Low-smoke-amount non-halogen flame-retardant cable compound and preparation method thereof

A flame-retardant cable material and low-smoke technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of high smoke release and insufficient light transmittance, achieve low smoke release, increase temperature range, and good phase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

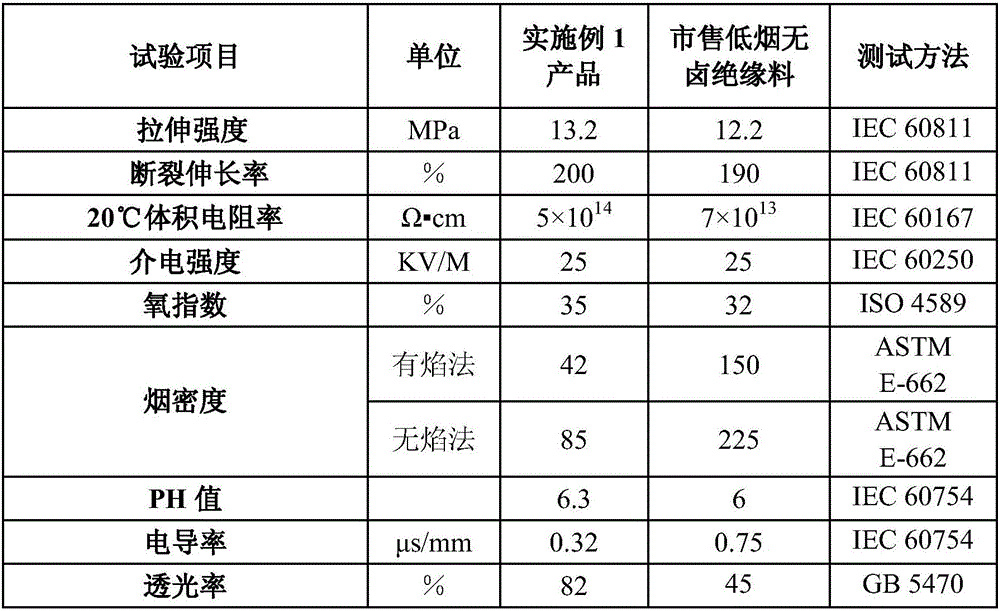

Embodiment 1

[0021] A low-smoke halogen-free flame-retardant cable material, the components of which are: ethylene-vinyl acetate copolymer 25%, polyethylene 4%, maleic anhydride grafted polyethylene 4%, inorganic resistance 60% of fuel, 1% of alkyl siloxane, 5% of smoke suppressant and 1% of antioxidant additive, the sum of the mass percentages of each component is 100%.

[0022] The vinyl acetate content of the ethylene-vinyl acetate copolymer is 40g / cm 3 , the melt index is 2g / 10min, and the density of polyethylene is 0.918g / cm 3 , the melt index is 2g / 10min, the graft rate of maleic anhydride grafted polyethylene is 0.8%, the melt index is 1.0g / 10min, the average particle size of the inorganic filler powder is 1-2μm; the inorganic filler is aluminum hydroxide , two mixtures of magnesium hydroxide, the mass ratio is 1:1, the alkyl siloxane is vinyl siloxane, the effective content is ≥99%, the smoke suppressant is zinc molybdate powder, and the average particle size is 1-2 μm , the anti...

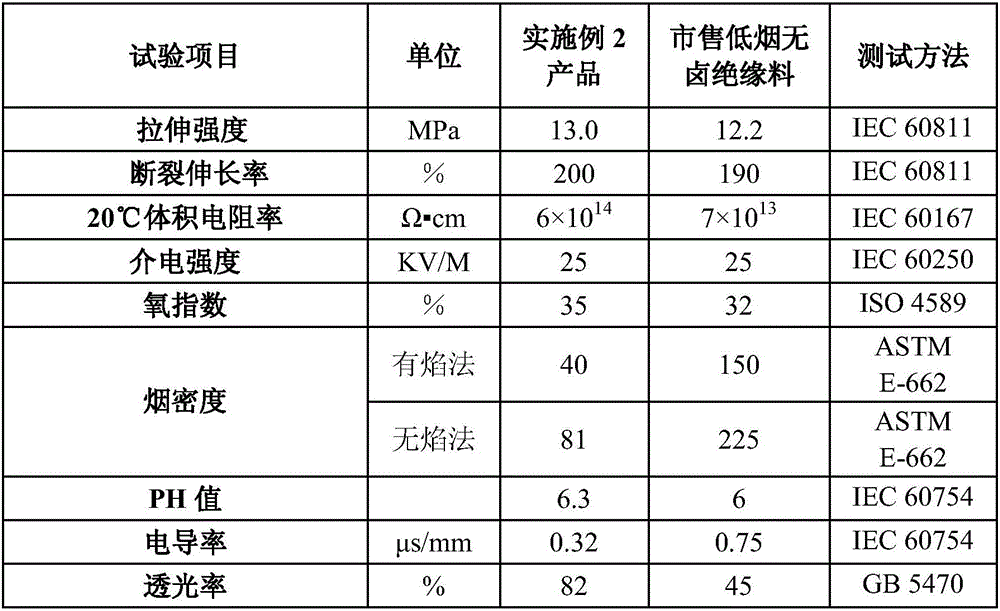

Embodiment 2

[0030] A low-smoke halogen-free flame-retardant cable material, the components of which are: ethylene-vinyl acetate copolymer 27%, polyethylene 4%, maleic anhydride grafted polyethylene 2%, inorganic resistance 62% of fuel, 1% of alkyl siloxane, 3% of smoke suppressant and 1% of antioxidant additive, the sum of the mass percentages of each component is 100%.

[0031] The vinyl acetate content of the ethylene-vinyl acetate copolymer is 40g / cm 3 , the melt index is 2g / 10min, the density of polyethylene is 0.918, the melt index is 2g / 10min, the grafting rate of maleic anhydride grafted polyethylene is 0.8%, the melt index is 1.0g / 10min, the inorganic filler powder particles The average particle size is 1-2 μm; the inorganic filler is a mixture of aluminum hydroxide and magnesium hydroxide, the mass ratio is 1:1, the alkyl siloxane is vinyl siloxane, the effective content is ≥ 99%, and the smoke is suppressed The agent is zinc molybdate powder, the average particle size is 1-2 μm...

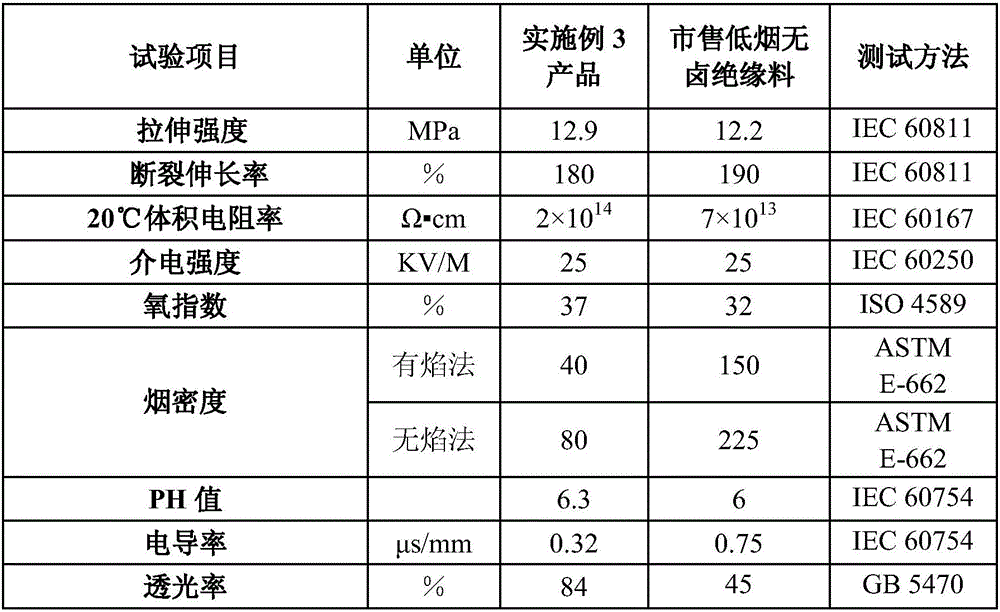

Embodiment 3

[0037] A low-smoke halogen-free flame-retardant cable material, the composition of which is: ethylene-vinyl acetate copolymer 25%, polyethylene 3%, maleic anhydride grafted polyethylene 2%, inorganic resistance 65% of fuel, 1% of alkyl siloxane, 3% of smoke suppressant and 1% of antioxidant additive, the sum of the mass percentages of each component is 100%.

[0038] The vinyl acetate content of the ethylene-vinyl acetate copolymer is 40g / cm 3 , the melt index is 2g / 10min, the density of polyethylene is 0.918, the melt index is 2g / 10min, the grafting rate of maleic anhydride grafted polyethylene is 0.8%, the melt index is 1.0g / 10min, the inorganic filler powder particles The average particle size is 1-2 μm; the inorganic filler is a mixture of aluminum hydroxide and magnesium hydroxide, the mass ratio is 1:1, the alkyl siloxane is vinyl siloxane, the effective content is ≥ 99%, and the smoke is suppressed The agent is zinc molybdate powder, the average particle size is 1-2 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com