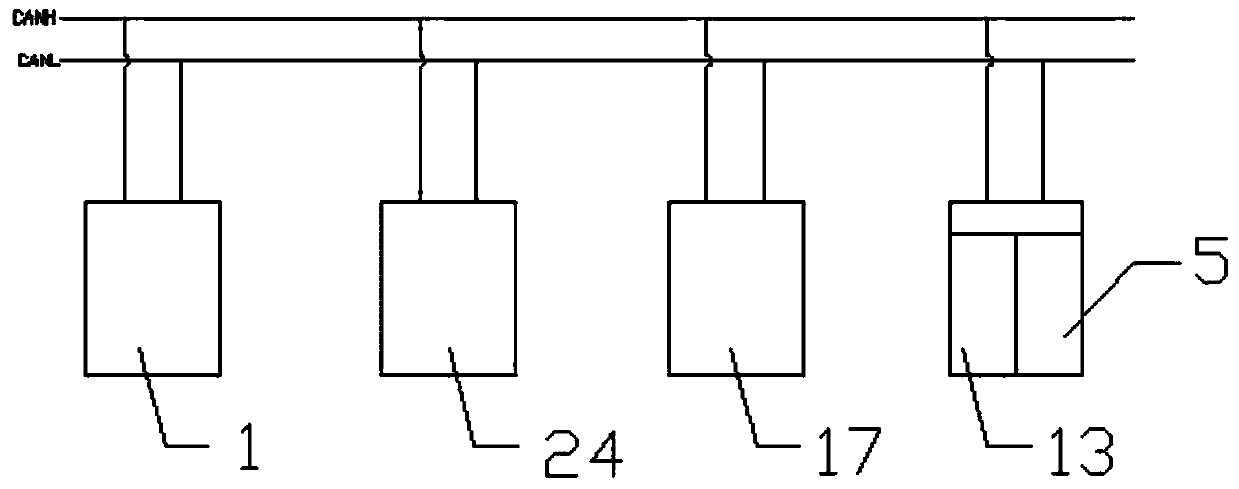

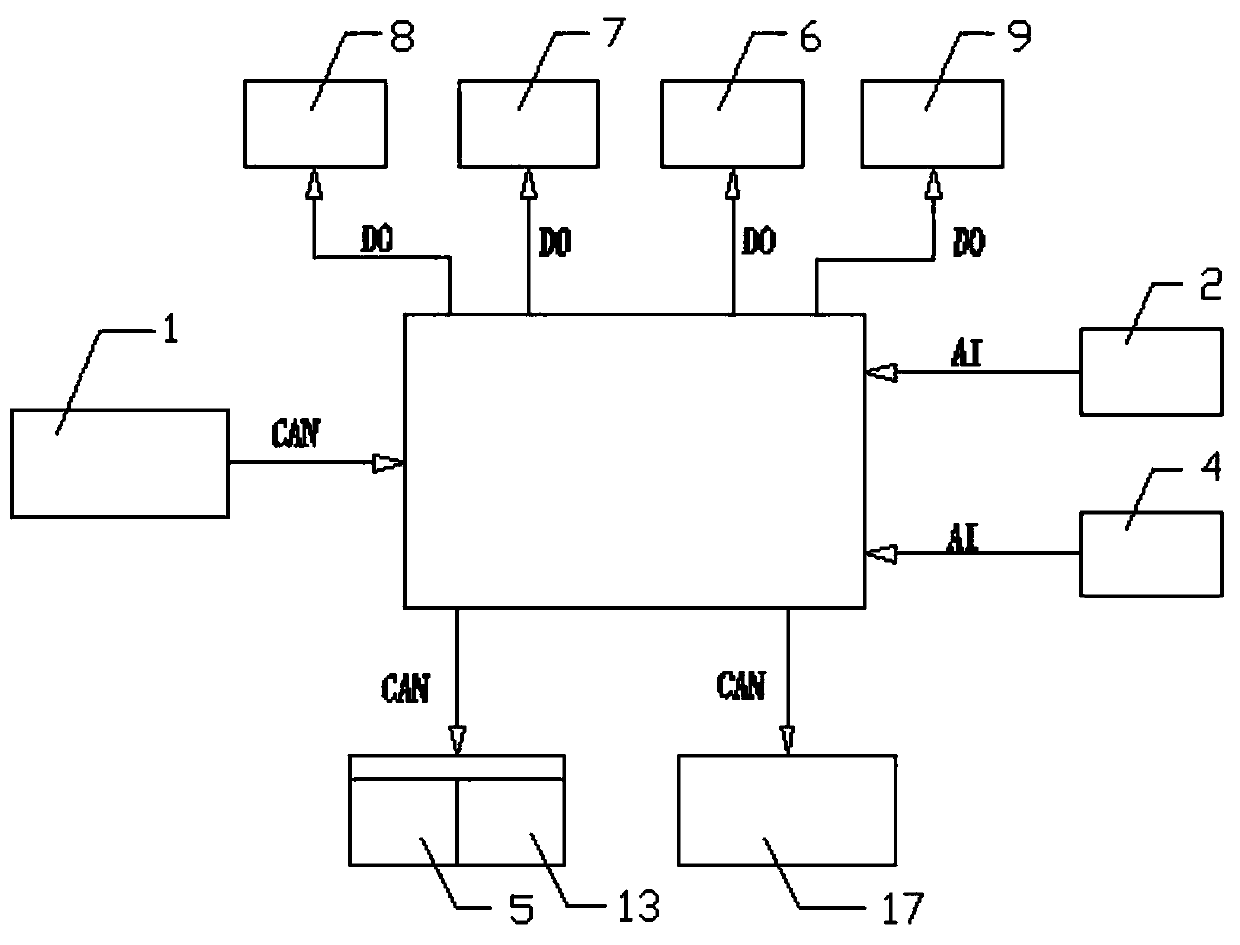

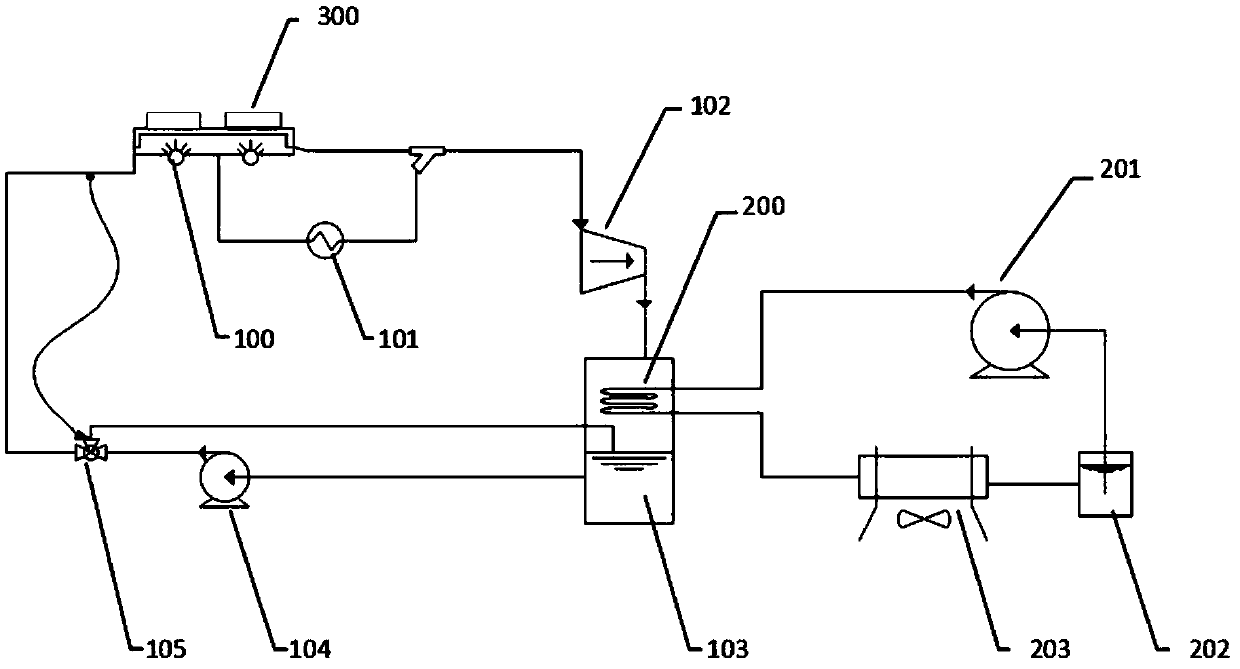

Dual circulation-based power battery pack thermal management system

PendingCN109768347AReasonable structural designWiden the temperature rangeSecondary cellsInlet temperatureChiller

The invention discloses a dual circulation-based power battery pack thermal management system. The dual circulation-based power battery pack thermal management system comprises a battery pack thermalmanagement system (BMS), a thermal management controller, a compressor, a PTC heater A and a PTC heater B, wherein one end of the battery pack BMS is connected with a battery pack water inlet temperature sensor, the other end of the battery pack BMS is connected with a battery pack water outlet temperature sensor, one side of the battery pack water inlet temperature sensor is connected with a three-way converter valve B, one side of a three-way converter valve A is connected with a cooler, the other side of the three-way converter valve A is connected with a battery heat sink, the compressor is connected with one side of the battery heat sink, one side of the compressor is connected with an electric water pump A, the other side of the compressor is connected with the cooler, and the PTC heater B is connected with one side of the electric water pump A. With the dual circulation-based power battery pack thermal management system, the problem of heating and cooling of a battery pack is solved, and the energy consumption of the compressor can be reduced to the greatest extent by introduction of dual circulation in a cooling working condition.

Owner:SHANDONG KINGOLD AUTOMOBILE CO LTD

Thermal sensitive ceramic material and preparation method thereof

The invention discloses a thermal sensitive ceramic material and a preparation method thereof, relating to the technical field of materials. The main components of the thermal sensitive ceramic material are metal oxides which include Co3O4, Fe2O3, Ni2O3, SnO2, TiO2, Li2O and rear earth oxides, wherein a molar ratio of the substances of components in the material is that the Co:Fe:Ni:Sn:Ti:Li:rear earth is 1:(1-3):(0.3-0.7):(0.01-0.05):(0.02-0.05):(0.01-0.03):(0.1-0.3). The preparation method of the thermal sensitive ceramic material comprises the following steps: weighing, grinding, ball-milling, calcining, cutting into slices and coating an electrode material. The thermal sensitive ceramic material provided by the invention as well as thermal sensitive ceramic with a negative temperature coefficient provided by the preparation method have the characteristics of wide working temperature region and high sensitivity; and moreover, the thermal sensitive ceramic material has the advantages of simple preparation process, stable material performance and capacity of being recycled, and the like.

Owner:常熟市董浜科技创业投资发展有限公司

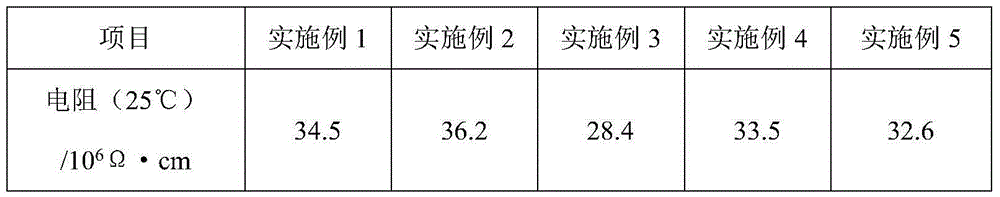

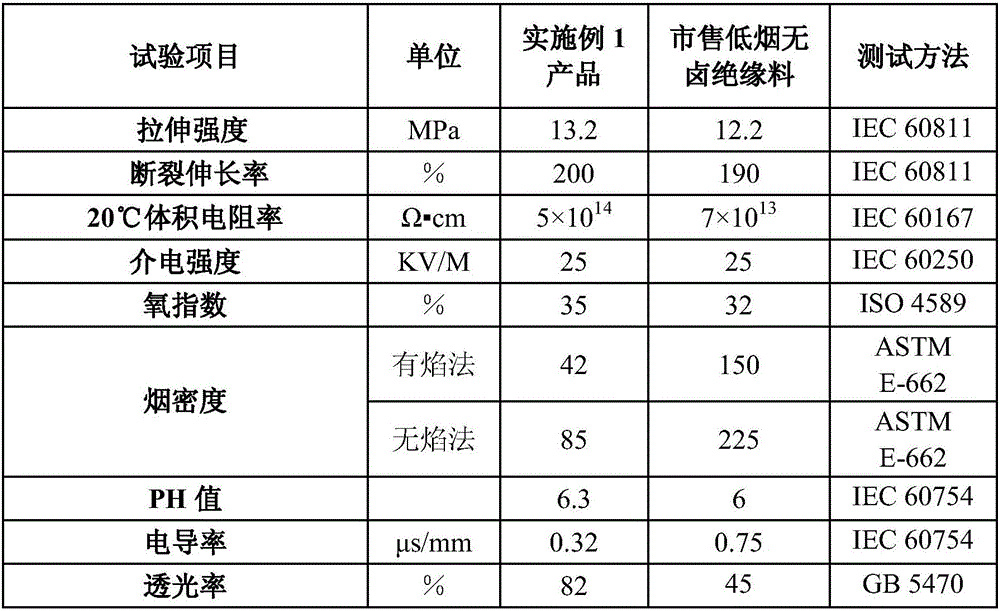

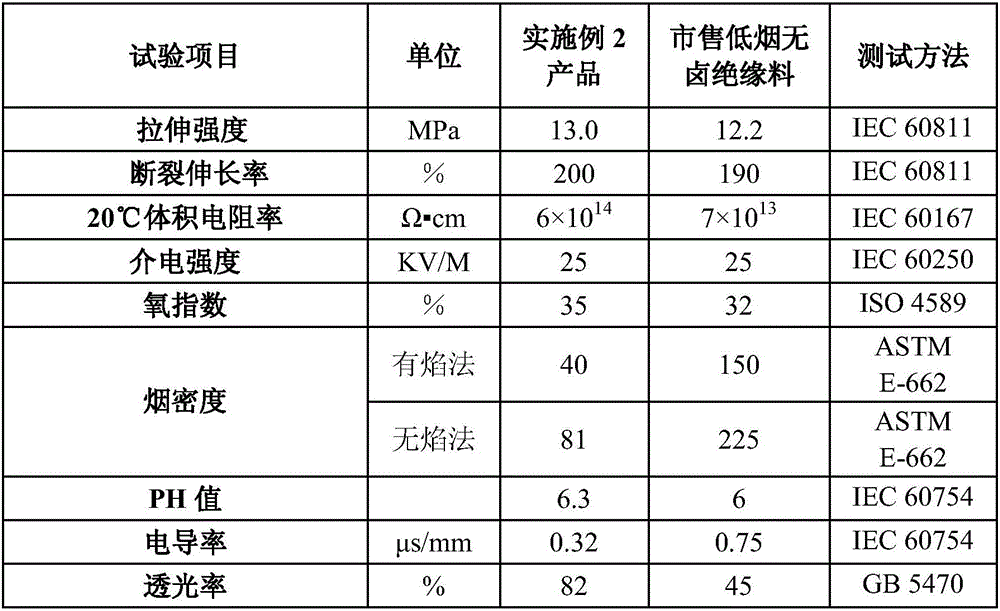

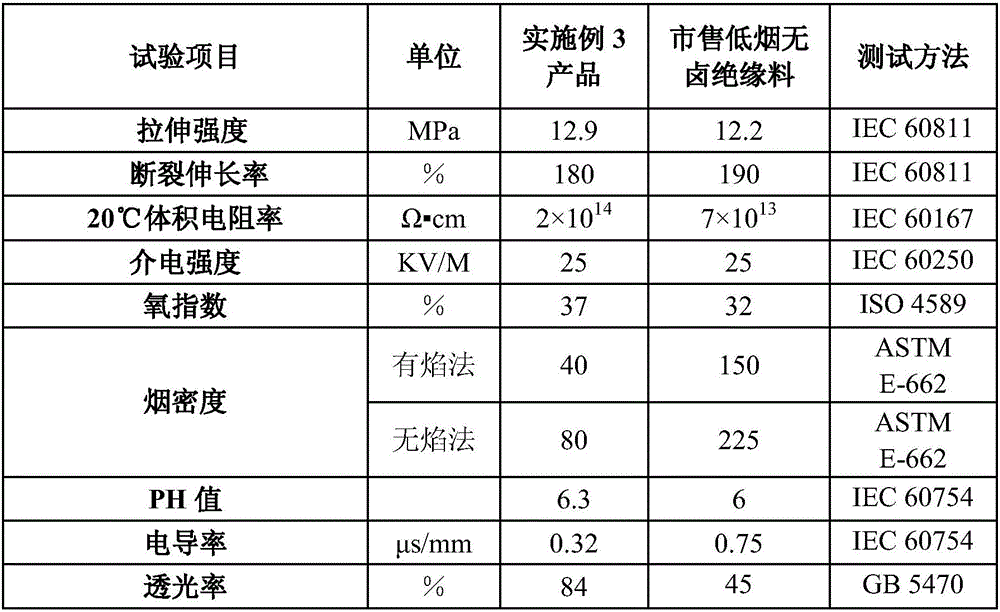

Low-smoke-amount non-halogen flame-retardant cable compound and preparation method thereof

InactiveCN106349554AWiden the temperature rangeReduce smoke productionPlastic/resin/waxes insulatorsInsulated cablesHalogenCombustion

The invention discloses a low-smoke-amount non-halogen flame-retardant cable compound. The low-smoke-amount non-halogen flame-retardant cable compound comprises the following components in mass percent: 25 to 28 percent of ethylene-vinyl acetate copolymer, 3 to 5 percent of polyethylene, 2 to 4 percent of maleic anhydride grafted polyethylene, 60 to 65 percent of an inorganic flame retardant, 0.5 to 1 percent of alkylsiloxane, 3 to 5 percent of a smoke inhibitor, and 1 to 3 percent of an antioxidant assistant, and the sum of the mass percent of all the components is 100 percent. The invention further discloses a preparation method of the low-smoke-amount non-halogen flame-retardant cable compound. The low-smoke-amount non-halogen flame-retardant cable compound has excellent mechanical properties and electrical properties, greatly reduces the density of flame smoke and the density of flameless smoke during combustion, greatly improves the light transmittance of finished cables, and is particularly suitable for the preparation of cables with large sections or complex structures.

Owner:OPTA POLYMER JIANGSU

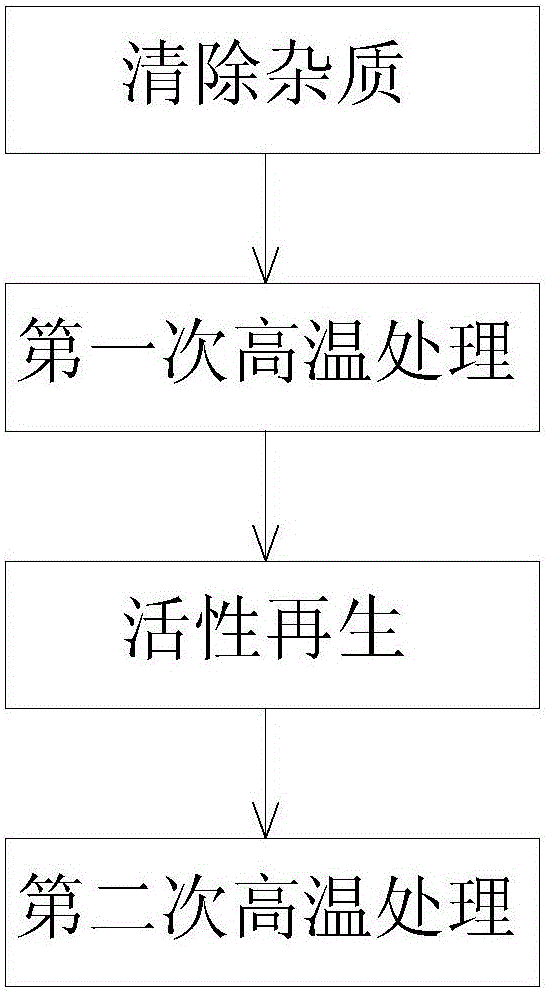

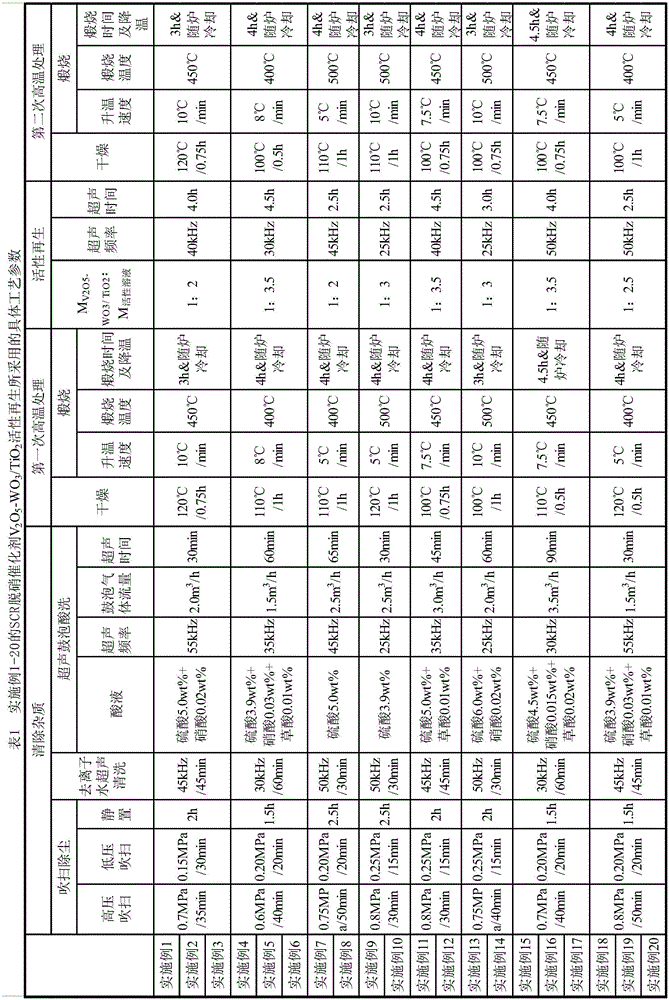

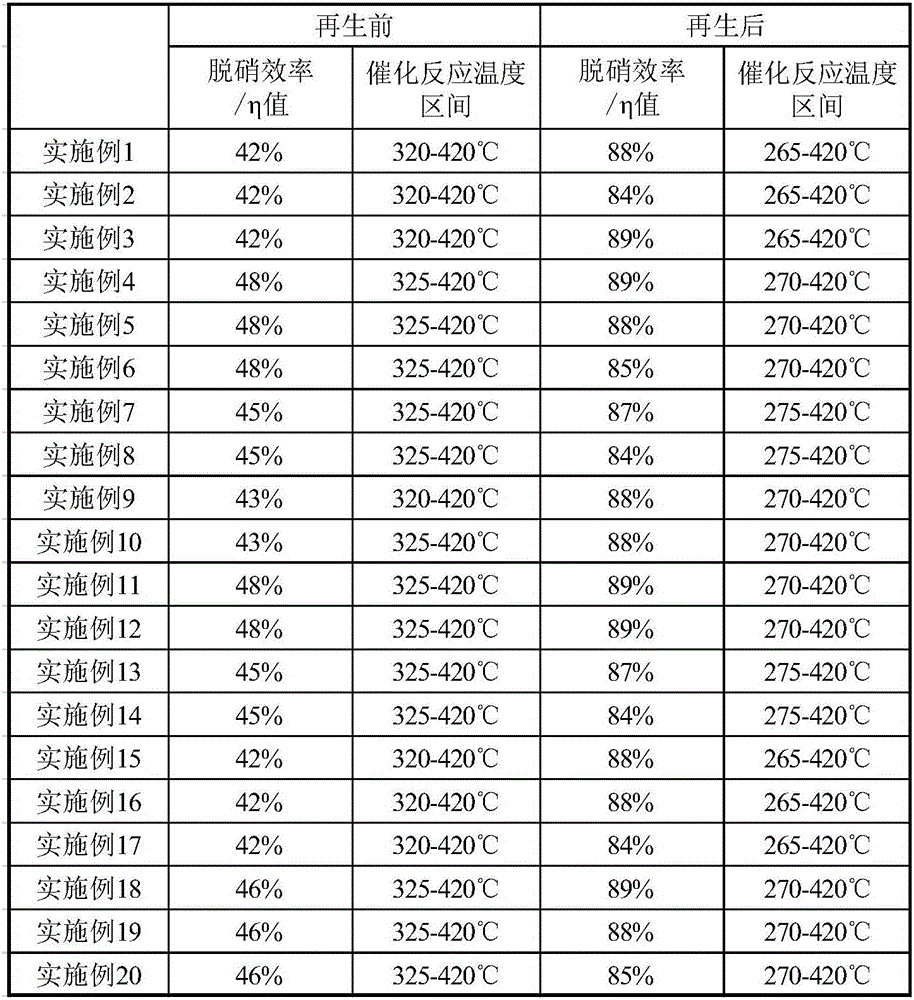

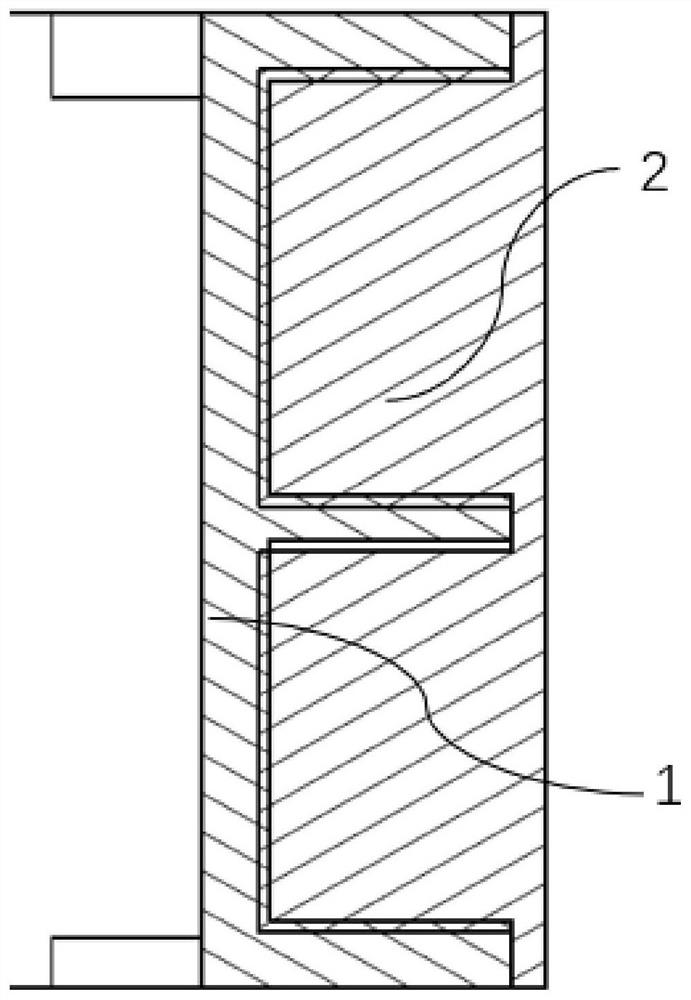

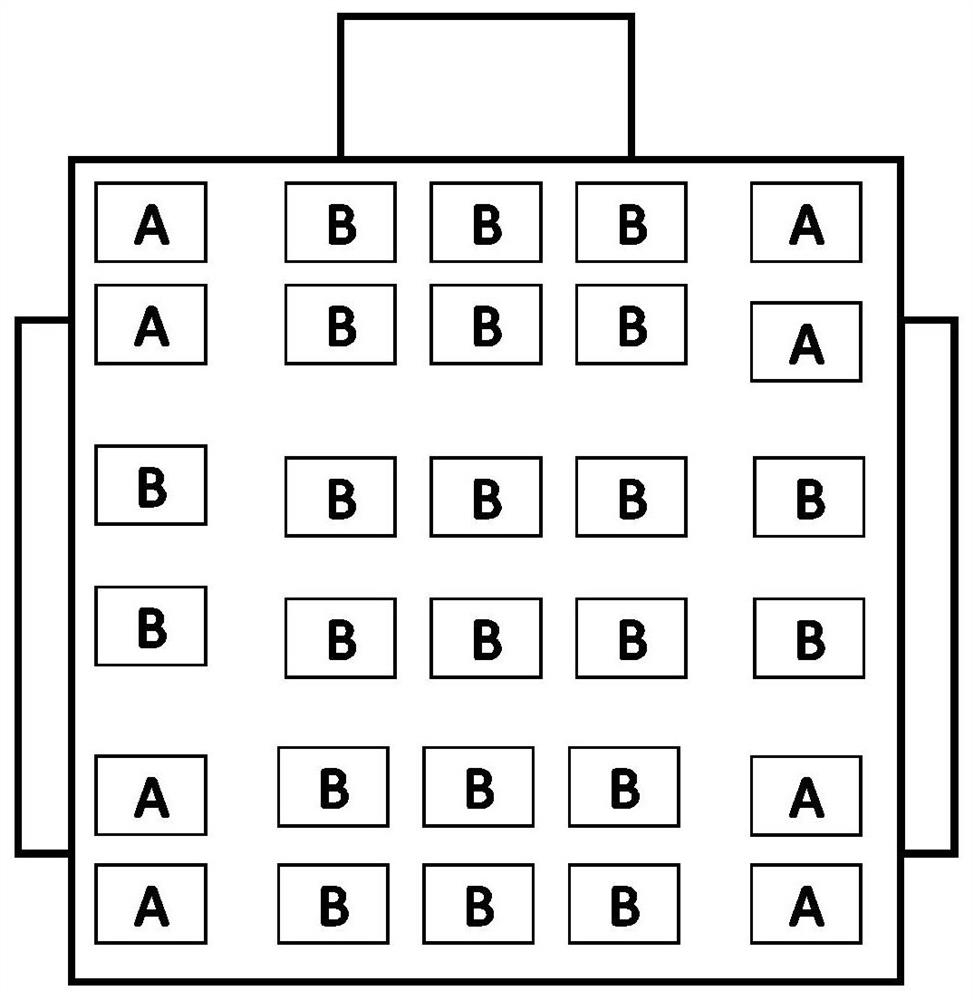

Regeneration method for SCR (Selective Catalytic Reduction) denitration catalyst V2O5-WO3/TiO2

InactiveCN105772028AWiden the temperature rangeRecovery of denitrification efficiencyCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsMANGANESE ACETATECerium nitrate hexahydrate

The invention discloses a regeneration method for an SCR (Selective Catalytic Reduction) denitration catalyst V2O5-WO3 / TiO2. The method comprises the following four steps: (1) carrying out impurity removal; (2) carrying out first-time high-temperature treatment; (3) carrying out activity regeneration; (4) carrying out second-time high-temperature treatment. According to the regeneration method, one or a mixture solution of more of a cerous nitrate solution, a cerous acetate solution, a manganous nitrate solution and a manganese acetate solution is adopted as an active solution, so that the denitration efficiency of the regenerated SCR denitration catalyst V2O5-WO3 / TiO2 is obviously increased, and the temperature range of a denitration reaction can be effectively widened; meanwhile, a template agent is added, so that the distribution of active substances is more uniform, and the activity recovery is facilitated. The regeneration method provided by the invention is simple and easy in control, and required equipment is readily available and cheap; compared with the existing regeneration methods, the regeneration method has greater technical and economic advantages, thereby having powerful market competitiveness.

Owner:WUHAN LONGKING ENVIRONMENTAL PROTECTION TECH

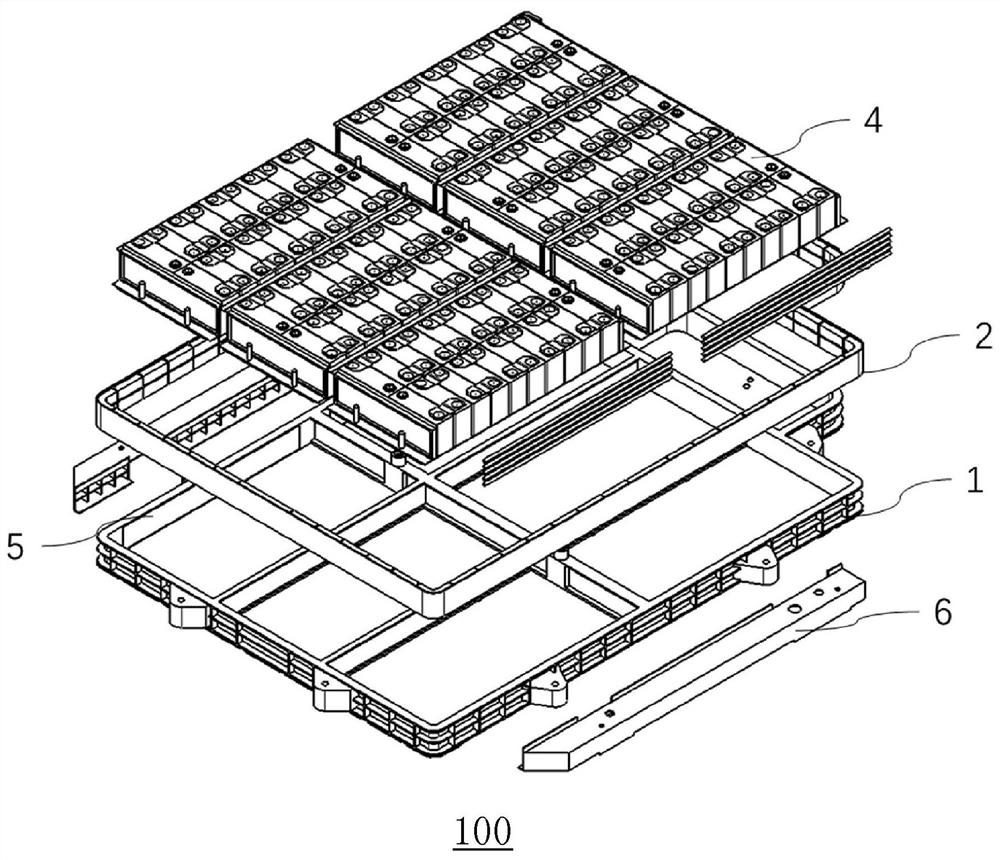

Battery pack and vehicle

PendingCN112599891AWiden the temperature rangePassive hold time extendedElectric propulsion mountingSecondary cellsBattery cellBattery pack

Owner:NIO TECH ANHUI CO LTD

Sulfur positive electrode material with functional intermediate layer and preparation and application thereof

ActiveCN111416121ARich in amide functional groupsImprove heat resistanceSecondary cellsPositive electrodesLithium–sulfur batteryElectrical battery

The invention relates to a sulfur positive electrode material with a functional intermediate layer and preparation and application thereof, and the sulfur positive electrode material with the functional intermediate layer is prepared by taking commercial Kevlar fibers and a transition metal salt solution as raw materials. Compared with the modification of other lithium-sulfur batteries, due to a fact that the raw materials come from aramid fibers produced by Dupont Company and the production technology is mature, the material can be produced in a large scale, and the dissolving and compoundingsteps are simple; the preparation is easy, the sulfur positive electrode material with the functional middle layer obtained after coating and drying is applied to the lithium-sulfur battery, the cycle performance and the rate capability are greatly improved, the battery can also normally operate at the high temperature of 70 DEG C, and the applicable temperature interval of the lithium-sulfur battery is widened; the preparation method is simple, low in cost, excellent in performance and suitable for production of large-scale commercial batteries.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

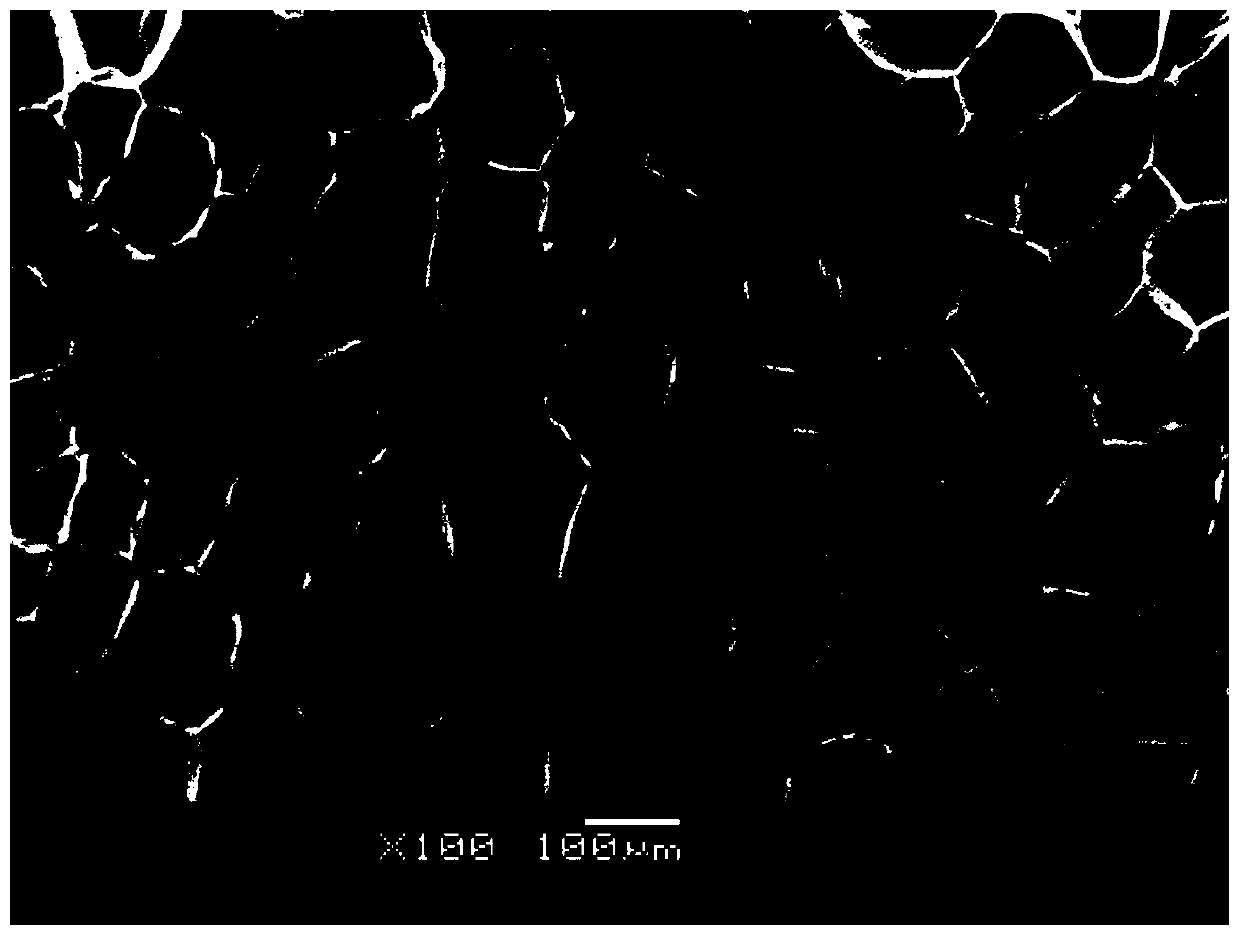

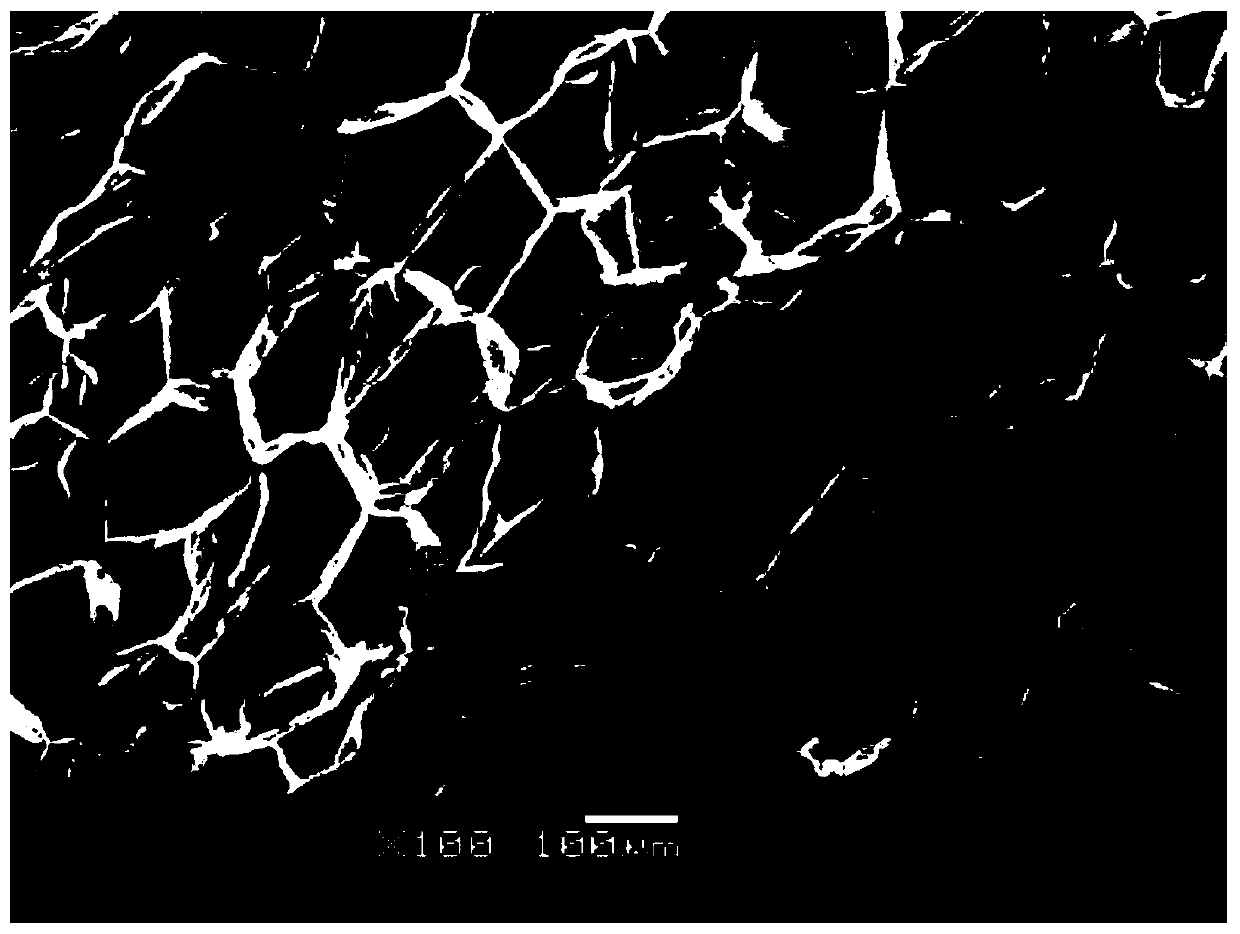

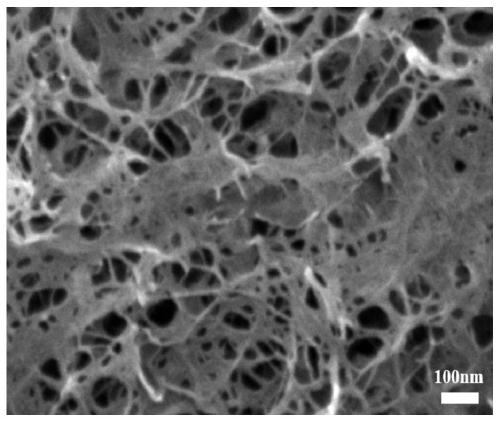

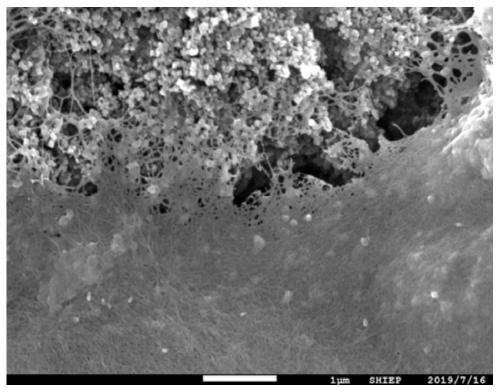

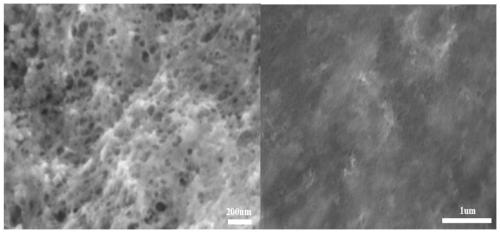

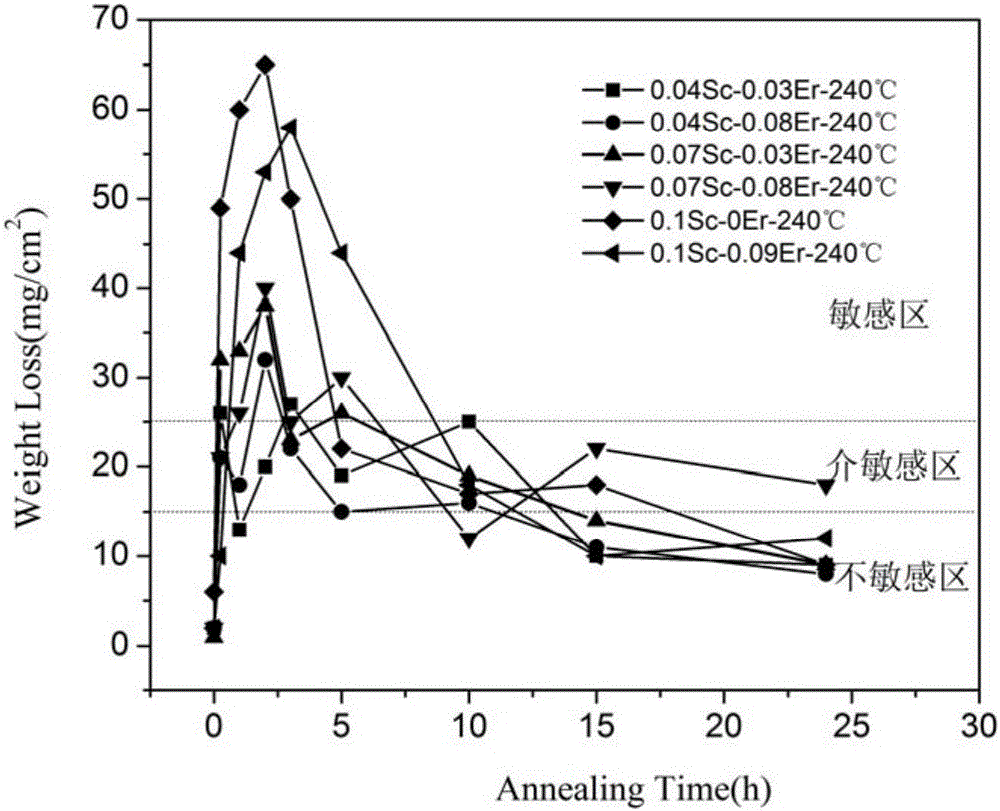

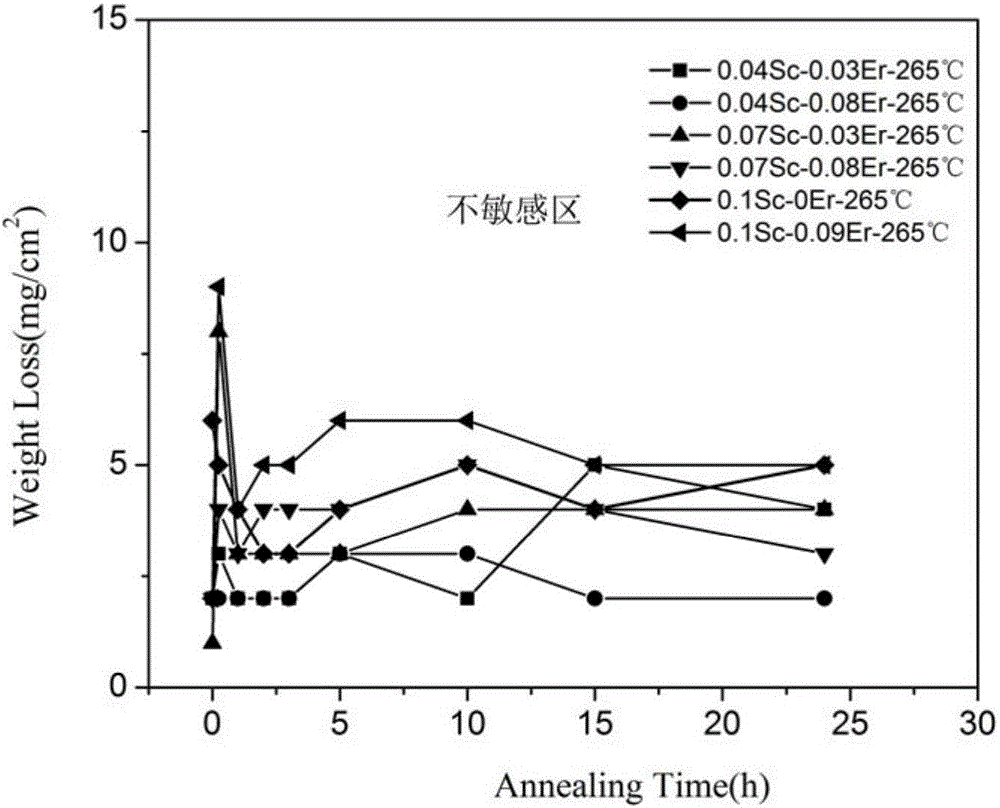

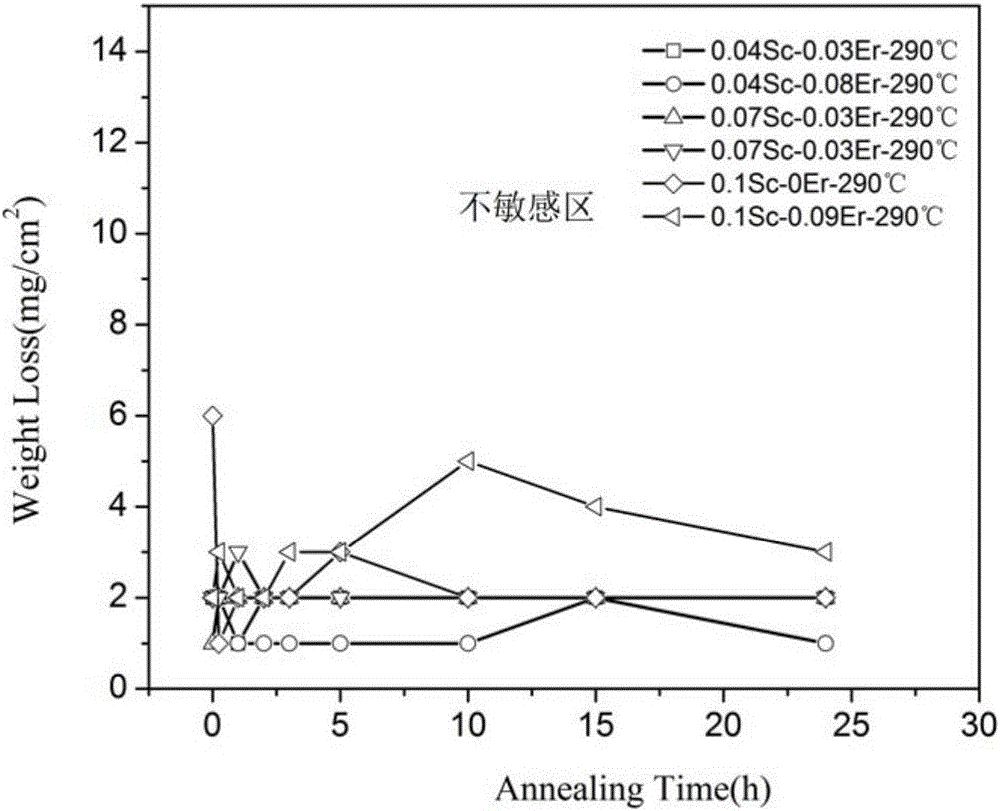

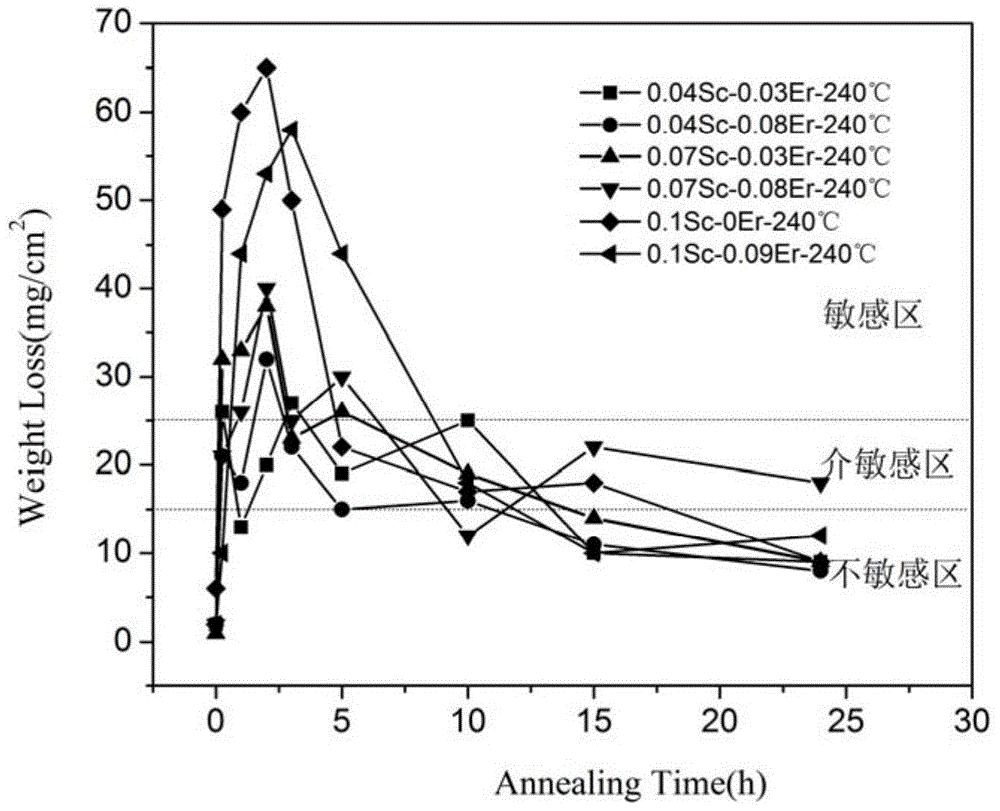

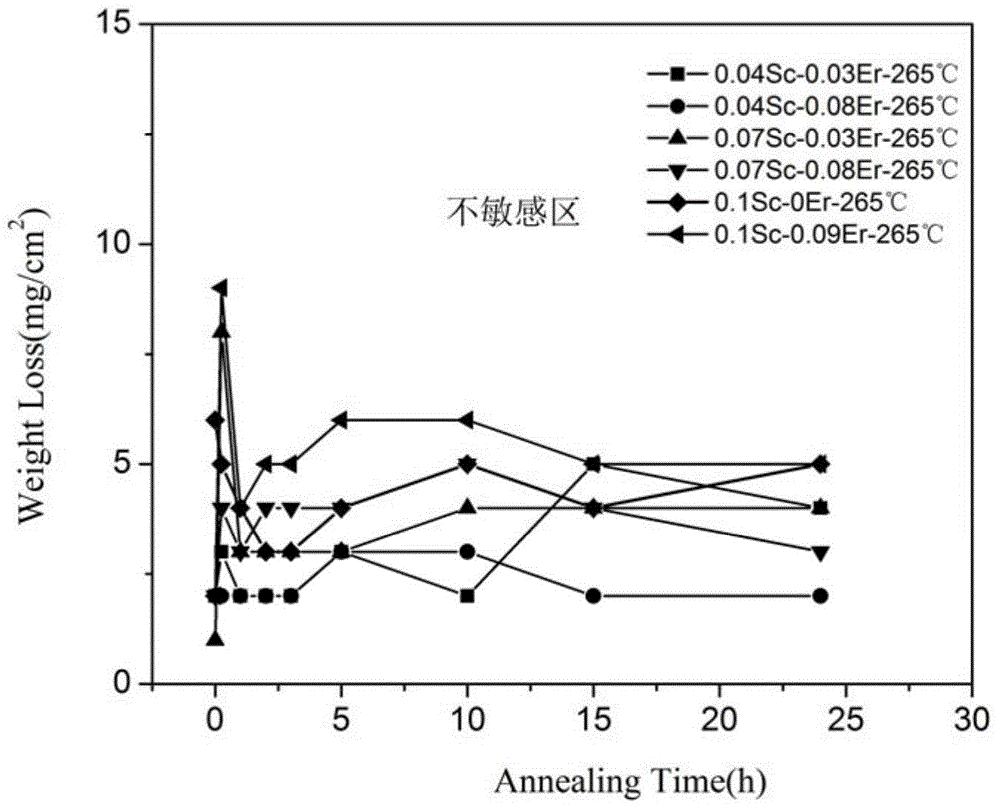

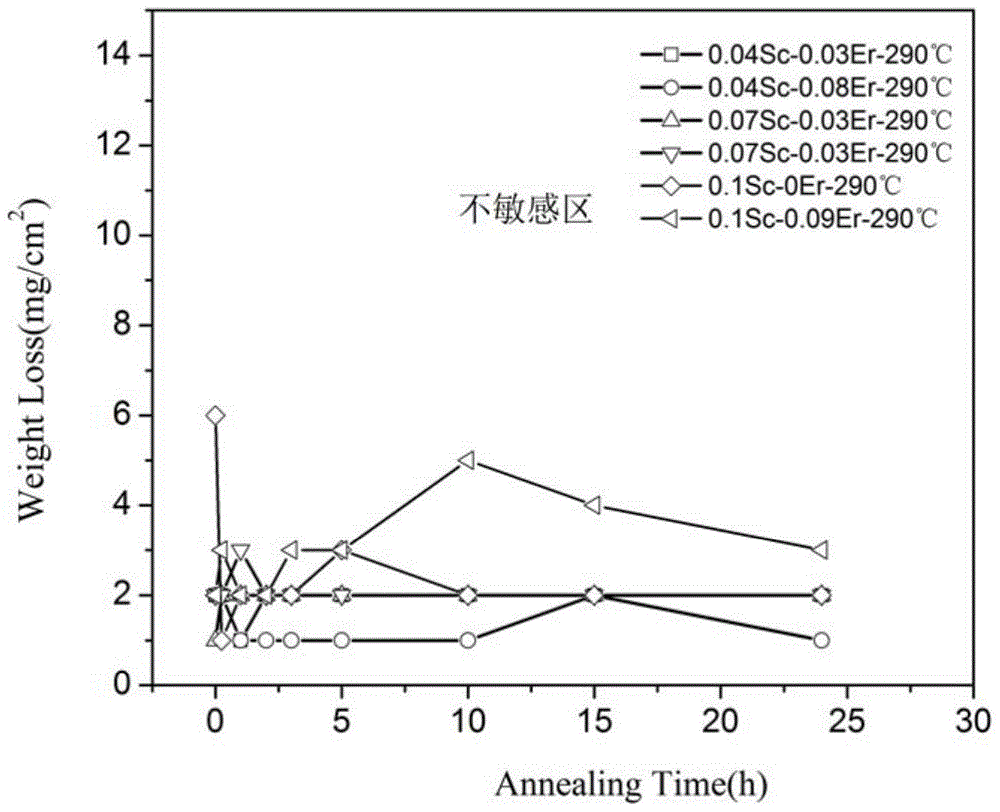

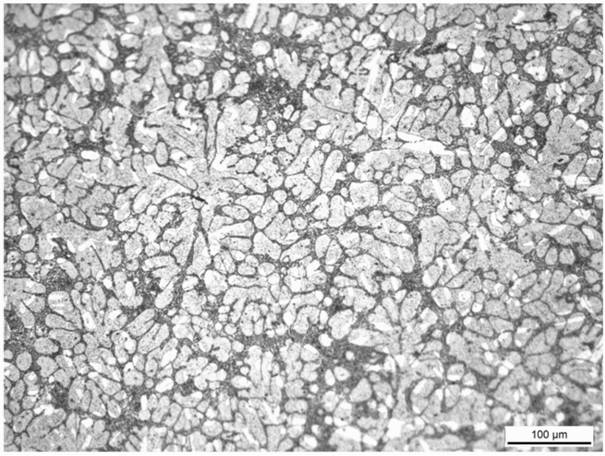

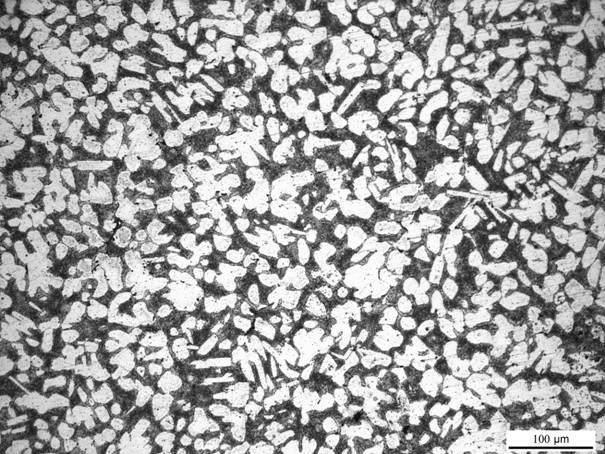

An er/sc/zr composite micro-alloyed al-6mg-0.4mn alloy stabilization annealing process

ActiveCN105039803BRaise the recrystallization temperatureWiden the temperature rangeAlloyUltimate tensile strength

The invention discloses a technique for stabilizing annealing of Er / Sc / Zr composite microalloyed Al-6Mg-0.4Mn alloy and belongs to the technical field of non-ferrous metal. The Er / Sc / Zr composite microalloyed Al-6Mg-0.4Mn alloy comprises, by mass, 5.5%-6.5% of Mg, 0.4%-0.5% of Mn, 0%-0.09% of Er, 0.1%-0.15% of Zr, 0.04%-0.1% of Sc and less than 0.4% of inevitable impurities. Homogenizing annealing is conducted on the Er / Sc / Zr composite microalloyed Al-6Mg-0.4Mn alloy at the temperature of 300 DEG C for 7-12 hours and at the temperature of 475 DEG C for 15 hours, hot rolling is conducted on the Er / Sc / Zr composite microalloyed Al-6Mg-0.4Mn alloy after the temperature is maintained to be 450 DEG C for two hours, and the hot rolling deformation is about 70%+ / -2%; cold rolling is conducted after intermediate annealing is conducted at the temperature of 475 DEG C for five hours till the final cold deformation is 60%+ / -2%; and then stabilizing annealing is conducted at the temperature of 240 DEG C for 10-24 hours, at the temperature of 250 DEG C for 5-24 hours and at the temperature of 265 DEG C for 2-24 hours. According to the technique, the precipitation position and the morphology of the beta phase are controlled through stabilizing treatment, and the long-term intercrystalline corrosion resistance of the alloy is improved. Meanwhile, high strength can be guaranteed, and the service life of a plate is remarkably prolonged.

Owner:BEIJING UNIV OF TECH

Technique for stabilizing annealing of Er/Sc/Zr composite microalloyed Al-6Mg-0.4Mn alloy

ActiveCN105039803ARaise the recrystallization temperatureWiden the temperature rangeUltimate tensile strengthImpurity

The invention discloses a technique for stabilizing annealing of Er / Sc / Zr composite microalloyed Al-6Mg-0.4Mn alloy and belongs to the technical field of non-ferrous metal. The Er / Sc / Zr composite microalloyed Al-6Mg-0.4Mn alloy comprises, by mass, 5.5%-6.5% of Mg, 0.4%-0.5% of Mn, 0%-0.09% of Er, 0.1%-0.15% of Zr, 0.04%-0.1% of Sc and less than 0.4% of inevitable impurities. Homogenizing annealing is conducted on the Er / Sc / Zr composite microalloyed Al-6Mg-0.4Mn alloy at the temperature of 300 DEG C for 7-12 hours and at the temperature of 475 DEG C for 15 hours, hot rolling is conducted on the Er / Sc / Zr composite microalloyed Al-6Mg-0.4Mn alloy after the temperature is maintained to be 450 DEG C for two hours, and the hot rolling deformation is about 70%+ / -2%; cold rolling is conducted after intermediate annealing is conducted at the temperature of 475 DEG C for five hours till the final cold deformation is 60%+ / -2%; and then stabilizing annealing is conducted at the temperature of 240 DEG C for 10-24 hours, at the temperature of 250 DEG C for 5-24 hours and at the temperature of 265 DEG C for 2-24 hours. According to the technique, the precipitation position and the morphology of the beta phase are controlled through stabilizing treatment, and the long-term intercrystalline corrosion resistance of the alloy is improved. Meanwhile, high strength can be guaranteed, and the service life of a plate is remarkably prolonged.

Owner:BEIJING UNIV OF TECH

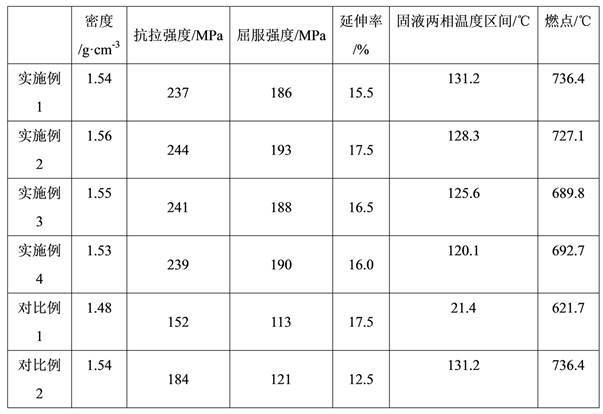

High-strength semi-solid double-phase die-casting magnesium-lithium alloy and preparation method thereof

ActiveCN112593132AWiden the temperature rangeImprove flame retardant performanceVacuum castingBatch production

The invention belongs to the technical field of preparation of magnesium-lithium alloy materials, and particularly relates to a high-strength semi-solid double-phase die-casting magnesium-lithium alloy and a preparation method thereof. Aiming at the problems that an as-cast magnesium-lithium alloy is low in mechanical property, narrow in temperature interval of a solid-liquid double-phase region and low in ignition point, the high-strength semi-solid double-phase die-casting magnesium-lithium alloy low in cost and high in flame retardance is obtained through the means of alloy component design, vacuum casting, semi-solid die-casting forming and the like. The preparation method of the high-strength semi-solid double-phase die-casting magnesium-lithium alloy is a near-net forming technology,the preparation technological process is short, the cost is controllable, and batch production of magnesium-lithium alloy parts can be achieved. By means of the alloy, a magnesium-lithium alloy product with the tensile strength not lower than 230 MPa, the yield strength not lower than 180 MPa and the elongation not lower than 15% can be obtained. The high-strength semi-solid magnesium-lithium alloy can be applied in batch in the fields of 3C, optics, precision electronic products and the like.

Owner:郑州轻研合金科技有限公司

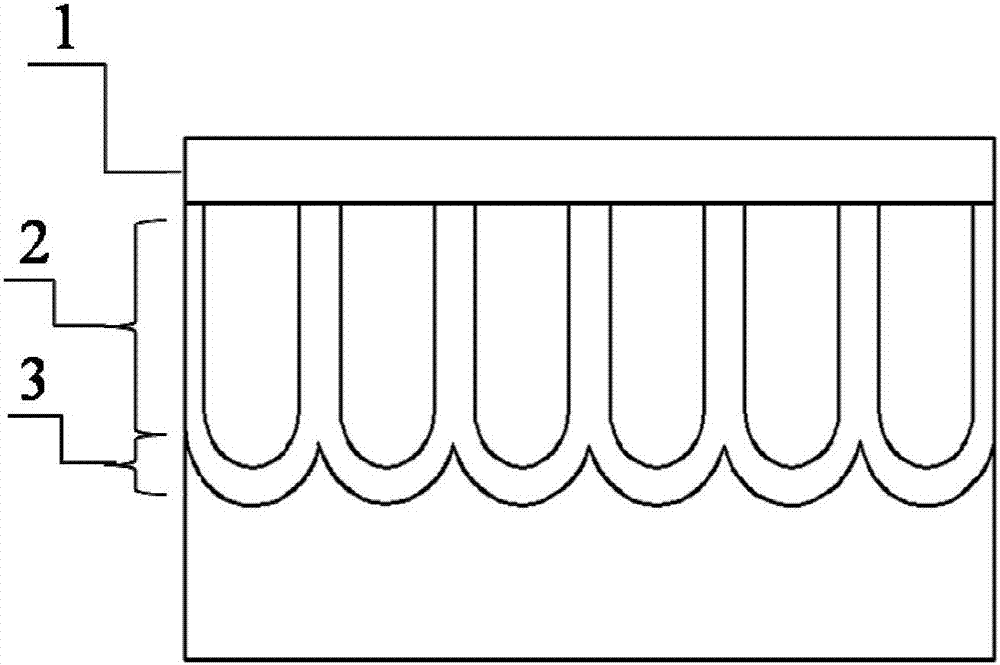

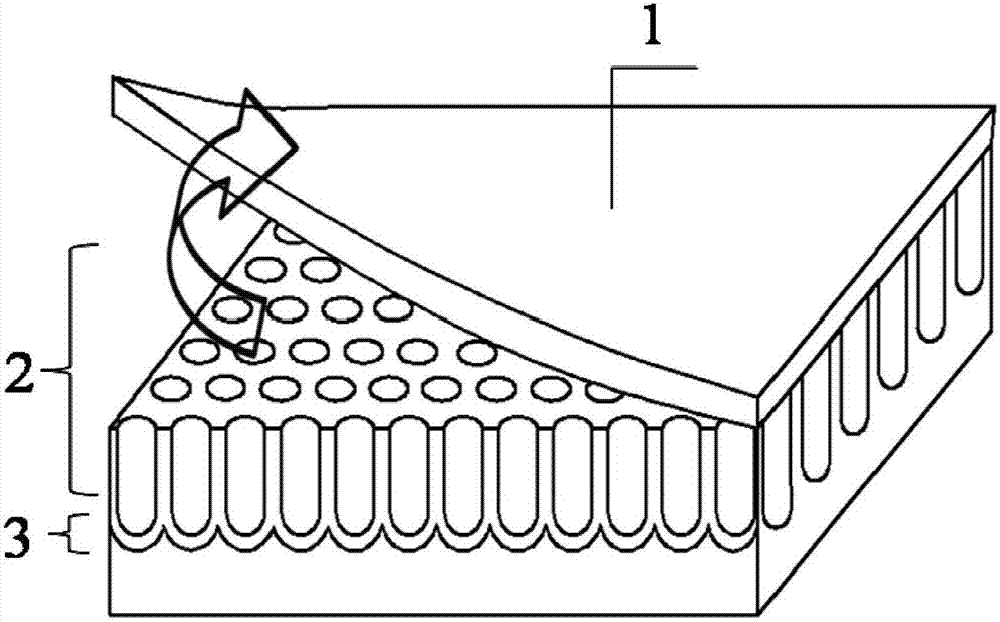

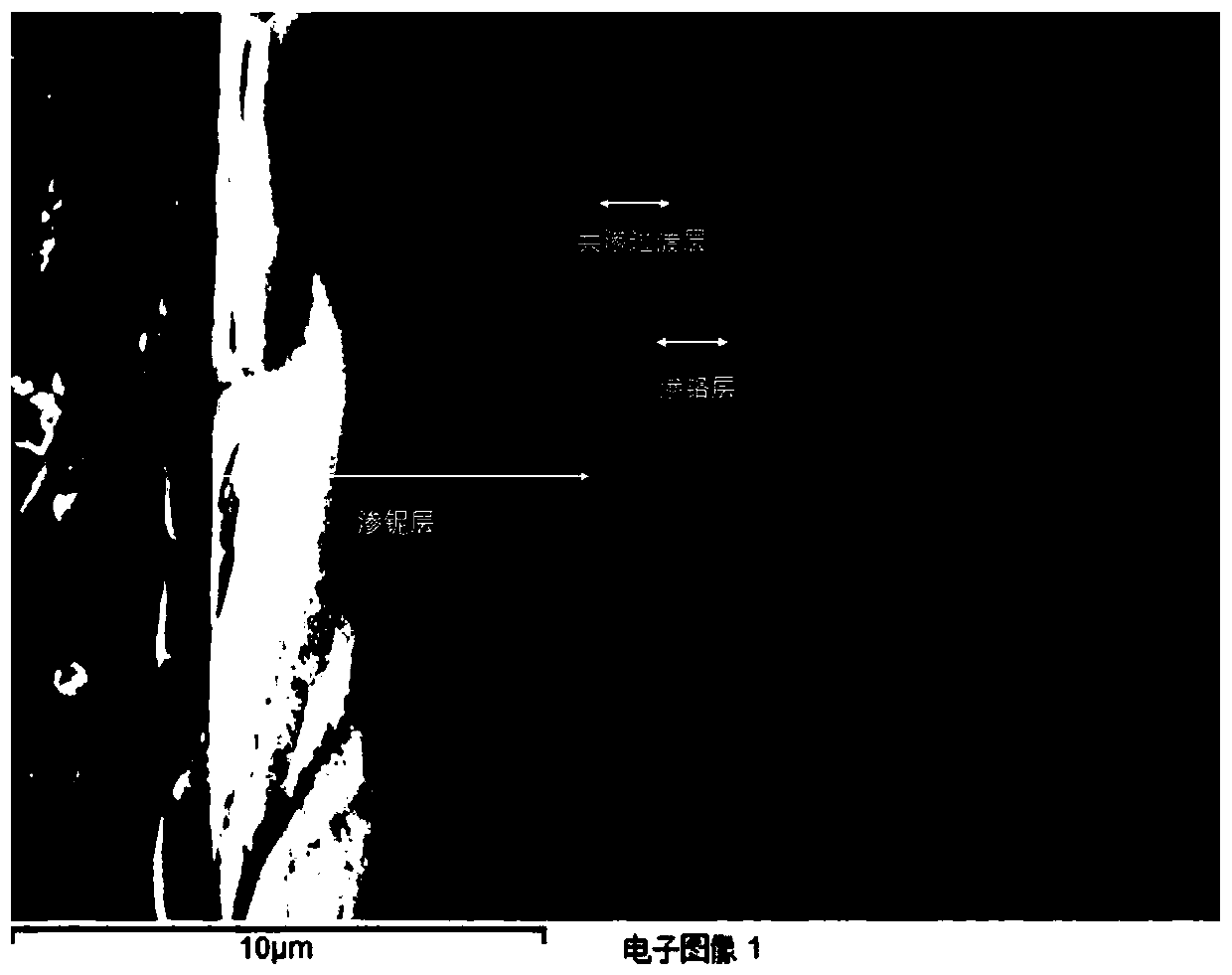

Aluminum alloy anode oxide film with porous subsurface layer and wear-resistant surface layer and preparation method of aluminum alloy anode oxide film

ActiveCN107400915AImprove wear resistanceWiden the temperature rangeAnodisationAnodic oxidationOxide

The invention provides an aluminum alloy anode oxide film with a porous subsurface layer and a wear-resistant surface layer. The anode oxide film is of a three-layer structure, namely a shielding layer, the porous subsurface layer and the wear-resistant surface layer from an aluminum alloy matrix to exterior. The anode oxide film achieves the effects of greatly improving the wear resistance of the aluminum alloy and widening the application field of the aluminum alloy. In addition, with the adoption of an anodic oxidation method, the aluminum alloy serves as an anode and a cathode in the anodic oxidation process, the electrolyte comprises sulfuric acid, a wide temperature range oxidant and an aluminum ion, and the growth speed and dissolution rate of the anode oxide film are controlled by an electrolyte formula by controlling the anodic oxidation current density, so that the aluminum alloy anode oxide film with the porous subsurface layer and the wear-resistant surface layer is obtained.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

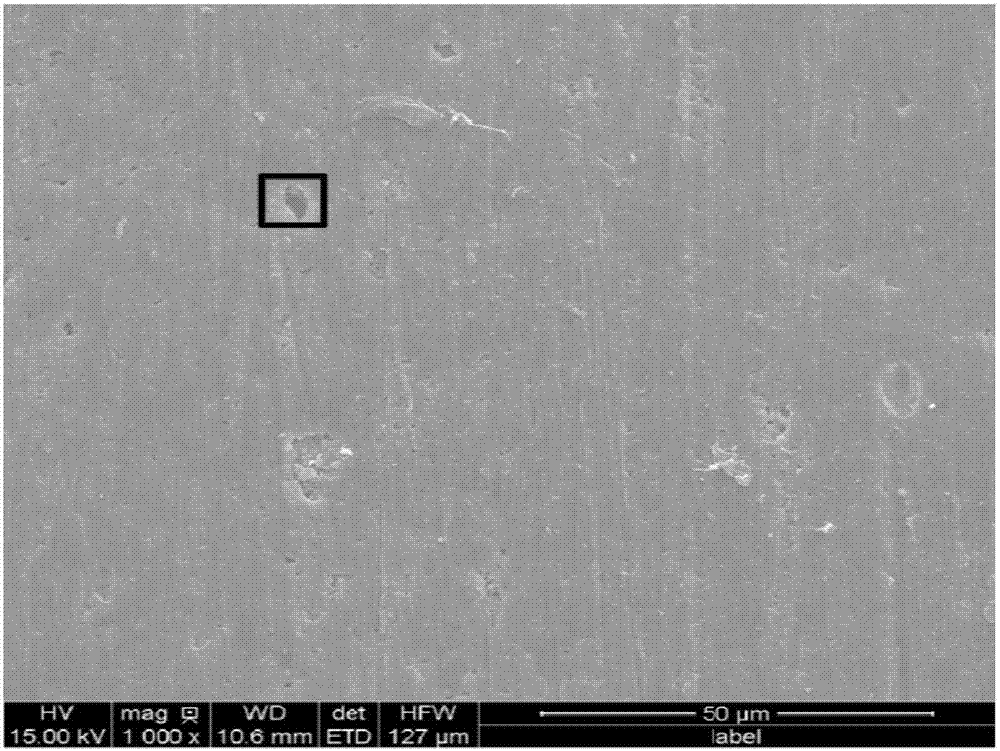

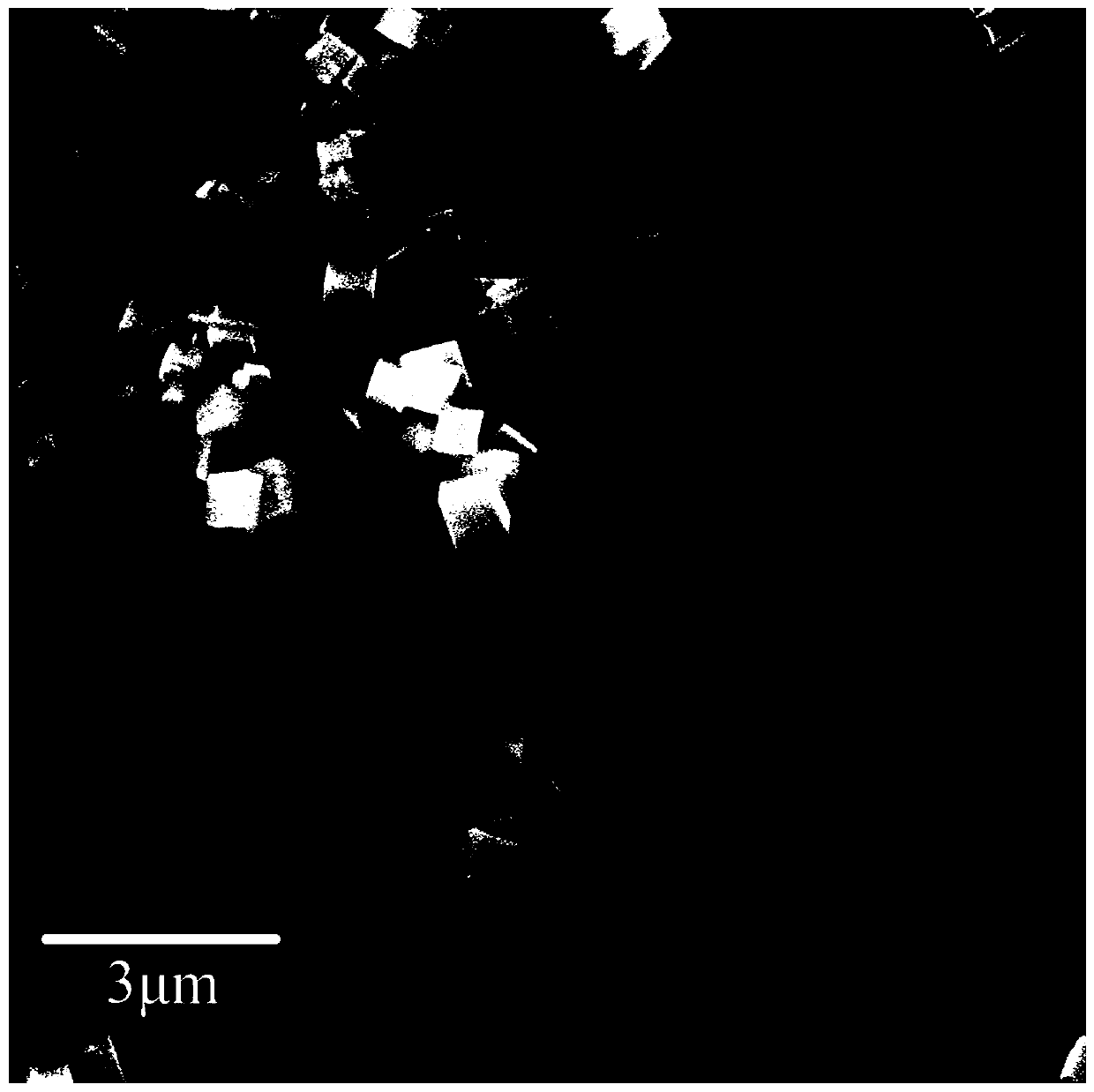

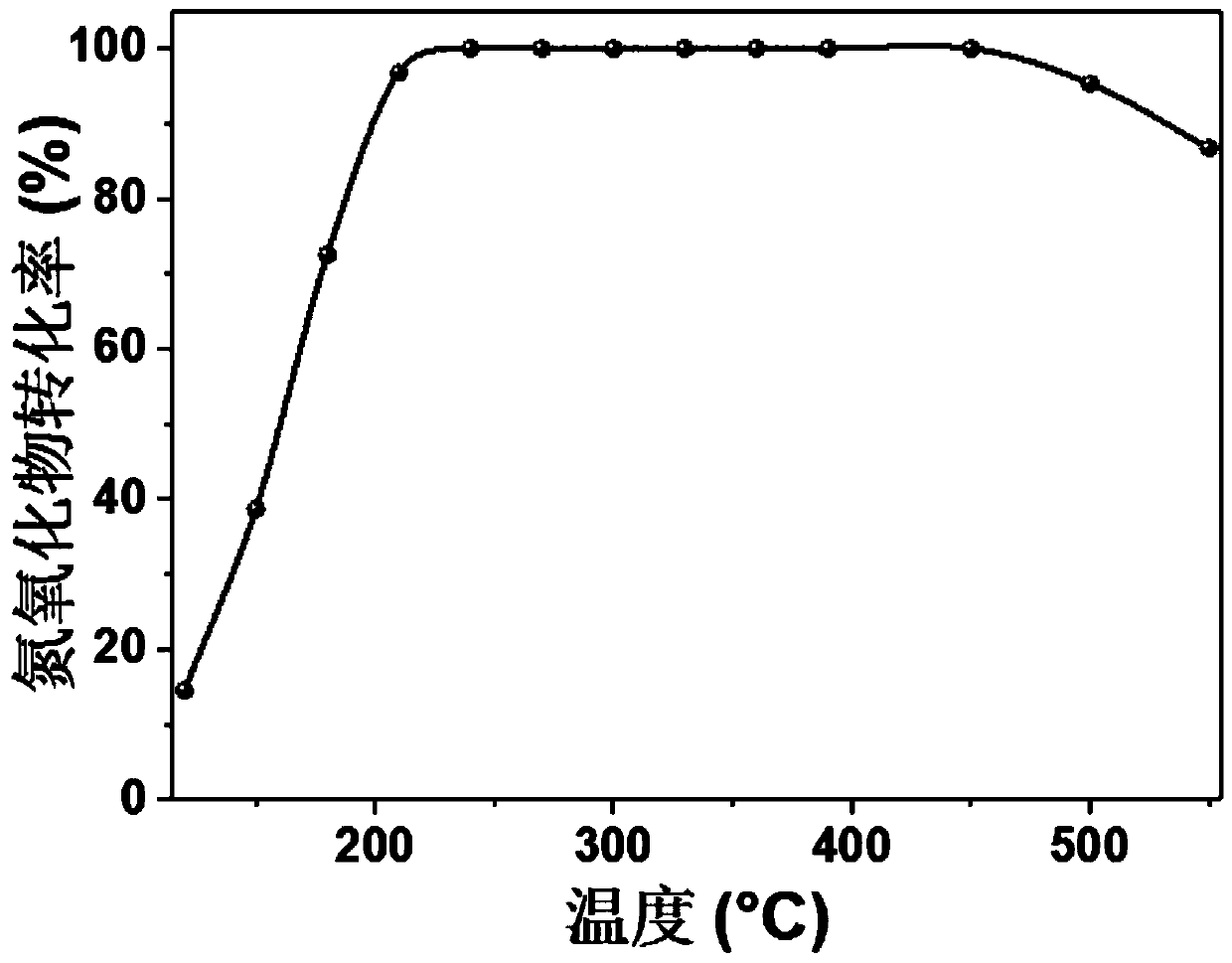

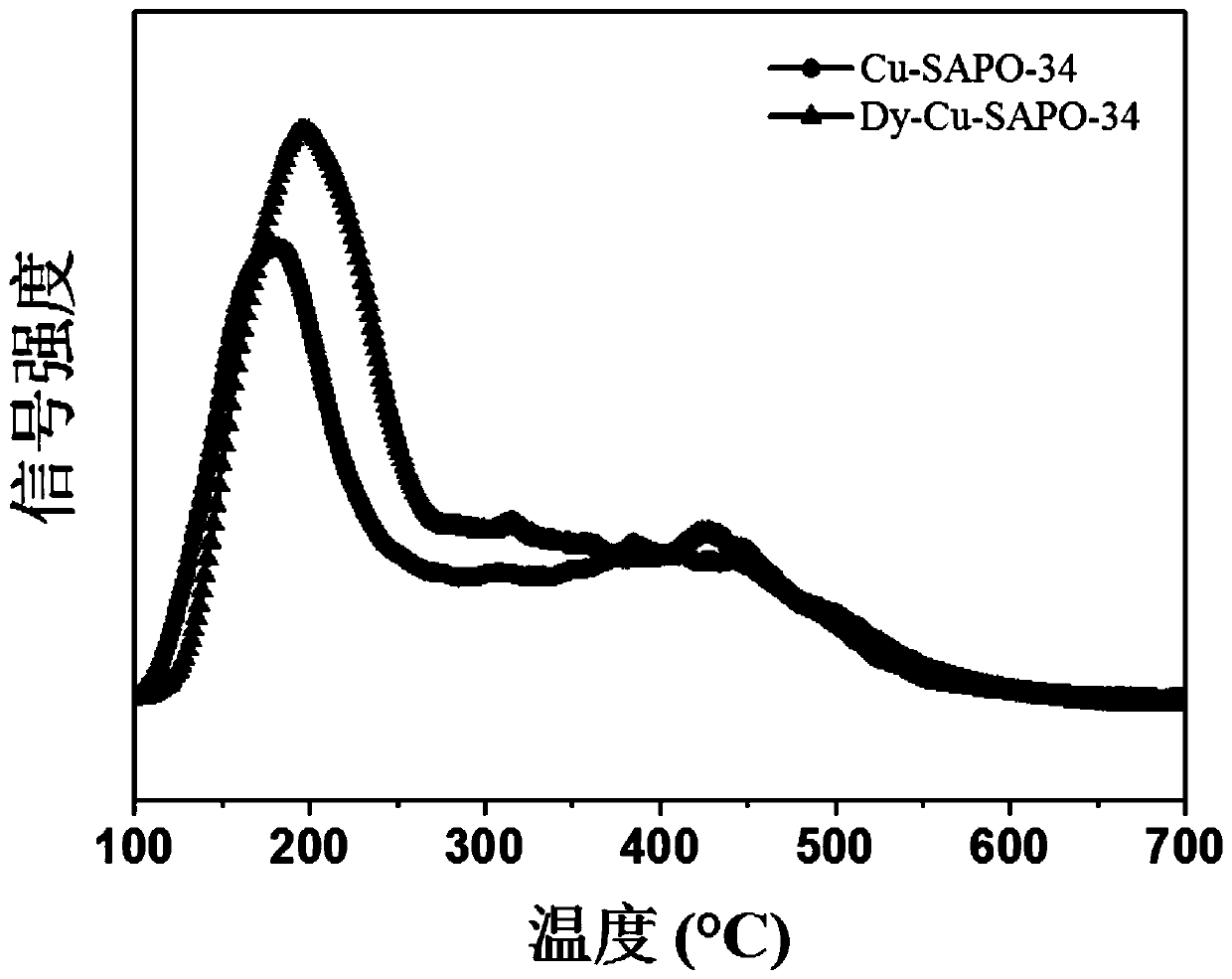

Dysprosium-modified Cu-SAPO-34 molecular sieve denitration catalyst and preparation method thereof

PendingCN110479358AHigh reactivityReduce NOx emissionsMolecular sieve catalystsMolecular sieveDysprosium nitrate

The invention discloses a dysprosium-modified Cu-SAPO-34 molecular sieve denitration catalyst and a preparation method thereof. The preparation method comprises the steps that: 1, weighing an aluminumsource, a silicon source, phosphoric acid, a template agent, copper nitrate, dysprosium nitrate and deionized water, and preparing a homogeneous aqueous solution A; 2, carrying out a hydrothermal reaction on the aqueous solution A obtained in the step 1, and aging the reaction product at 160-200 DEG C to obtain a reaction product B; and 3, washing and drying the reaction product B obtained in thestep 2, and calcining the reaction product B at the temperature of 450 DEG C or above to obtain the dysprosium-modified Cu-SAPO-34 molecular sieve denitration catalyst. The preparation method disclosed by the invention can be used for preparing the dysprosium modified Cu-SAPO-34 molecular sieve denitration catalyst disclosed by the invention; the dysprosium-modified Cu-SAPO-34 molecular sieve denitration catalyst provided by the invention can be used for selective catalytic reduction removal of nitrogen oxides in diesel vehicle tail gas, and has certain sulfur dioxide poisoning resistance andgood low-temperature catalytic performance.

Owner:XI AN JIAOTONG UNIV

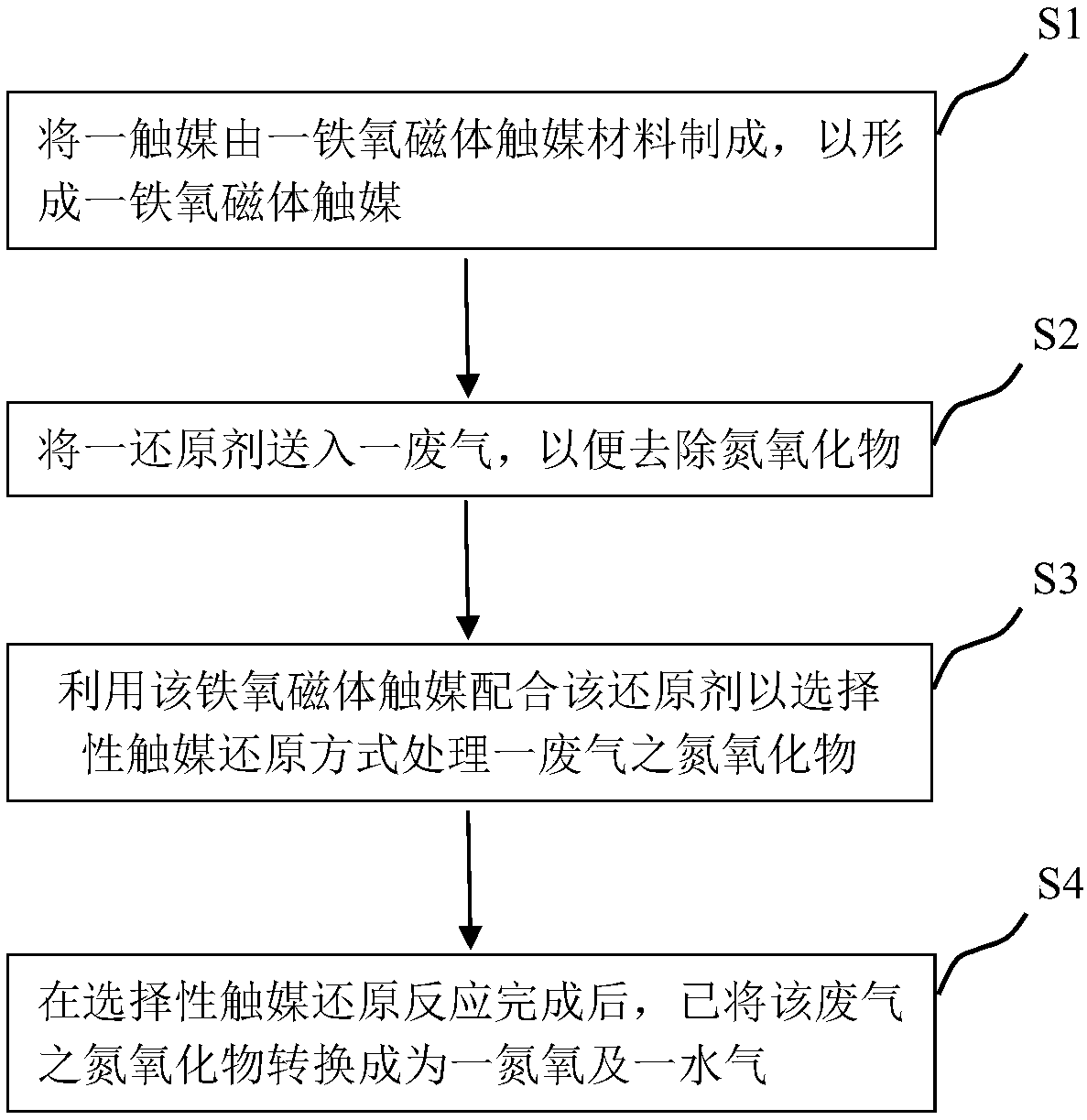

Ferromagnetic catalyst for treating nitric oxides in exhaust gas through selective catalytic reduction reaction and method thereof

InactiveCN108283884ALower starting temperatureImprove processing efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsExhaust gasNitric oxide

The invention discloses a method for treating nitric oxides in exhaust gas through a selective catalytic reduction reaction. The method comprises the following steps: preparing a catalytic agent froma ferromagnetic catalyst material so as to form a ferromagnetic catalyst; feeding a reducing agent into exhaust gas so as to conveniently remove nitric oxides in the exhaust gas; matching the ferromagnetic catalyst and the reducing agent, and treating a nitric oxide in the exhaust gas in a selective catalytic reduction reaction manner; transforming the nitric oxide in the exhaust gas into nitrogenand water vapor after the selective catalytic reduction reaction is completed. The treatment temperature of the ferromagnetic catalyst reduction reaction ranges from 50 DEG C and 450 DEG C.

Owner:NAT KAOHSIUNG UNIV OF SCI & TECH

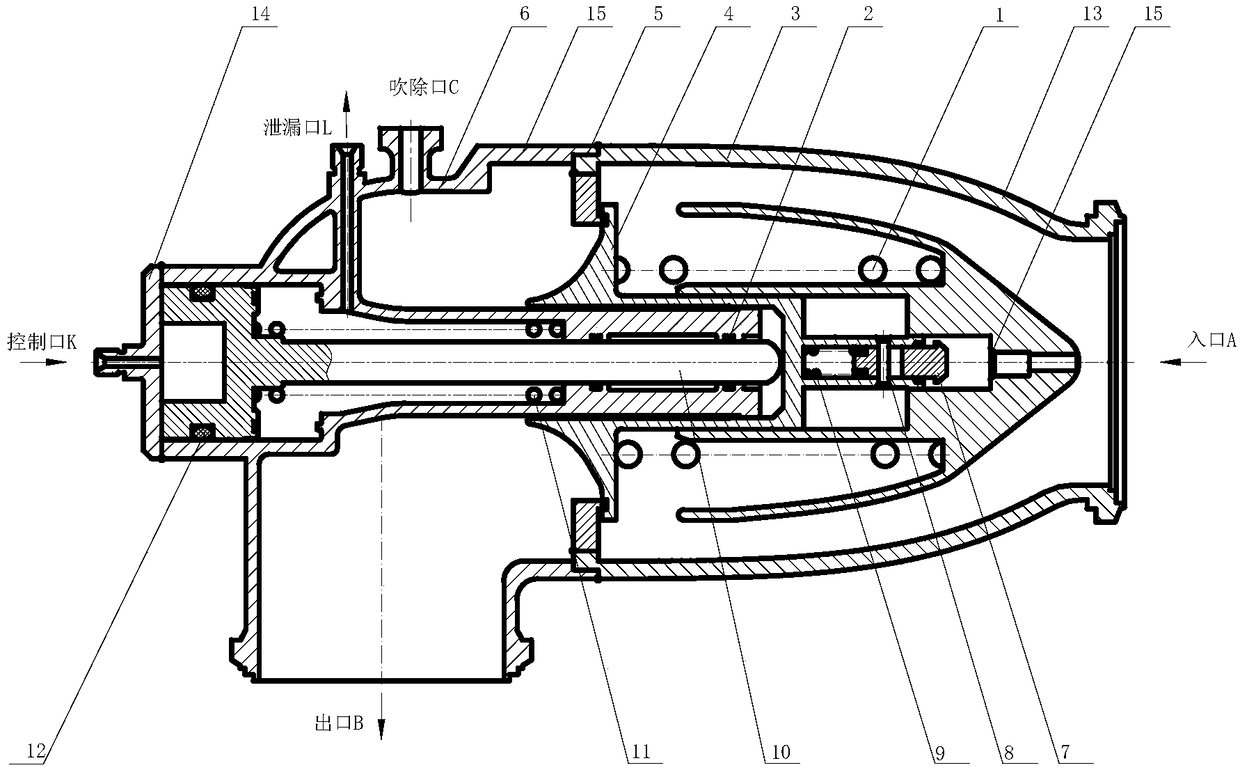

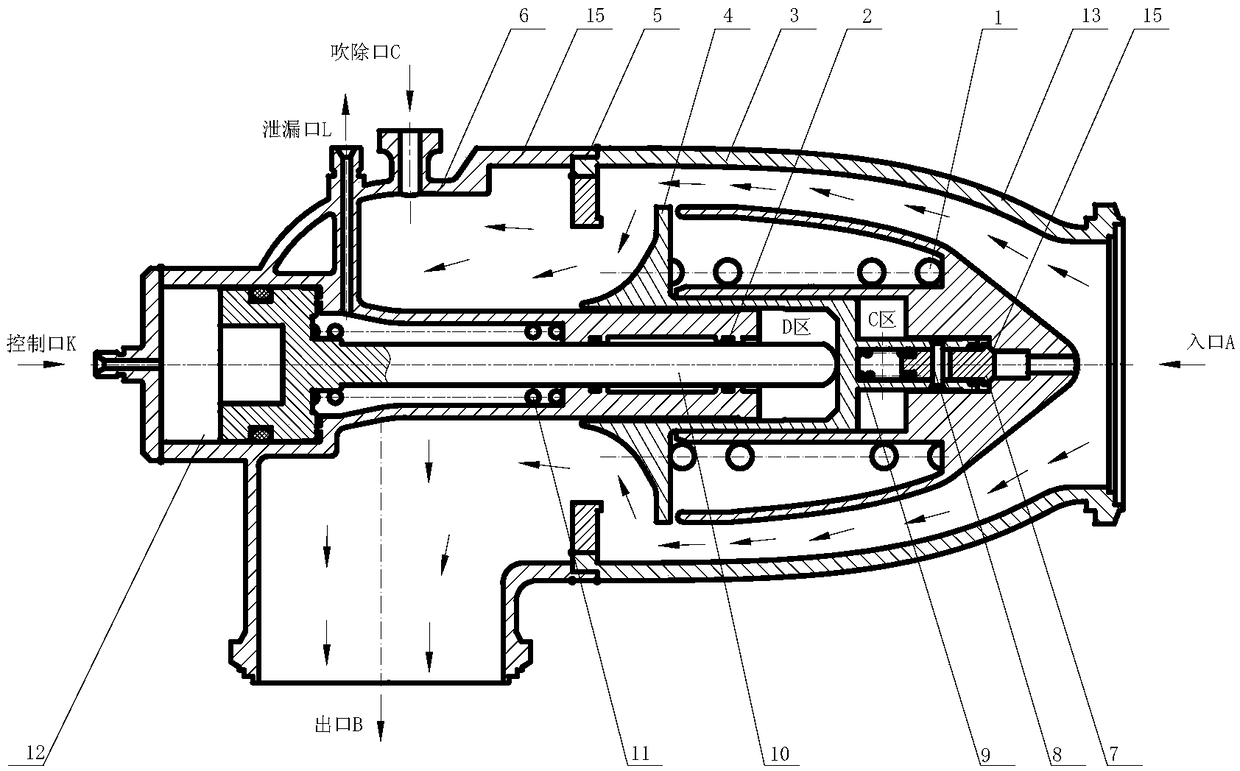

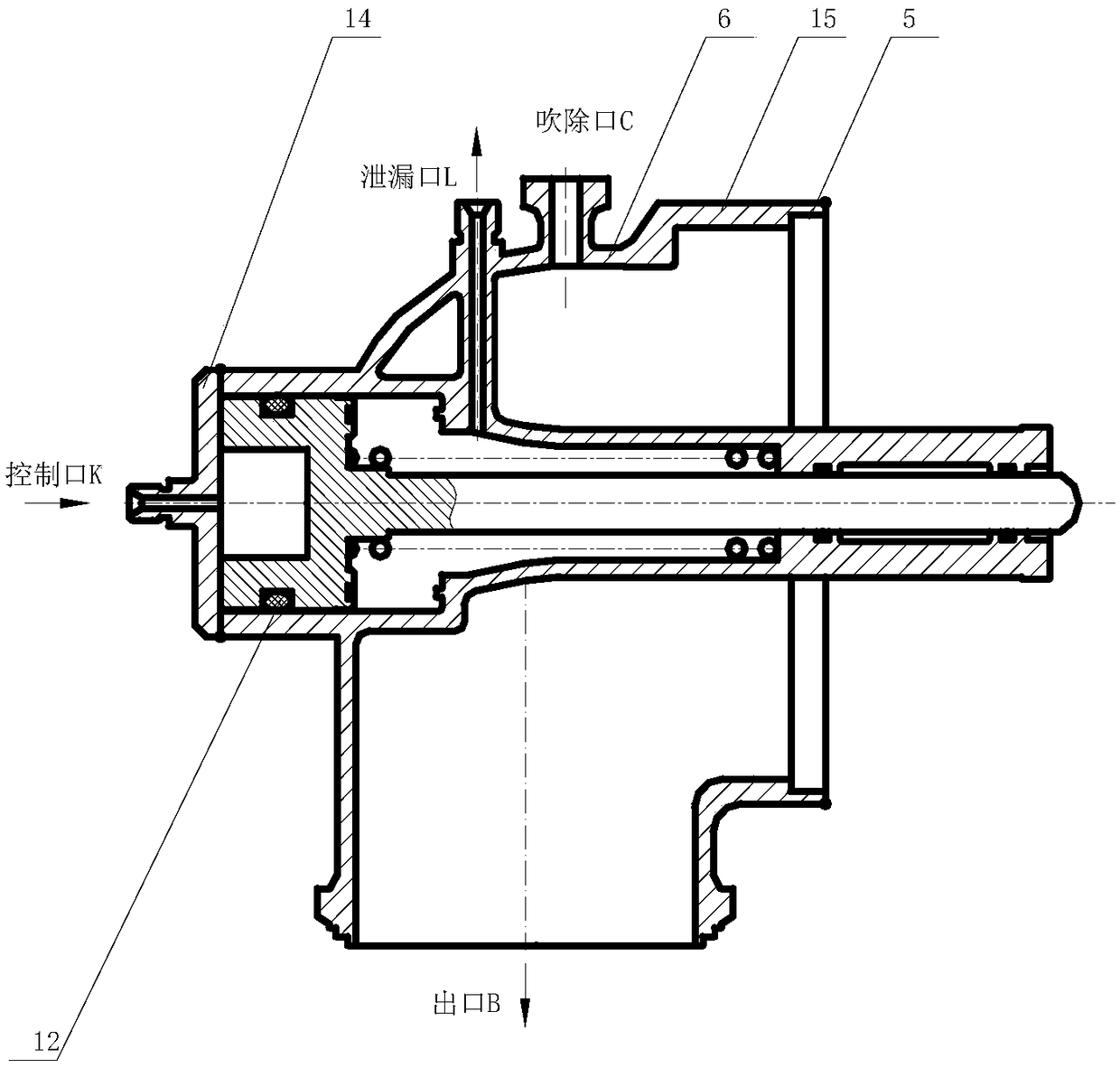

Ultralow-temperature piston actuating type high-pressure valve with buffer function

PendingCN108869050AImprove assembly manufacturabilityGood maintainability and testabilityTurbine/propulsion fuel valvesEngineeringHigh pressure

The invention discloses an ultralow-temperature piston actuating type high-pressure valve with a buffer function. The ultralow-temperature piston actuating type high-pressure valve comprises an inletmultilayer shell component and an outlet shell component, wherein the outlet shell component comprises an outlet shell and the like; the outlet shell is of an integral structure and comprises a shelland a guiding barrel; the shell is of a bending pipe shape; one end of the guiding barrel extends out of the hole of one end of the shell, and the other end extends out of a barrel wall on the turn ofthe shell; a leakage hole is introduced out of the shell from the side wall of the guiding barrel, and a blowdown hole is positioned on the barrel wall of the shell and corresponds to the hole of theother end of the shell; a piston rod is installed in the guiding barrel; a control cavity cover plate is installed on one end, which extends out of the barrel wall of the shell, of the guiding barrel; the center of the control cavity cover plate is provided with a control hole; a second auxiliary spring is installed on the piston rod; the outlet shell is connected with the end of the inlet multilayer shell; the guiding barrel is inserted into a main valve. According to the ultralow-temperature piston actuating type high-pressure valve, a valve actuating mechanism is matched and optimized withlarge-flow lower flow resistance so as to meet the requirements of high working condition and reuse for multiple times.

Owner:BEIJING AEROSPACE PROPULSION INST

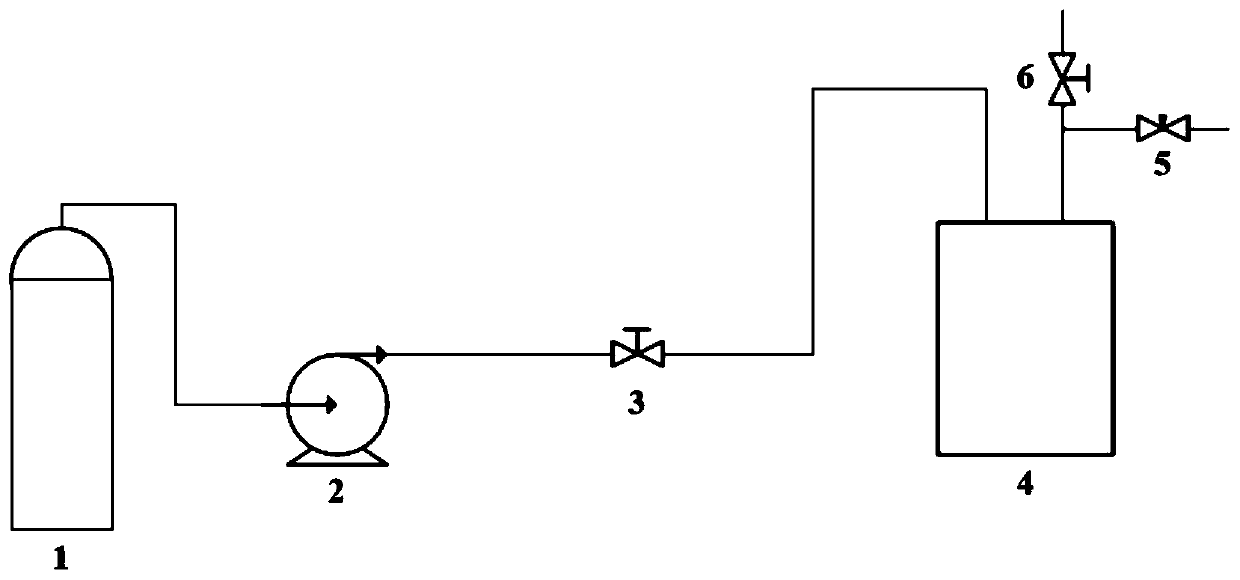

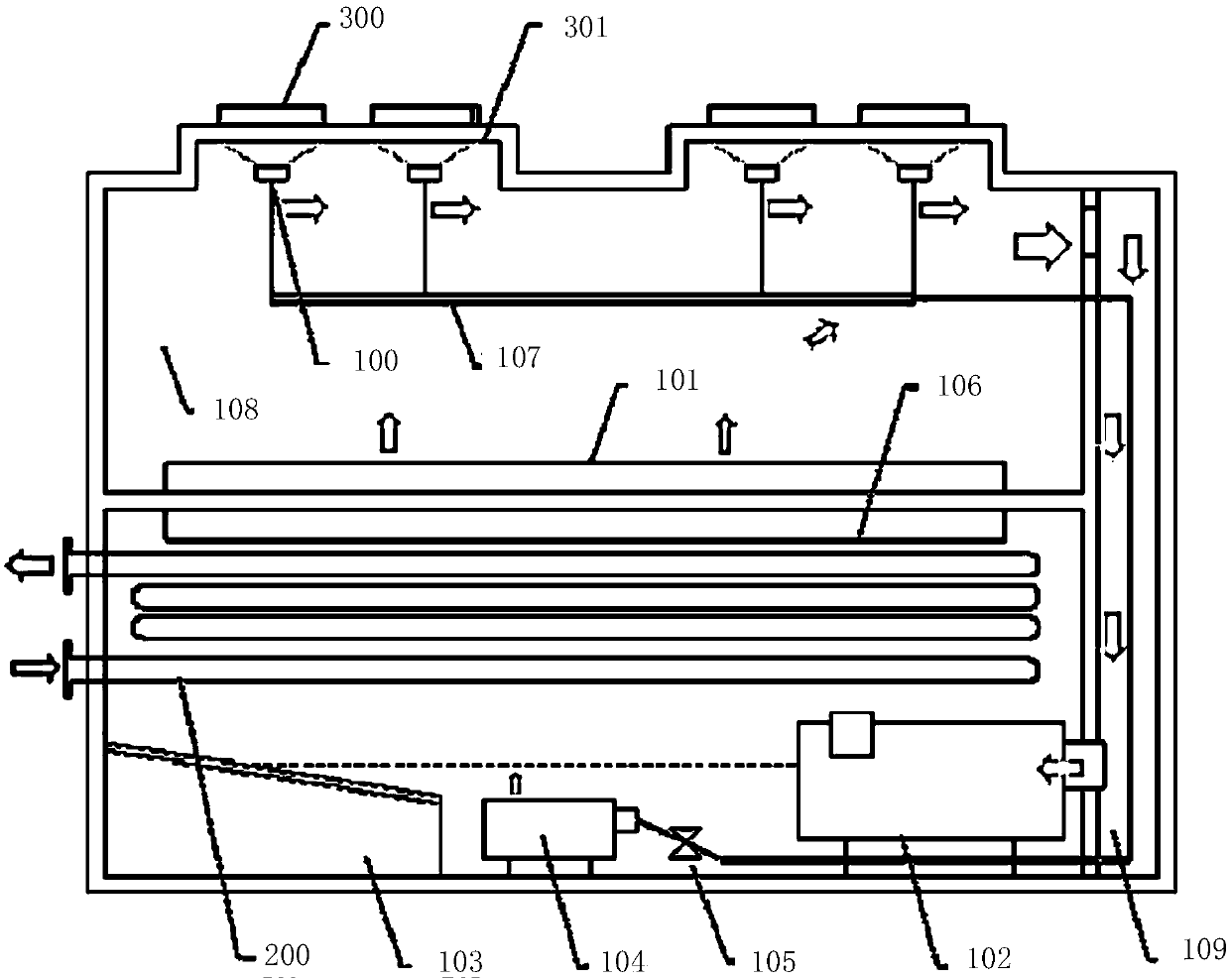

Power module life test cooling device

ActiveCN109755193AImprove cooling efficiencyWiden the temperature rangeSemiconductor/solid-state device detailsSolid-state devicesEvaporationComputer module

The invention discloses a power module life test cooling device comprising a cooling chamber, a condenser, an air pressure regulating pump, a coolant circulating pump, a partition, a coolant conveyingpipe and a spraying hole disposed at the outlet of the coolant conveying pipe and used for spraying the coolant to the position of the power module, wherein the partition divides the cooling chamberinto an evaporation cavity and a condensation cavity located at the lower portion of the evaporation cavity, the evaporation cavity is connected with the condensation cavity, the cooling chamber is asealed chamber, the coolant circulating pump is disposed on the coolant conveying pipe, the condenser is located in the condensation cavity, the inlet of the coolant conveying pipe is located in the coolant of the condensation cavity, and the air pressure regulating pump is configured to pump the air in the evaporation cavity to the condensation cavity. The cooling efficiency of the power module life test cooling device is improved.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

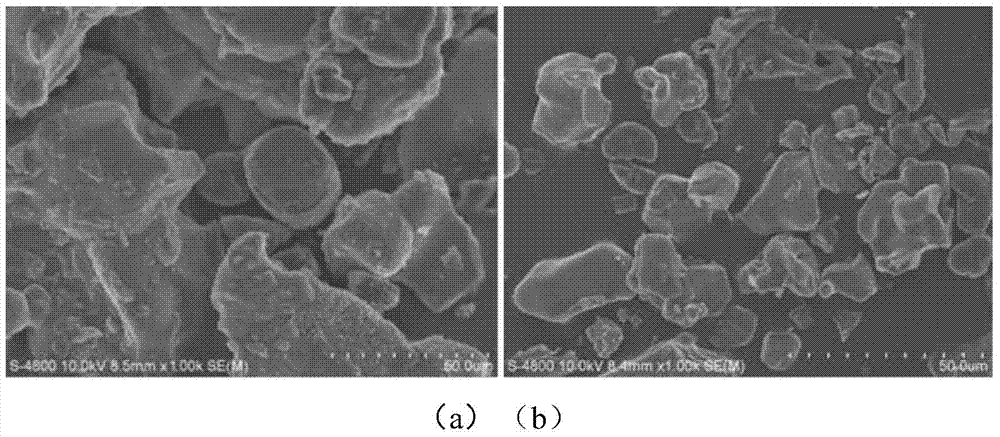

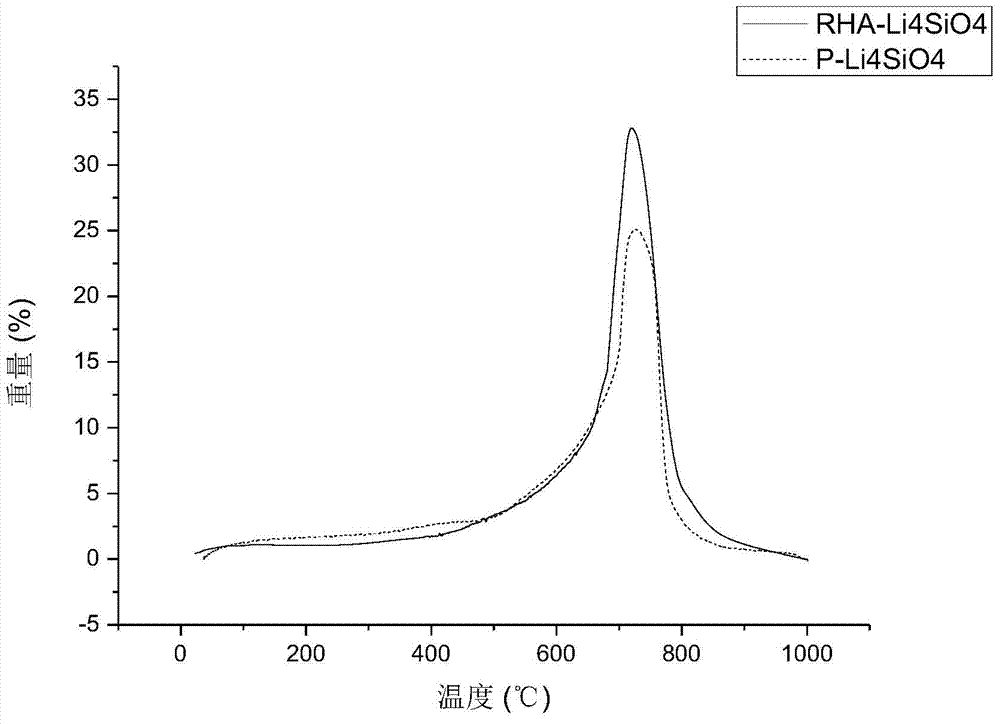

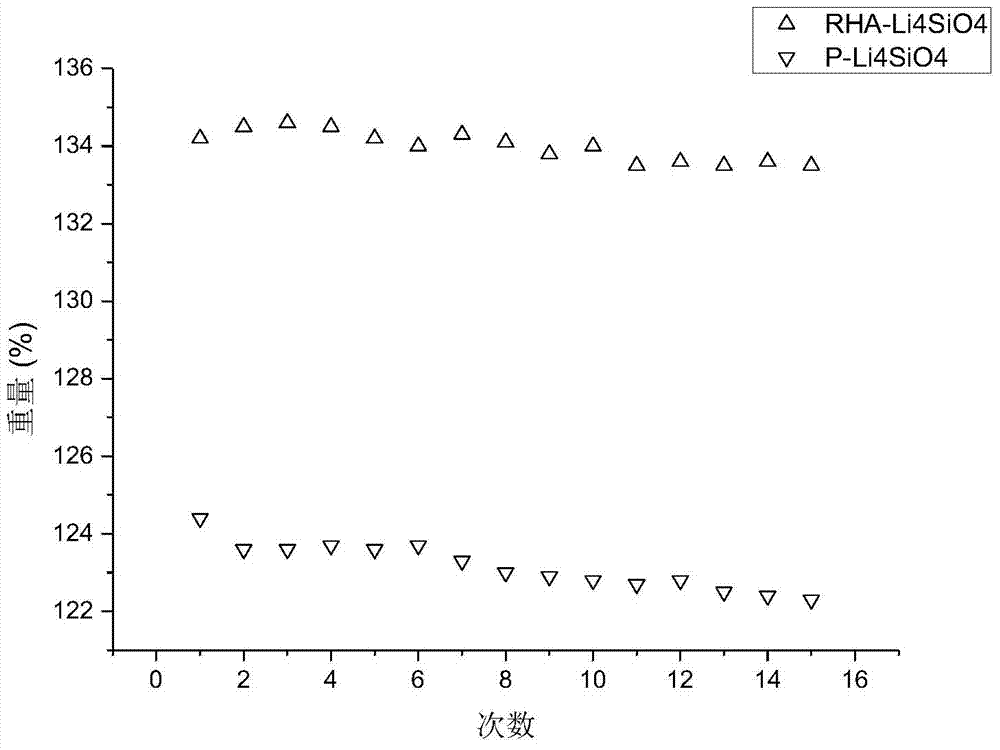

Method for producing hydrogen by reforming of methane steam

InactiveCN104495750AImprove adsorption capacityImprove cycle stabilityHydrogenBulk chemical productionSorbentReaction rate

The invention discloses a method for producing hydrogen by reforming of methane steam and belongs to the field of hydrogen production. A mixture formed by mixing rice hull ash lithium silicate and a catalyst is applied in methane steam for producing hydrogen at a reaction temperature of 550-720 DEG C, wherein the rice hull ash lithium silicate is obtained by calcining rice husk and lithium carbonate at a high temperature of 1000 DEG C and has the particle size of 150mu m-300mu m, and the rice hull ash lithium silicate comprises a lithium element and a silicon element at a molar ratio is (4.2:1)-(8:1). Compared with the existing process for producing hydrogen, the method for producing hydrogen by reforming of methane steam and using rice hull ash lithium silicate as an adsorbent has the advantages of low cost, stable reaction, high reaction rate, high yield of hydrogen and high purity.

Owner:HUAZHONG UNIV OF SCI & TECH

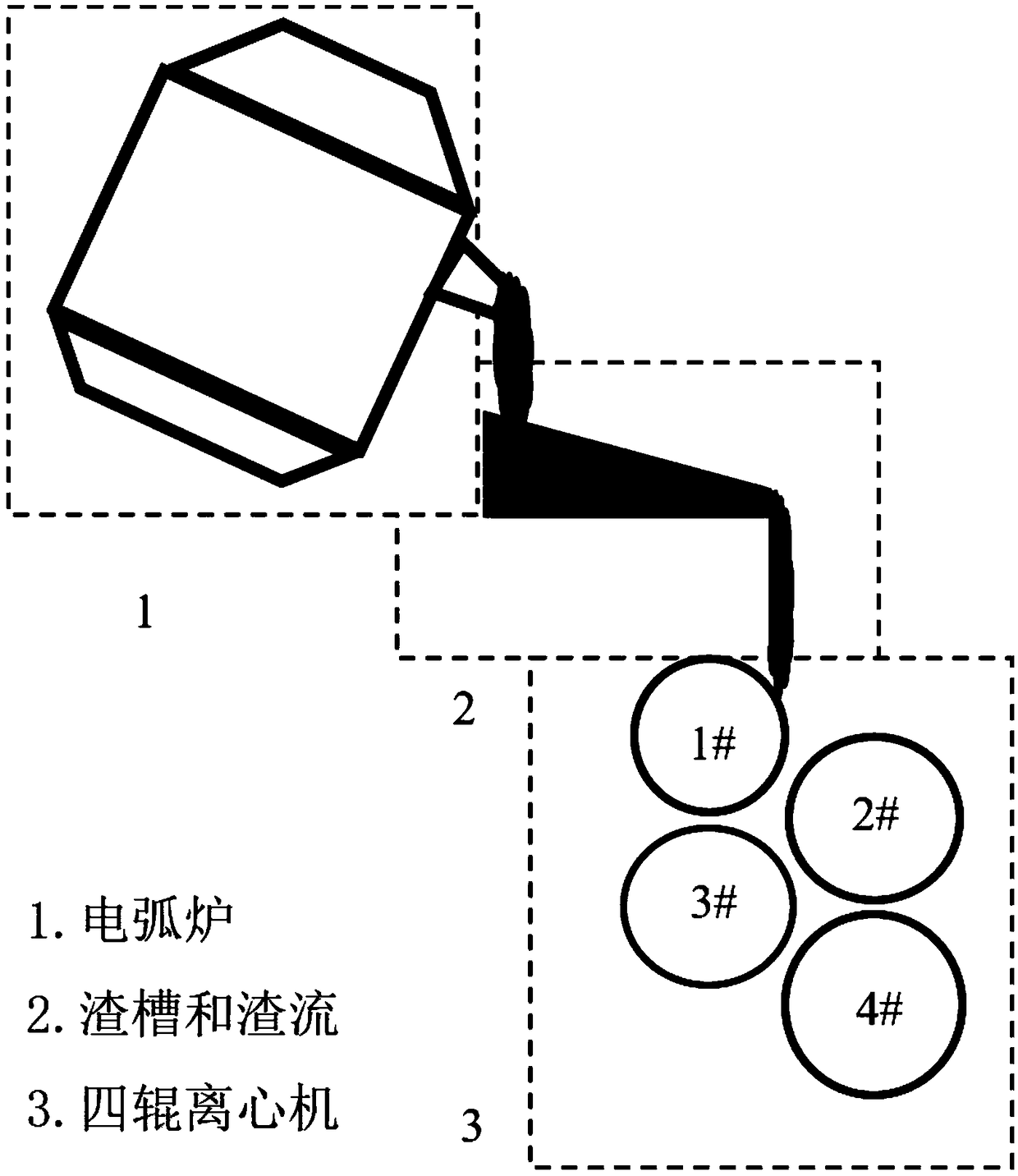

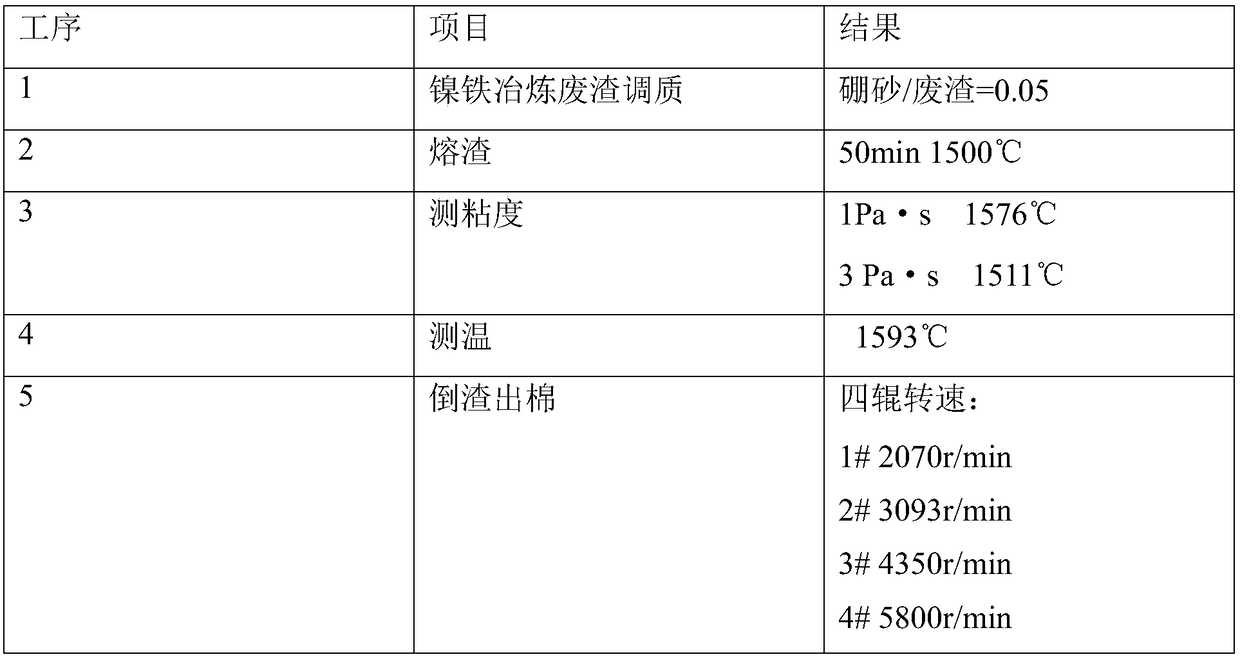

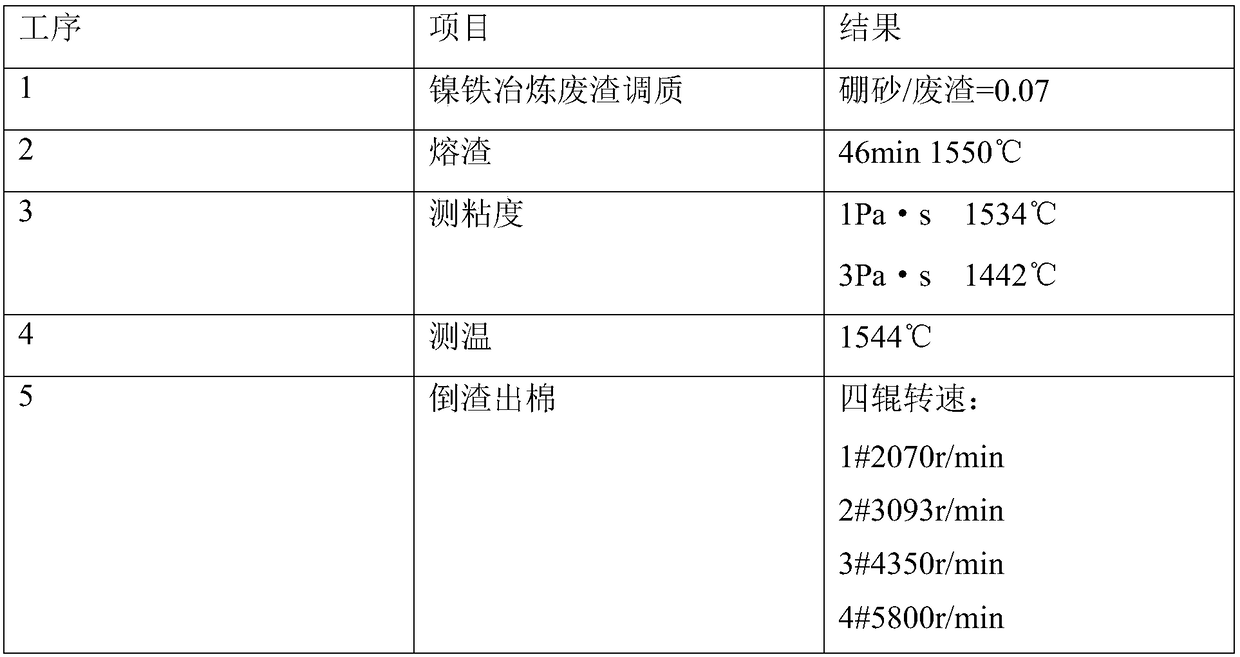

Application of boron-oxygen-containing compound to production of mineral wool

ActiveCN109052976AImprove physicsGood chemical propertiesGlass making apparatusManufacturing technologySlag

The invention relates to application of a boron-osxygen-containing compound to production of mineral wool and belongs to the technical field of production and manufacturing of the mineral wool. According to the application of the boron-oxygen-containing compound to the production of the mineral wool, provided by the invention, smelting slag is used as a raw material and the boron-oxygen-containingcompound is taken as a process control agent; the process control agent is added into the smelting slag and is heated to be fused; a fused melt is prepared into the mineral wool; when the process control agent is used, a temperature spanning range is 65 to 100 DEG C when a viscosity range of the melt is 1 to 3Pa.s. According to the application provided by the invention, reasonable proportioning between borax and ferro-nickel smelting waste slag is ingeniously utilized, and physical and chemical properties of the ferro-nickel smelting waste slag are remarkably improved, so that the ferro-nickel smelting waste slag is changed into a high-quality raw material and the problem that ferro-nickel waste slag is not suitable for producing the mineral wool is solved; a produced product can be widely applied to the fields of buildings and the like, and recycling and economic application of the waste dreg is realized.

Owner:CENT SOUTH UNIV

Multiple-temperature-zone double-flow-way refrigeration equipment

InactiveCN106568219AWiden the temperature rangeImprove energy efficiencyMechanical apparatusCompression machines with cascade operationEngineeringVapor–liquid separator

The invention provides multiple-temperature-zone double-flow-way refrigeration equipment. The multiple-temperature-zone double-flow-way refrigeration equipment includes a double refrigeration system, a blower fan, an outdoor casing and a plurality of indoor storage cabinets, wherein a first condenser in the double refrigeration system and a first gas-liquid separation device in the double refrigeration system are connected; the first gas-liquid separation device is connected with a first heat exchanger; the first heat exchanger is connected with a second evaporator; the first gas-liquid separation device is connected with a first evaporator; the first evaporator is connected with the first heat exchanger; the second evaporator and the first heat exchanger are connected with a first compressor through a third heat exchanger; a third capillary and a first back heating pipe are arranged in a first heat regenerator, and perform heat exchange with each other; a fourth capillary and a second back heating pipe are arranged in a second heat regenerator, and perform heat exchange with each other; a heat exchange channel of the second heat exchanger is connected with an inlet of a second compressor through the first back heating pipe; and an outlet of a fourth evaporator is connected with an outlet of the second compressor through the second back heating pipe. The multiple-temperature-zone double-flow-way refrigeration equipment can improve the utilization rate of energy and the refrigeration performance, and can enlarge the refrigeration temperature range to improve the universality.

Owner:QINGDAO HAIER SPECIAL ICEBOX

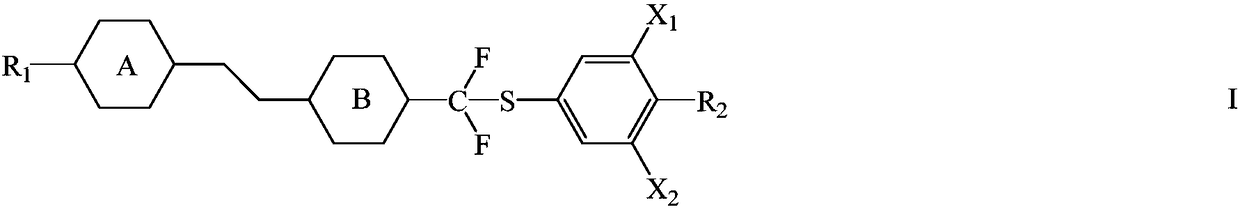

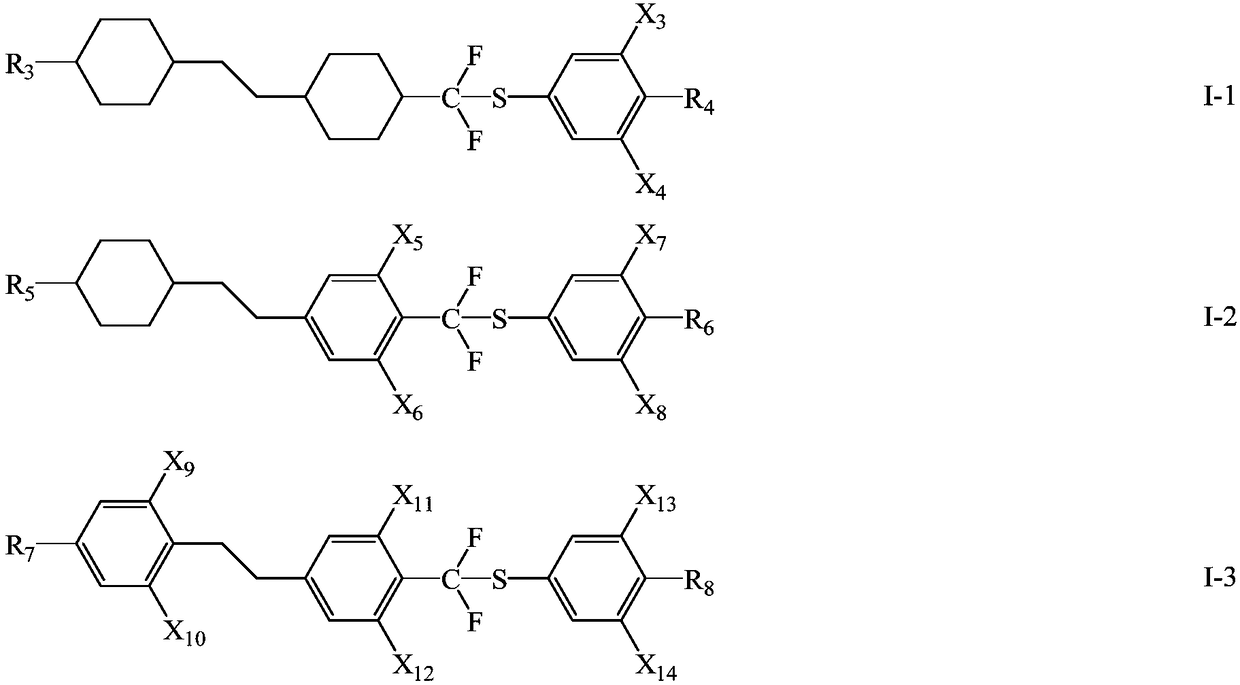

Liquid crystal compound, liquid crystal composition containing liquid crystal compound and photoelectric element

ActiveCN108822870AImprove the display effectGood compatibilityLiquid crystal compositionsNon-linear opticsIn planeWorking temperature

The invention discloses a liquid crystal compound, a liquid crystal composition containing the liquid crystal compound and a photoelectric element. The liquid crystal compound is prepared from components in percentage by weight: 6% to 21% of first component (liquid crystal compound) and 79% to 94% of second component; the weight percentage sum of all the components is 100%. The liquid crystal compound provided by the invention has good intermiscibility, broadens a temperature region in low-temperature application and reduces the viscosity; the liquid crystal composition containing the liquid crystal compound reduces Tcn, a low-temperature storage temperature and a low-temperature working temperature of the liquid crystal compound, has a lower viscosity, is beneficial for improving a liquidcrystal display effect and shortening response time, is related to proper optical anisotropy, higher dielectric anisotropy, a lower threshold voltage, a higher VHR (Voltage Holding Ratio), excellentreliability and thermal stability, and is applied to positive TN-TFT (Twisted Nematic Thin Film Transistor), IPS (In-Plane Switching), FFS (Fringing Field Switching), PSA (Polymer-Stabilized) mode liquid crystals.

Owner:XIAN CAIJING OPTO ELECTRICAL SCI & TECH

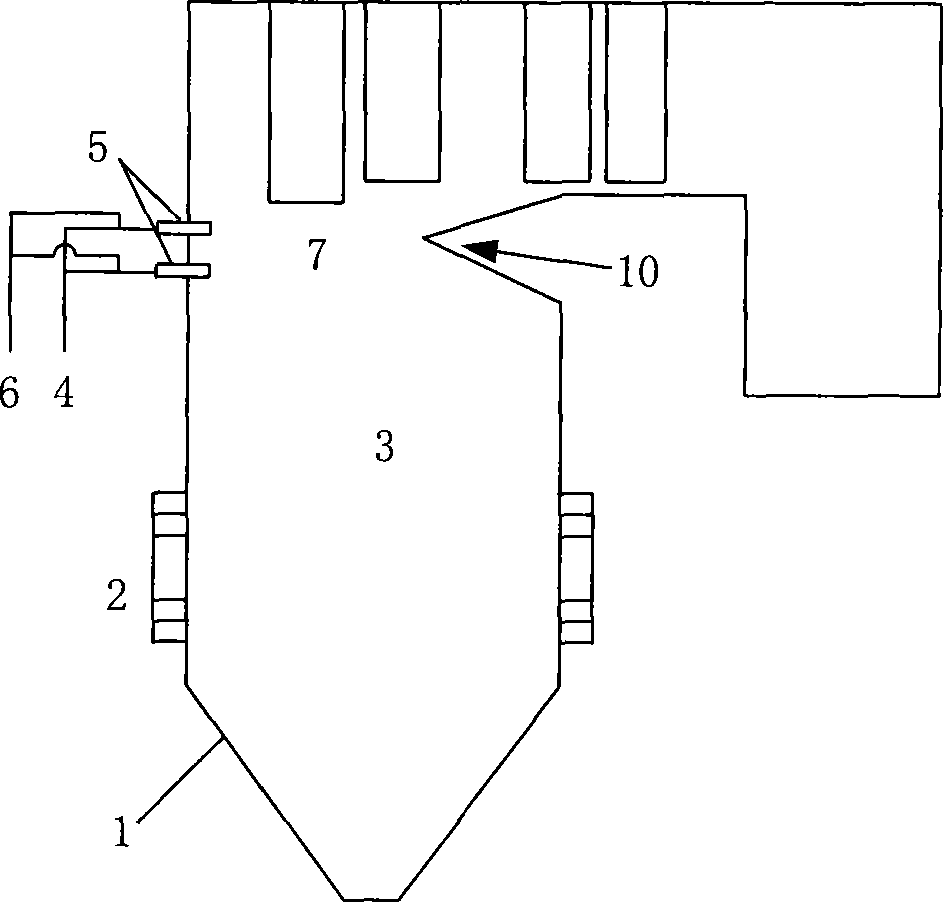

Method for accelerating selective non-catalytic reduction of nitrogen oxides

InactiveCN101244361BWiden the temperature rangeIncrease reaction rateDispersed particle separationRetention timeReaction rate

The invention relates to a promoting method for selective non-catalytic reduction (SNCR) of nitrogen-oxide, which is a technological method of adding addition agent to promote the denitrification process in the SNCR denitrification process for the power plant boiler and industrial furnace and other members, belonging to the nitrogen-oxide control technical field. The invention discloses a SNCR nitrogen-oxide method with the coal dust, natural gas or syngas as addition agent, in allusion to the problem of narrow suitable temperature range and lacking retention time existing in general SNCR denitrification technical application, which is characterized in that: the denitrification reaction rate is increased; the temperature range suitable for SNCR reaction is widen; the denitrification rate is increased and the leakage of ammonia is decreased. The promoting SNCR nitrogen-oxide method has advantages that: the reform is simple; the implementing is easy; the adoptive addition agent is cheapand available; the dosage is a little, so the combust process in the furnace is not influenced and no obvious secondary pollution is brought.

Owner:TSINGHUA UNIV

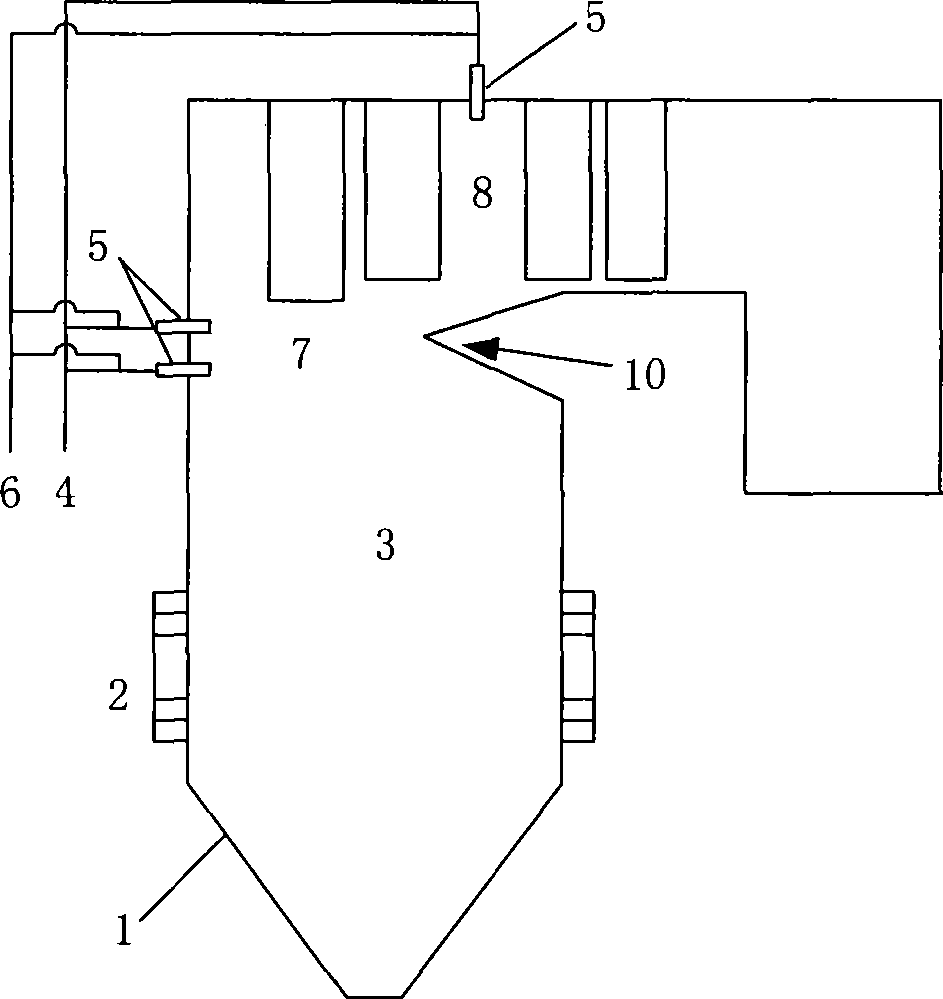

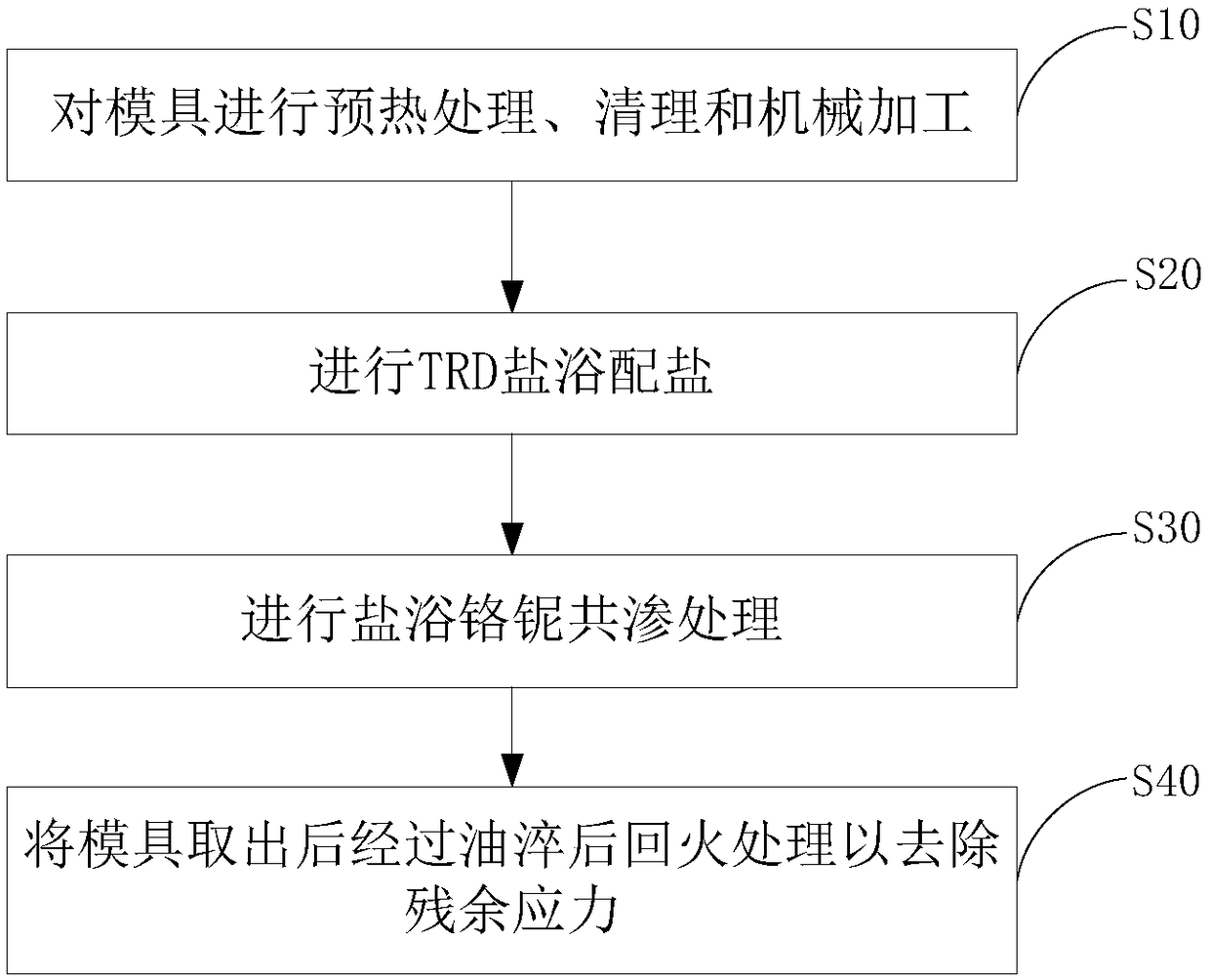

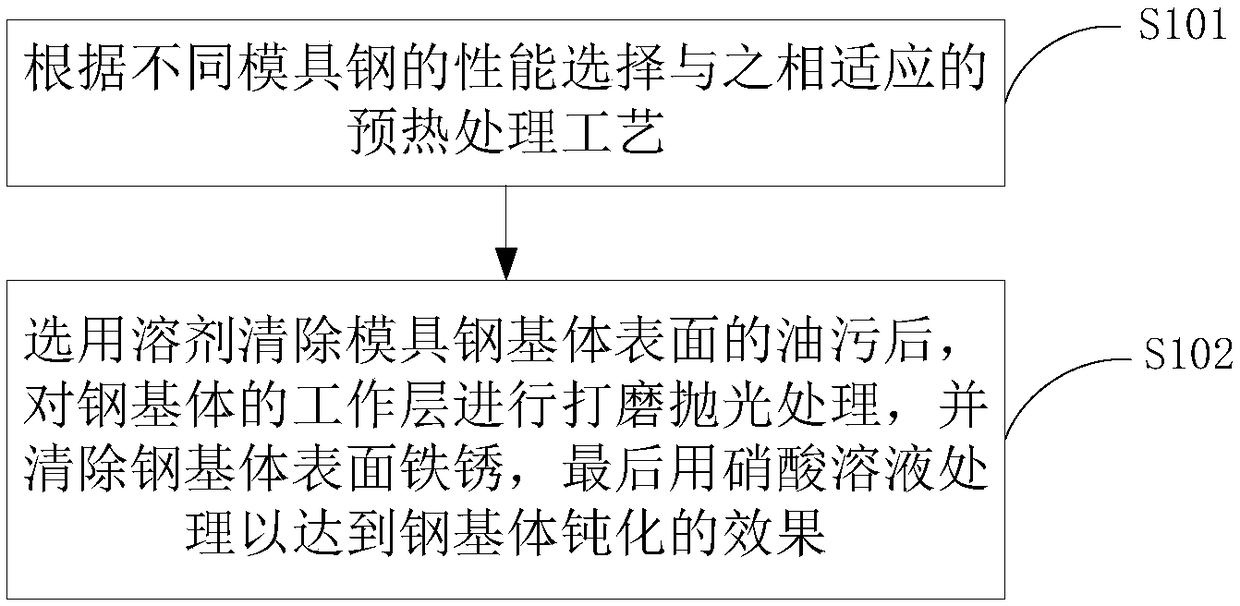

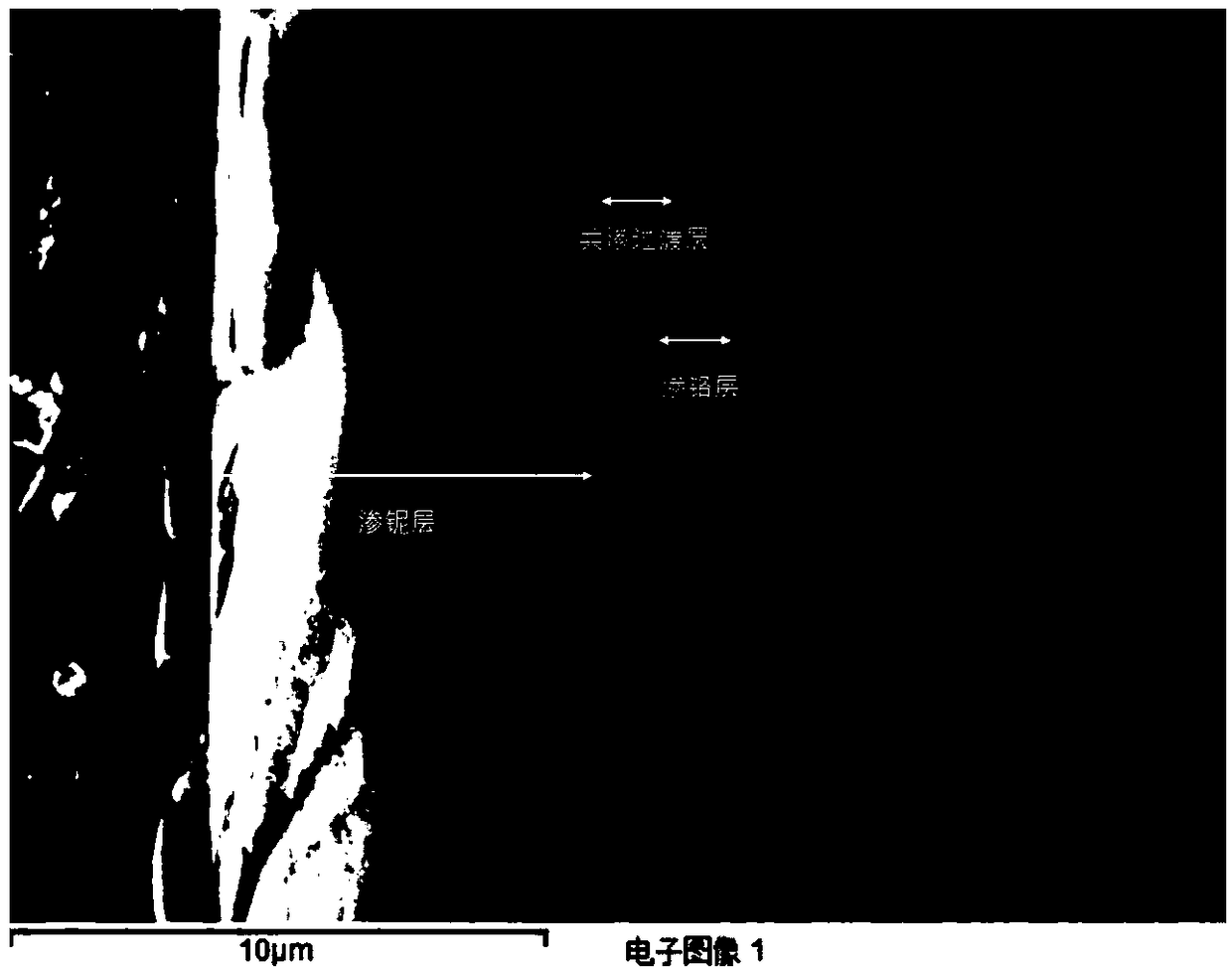

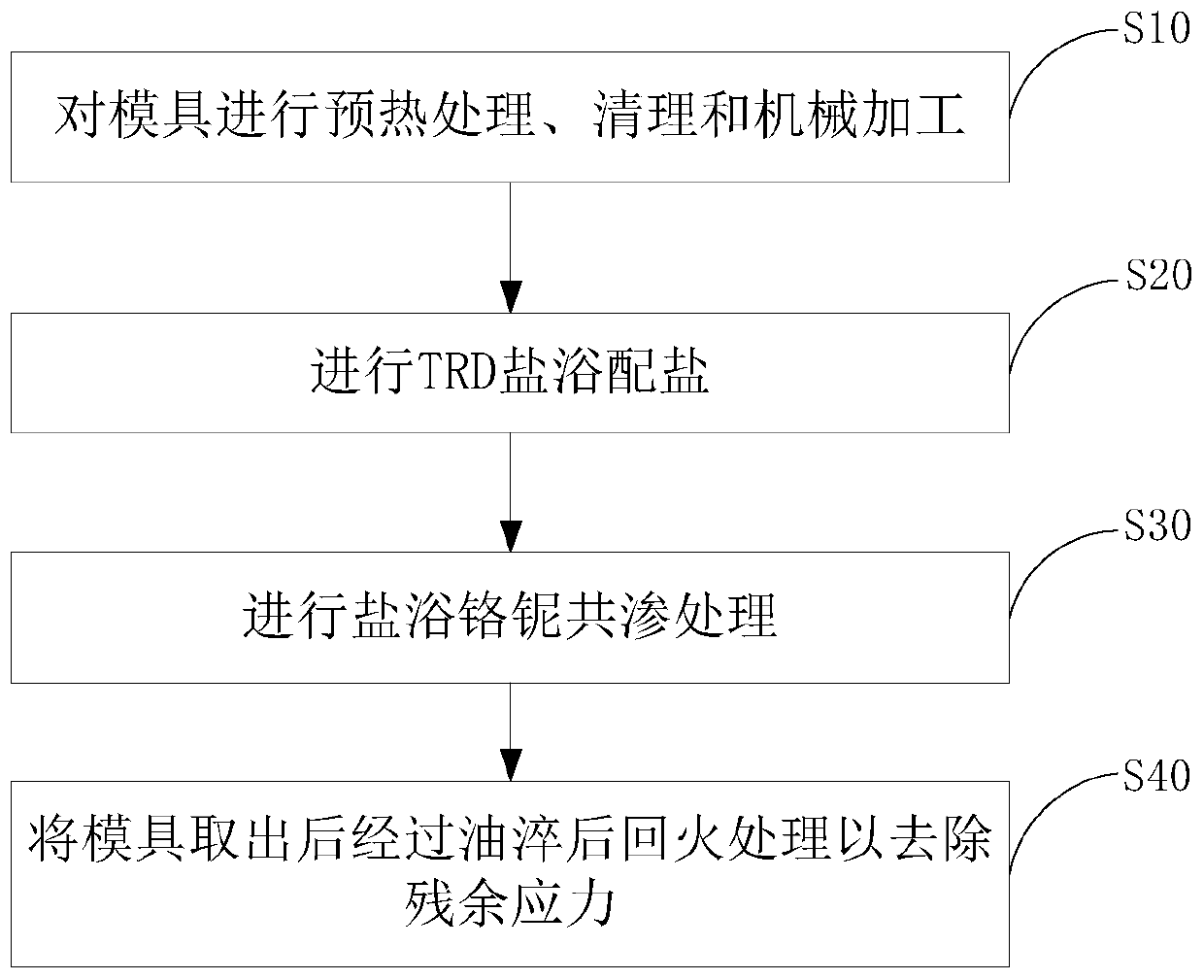

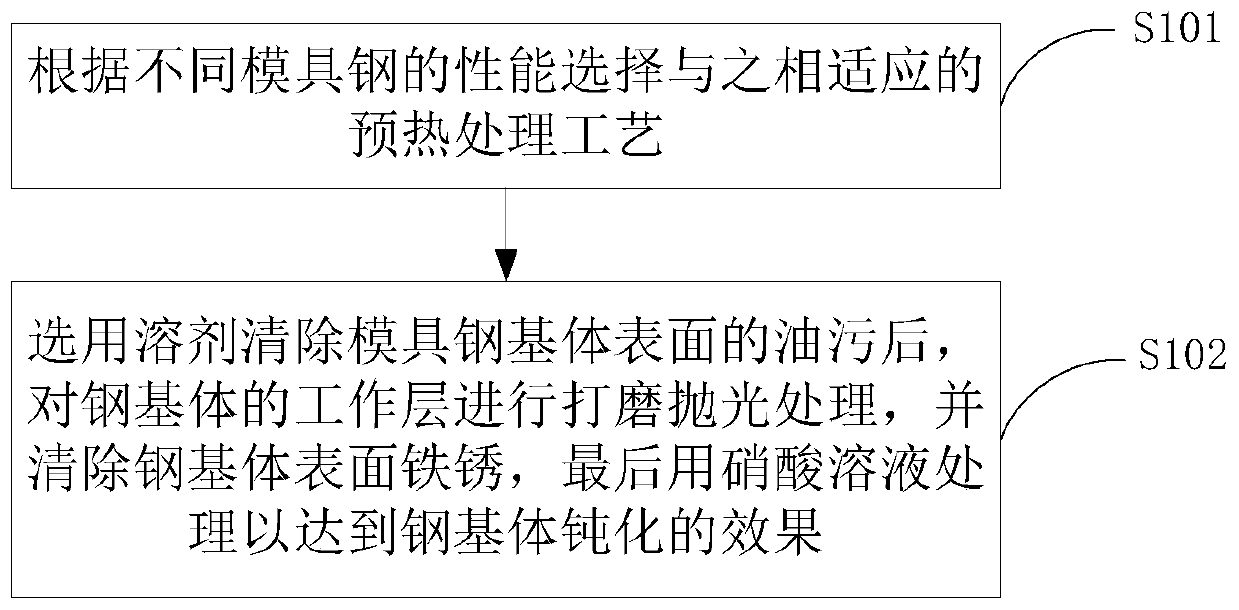

Preparation method of gradient cladding for blanking die surface reinforcing

ActiveCN108754410AImprove bindingImprove wear resistanceSolid state diffusion coatingProcess efficiency improvementNiobiumMolten salt

The invention discloses a preparation method of gradient cladding for blanking die surface reinforcing. The preparation method comprises the following steps that a die is preheated, cleared and machined; TRD salt bath salt preparation is conducted, specifically, a salt bath formula comprises, by mass, 70-75% of borax anhydrous, 8-12% of a chrome supplying agent, 4-6% of a niobium supplying agent,3-6% of a reducing agent and 8-10% of an activating agent; salt bath chrome and niobium co-soaking treatment is conducted, specifically, the die is soaked in a molten salt bath, the temperature of thefirst stage is 880-910 DEG C, and the heat-preservation time is 2-3.5 h; the temperature of the second stage is 930-940 DEG C, and the heat-preservation time is 2-3 h; the temperature of the third stage is 980-1040 DEG C, and the heat-preservation time is 3-4 h; and the die is taken out and then tempered after being subjected to oil quenching. According to the preparation method of the gradient cladding for blanking die surface reinforcing, the phenomenon that stress transition of the cladding is uneven is avoided, the service performance of the die is improved, and the service life of the die is prolonged.

Owner:WUHAN UNIV OF TECH

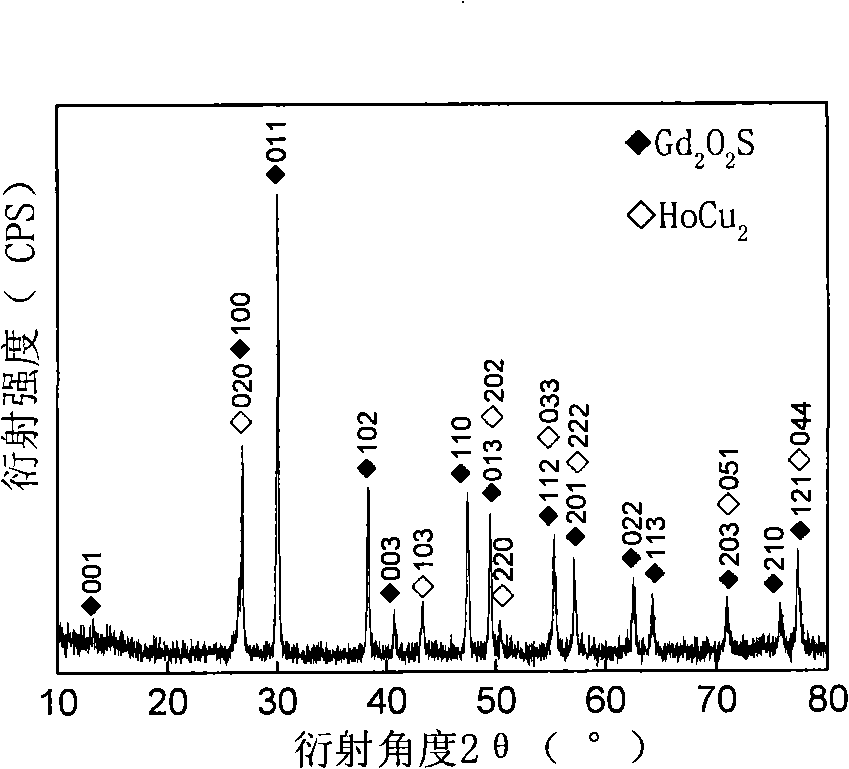

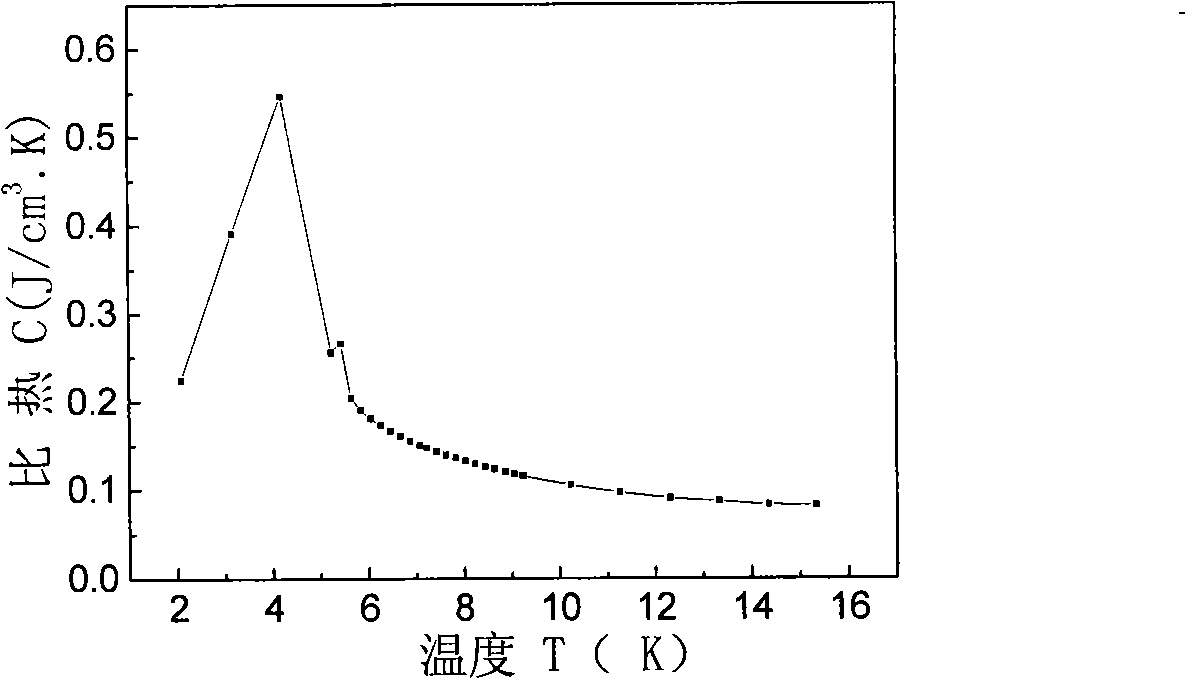

Rare earth doped oxysulfide - HoCu2 ceramic-metal composite magnetic cold-storage material

InactiveCN101275069AWiden the temperature rangeRealize disadvantagesHeat-exchange elementsCool storageDecomposition

The present invention belongs to function material field, relating to a rare earth oxysulfide-HoCu2 composite magnetic regenerator material, the regenerator material has a higher specific heat in 3-10K temperature range, beneficial to simplify the structure of regenerator, characterized in that the ratio of the composite magnetic regenerator material is based on Wt %, let the ration of rare earth doped oxysulfide is x, the ratio of HoCu2 is 1-x, the change range x of the rare earth doped oxysulfide ration is 30-70%, the specific process includes following steps: firstly, according to the ratio, weighing rare earth doped oxysulfide and HoCu2 two powder to place in a spheroidal miller, then adding a grinding ball and a milling medium, then adequately milling after sealed, then, filtering, drying the milled material, finally, pressing forming and processing sintering treatment, obtaining the rare earth oxysulfide-HoCu2 composite magnetic regenerator material. The composition of the rare earth oxysulfide magnetic regenerator material and HoCu2 avoids the problem of decomposition of the rare earth oxysulfide caused by the sintering in a high temperature. The cool storage ability of the new type magnetic regenerator material obtained after being combined is greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

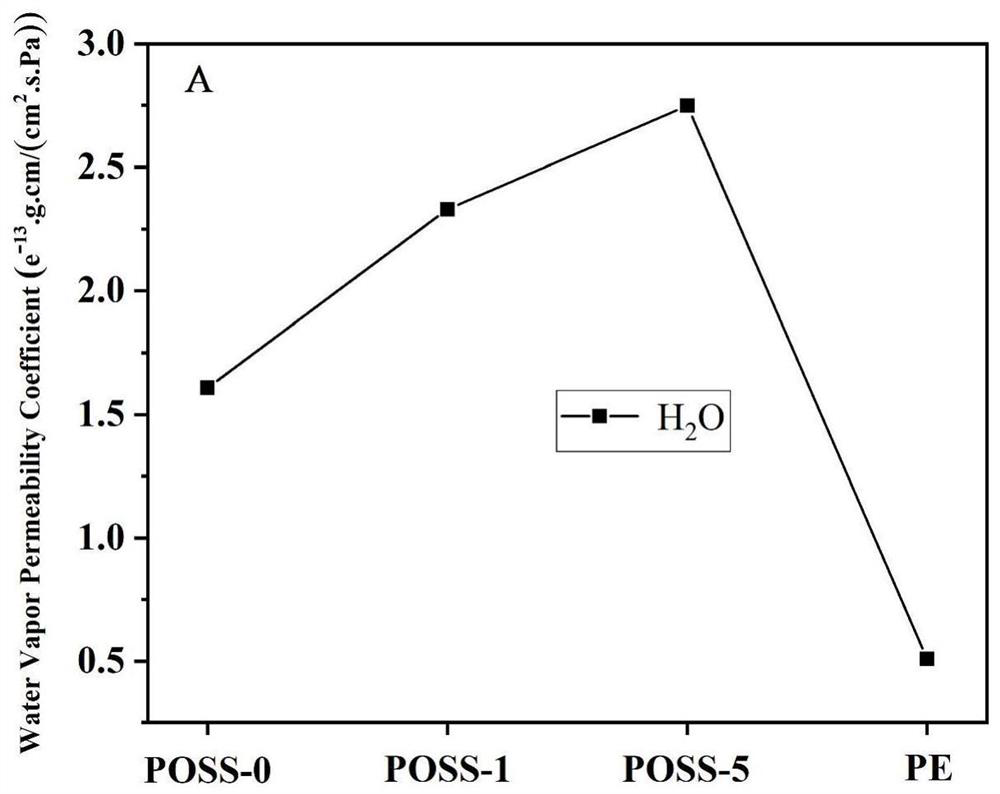

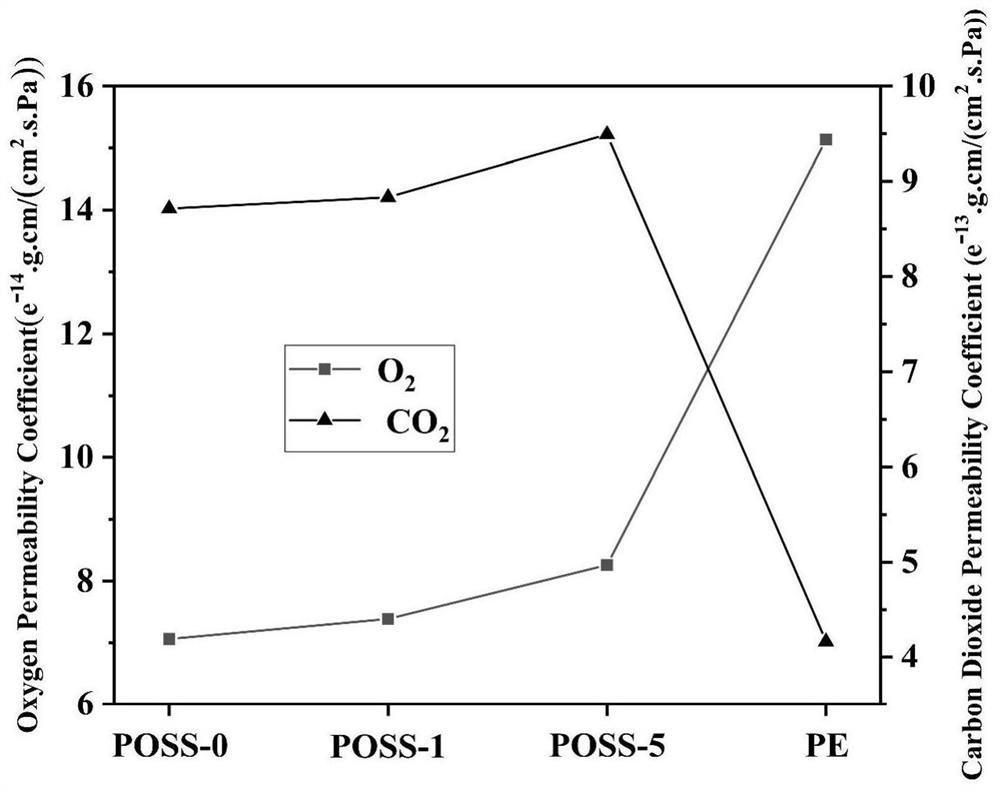

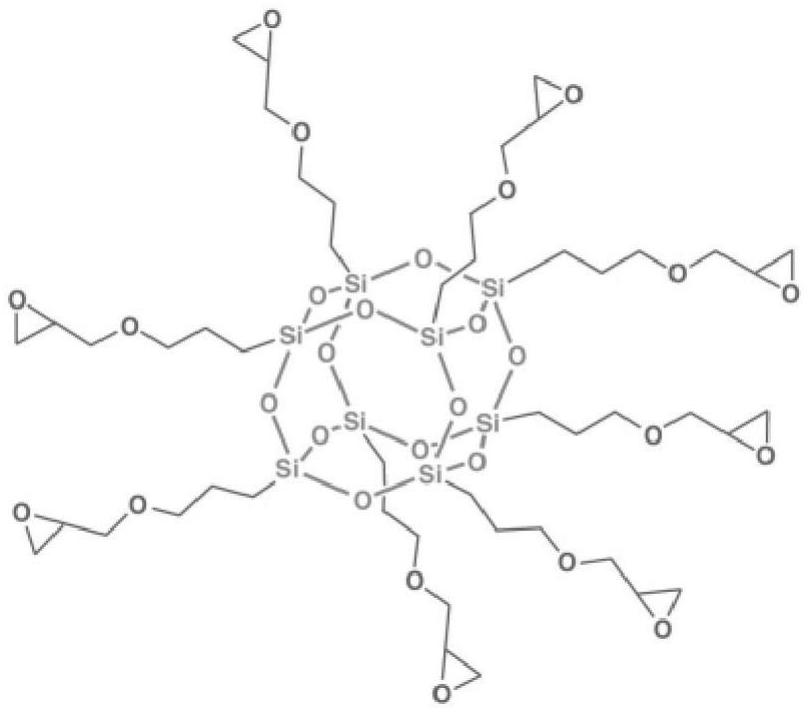

Reinforced and toughened polyadipic acid/butylene terephthalate-polylactic acid composite film and preparation method thereof

The invention belongs to the field of agricultural polymer materials. The invention relates to a film, in particular to a reinforced and toughened polyadipic acid / polybutylene terephthalate-polylacticacid composite film and a preparation method thereof. The specific scheme is as follows: firstly, mixing polyadipic acid / polybutylene terephthalate, polylactic acid granules and polyhedral oligomericsilsesquioxane (POSS (epoxy) 8) containing eight epoxy groups, then extruding by a twin-screw extruder, granulating by a granulator, and then blowing by a film blowing machine to obtain a film product. The provided preparation method is simple, polylactic acid and polyadipic acid / polybutylene terephthalate which are wide in source are used as main raw materials, excellent properties of polylacticacid and polyadipic acid / polybutylene terephthalate are combined, films with different air permeability are prepared by adding different contents of polyhedral oligomeric silsesquioxane containing eight epoxy groups, and different actual use requirements can be met; the obtained film has excellent comprehensive performance, is a fully biodegradable film, and plays an important role in relieving white pollution.

Owner:SHANDONG AGRICULTURAL UNIVERSITY +1

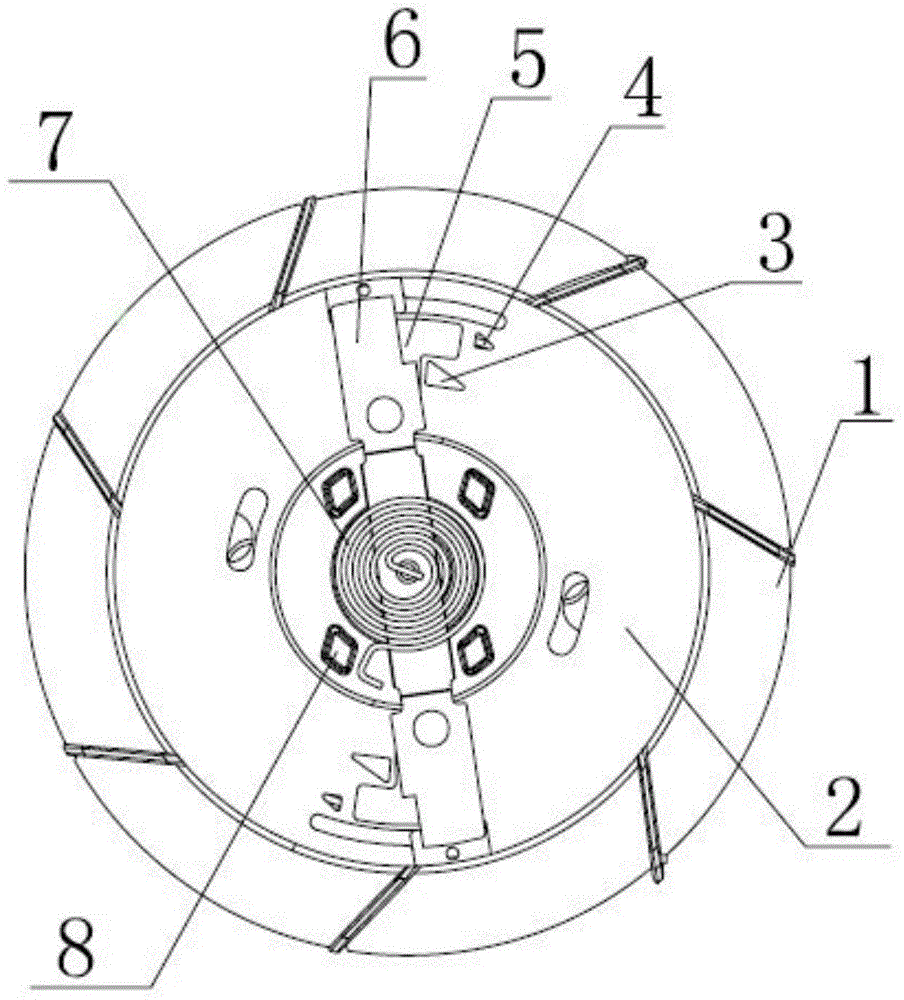

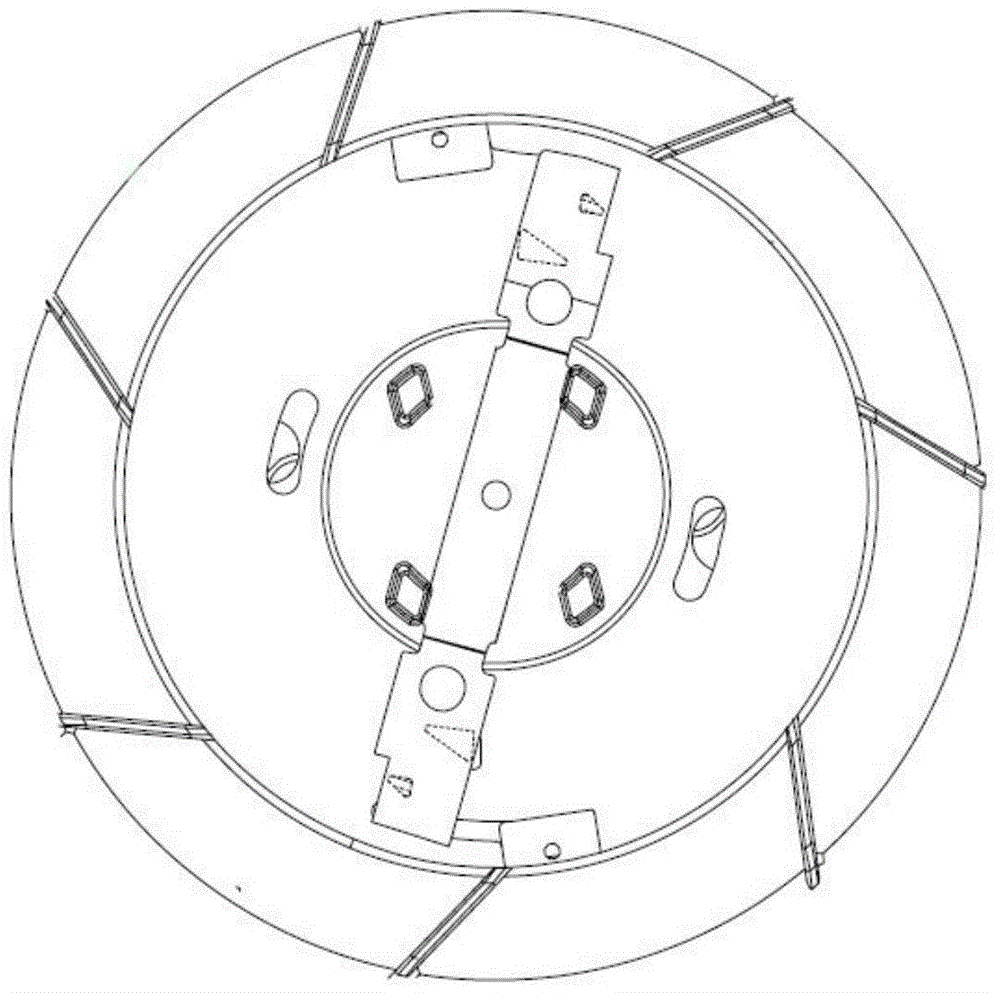

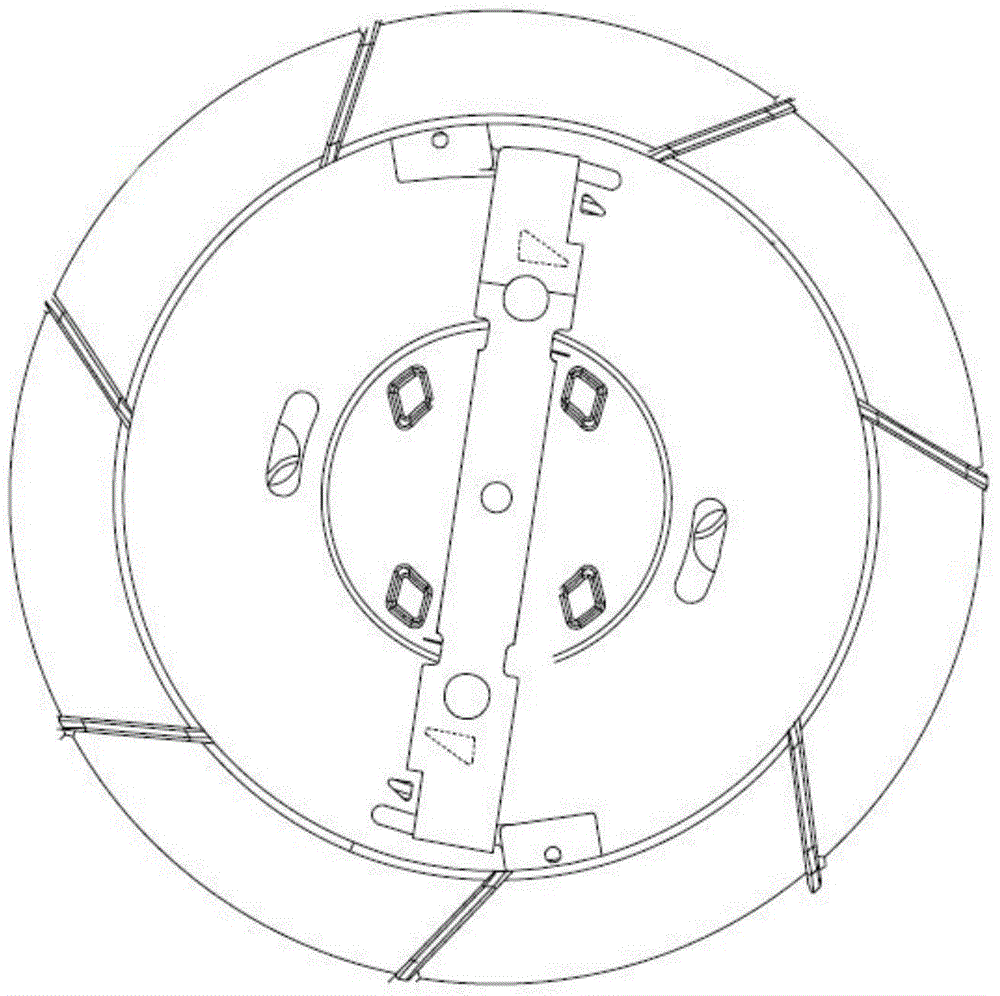

Continuously speed-variable fan silicone oil clutch with adjustable temperature region

ActiveCN104533982AExtended service lifeRealize the function of continuously variable speedCoolant flow controlMachines/enginesSecondary stageSilicone oil

The invention relates to a continuously speed-variable fan silicone oil clutch with an adjustable temperature region. The continuously speed-variable fan silicone oil clutch comprises a housing, a driven plate and a valve plate, wherein the driven plate is arranged in the middle of the front end surface of the housing; the front end surface of the driven plate is tightly adhered with the valve plate rotating around the center in an anticlockwise manner; a pair of large oil outlets is symmetrically formed around the center in the front surface of the driven plate; small oil outelts are formed in a position, close to the edge of the driven plate, at one side of the clockwise direction; the large oil outlets and the small oil outlets are sealed and sequentially opened in a rotary process; rectangular notches are formed in positions, corresponding to the small oil outlets, in one side reverse to the rotary direction in the two ends of the valve plate. The continuously speed-variable fan silicone oil clutch is simple in structure; the small oil outlets are opened in advance through the small oil outlets, so that primary-stage rotation speed is reached in advance, interval time between the primary-stage rotation speed and the secondary-stage rotation speed is prolonged, a temperature region between the two rotation speeds is expanded, the service life of an engine is prolonged, and remarkable effects of saving energy and reducing noises are achieved.

Owner:XUELONG GRP

Zirconium diboride and short carbon fiber modified thermal shock resistant and ablation resistant SiBCN ceramic material and preparation method thereof

The invention discloses a zirconium diboride and short carbon fiber modified thermal shock resistant and ablation resistant SiBCN ceramic material and a preparation method thereof, and relates to a SiBCN ceramic material and a preparation method thereof. The invention aims to solve the problem of poor thermal shock resistance and poor ablation resistance of SiBCN ceramic at present. The SiBCN ceramic material disclosed by the invention is prepared by compounding SiBCN, short carbon fiber and ZrB2. The preparation method comprises the following steps: performing ball milling of silica powder, graphite powder, hexagonal boron nitride powder and zirconium diboride powder to obtain nano SiBCN-ZrB2 powder; compounding the SiBCN-ZrB2 powder with short carbon fiber, then performing dispersion andball milling to obtain ceramic slurry; finally, drying, levigating and sintering in turn to finish the preparation. According to the preparation method disclosed by the invention, by modifying SiBCNwith ZrB2 and Cf, the prepared SiBCN ceramic has excellent thermal shock resistance and ablation resistance, and the temperature interval of high-temperature service of the SiBCN ceramic material is expanded. The preparation method disclosed by the invention is suitable for preparing SiBCN ceramic.

Owner:HARBIN INST OF TECH

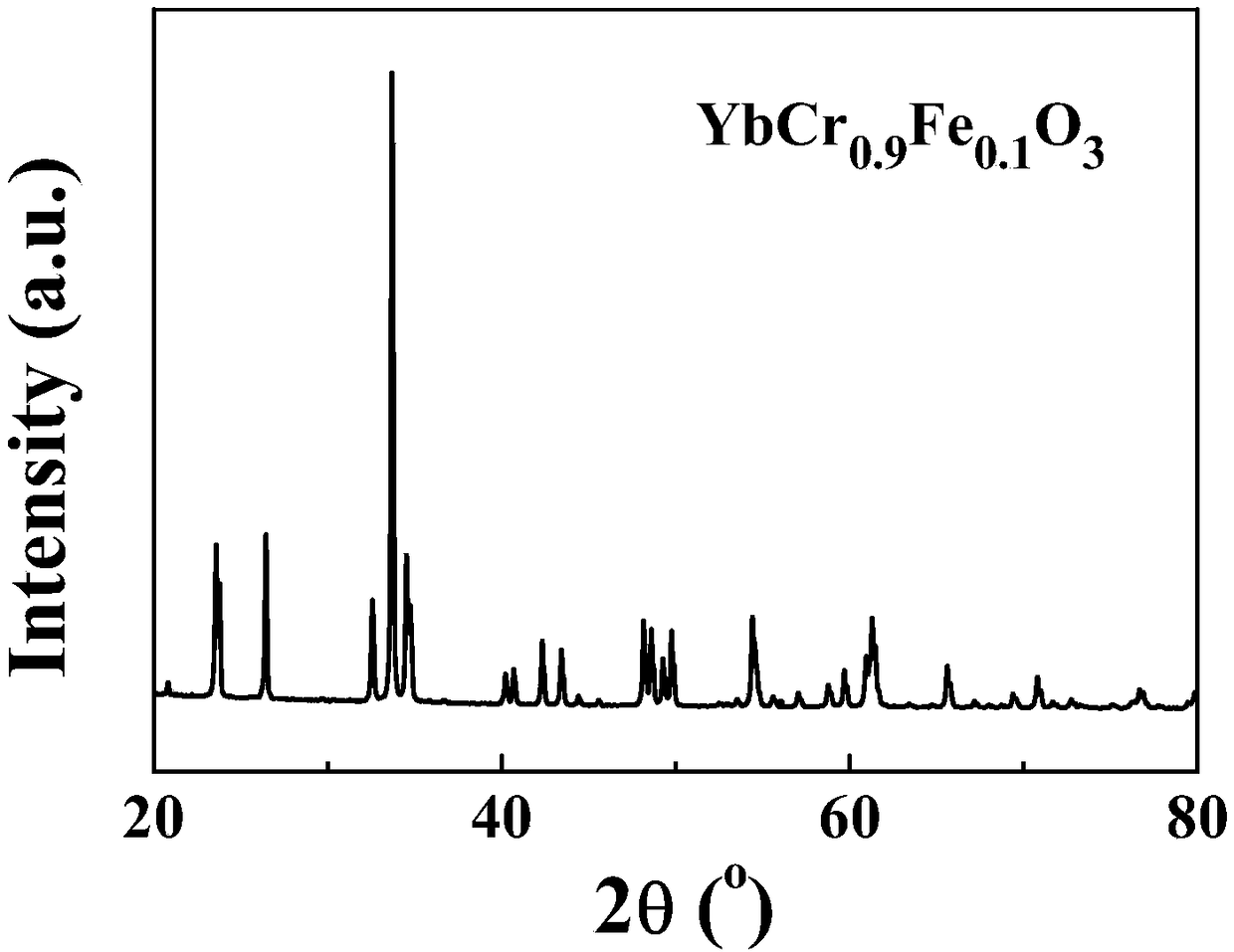

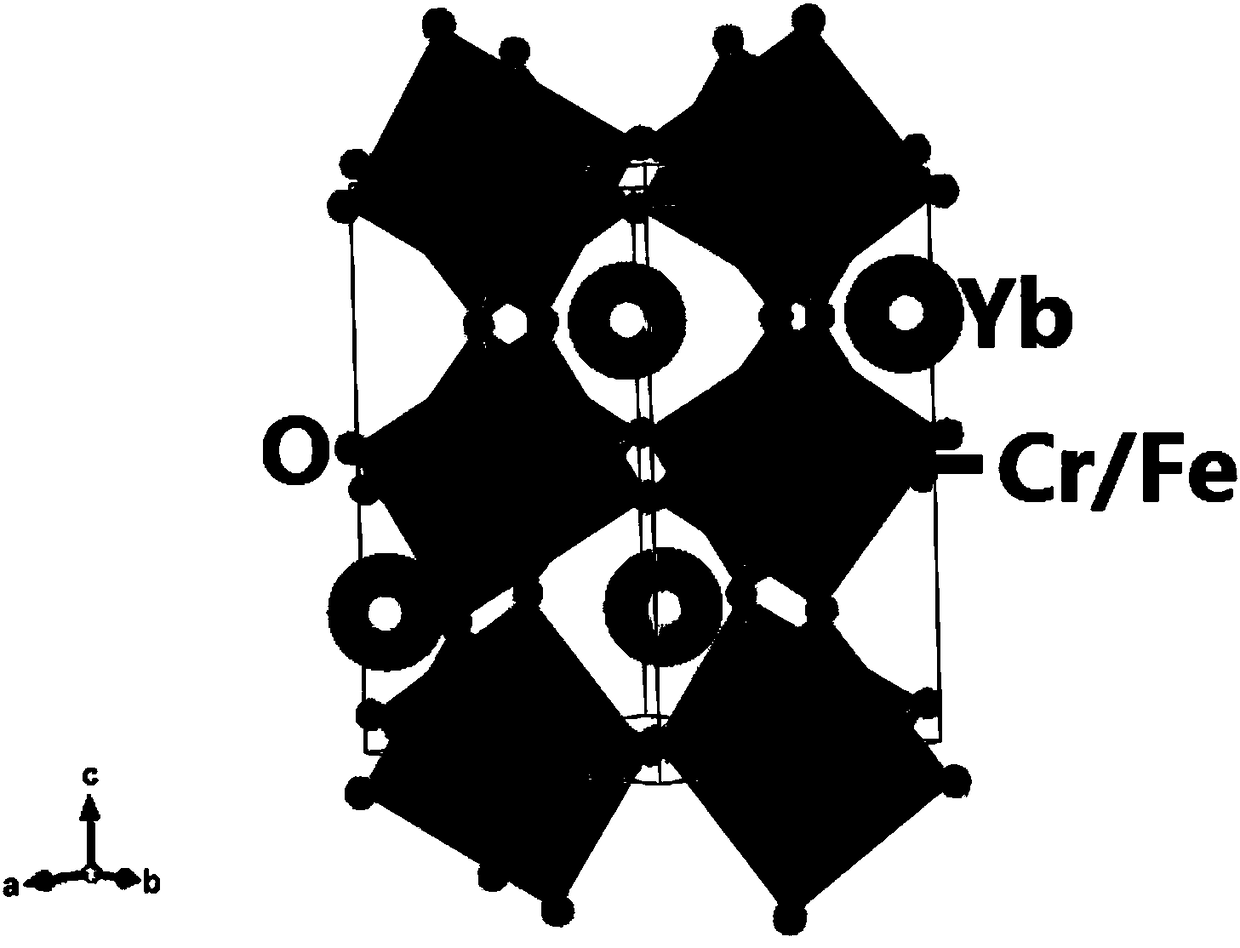

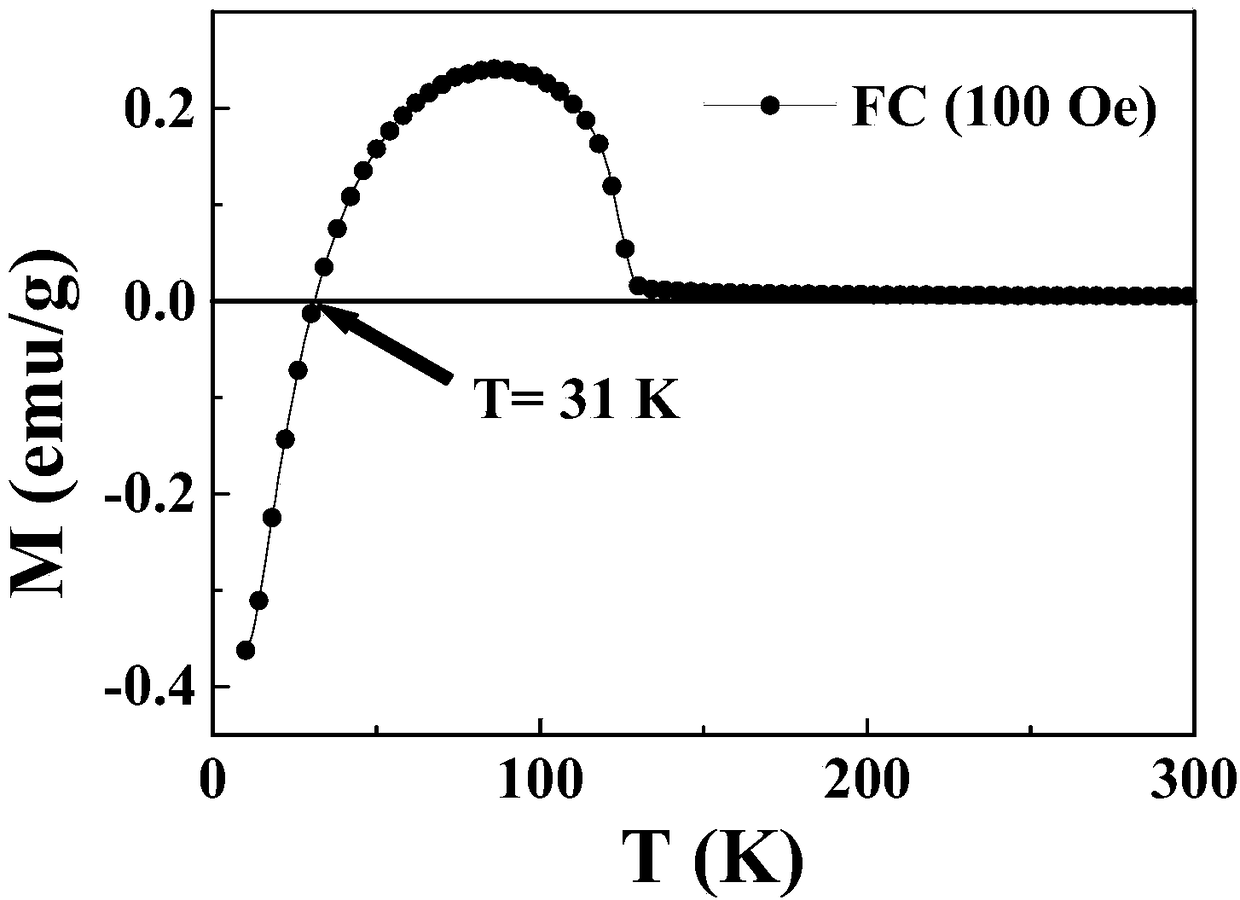

Rare earth oxide ceramic material with exchange bias reversal and preparation method of rare earth oxide ceramic material

ActiveCN108117390AWiden the temperature rangeRaise exchange bias reversal temperatureSolid phasesSingle phase

The invention belongs to the field of rare earth magnetic functional materials and particularly relates to a rare earth oxide ceramic material with exchange bias reversal and a preparation method of the rare earth oxide ceramic material. The molecular formula of the rare earth oxide ceramic material is YbCr0.9Fe0.1O3. The preparation method of the rare earth oxide ceramic material comprises the following steps: uniformly mixing a powdery ytterbium source compound, a chromium source compound and an iron source compound according to the percentage of metal atoms; compacting the uniformly-mixed powder; carrying out pre-sintering and high temperature solid phase sintering on the obtained compact, and then cooling; detecting the single-phase property of the obtained product by X-ray diffraction, and carrying out sufficient solid-phase reaction to form a perovskite type Yb(Cr.Fe)O3 single phase, namely a target product YbCr0.9Fe0.1O3. According to the preparation method disclosed by the invention, the exchange bias reversal temperature and the exchange bias cut-off temperature are respectively improved to 31K and 130 K, the temperature range of the exchange bias effect is widened, and the exchange bias reversal temperature is increased, therefore, a new step is stepped for practical application.

Owner:JIANGXI UNIV OF SCI & TECH

Preparation method of gradient coating for surface strengthening of blanking die

ActiveCN108754410BImprove bindingImprove wear resistanceSolid state diffusion coatingProcess efficiency improvementMolten saltEngineering

The invention discloses a preparation method of gradient cladding for blanking die surface reinforcing. The preparation method comprises the following steps that a die is preheated, cleared and machined; TRD salt bath salt preparation is conducted, specifically, a salt bath formula comprises, by mass, 70-75% of borax anhydrous, 8-12% of a chrome supplying agent, 4-6% of a niobium supplying agent,3-6% of a reducing agent and 8-10% of an activating agent; salt bath chrome and niobium co-soaking treatment is conducted, specifically, the die is soaked in a molten salt bath, the temperature of thefirst stage is 880-910 DEG C, and the heat-preservation time is 2-3.5 h; the temperature of the second stage is 930-940 DEG C, and the heat-preservation time is 2-3 h; the temperature of the third stage is 980-1040 DEG C, and the heat-preservation time is 3-4 h; and the die is taken out and then tempered after being subjected to oil quenching. According to the preparation method of the gradient cladding for blanking die surface reinforcing, the phenomenon that stress transition of the cladding is uneven is avoided, the service performance of the die is improved, and the service life of the die is prolonged.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com