Continuously speed-variable fan silicone oil clutch with adjustable temperature region

A silicon oil clutch and continuously variable transmission technology, which is applied to clutches, fluid clutches, machines/engines, etc., can solve problems such as high manufacturing costs and poor product versatility, and achieve energy consumption reduction, ingenious structure, and extended interval time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

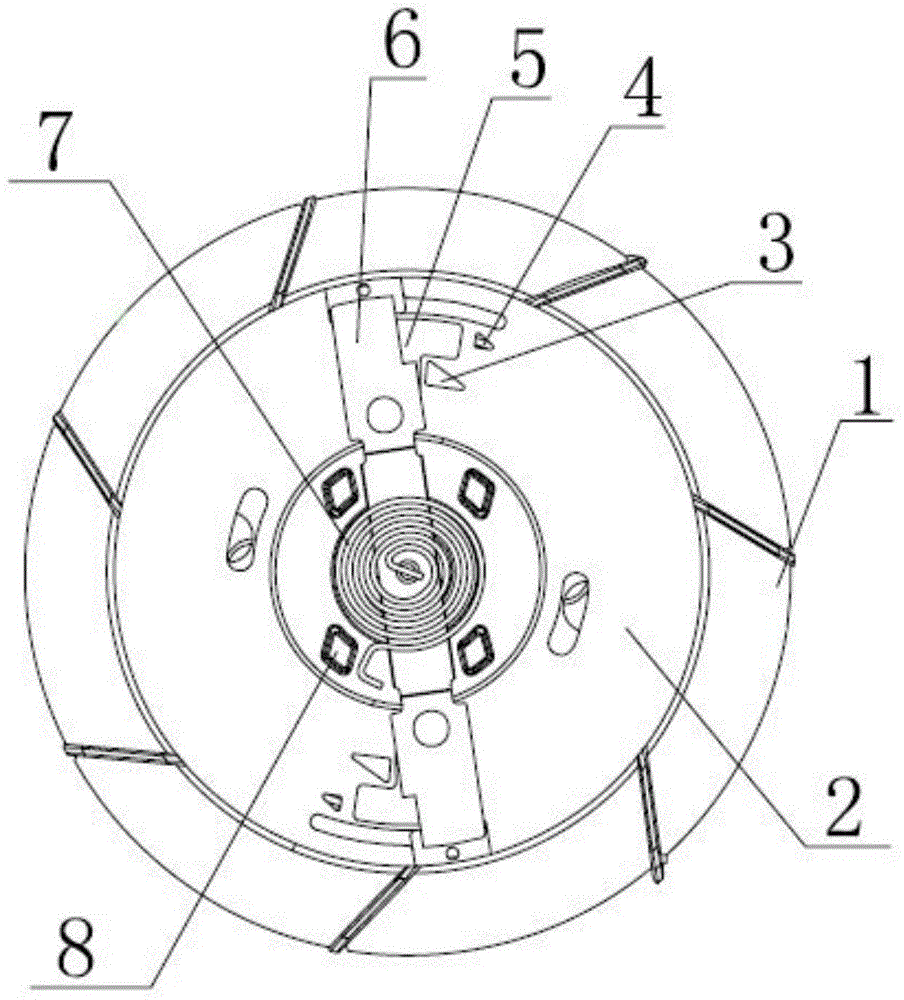

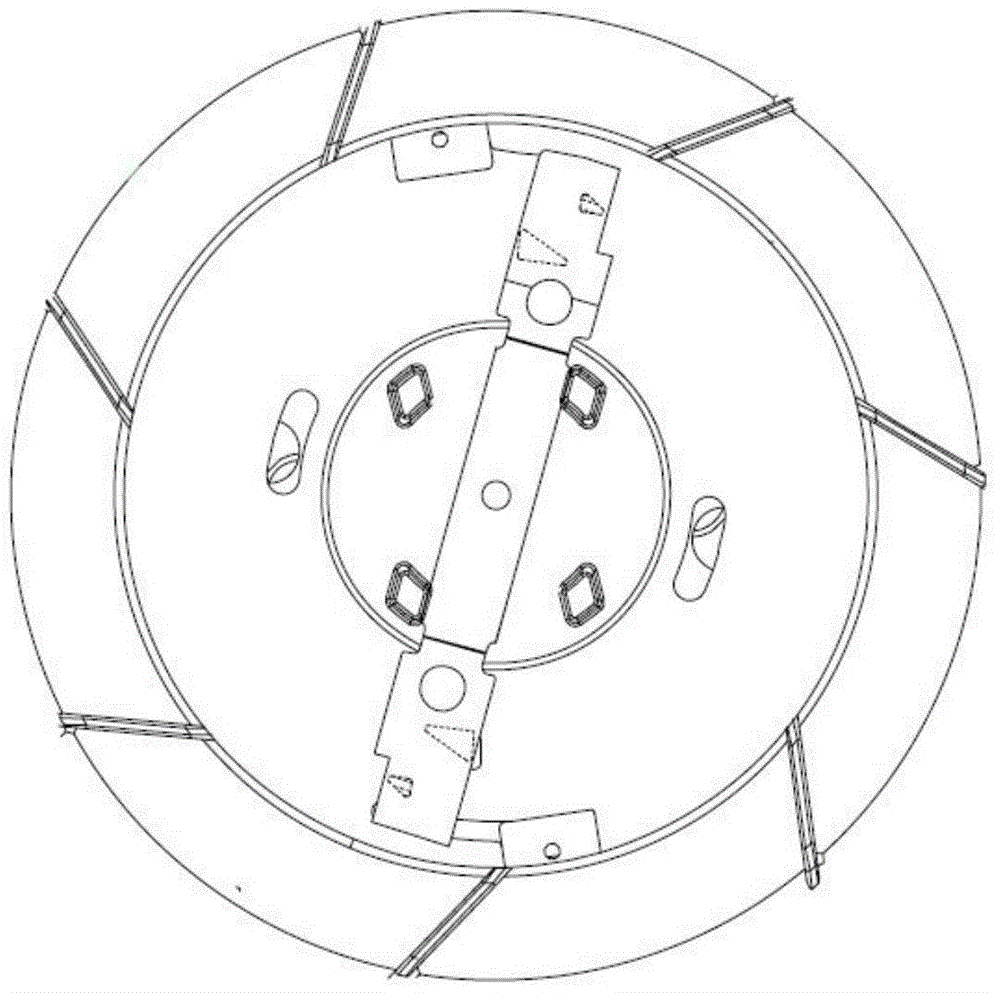

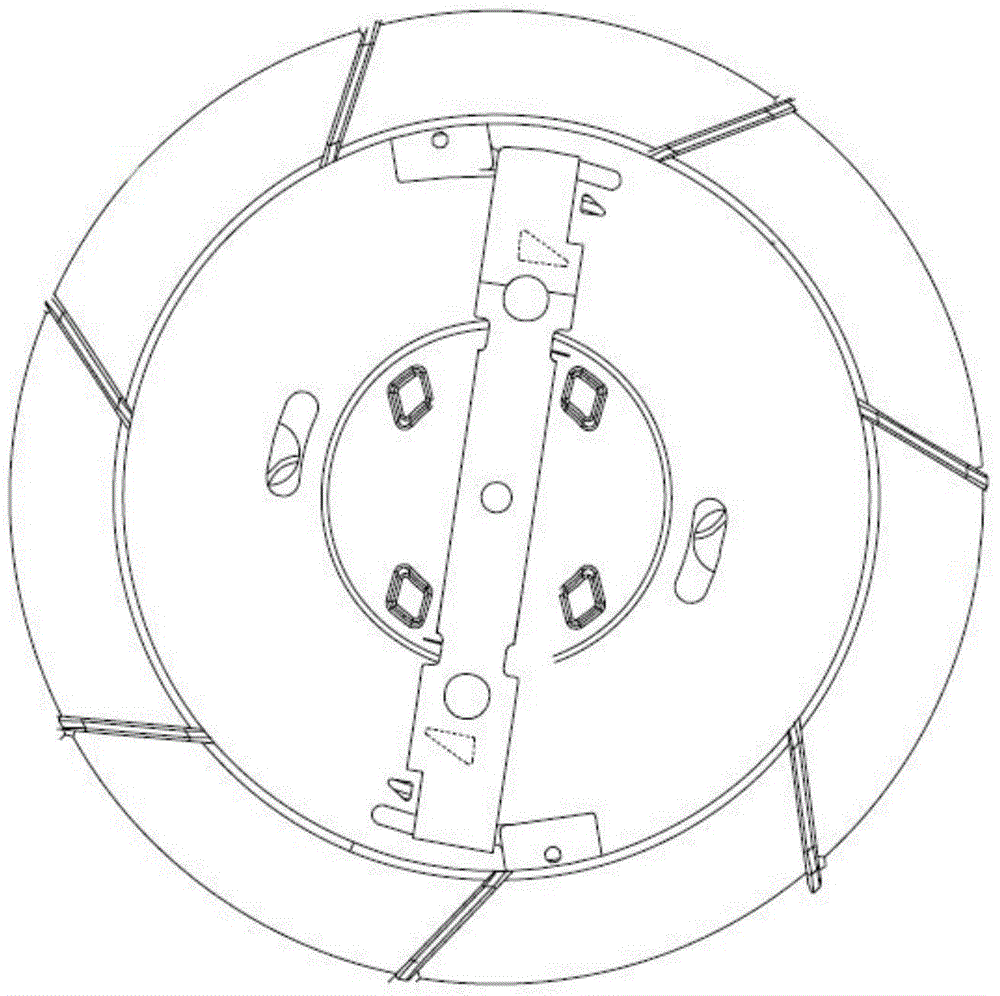

[0026] Such as figure 2 As shown, in the initial state, both ends of the valve plate 6 seal the large oil outlet hole 3 and the small oil outlet hole 4. When the temperature reaches 50°C, the valve plate 6 starts to rotate counterclockwise slowly. 5, the small oil outlet hole 4 is opened early at first, and the small oil outlet hole 4 is a right triangle. When opening, the opening area gradually increases until the small oil outlet hole 4 is fully opened, at which time the temperature has risen to 60 °, the speed of the fan is also gradually increased until it reaches 1800rpm, so that the fan enters the first-level speed rotation (such as image 3 , 5 shown);

[0027] Such as figure 1 As shown, in the next rotation process, the temperature continues to rise, the valve plate 6 also continues to rotate, and the large oil outlet hole 3 is also a right triangle. The oil outlet hole 3 slides along the mouth, and the opening area of the large oil outlet hole 3 gradually incr...

Embodiment 2

[0030] Such as figure 2 As shown, in the initial state, both ends of the valve plate 6 seal the large oil outlet hole 3 and the small oil outlet hole 4. When the temperature reaches 50°C, the valve plate 6 starts to rotate counterclockwise slowly. 5, the small oil outlet hole 4 is opened early at first, and the small oil outlet hole 4 is a right triangle. When opening, the opening area gradually increases until the small oil outlet hole 4 is fully opened, at which time the temperature has risen to 60 °, the speed of the fan is also gradually increased until it reaches 1800rpm, so that the fan enters the first-level speed rotation (such as image 3 , 5 shown);

[0031] Such as figure 1As shown, in the next rotation process, the temperature continues to rise, the valve plate 6 also continues to rotate, and the large oil outlet hole 3 is also a right triangle. The oil outlet hole 3 slides along the mouth, and the opening area of the large oil outlet hole 3 gradually incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com