Patents

Literature

156results about How to "Extend the interval" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Testing Efficacy of Therapeutic Mechanical or Electrical Nerve or Muscle Stimulation

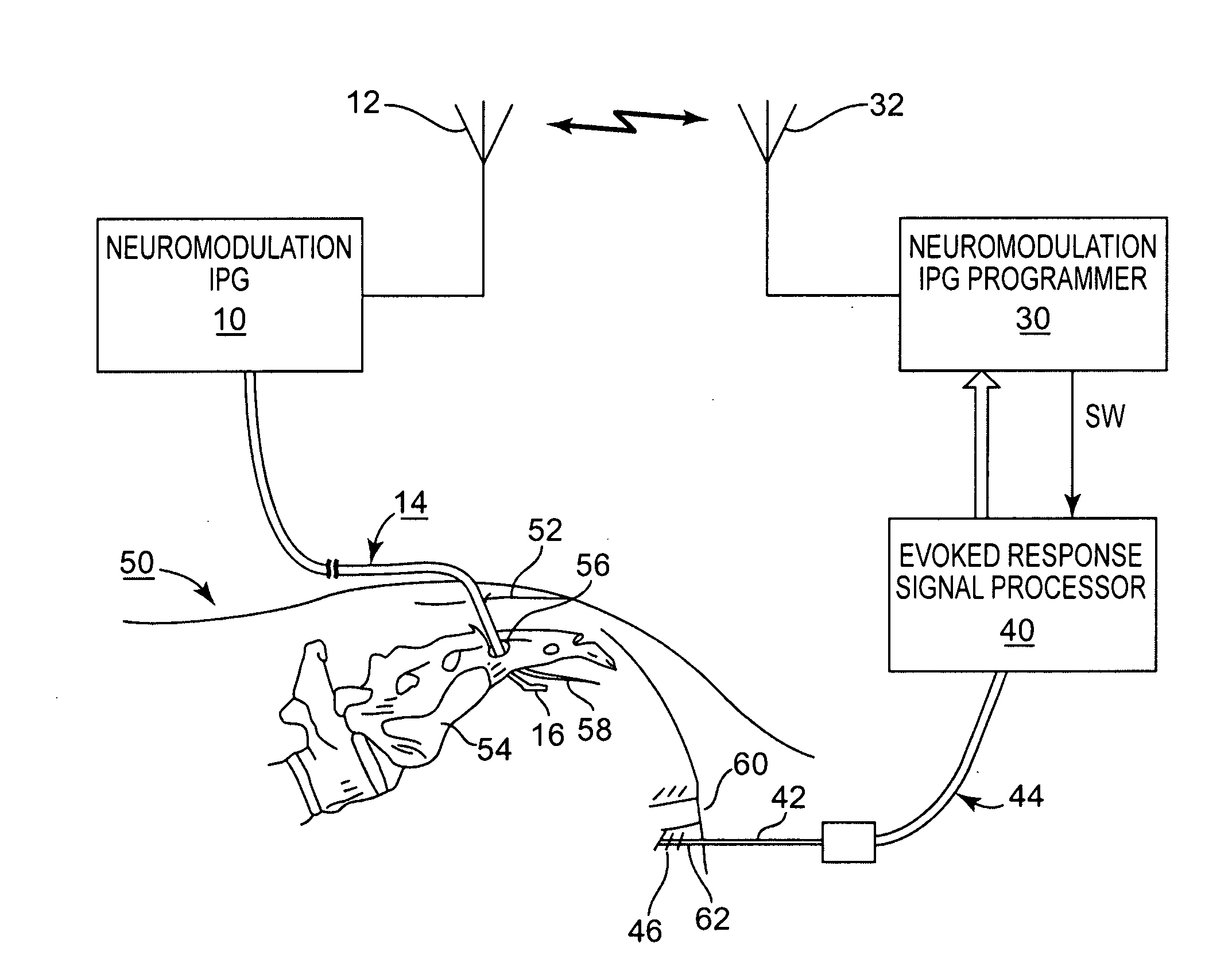

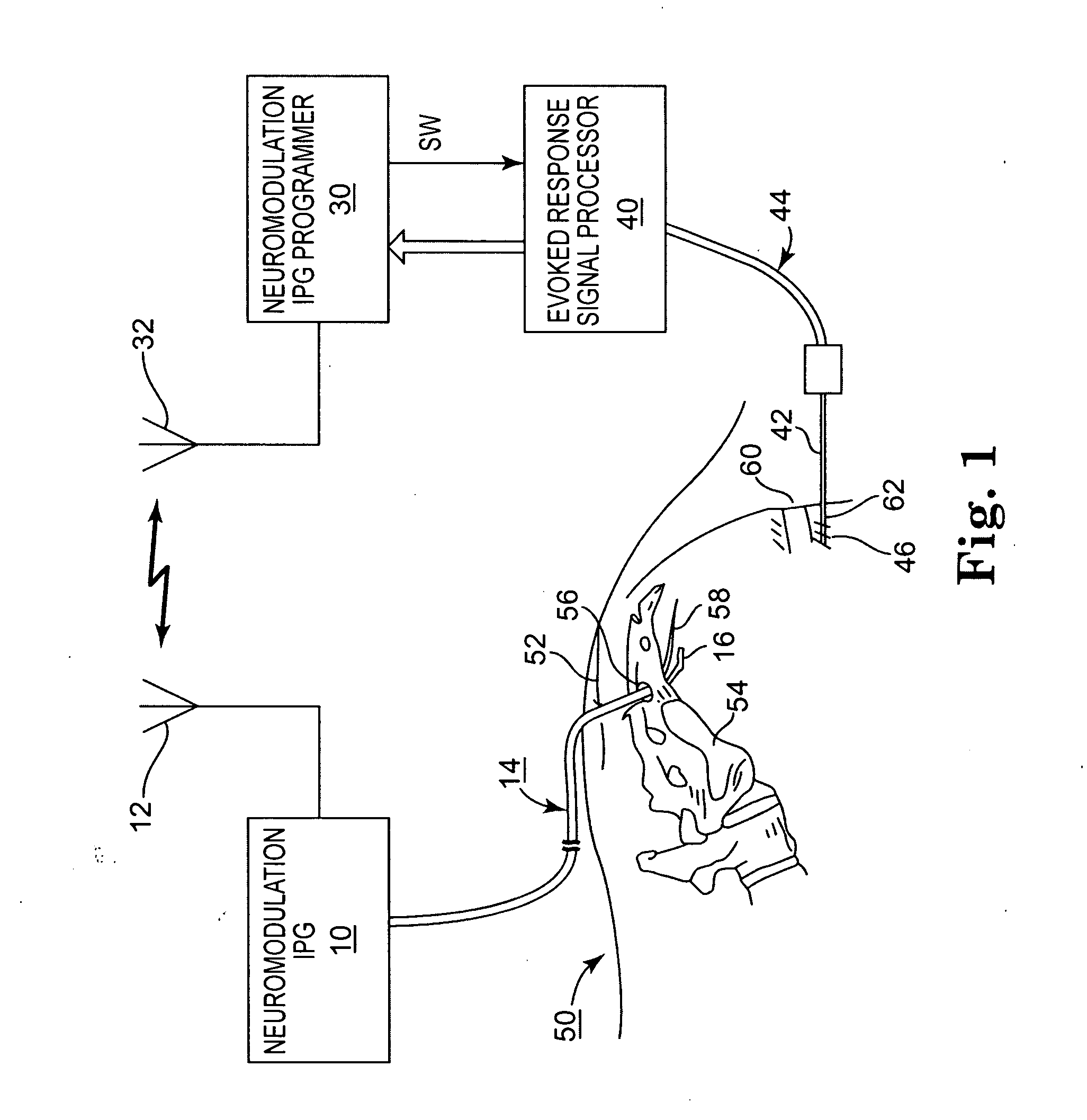

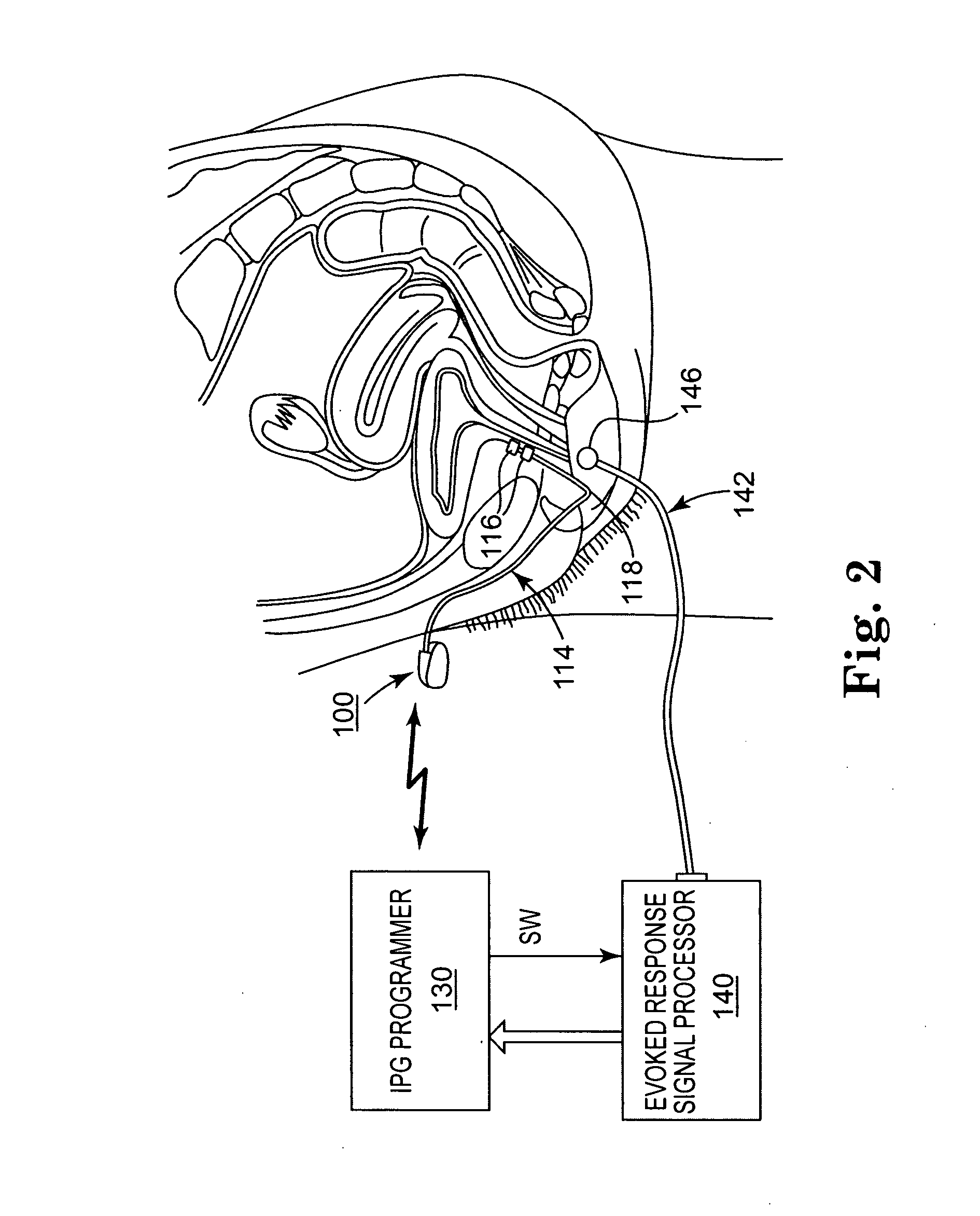

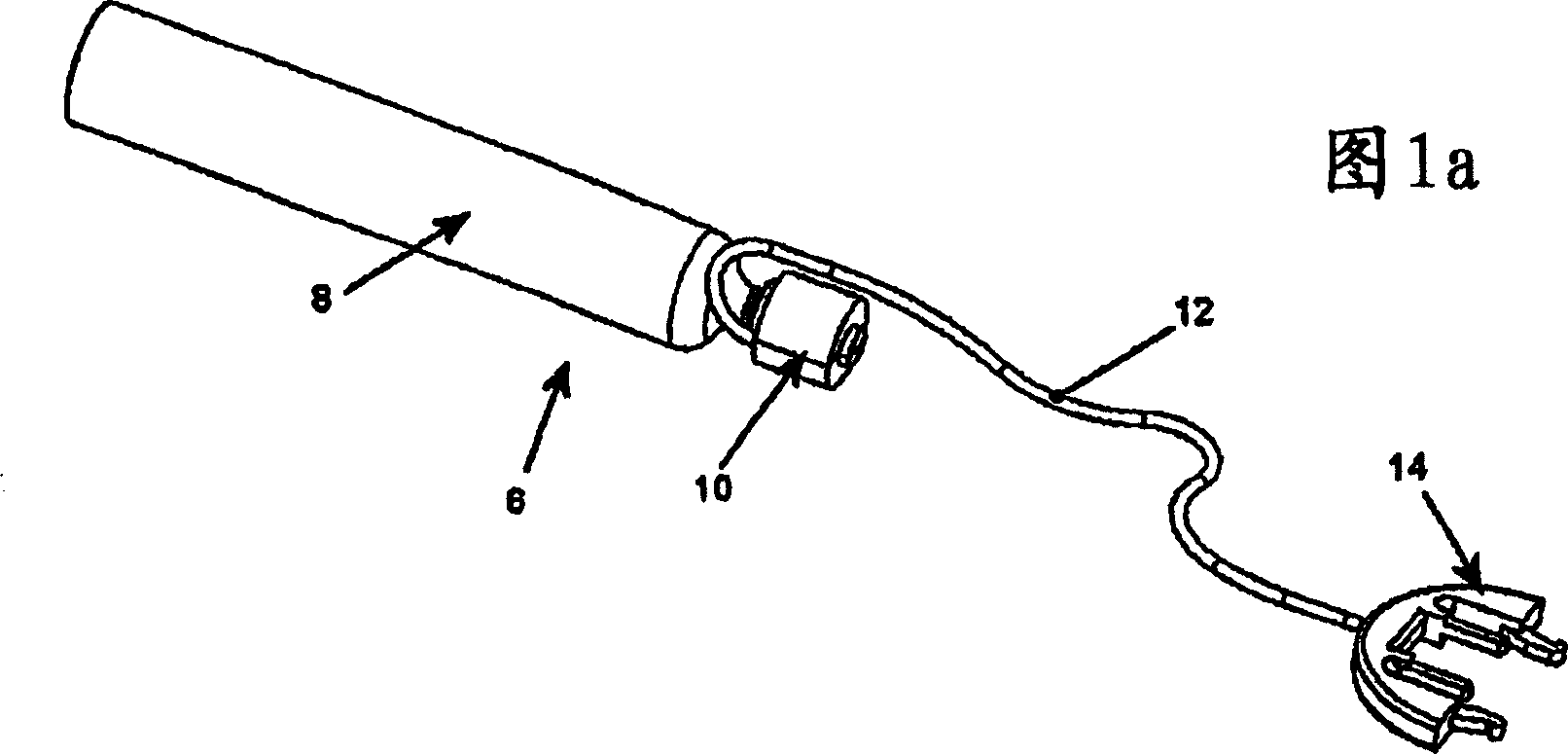

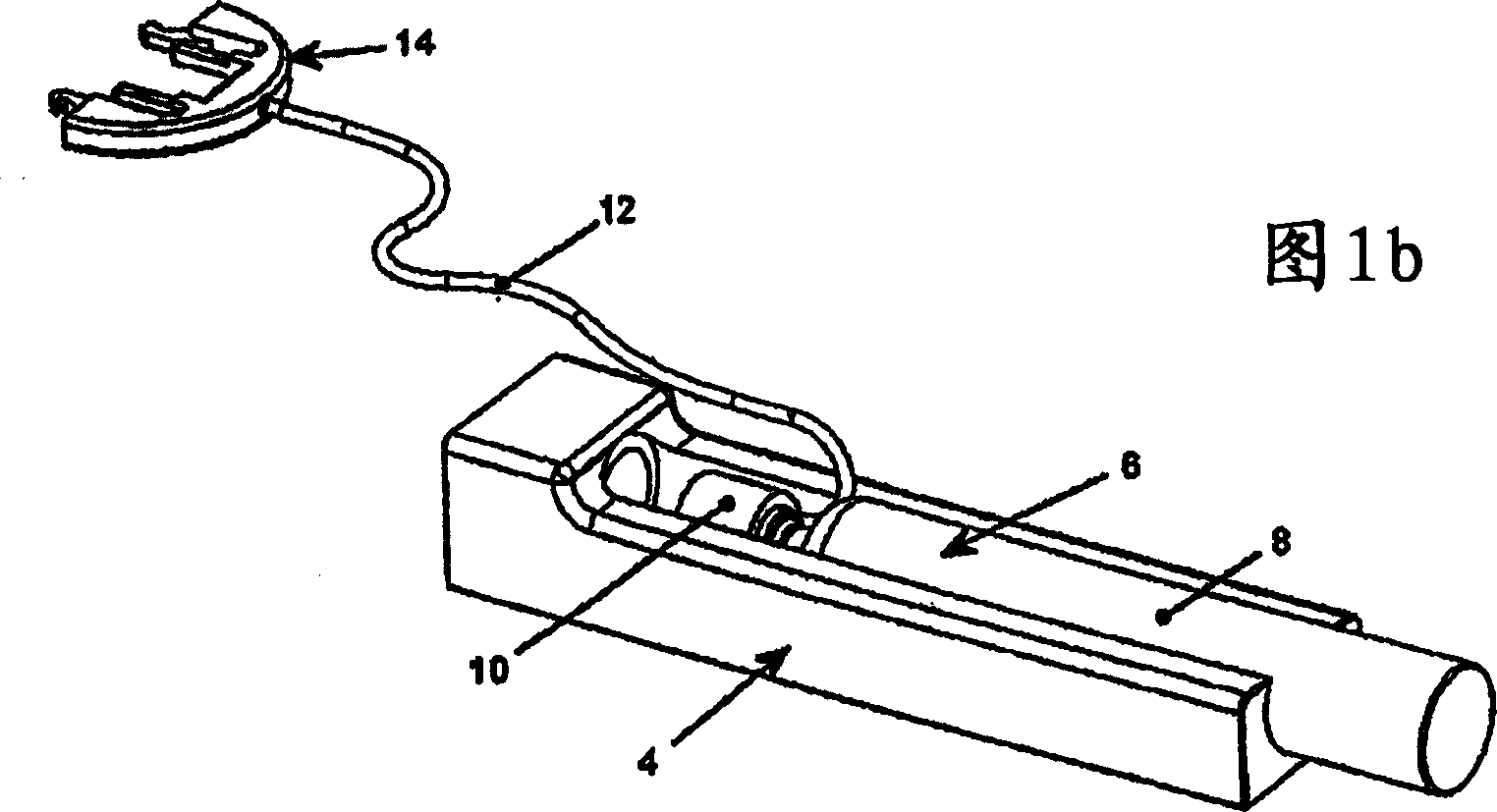

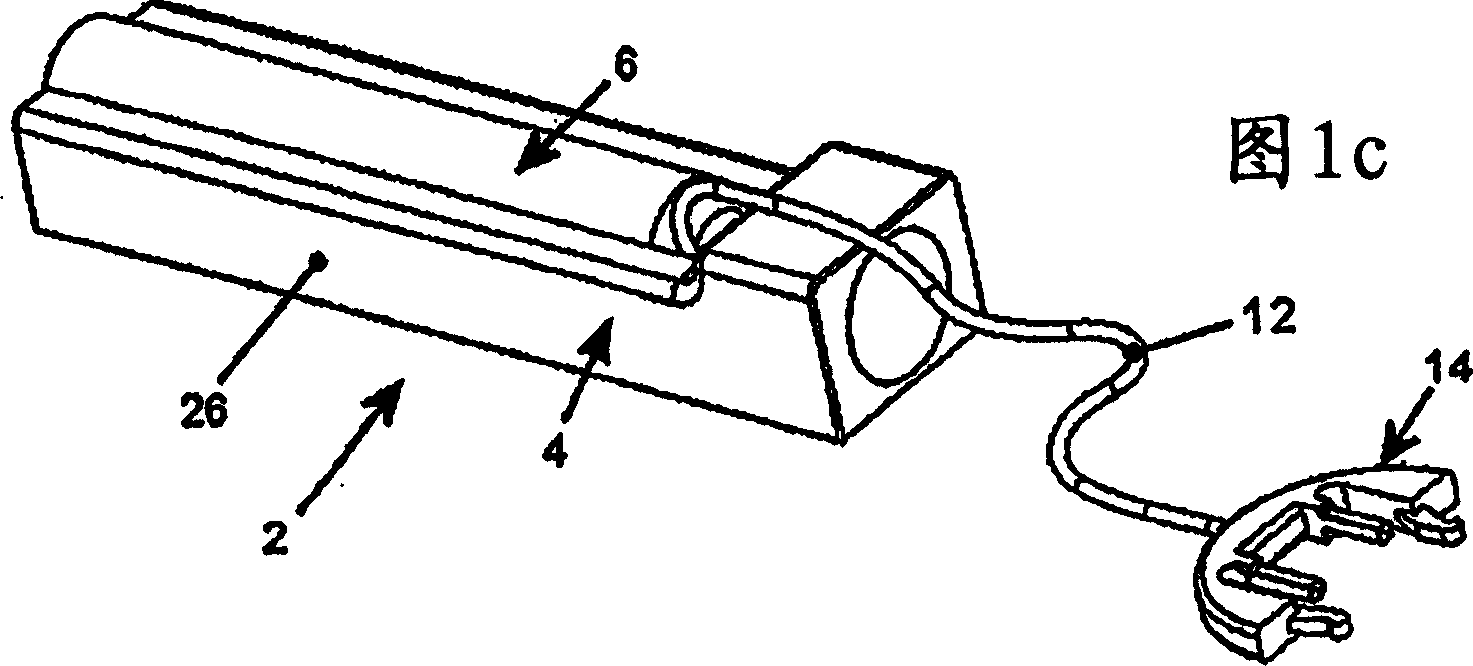

InactiveUS20070265675A1Rule out the possibilityReduce complicationsElectrotherapyMuscle tissuePelvic nerve

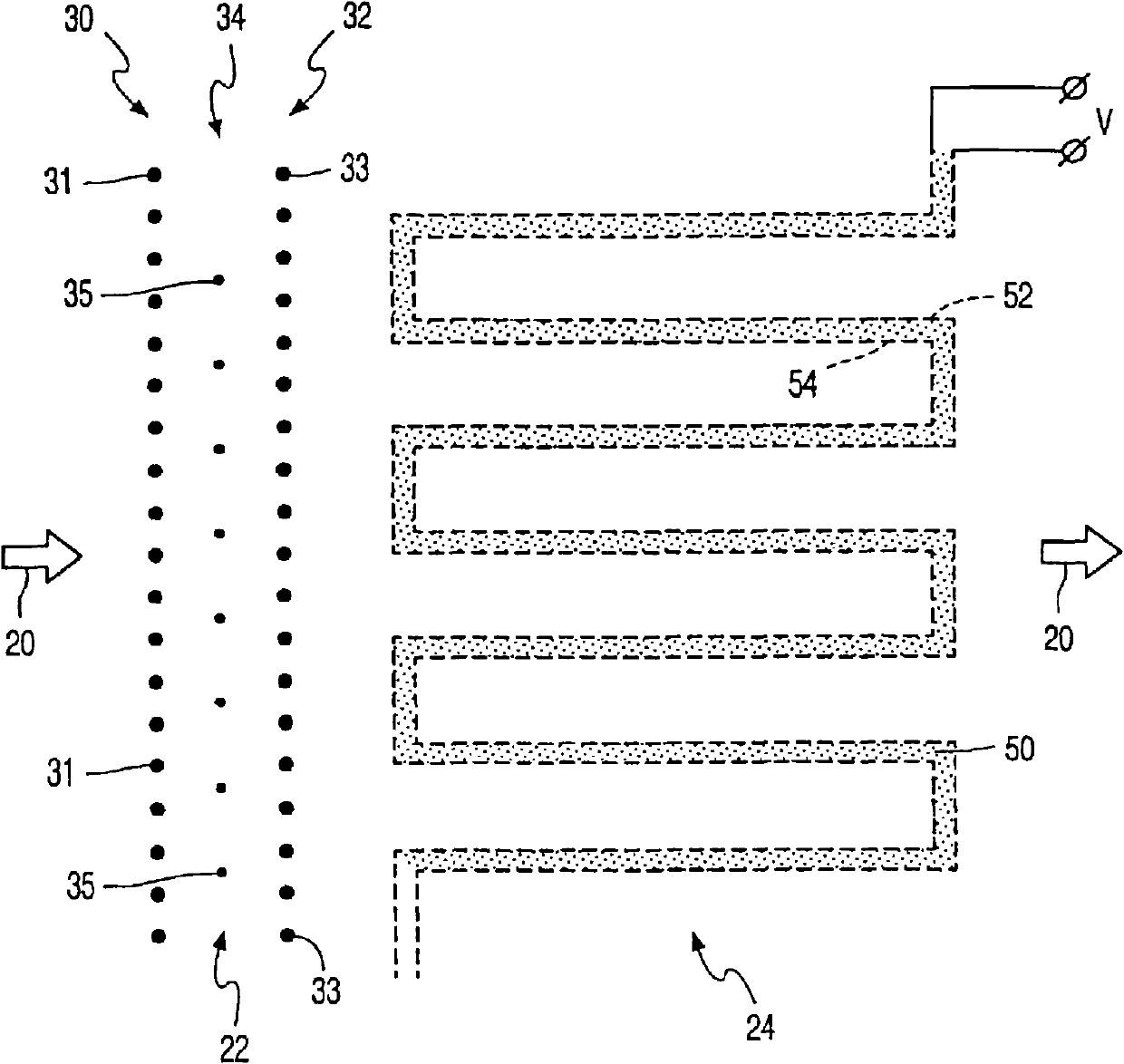

Methods and apparatus for testing of the efficacy of therapeutic stimulation of pelvic nerves or musculature to alleviate one of incontinence or sexual dysfunction are disclosed. A therapy delivery device is operable in a therapy delivery mode and a test mode and an evoked response detector is employed in the test mode to detect the evoked response to applied test stimuli. The test stimuli parameters of the test stimulation regimen are adjusted prior to delivery of each test stimulation regimen, and the evoked responses to the applied test stimulation regimens are compared to ascertain an optimal test stimulation regimen. The therapy stimulation regimen parameters are selected as a function of the test electrical stimulation parameters causing the optimal evoked response.

Owner:AMS RES CORP

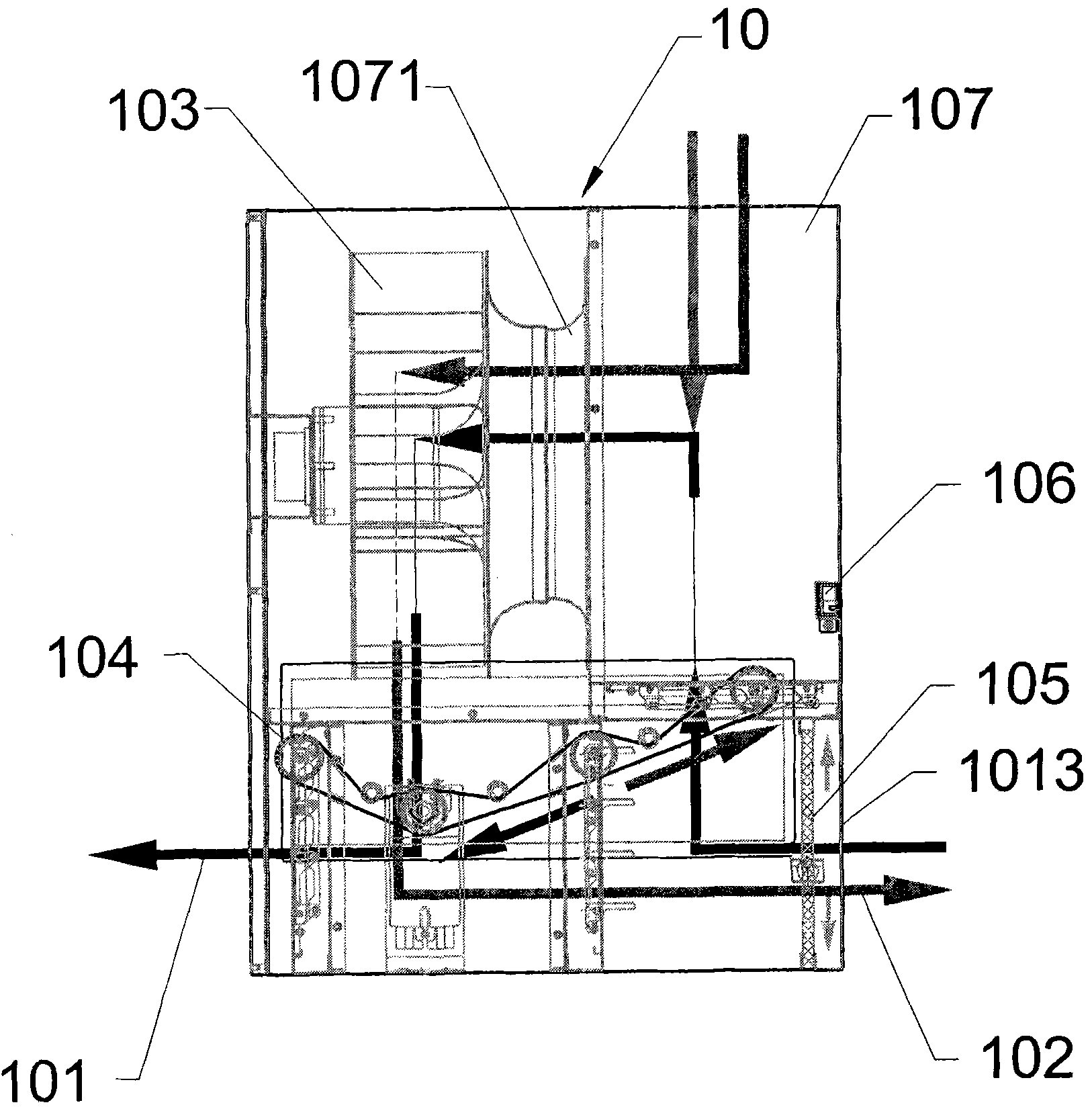

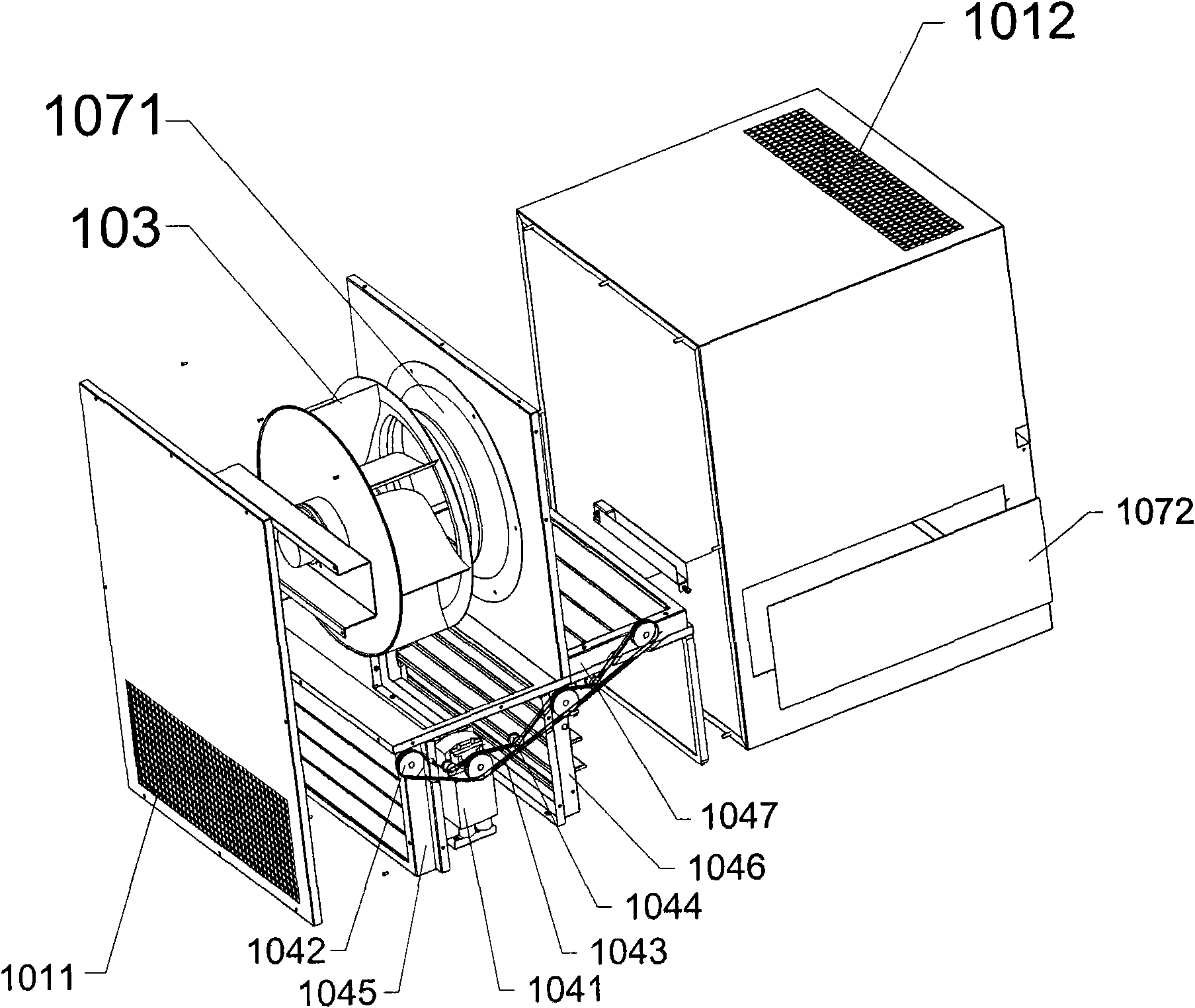

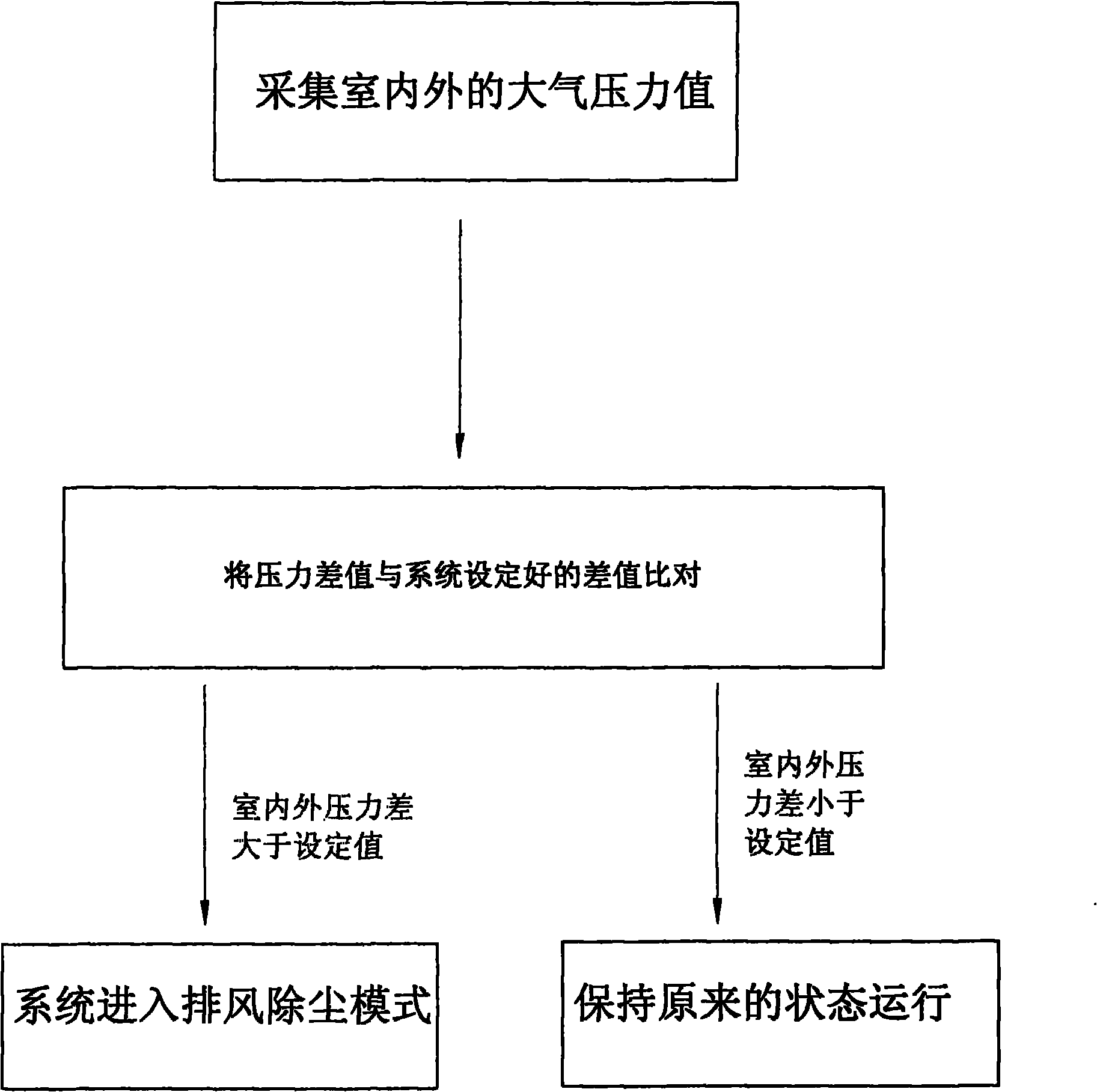

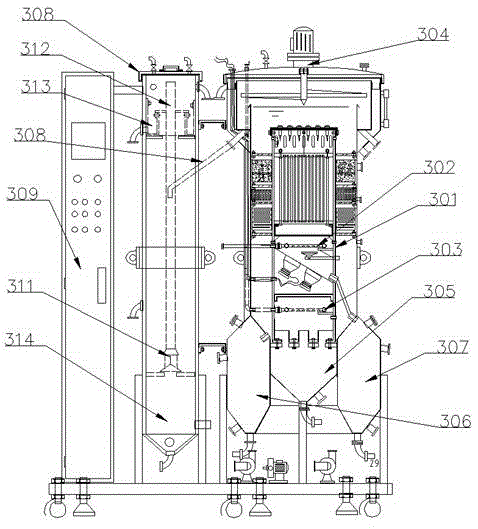

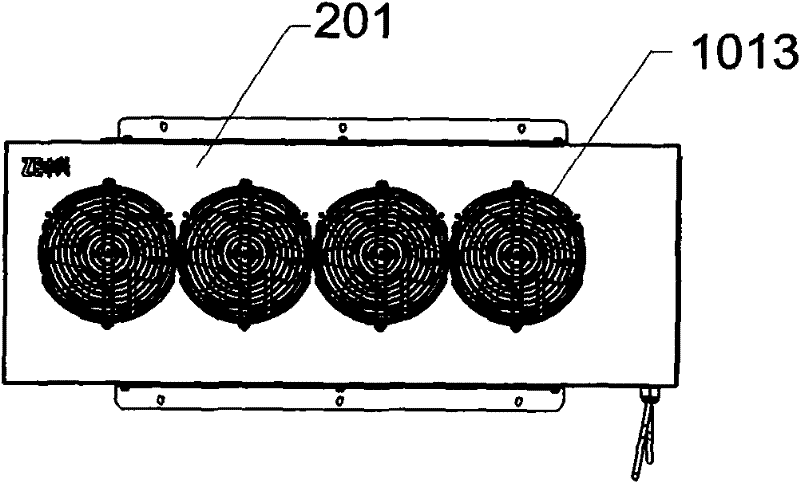

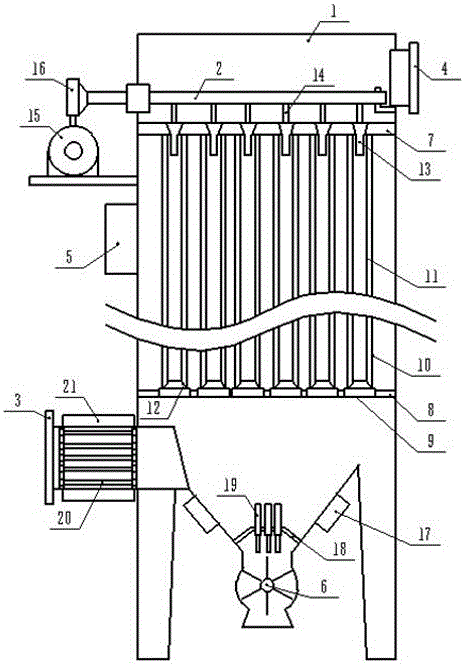

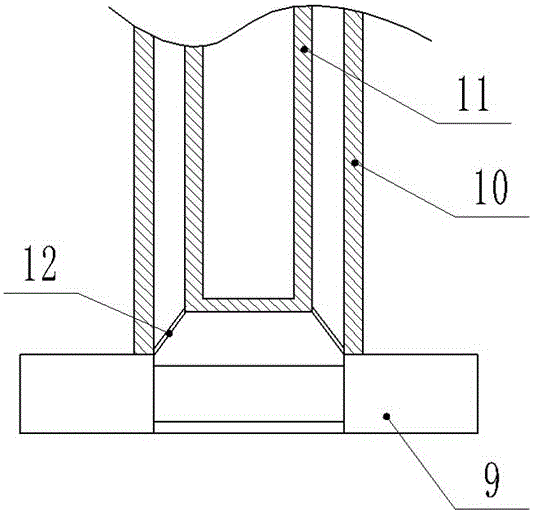

Efficient automatic dust-removing and intelligent ventilation system and automatic dust-removing method

InactiveCN101832612AGuarantee heat dissipation safetyImprove cooling effectSpace heating and ventilation safety systemsLighting and heating apparatusControl systemTime-sharing

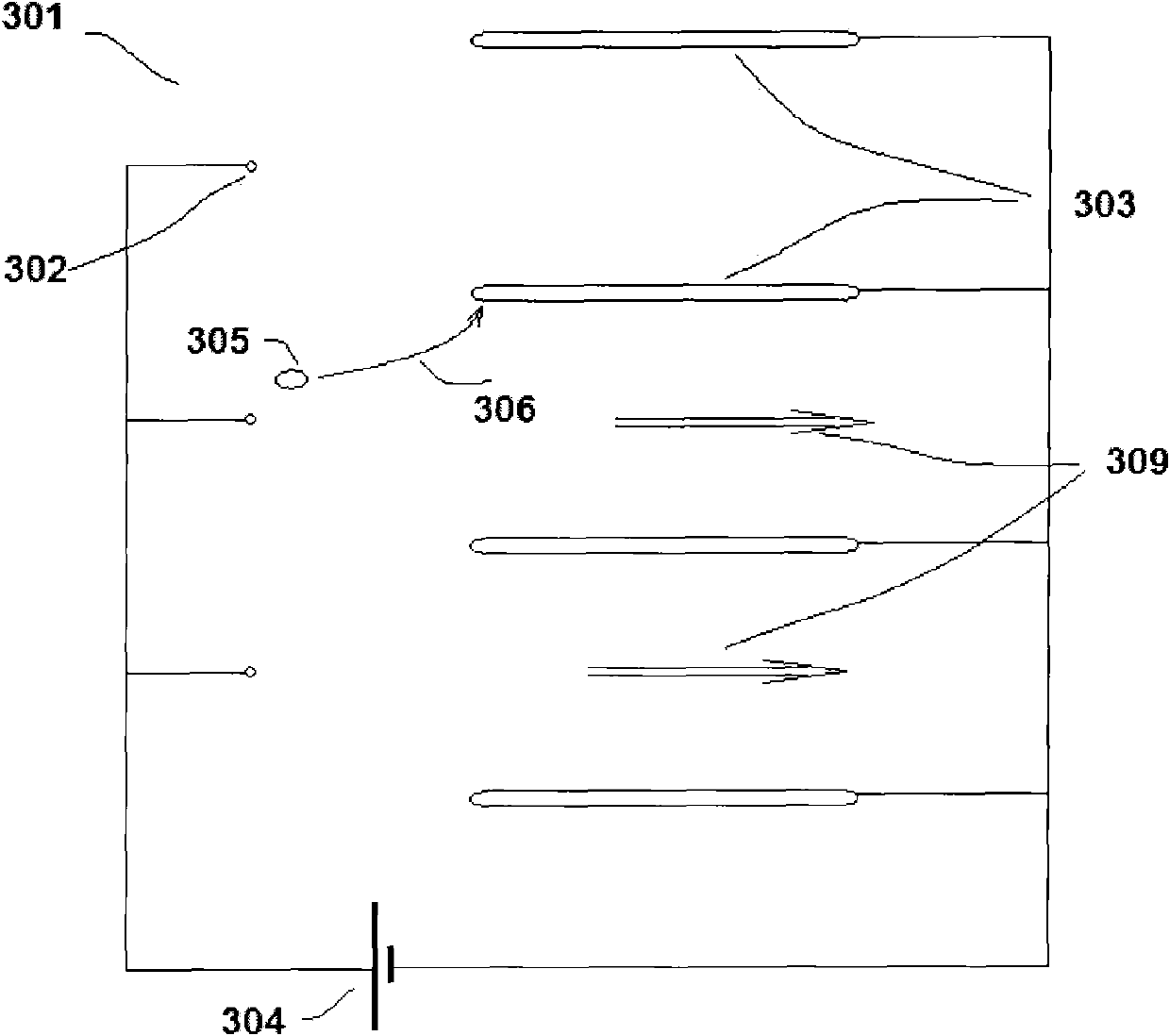

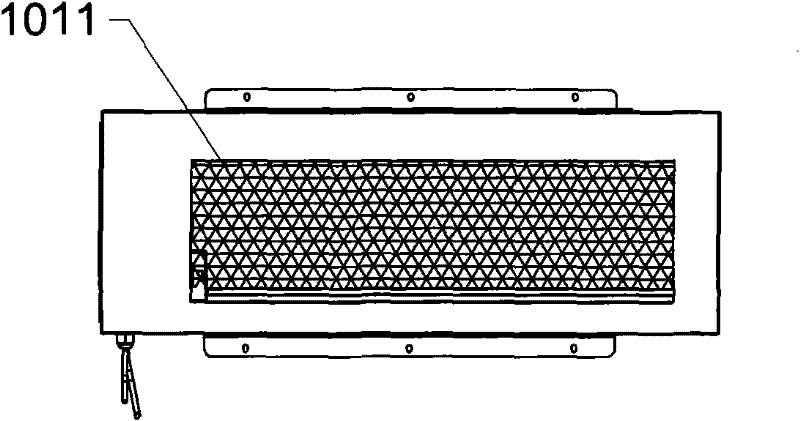

The invention relates to the ventilation system field, in particular to an efficient automatic dust-removing and intelligent ventilation system and an automatic dust-removing method. The system comprises an intelligent energy-saving ventilation system housing component and a fan, wherein the intelligent energy-saving ventilation system housing component comprises a dual duct, a dust-discharging duct, a throttle actuating mechanism, a dust screen, a temperature and humidity sensor and a distributed pressure sensor, wherein the temperature and humidity sensor and the distributed pressure sensor are connected with a control system, and the control system drives the throttle actuating mechanism to realize time-sharing and smooth transition of the dual duct and the dust-discharging duct. The beneficial effects of the invention are as follows: the fans of the air feeder unit can be used for several purposes such as air supply and dust removing, thus reducing the equipment cost; the self-cleaning of the filtering screen can be realized, thus prolonging the service life of the filtering screen, reducing replacement frequency and lowering maintenance cost; and by turning on / off the automatic dust-removing and intelligent ventilation system, the normal operation of the devices in an equipment room can be ensured.

Owner:SHENZHEN ZHONGXING SINDI TECH CO LTD

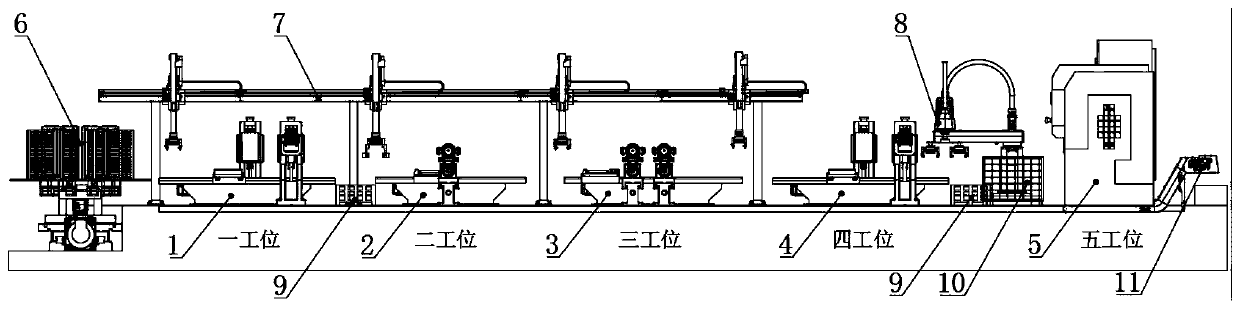

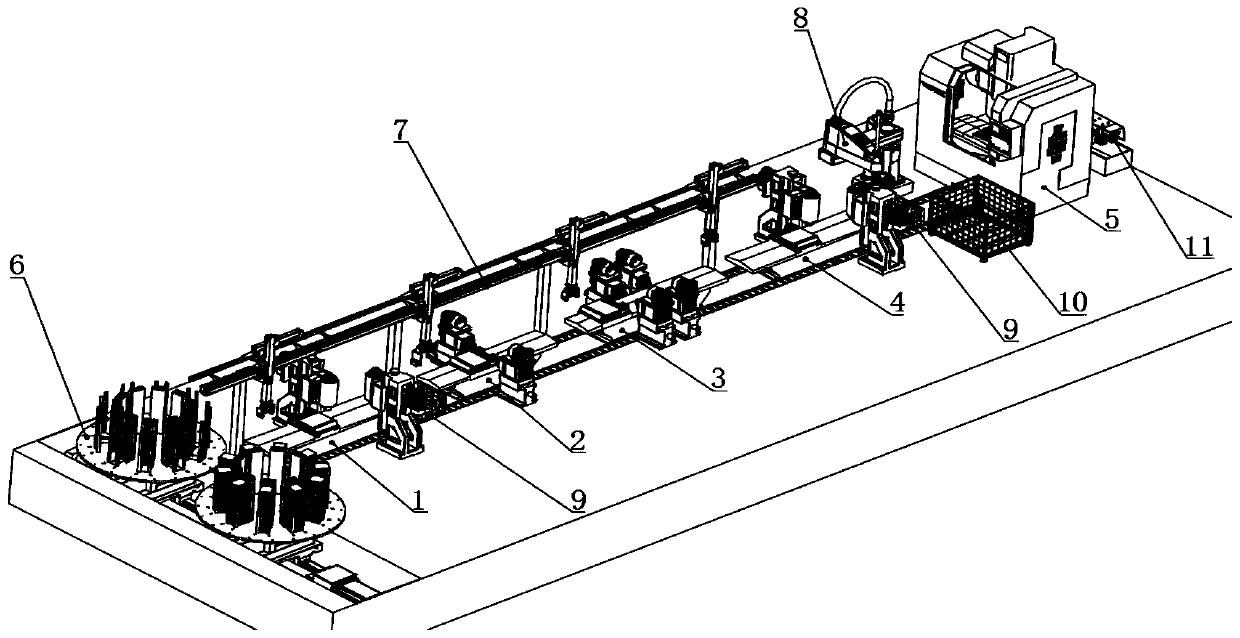

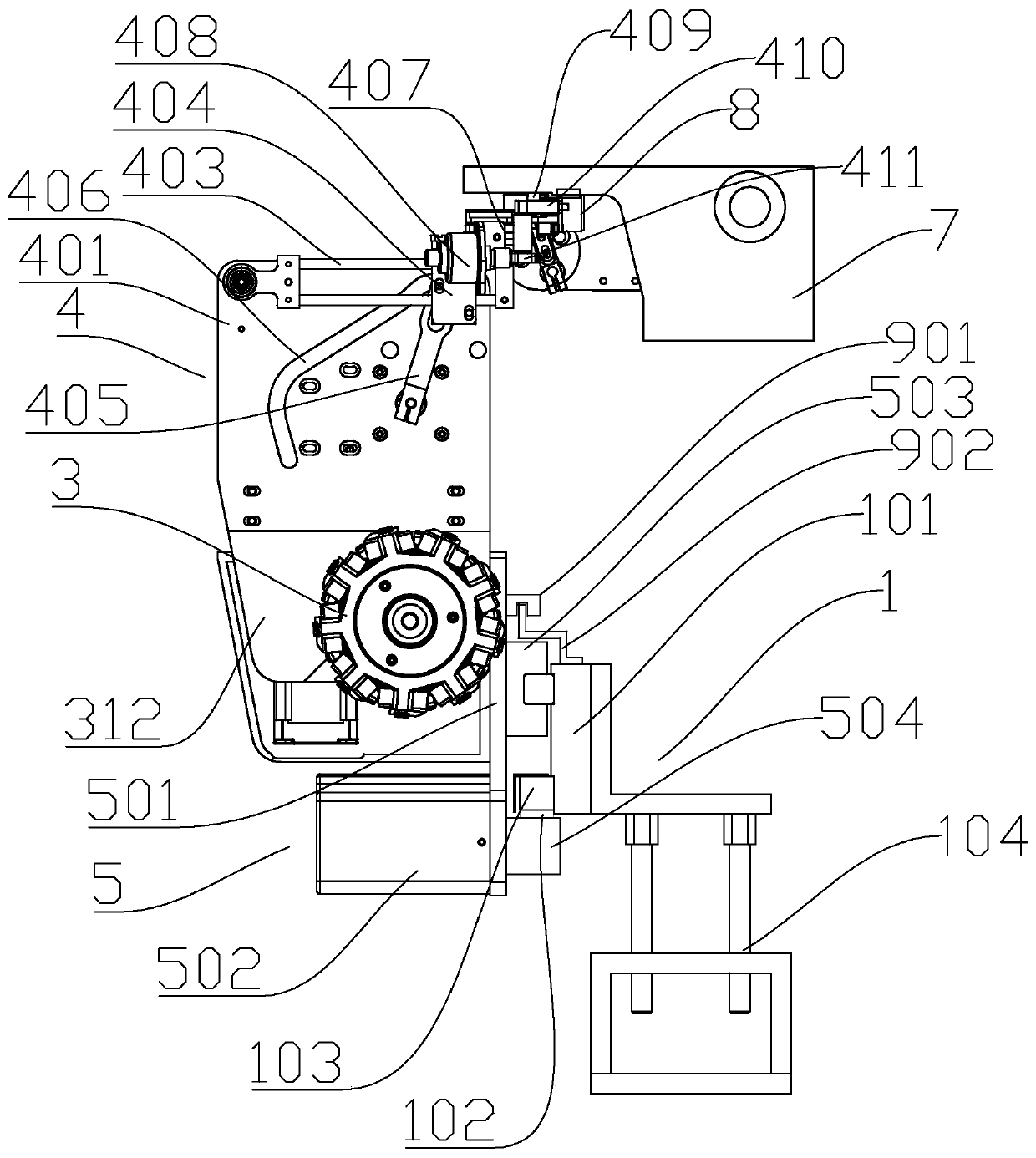

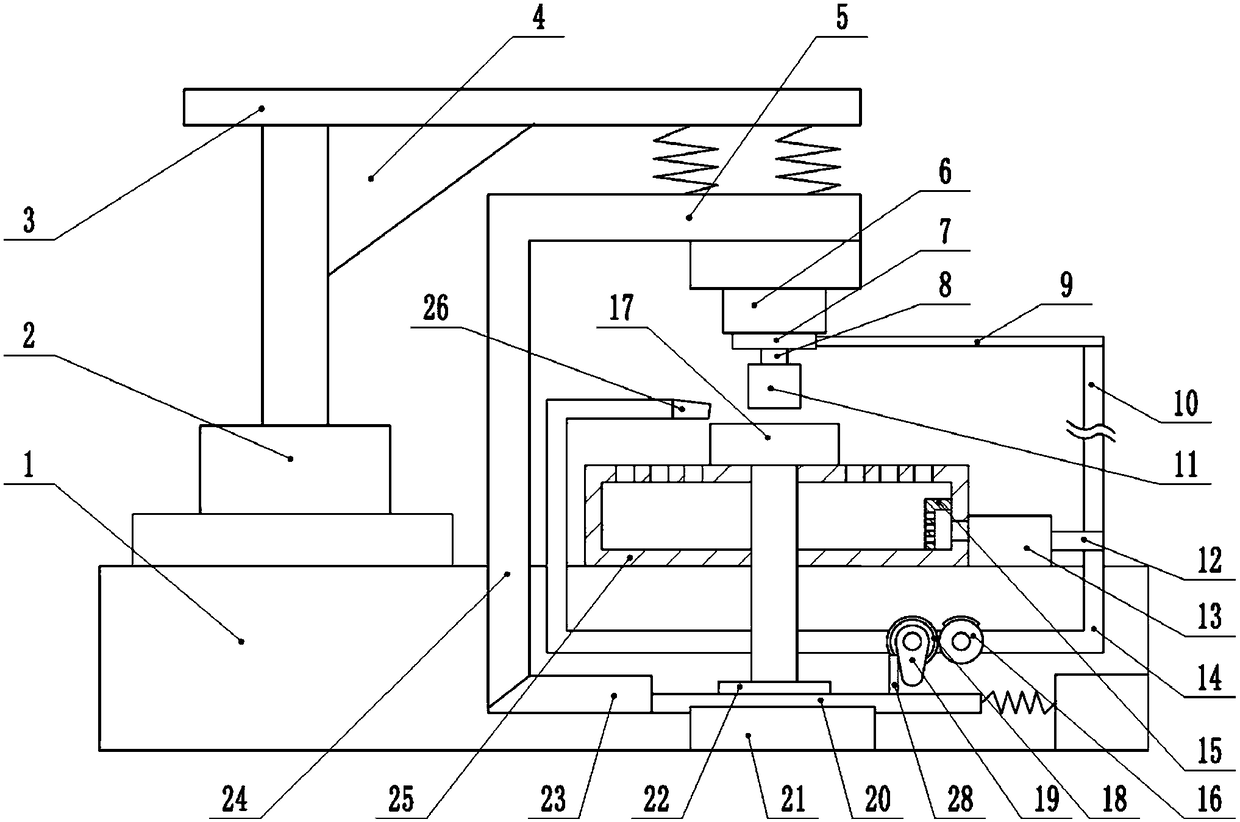

Intelligent plate part machining production line provided with universal equipment and special equipment

ActiveCN110773779AGuaranteed production efficiencyImprove production efficiencyOther manufacturing equipments/toolsMilling equipment detailsProduction lineRobot hand

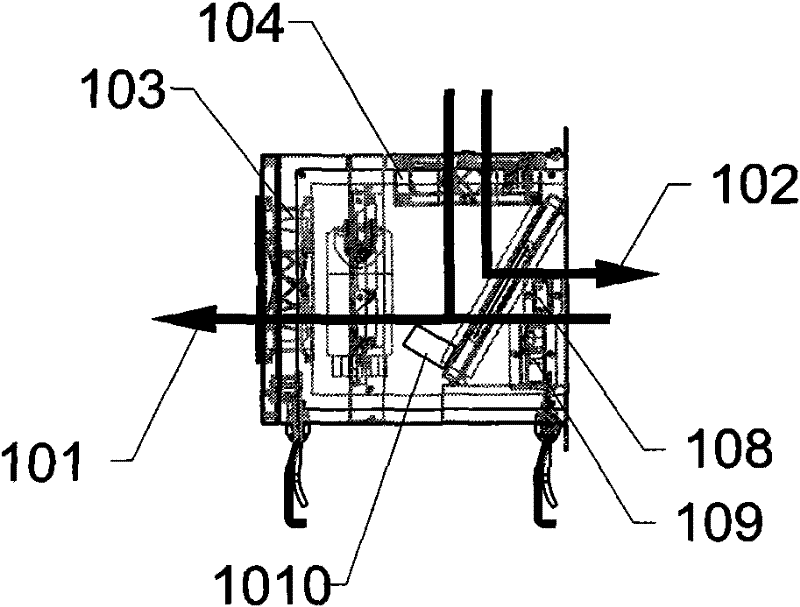

The invention provides an intelligent plate part machining production line provided with universal equipment and special equipment. Four special machining tools and a universal machining tool are sequentially and linearly arranged from an automatic feeding device, wherein the four special machining tools are located on a first station, a second station, a third station and a fourth station, and the universal machine tool is located on a fifth station; a truss conveying transport device is arranged behind the first station, the second station, the third station and the fourth station in parallel, and four mechanical arms are arranged on the truss transport device to transfer materials on the corresponding stations; a four-axis manipulator is arranged between the fourth station and the fifthstation and is used for transferring the materials between the fourth station and the fifth station and discharging finished products; industrial cameras are arranged on the second-station mechanicalarm and the four-axis manipulator and are used for recognizing defective products; waste boxes are arranged between the first station and the second station as well as between the fourth station andthe fifth station and are used for storing the defective products; a discharging box is arranged on the front side of the fifth station and is used for storing the finished products; and a scrape conveying mechanism is arranged below the whole production line and is used for collecting and transferring scrapes. According to the intelligent plate part machining production line, the universal equipment and the special equipment are combined, and flexible clamps and sliding rail cylinders are used, so that the production line is flexible, the machining times of the stations are balanced, and theproduction efficiency is improved.

Owner:JIANGSU UNIV OF SCI & TECH +1

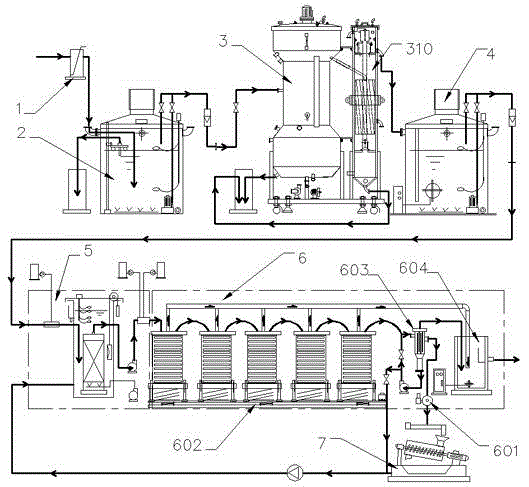

Garbage compression leachate comprehensive waste water treatment device and technological method

ActiveCN104529093AIncreased hydraulic shear strengthStable fluxWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningWater storage tankFiltration

The invention provides a garbage compression leachate comprehensive waste water treatment device and technological method. The device comprises a grille, a waste water storage tank, an ultrasonic Electro-Fenton reactor, an intermediate water storage tank, an ultrasonic vibration film reactor and a vortex vibration film filtration system, wherein the grille, the waste water storage tank, the ultrasonic Electro-Fenton reactor, the intermediate water storage tank, the ultrasonic vibration film reactor and the vortex vibration film filtration system are sequentially connected. The device further comprises a sludge dewatering drying pool which is connected with a vortex energy-saving heat pump flash evaporator of the vortex vibration film filtration system and provided with a circuit connected with the ultrasonic vibration film reactor. Waste water sequentially flows through the grille, the waste water storage tank, the ultrasonic Electro-Fenton reactor, the intermediate water storage tank, the ultrasonic vibration film reactor and the vortex vibration film filtration system for redox reactions and filtration. The device is high in operability, high in regeneration cycle use rate and low in operation cost.

Owner:樊利华

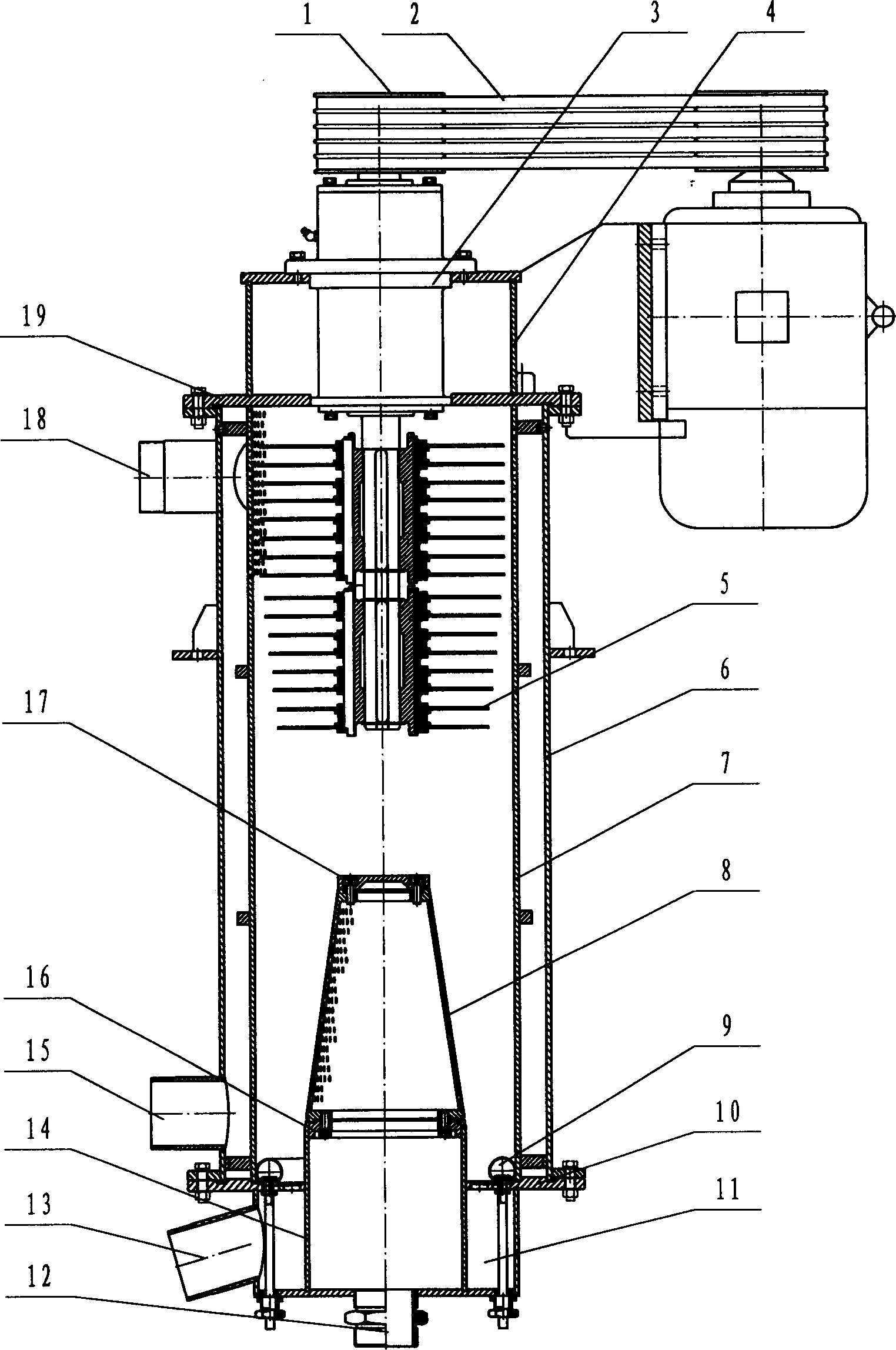

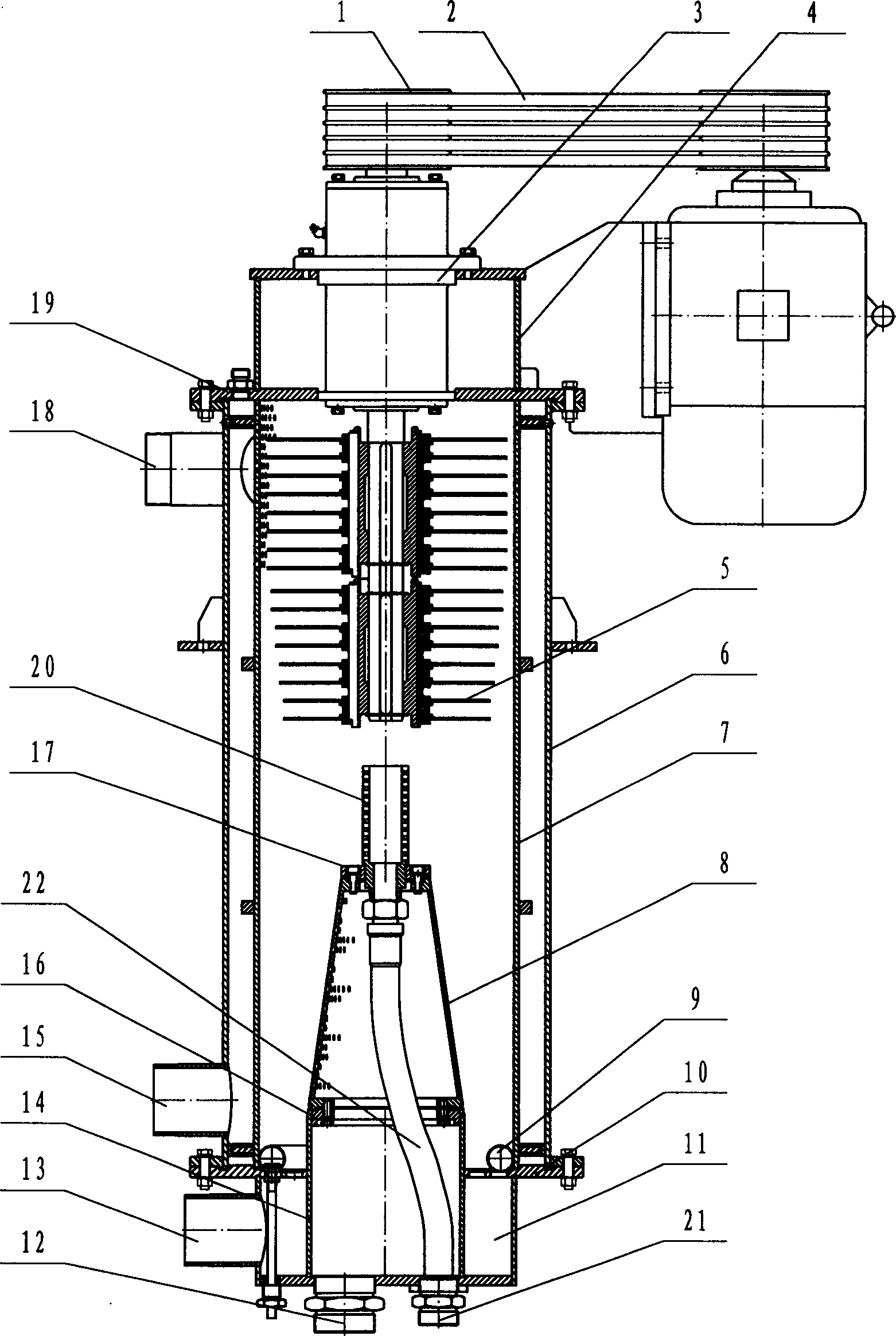

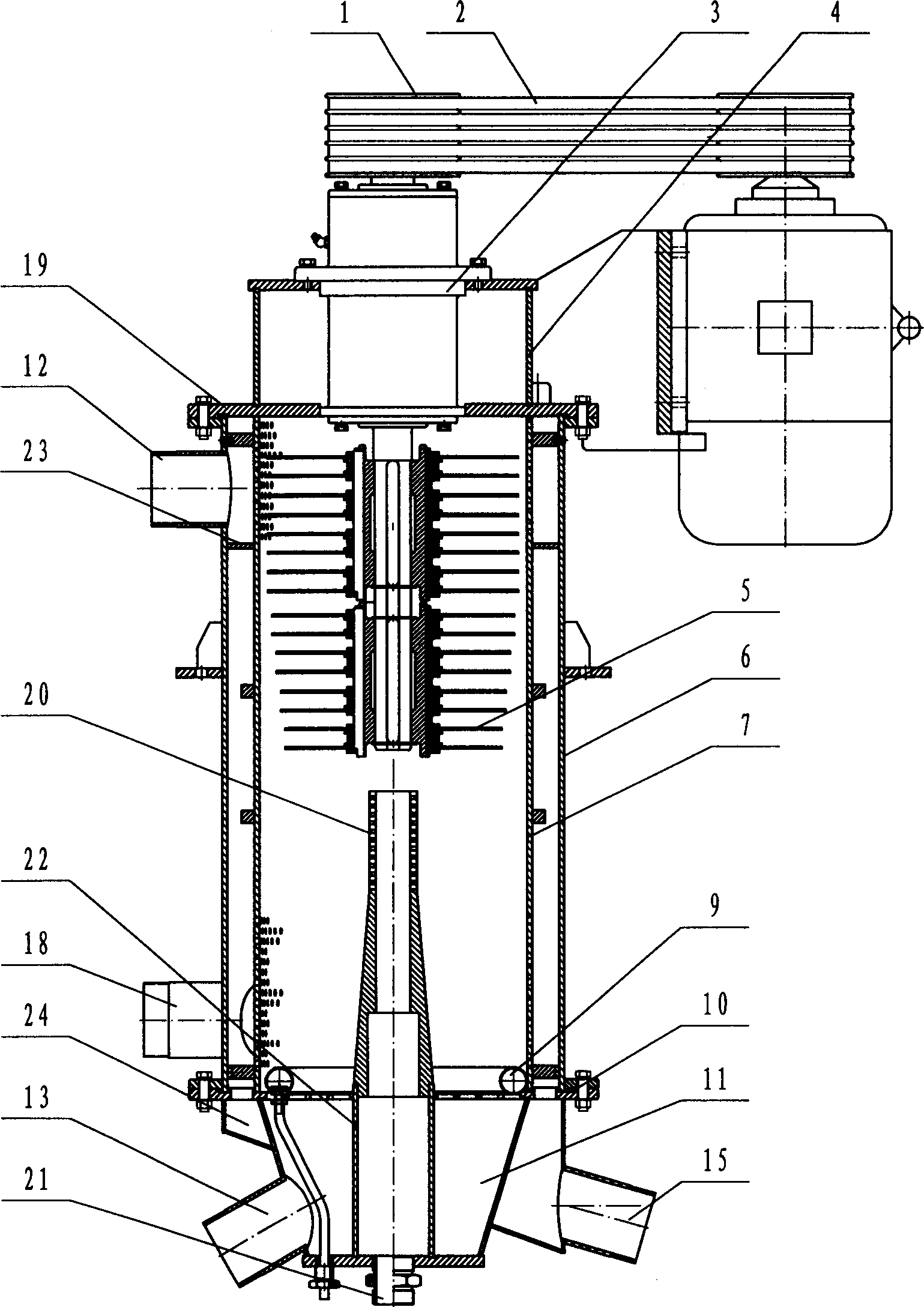

Settling centrifuger with internal rotor

InactiveCN1383926ADiffusion evenly distributedEasy to separateWater/sewage treatment by centrifugal separationCentrifugal force sediment separationSlurrySewage treatment

The present invention relates to the technology of centrifugal separation of mixed liquid. The centrifuge incldues transmission mechanism, pin wheel rotor with extending area covering at least partial centrifugal cavity space, slurry intake, casing and filtering cylinder assembly, aerator, slurry outlet filter and light phase skimming out device. The centrifugal cavity has several modes and several slurry and material discharge combinations. The material in slurry discharge filter is eliminated by centrifugal vortex and gravity. The present invention is used in solid-solid, liquid-liquid and solid-liquid-liquid separation, mass-transferring reaction and sewage treatment.

Owner:高根树

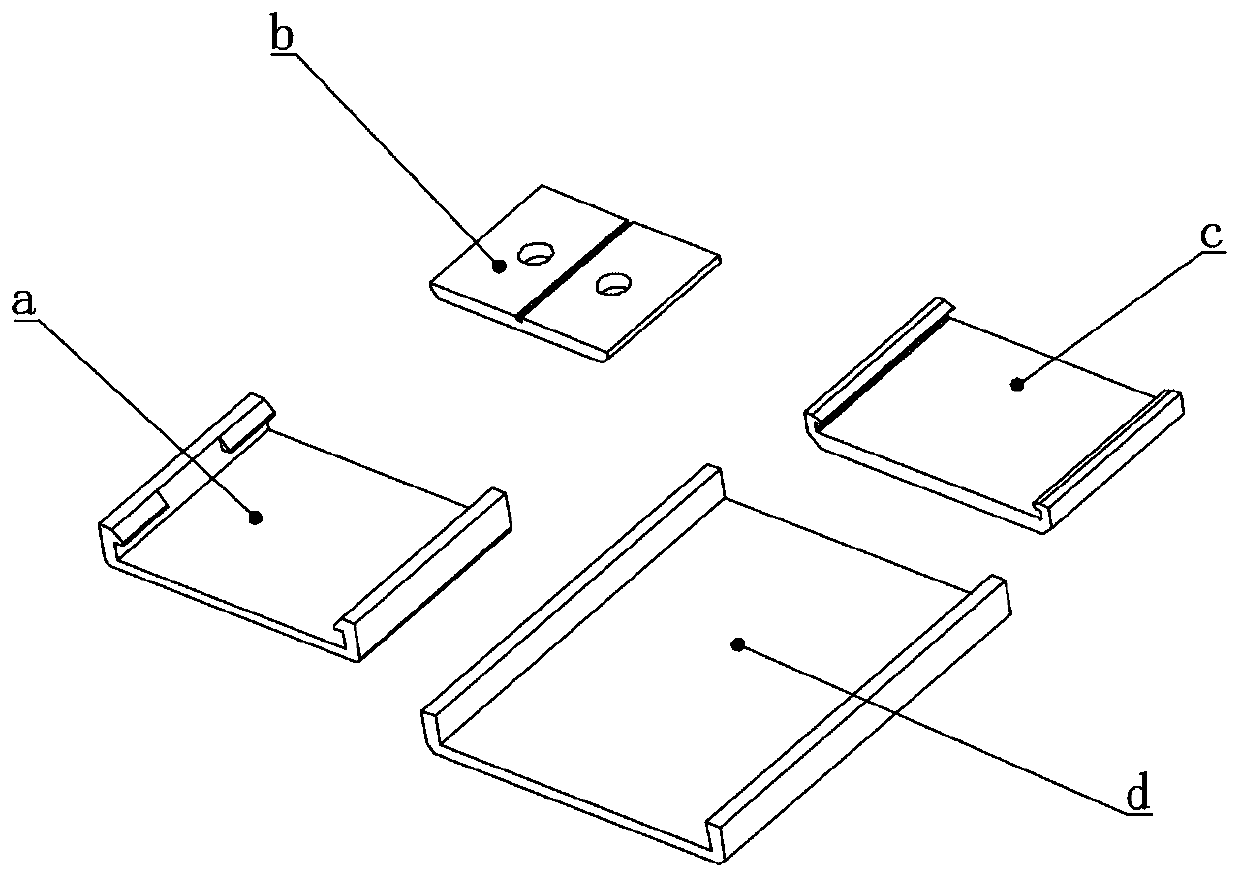

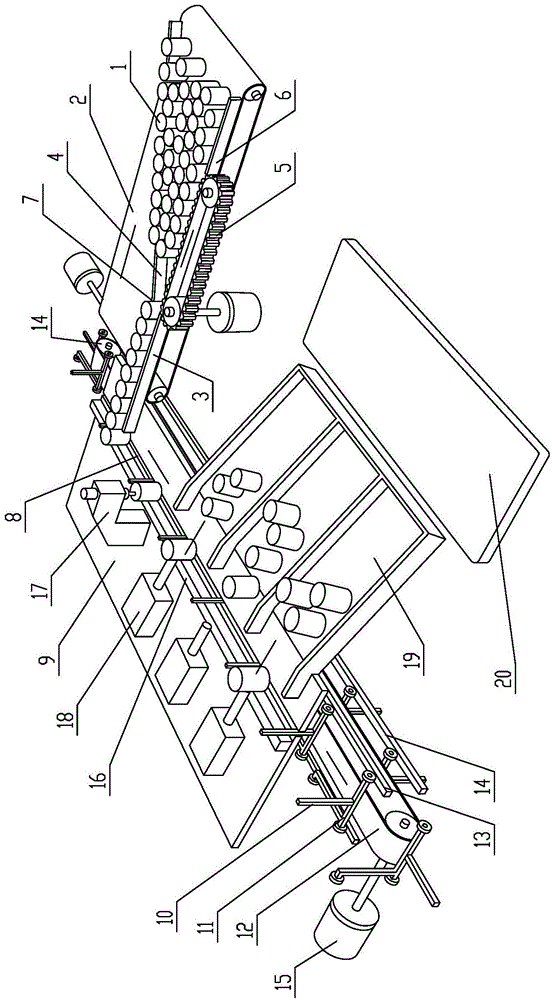

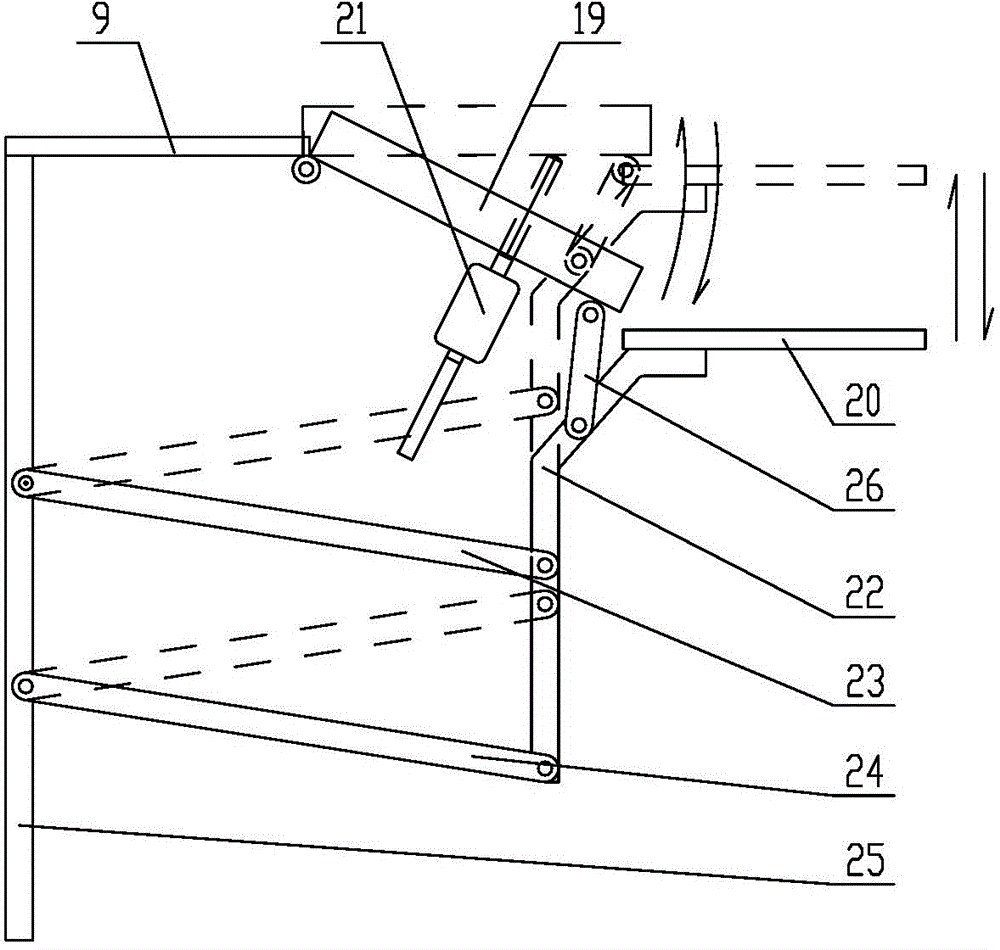

Multi-parameter workpiece sorting machine capable of moving workpieces by push rods

ActiveCN104438140AExtend the intervalSave the hassle of replacing discs of different specificationsSortingTransmission beltEngineering

The invention relates to a multi-parameter workpiece sorting machine capable of moving workpieces by push rods. An upper arm and a lower arm are hinged to a base frame; a panel is fixedly arranged at the upper end of the base frame; a material pushing device and a sensor are fixedly arranged on the upper surface of the panel; a guide strip is fixedly arranged on the upper surface of the panel, on one side of a gap; a conveyor belt is arranged on one side of the panel; a first baffle plate, a second baffle plate, a first groove plate and a second groove plate are arranged on the conveyor belt; an interval material pushing mechanism is arranged under the panel and comprises an annular transmission belt under the panel; the transmission belt is driven by a transmission belt motor; three-wheel trolleys are fixedly arranged on the transmission belt at equal intervals; the push rods are fixedly arranged on the three-wheel trolleys; trolley upper-layer rails are arranged on the transmission belt and trolley lower-layer rails are arranged under the transmission belt; and the three-wheel trolleys are matched with the trolley upper-layer rails and the trolley lower-layer rails. The multi-parameter workpiece sorting machine capable of moving the workpieces by the push rods has the advantages of compact structure, and convenience and reliability in utilization.

Owner:张澎年

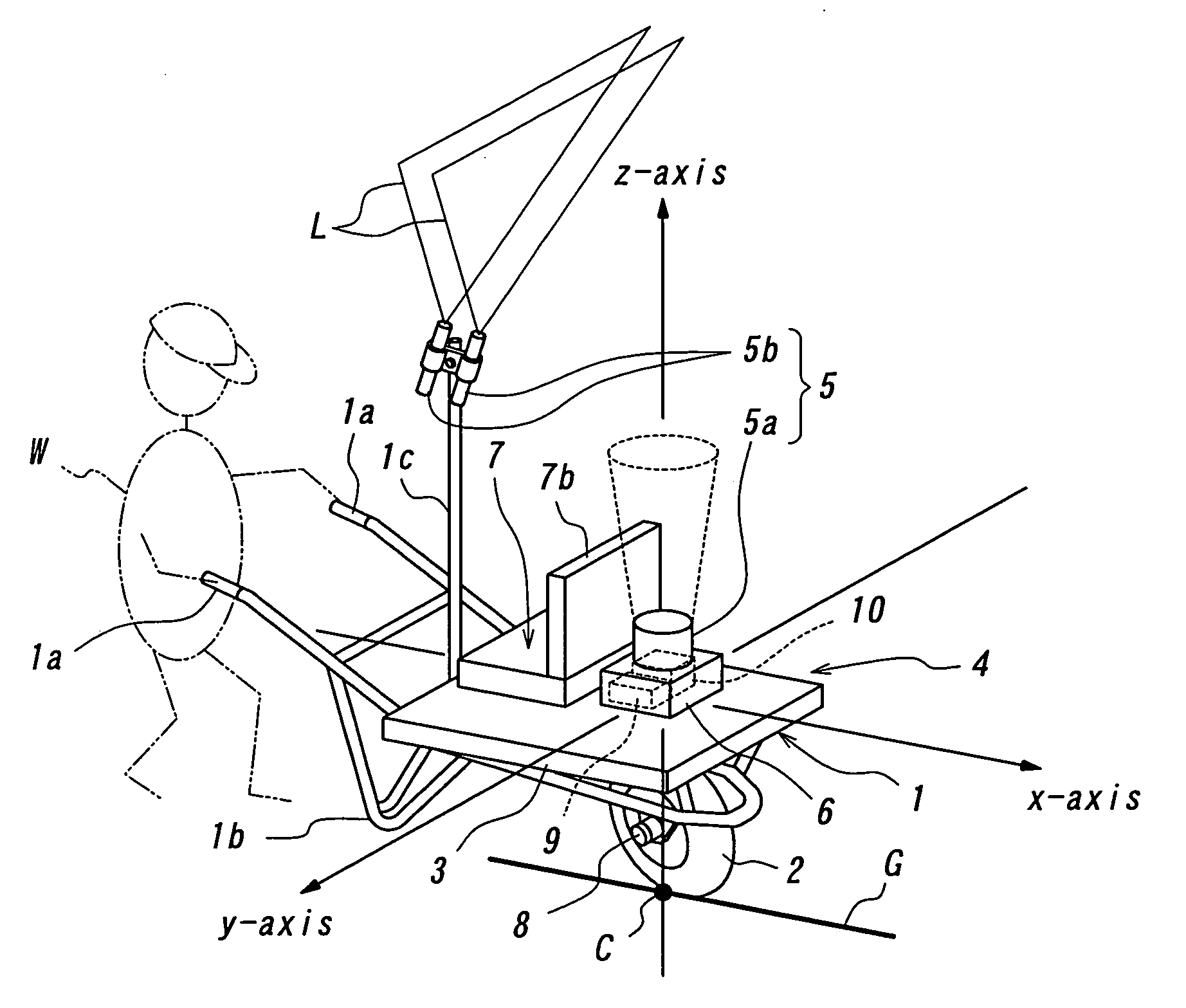

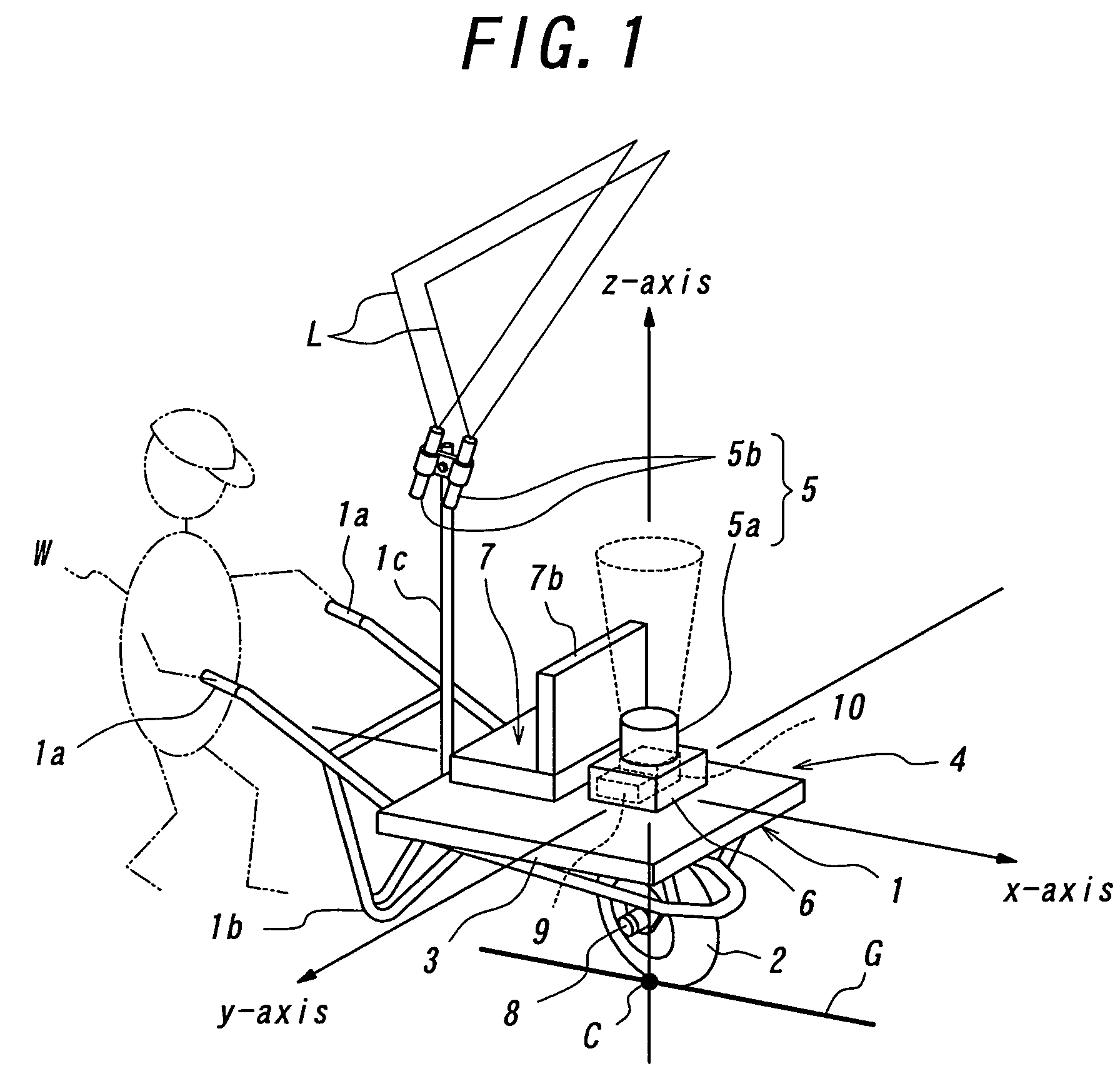

Mobile measurement system of three-dimensional structure

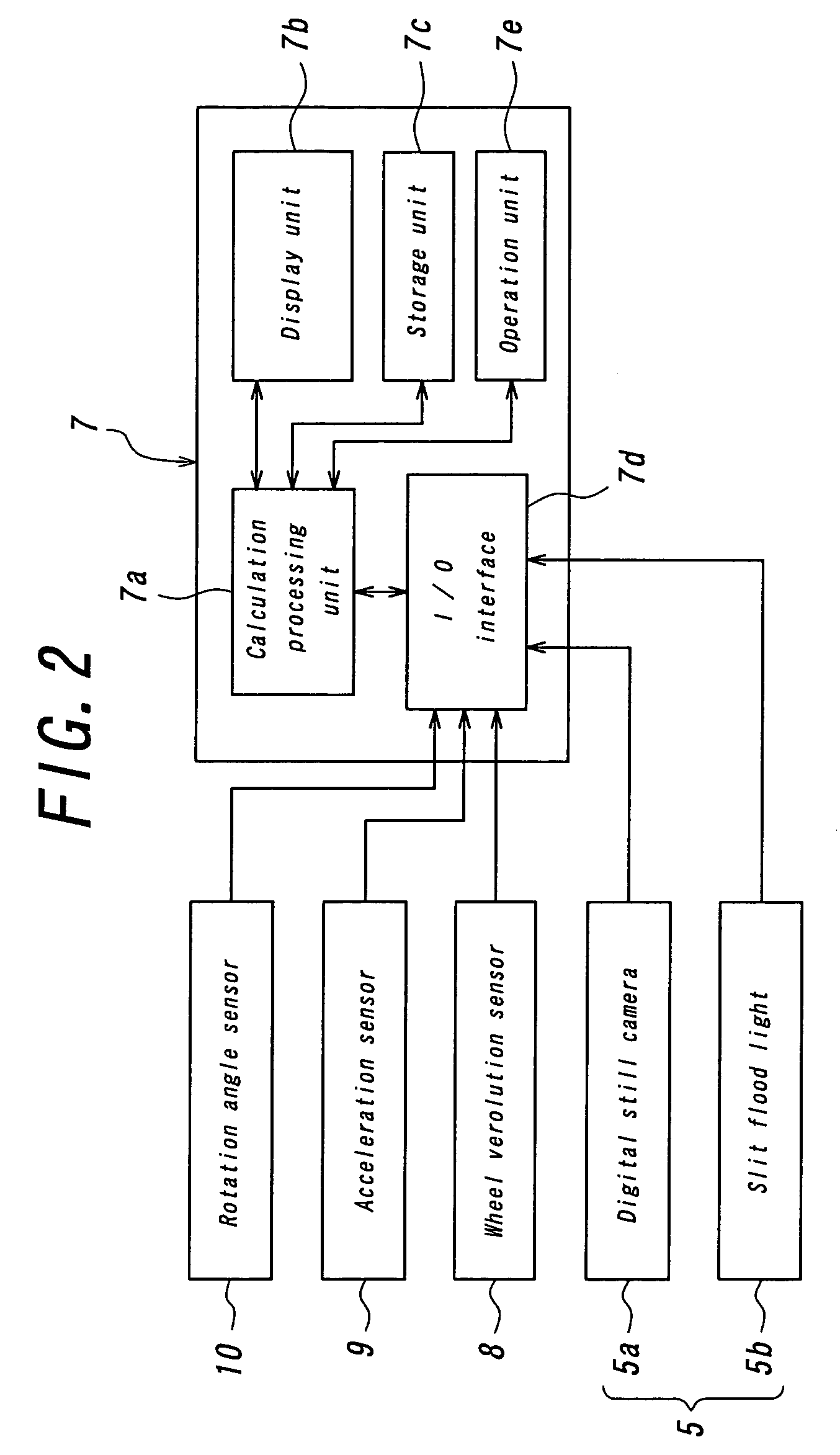

InactiveUS7032458B2Low costNo expenseAngle measurementMeasuring wheelsMarine navigationMeasuring equipment

This invention relates to a mobile measurement system of three-dimensional structure comprises a measuring equipment 5 to measure three-dimensional structure of an object for measurement and a barrow 4 for moving measurement which the equipment 5 is mounted. The measuring equipment 5 has a digital camera 5a, a slit floodlight 5b, and a three-dimensional structure calculating device that calculates and outputs three-dimensional structure of the object by using a light plane range-finding method from the each position and direction of the floodlight and the camera and the picture that is taken by the camera. The barrow has an measurement position and direction calculating device that calculate the each position of the floodlight and the camera, the direction of the floodlight, the direction of the camera at the measurement by the equipment in accordance with an information of self-contained navigation from an acceleration sensor 9 and a rotation angle sensor 10 that detects an acceleration and a rotation angle of the barrow, respectively, and an information of moving distance from the wheel revolution sensor 8 and transmit the result of the calculation to the three-dimensional structure calculating device 7.

Owner:NAGOYA UNIVERSITY

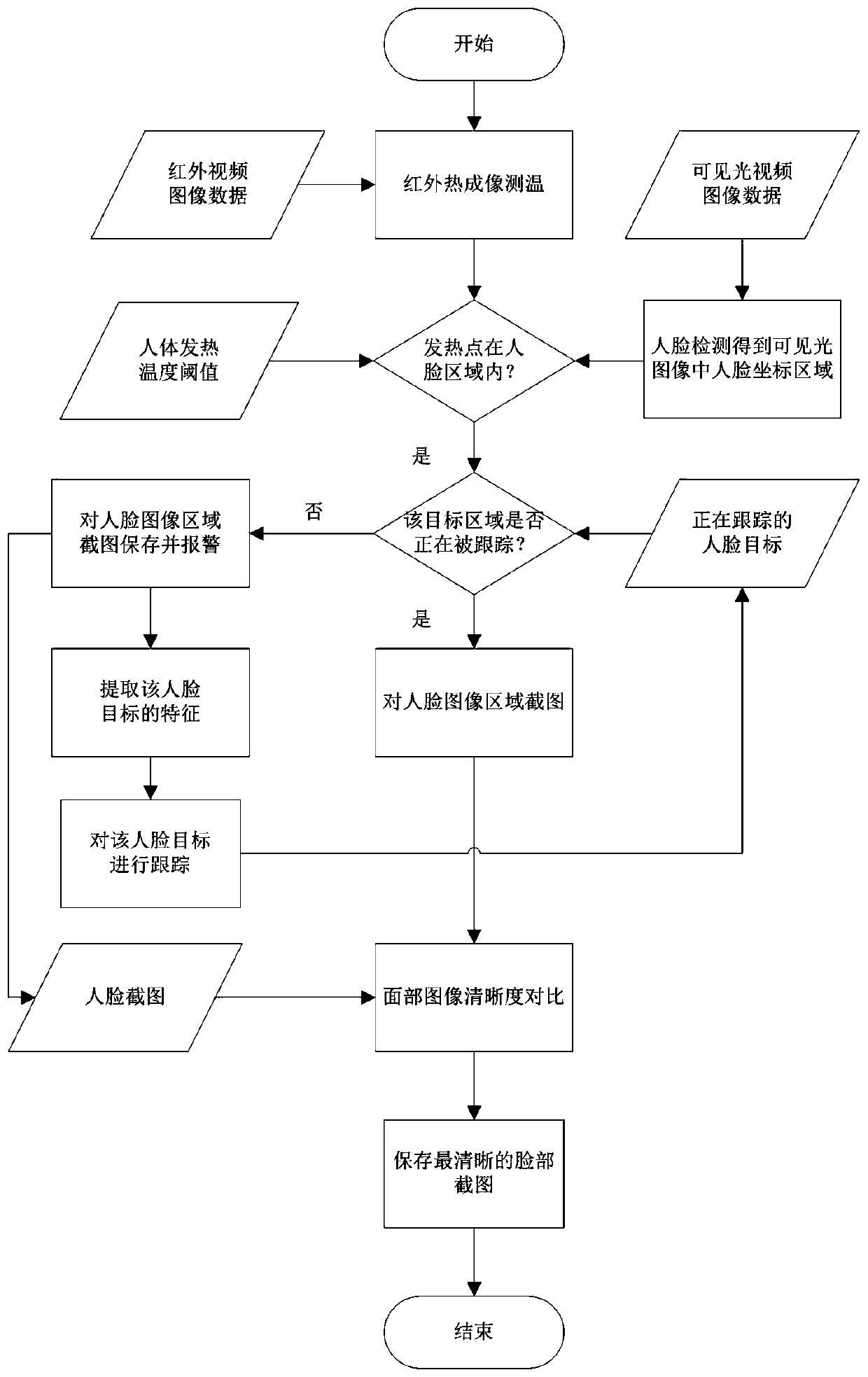

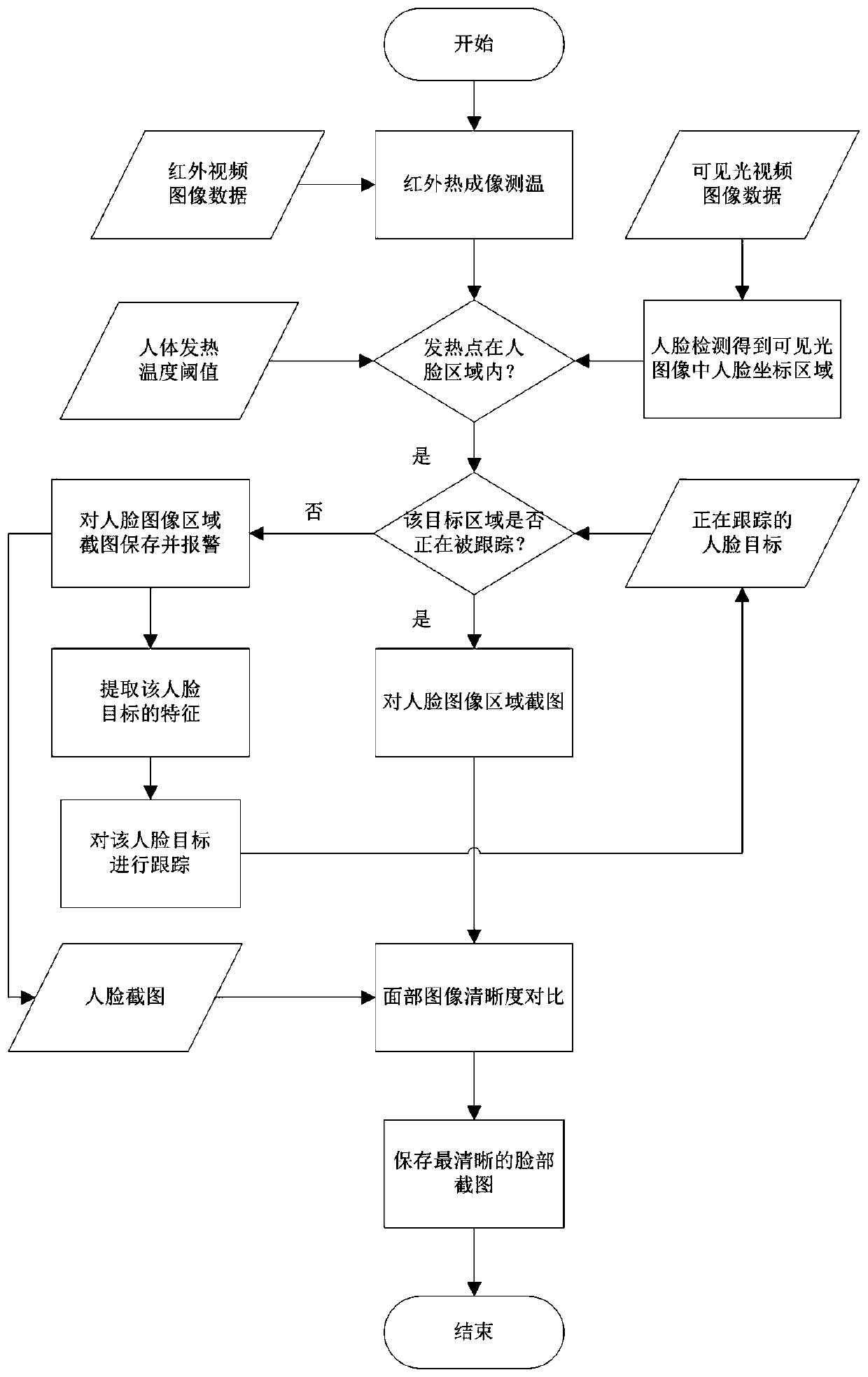

Method, device and equipment for avoiding repeated alarms in human body inspection and quarantine system

ActiveCN110044486AAvoid repeated alarmsRepeated alarms will notImage enhancementImage analysisHuman bodyQuarantine

The invention discloses a method, device and equipment for avoiding repeated alarms in a human body inspection and quarantine system. The method for avoiding repeated alarms in the human body inspection and quarantine system comprises the following steps that infrared video image data and visible light video image data of a human body are acquired, and heating personnel in the infrared video imagedata are measured by using an infrared thermal imaging temperature measurement method; when the heating personnel are monitored, a face image area of the heating personnel in a visible light video image is detected by using the matching relationship between an infrared image and the visible light image, and whether the face image area is tracked or not is judged; if the face image area is not tracked, screenshots of the face image area are saved, an alarm is given, and the face image area is tracked at the same time; and if the face image area is tracked, no alarm is given. The human body inspection and quarantine system is prevented from repeatedly alarming the same alarm personnel.

Owner:WUHAN GUIDE SENSMART TECH CO LTD

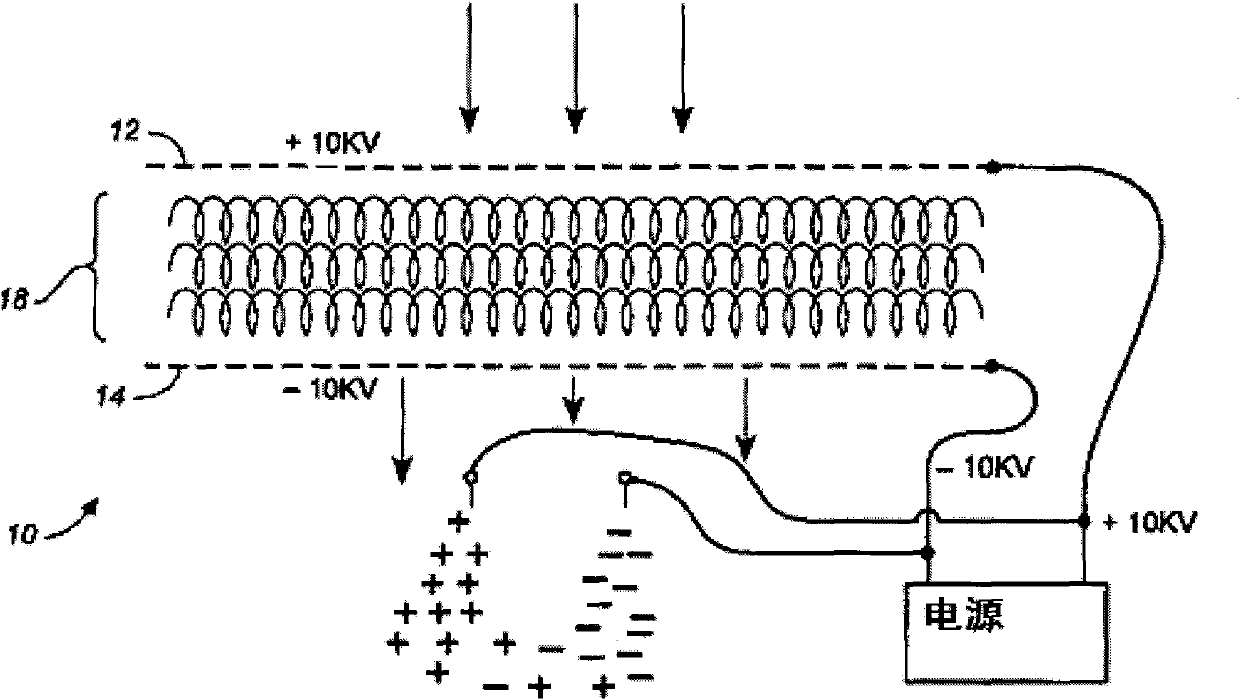

Electrostatic air cleaner

InactiveCN102000632ASave energyReduce ozone concentrationExternal electric electrostatic seperatorElectrode constructionsConductive materialsHigh intensity

The invention provides an electrostatic air cleaner, comprising a series of corona generators and a collector which are mutually separate and parallel. A power supply provides potentials for the corona generators and the collector, thus a high-intensity electric field is formed in the space between the corona generators and the collector. The ength side and height side of each collector which are mutually vertical are used for regulating the flow direction of required fluid, and the width side is used for regulating the flow direction of required air. The collector adopts porous conductive material, the porous structure thereof is beneficial to absorbing massive dust, and cost is low.

Owner:SUZHOU BEIANG TECH LTD

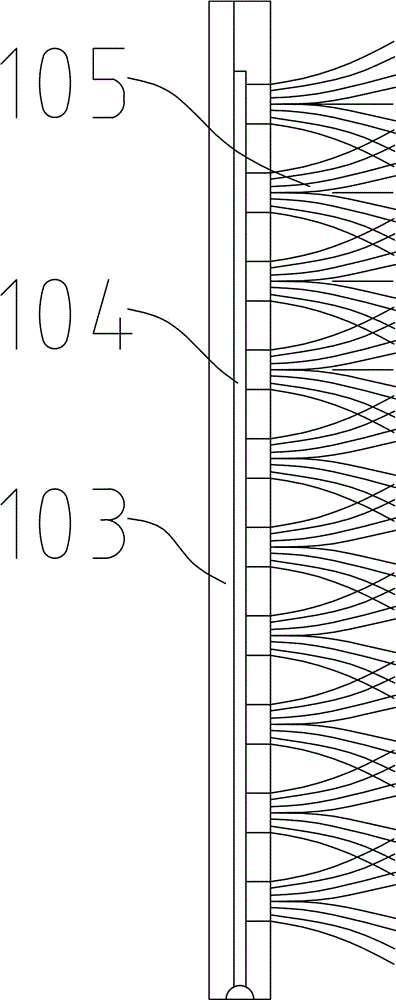

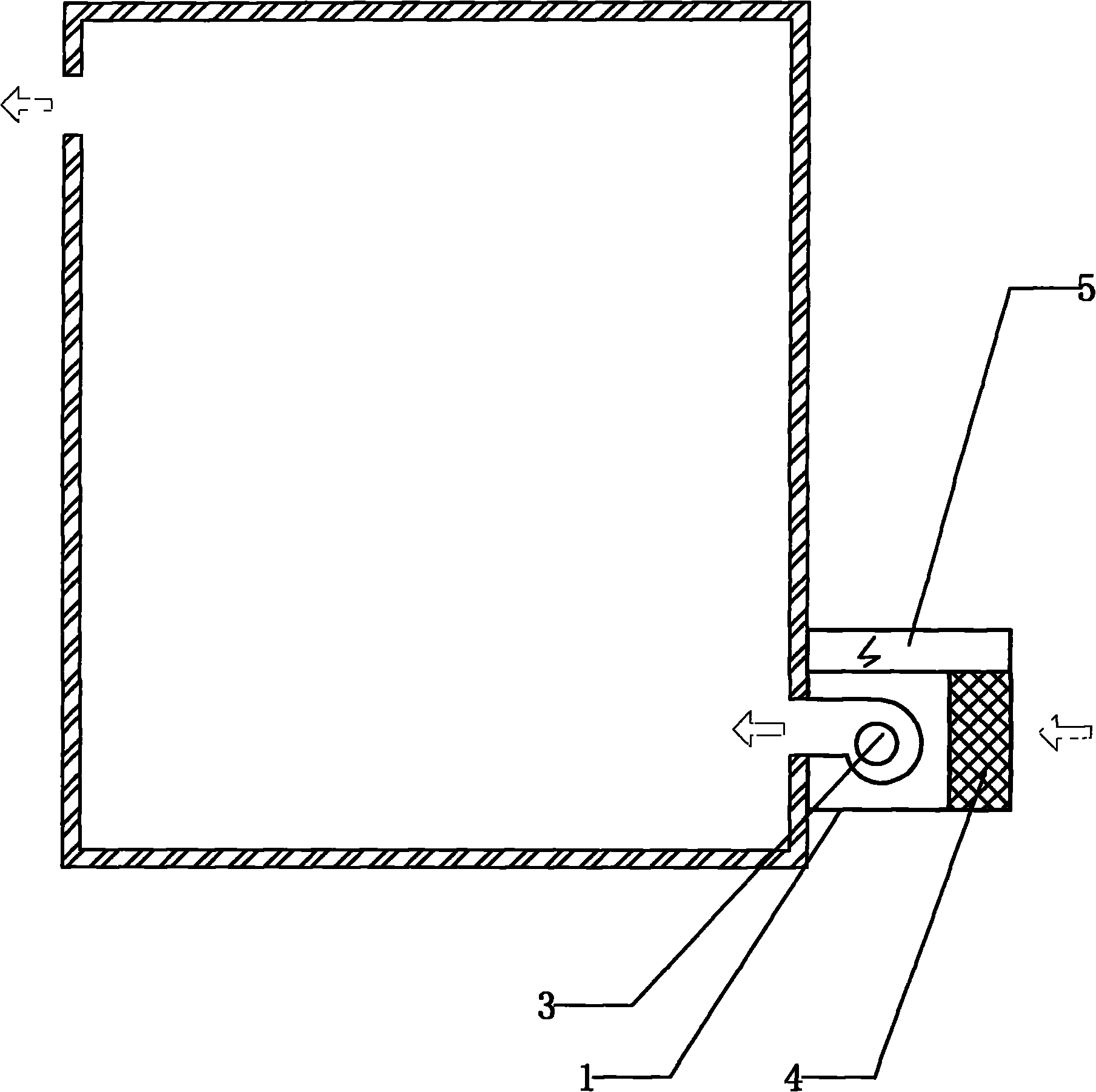

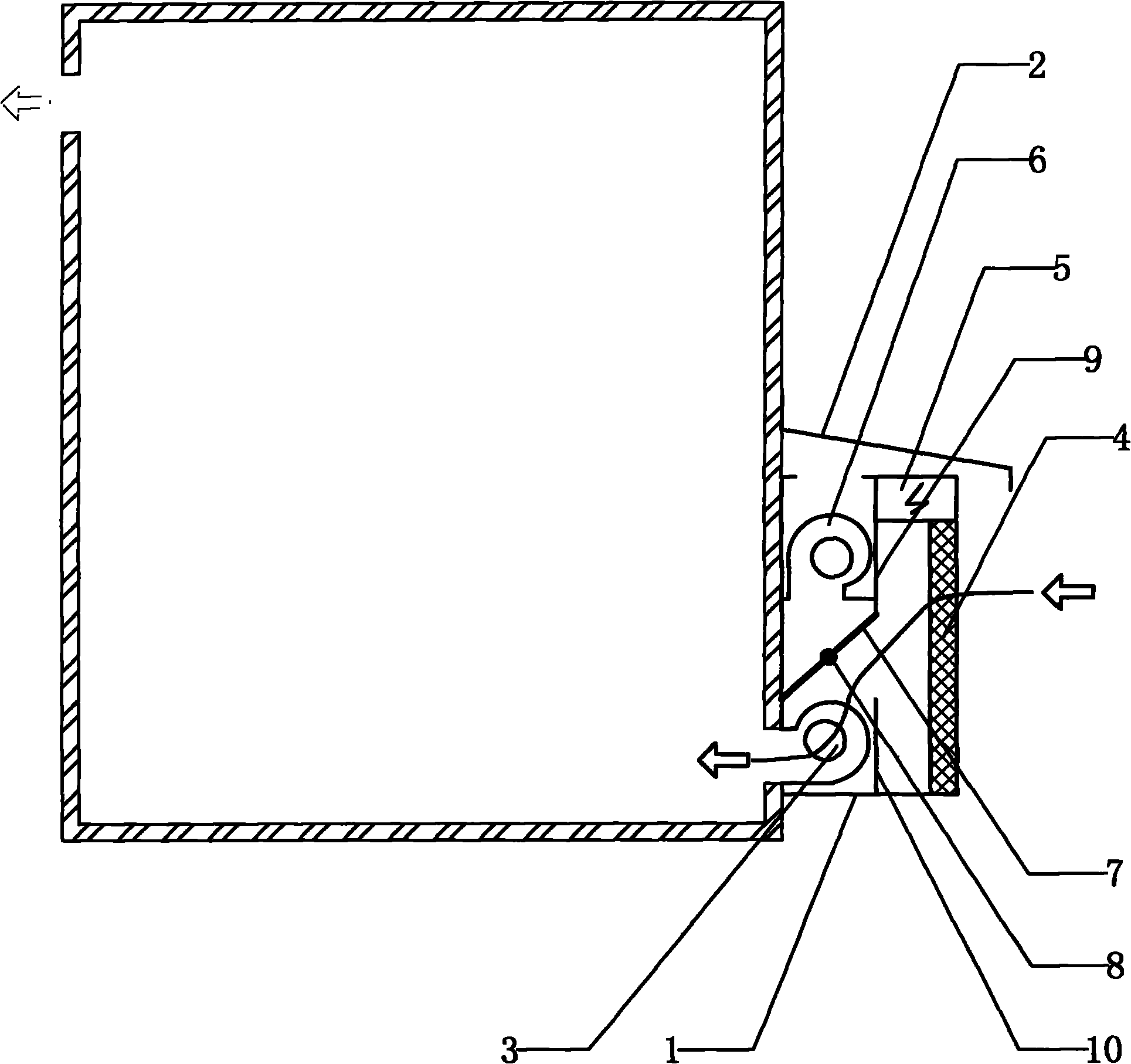

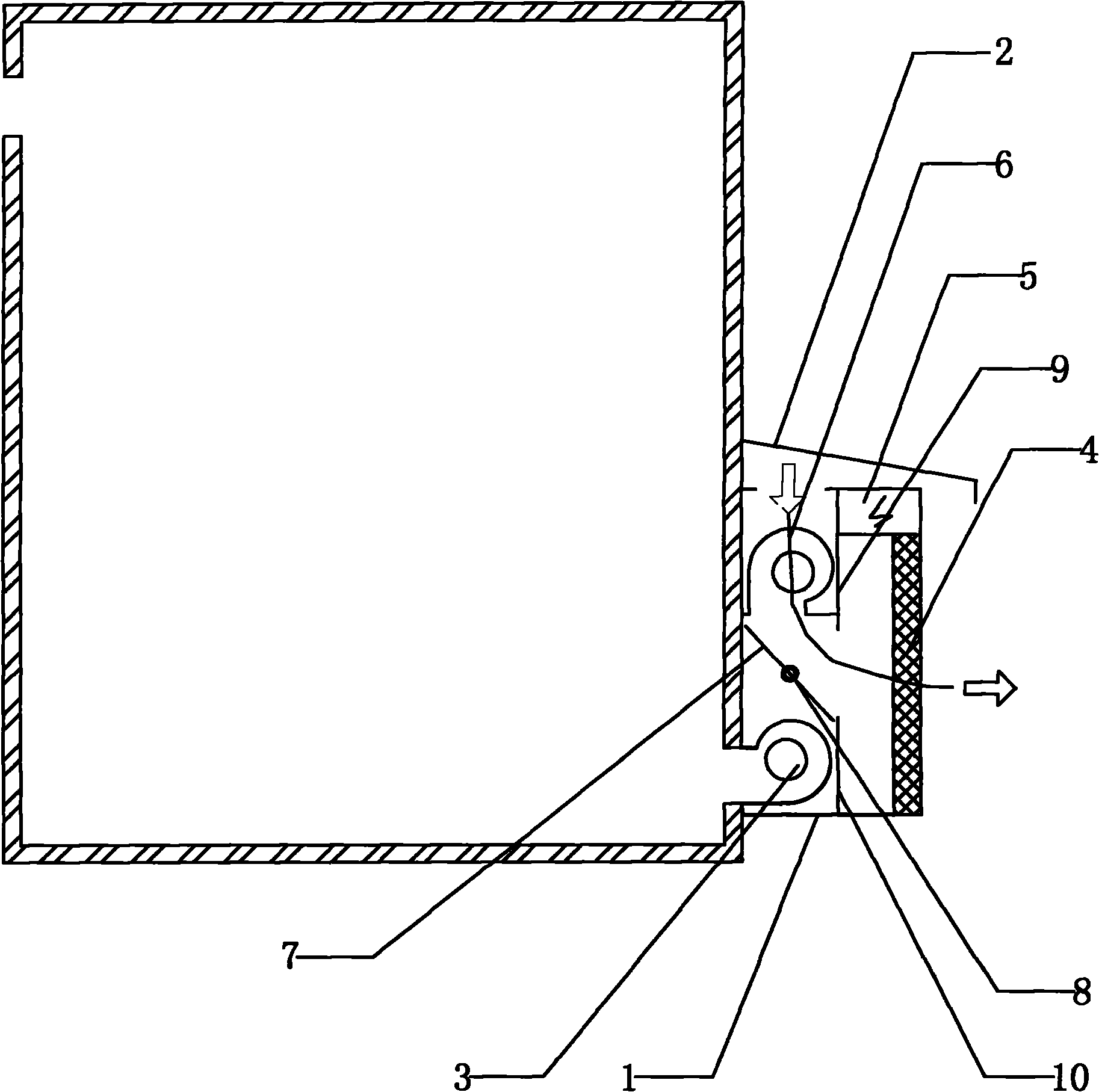

Automatic dust removal and intelligent ventilation system of fireproof linkage

ActiveCN102175055AExtend the intervalExtended service lifeSpace heating and ventilation safety systemsLighting and heating apparatusSmokeMoisture sensor

The invention relates to the field of ventilation and heat exchange systems, in particular to an automatic dust removal and intelligent ventilation system of fireproof linkage. The system comprises an intelligent energy-saving ventilation system shell; the intelligent energy-saving ventilation system shell comprises a mixed air flue, a dust discharge air flue, an air door, a dust screen, temperature and humidity sensors, a dust sensor and an intelligent energy-saving ventilation system shell component; the dust screen filters the outdoor air; the temperature and humidity sensors are used for controlling start and stop of an indoor air conditioner and an intelligent energy-saving ventilation system; and the dust sensor is used for feeding the outdoor air cleanliness condition back to a control system, and the control system controls the start and stop of the intelligent ventilation system according to the feedback condition. The system has the advantages that: the intelligent ventilation system is associated with machine room safety key equipment such as a machine room power environment monitoring system, a machine room air conditioner, a smoke sensor and the like, so that new ignition points caused by electric faults of the air conditioner under the fire condition are prevented; and the air door of the intelligent ventilation system is closed to cut off the supply source of fresh oxygen so as to prevent supporting flames.

Owner:SHENZHEN ZHONGXING SINDI TECH CO LTD

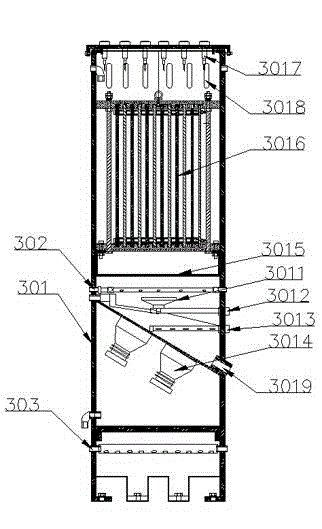

Double-filtration anti-blocking pulse bag dust collector

ActiveCN106390625AIncrease loading capacityImprove stabilityDispersed particle filtrationTransportation and packagingCarrying capacityBaghouse

The invention discloses a double-filtration anti-blocking pulse bag dust collector, comprising a box body and a spray pipe; a perforated plate and a cage frame are fixedly connected in the box body; a plurality of electromagnetic valves are fixedly connected to the cage frame, a first filter bag and a second filter bag are fixedly connected between every electromagnetic vale and the perforated plate, the lower ends of both the first and second filter bags are fixedly connected with valve bodies of the electromagnetic valves, venturi tubes are penetratingly connected to the perforated plate, and the spray pipe is fixedly connected above the perforated plate in the box body; a vibrating motor is fixedly connected to each side of lower funnel structure of the box body, the funnel part in the box body is fixedly connected with a plurality of electric telescopic rods through a mounting frame, an intake pipe is fixedly connected with a plurality of steel rods through a circular frame, and the intake pipe is also fixedly sleeved with an electromagnetic heating sleeve; the double-filtration anti-blocking pulse bag dust collector provides secondary dust collection, the filter bags are high in carrying capacity, dust collection efficiency is effectively improved, and the double-filtration anti-blocking pulse bag dust collector runs stably and is suitable for collecting dust in various cold and hot waste gases.

Owner:广西金邦泰科技有限公司

Automatic bee keeping device

ActiveCN105532513AExtend the intervalIncrease the level of automationBeehivesHoney collectionProduction rateBeekeeping

The invention relates to an automatic bee keeping device and belongs to the technical field of bee keeping. The automatic bee keeping device comprises an automatic comb moving hive and hive comb storage bins. The automatic comb moving hive comprises comb transfer manipulators, a comb and a support. The hive comb storage bins comprise interface boxes, relay boxes and main transmission devices. By means of the automatic bee keeping device, automatic placing-in of empty combs and automatic taking-out of combs filled with gathered honey are achieved; the combs are taken and placed automatically, so that the interval between comb taking and placing is greatly prolonged, great help is offered to the improvement in automatic level of bee houses, the bee keeping productivity can be greatly improved, labor cost is saved, production efficiency is improved, and foundation is laid to full-automatic bee keeping.

Owner:KUNMING UNIV OF SCI & TECH

Multi-functional environment-friendly type sewage disposal apparatus

InactiveCN1962491AExtend the intervalImprove cohesionWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningSiphonSludge

The invention discloses a multi-functional environmental protective effluent disposing equipment, which comprises the following steps: grinding big object in the effluent; transmitting into the squeezing device to form slag pie; concreting the separated effluent; sedimenting and condensing sludge downwards through rapid centripetal force pattern; dehydrating the sludge; transmitting into the squeezing device to form sludge pie; concreting the old effluent into new effluent through siphon dissolving; falling the concrete sediment; transmitting the dehydrated condensed sludge into squeezing device into sludge pie; circulating continuously.

Owner:朱明华

Intelligent air purifier

InactiveCN106731406AImprove adsorption capacityImprove water retentionCombination devicesGas treatmentParticulatesSorbent

The invention provides an intelligent air purifier which comprises a labyrinth adsorption area and an electrostatic adsorption area that are communicated with each other, wherein fluff is arranged on partition bodies forming a labyrinth partition in the labyrinth adsorption area; the air purifier is further provided with a gel filling device; the gel filling device is communicated with the fluff via pipe grooves in the partition bodies. With the adoption of a structure that the gel filling device is matched with the labyrinth adsorption area, the adsorption capacity of the labyrinth adsorption area is greatly improved; since gel has a good water retention property and strong dust adsorption capability; the problem that dust particulates enter air after evaporation of water for a common adsorbent can be avoided. The gel filling device continuously fills the gel; the cleaning time interval can be prolonged greatly; the operation difficulty is reduced. With the adoption of a gel adsorption structure, the evaporation capacity can be reduced greatly, and the use level of the adsorbent is reduced.

Owner:周书辉

Self-cleaning Intelligent ventilation device and utilization method thereof

InactiveCN101846374ARealize automatic cleaning functionExtended service lifeSpace heating and ventilation safety systemsLighting and heating apparatusAutomatic controlAir filter

The invention relates to a self-cleaning intelligent ventilation device, which comprises an intelligent ventilation device main body and a ventilation device rainproof cover. An upper sealing board and a lower sealing board are arranged oppositely in a ventilation box. The left sides of the upper sealing board and the lower sealing board are respectively provided with a recoil cleaning fan and a blower and the right sides thereof are provided with an air filter. A wind valve is arranged between the blower and the recoil cleaning fan. The wind valve has two work states of a natural cooling position and a recoil cleaning position. The utilization method is that through the automatic switching of the wind valve between the natural cooling position and the recoil cleaning position and the automatic control of the close and start of the blower and the recoil cleaning fan, the recoil cleaning fan blows away particles on the air filter at regular time. The invention has the beneficial effects of simple structure, convenient maintenance and good natural cooling effect.

Owner:AIRSYS REFRIGERATION ENG TECH BEIJING

Heartbeat connection method and heartbeat connection device

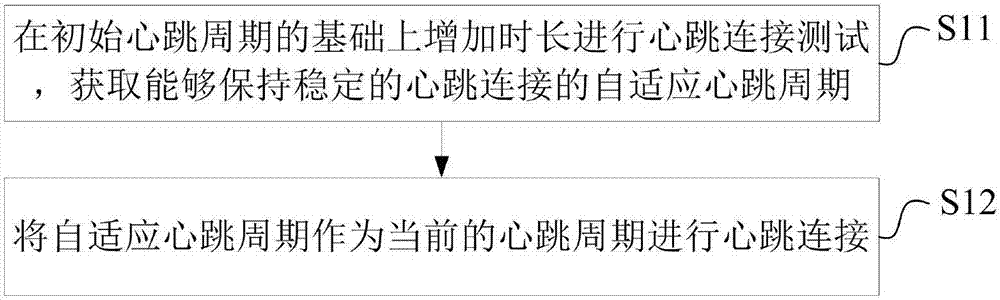

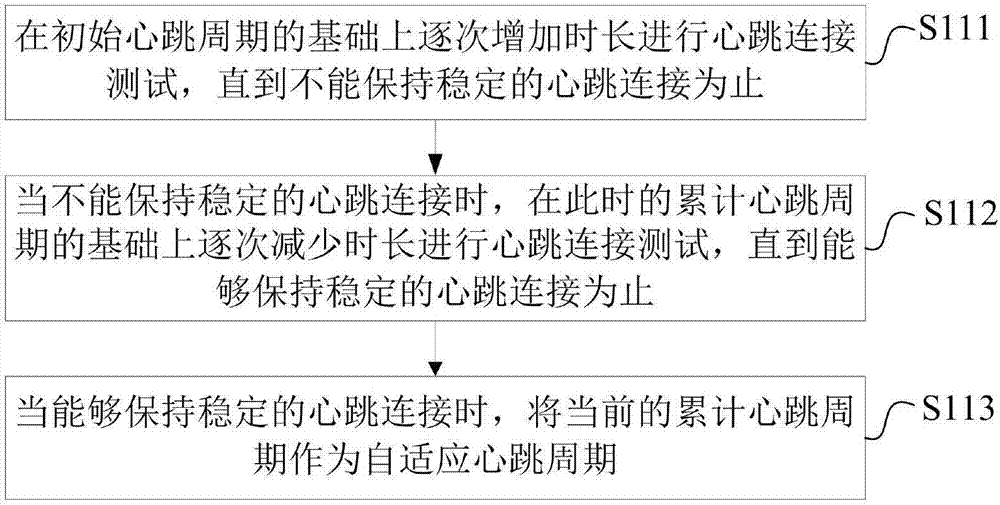

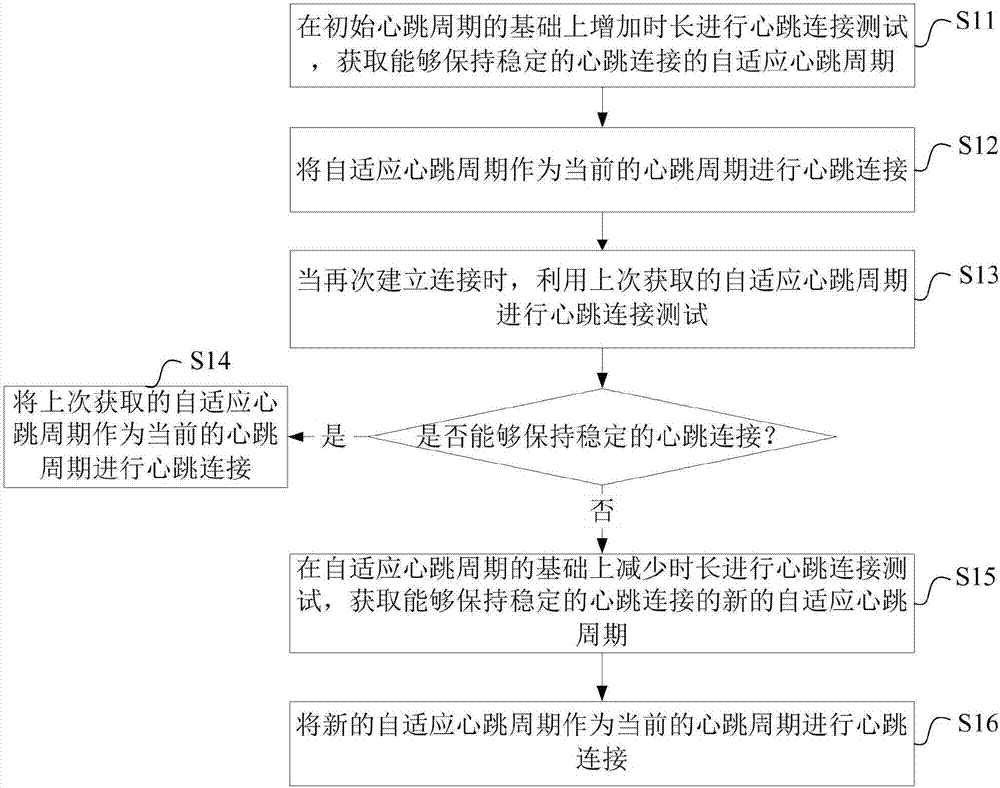

InactiveCN107197509AExtend the intervalReduce the number of timesPower managementConnection managementElectricitySelf adaptive

The invention discloses a heartbeat connection method and a heartbeat connection device. The method comprises the following steps: the time duration is added on the basis of the initial heartbeat cycle for heartbeat connection test, and an adaptive heartbeat cycle capable of keeping stable heartbeat connection is acquired; and the adaptive heartbeat cycle is regarded as the current heartbeat cycle for heartbeat connection. According to the heartbeat connection method provided by the embodiment of the invention, through carrying out adaptive adjustment on the heartbeat cycle, the adaptive heartbeat cycle which is longer than the initial heartbeat cycle and can keep stable heartbeat connection is acquired; in comparison with the initial heartbeat cycle, when the adaptive heartbeat cycle is used for heartbeat connection, the interval time for sending a heartbeat packet by a wakeup system is increased, the times of sending the heartbeat packet by the wakeup system are reduced, the power consumption is further saved, electricity consumption is reduced, the standby time is prolonged greatly, and the endurance ability is improved.

Owner:SHENZHEN WATER WORLD CO LTD

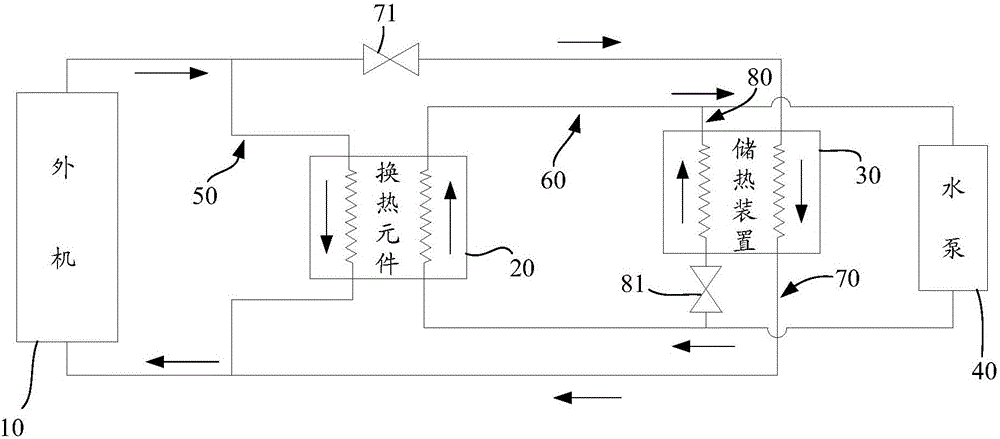

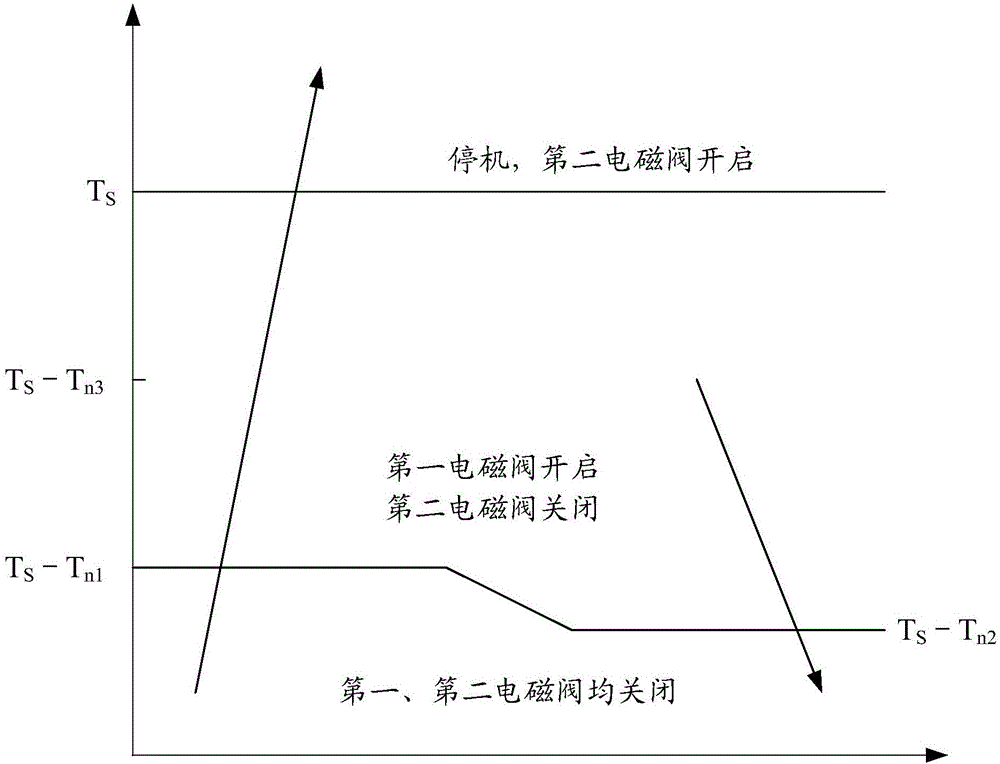

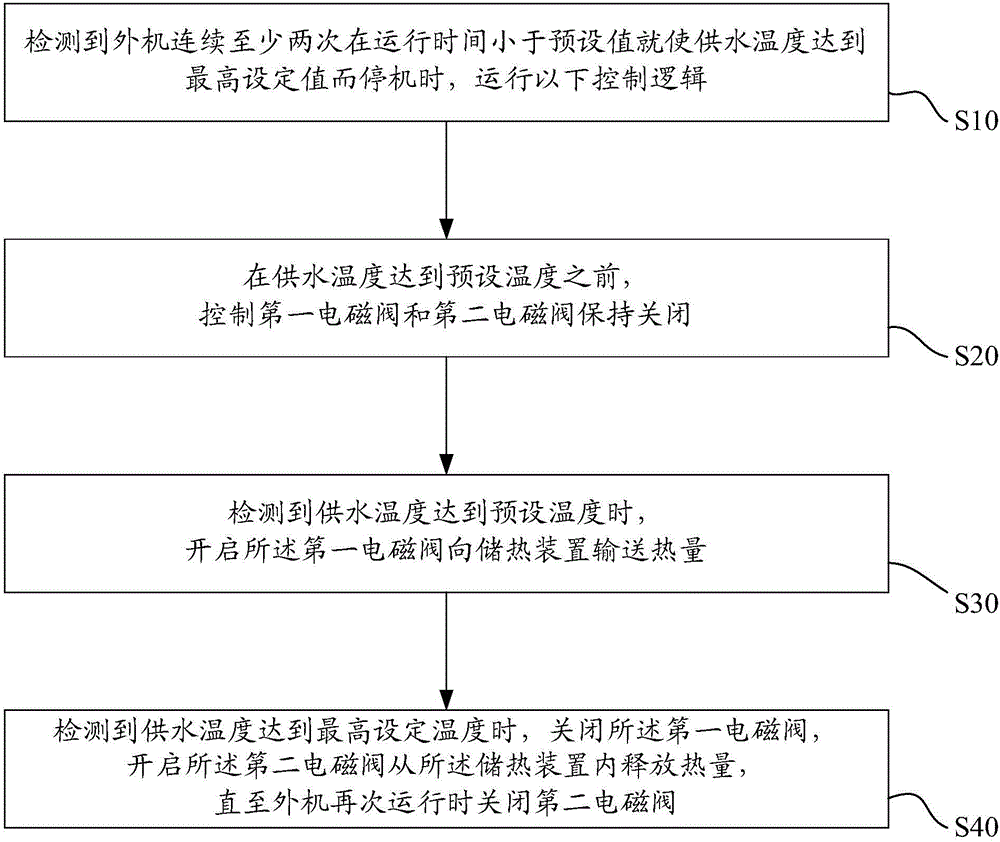

Flow path system of heat pump unit, heat pump unit and control method of heat pump unit

ActiveCN106765499AExtended run timeExtend the intervalHeating fuelLighting and heating apparatusEngineeringHeat pump

The invention provides a flow path system of a heat pump unit, the heat pump unit and a control method of the heat pump unit. The flow path system comprises a refrigerant loop, a heating loop and a heat storage loop, wherein the refrigerant loop comprises an outer unit and a heat exchange element; the heating loop is formed by connecting a water pump and the heat exchange element in series; the heat storage loop is formed by connecting a heat storage device and the outer unit in series, and the heat storage device is connected with the heat exchange element in parallel; a first solenoid valve controlling on-off of the heat storage loop is arranged on the heat storage loop; the heating loop comprises a heating branch penetrating the heat storage device, and a second solenoid valve controlling on-off of the heating branch is arranged on the heating branch; the flow path system further comprises a controller connected with the first solenoid valve and the second solenoid valve; the controller controls the first solenoid valve to be opened to enable the heat storage device to store heat, and the operating time of the outer unit is prolonged; after the outer unit shuts down, the controller controls the second solenoid valve to be opened to enable the heat storage device to release heat, the interval time until next start of the outer unit is prolonged, the frequency of temperature-reaching start and stop of the outer unit is reduced, and the stability of temperature of supplied water is guaranteed.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

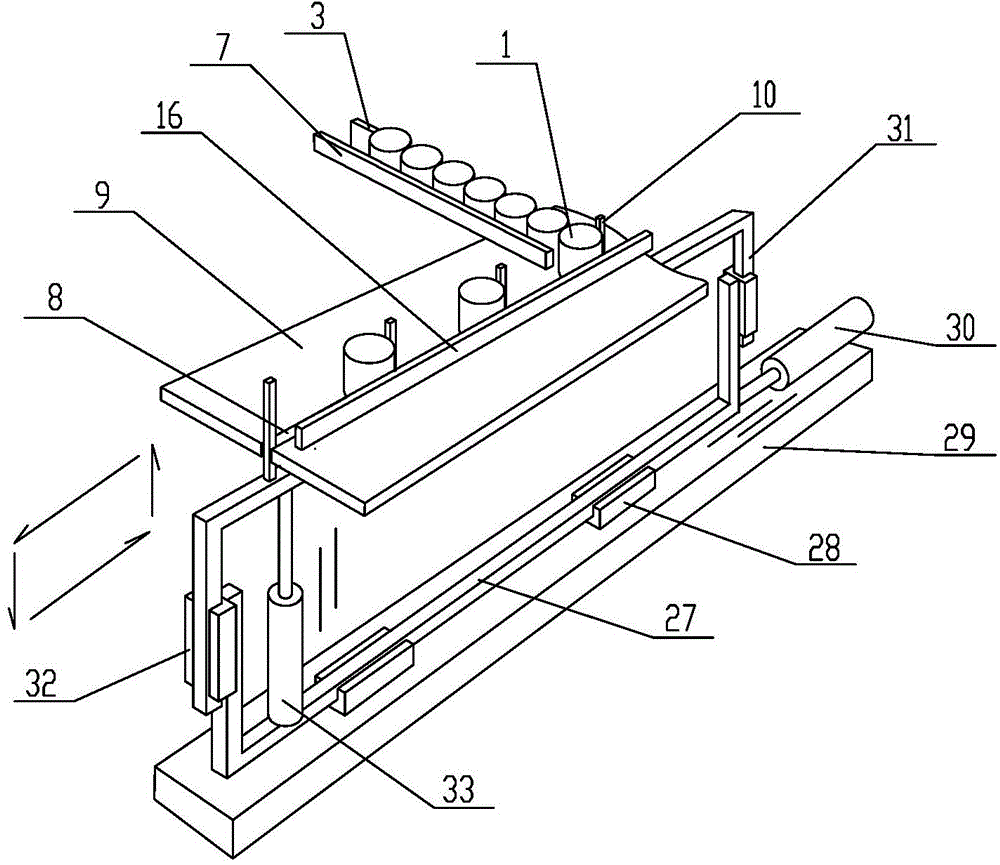

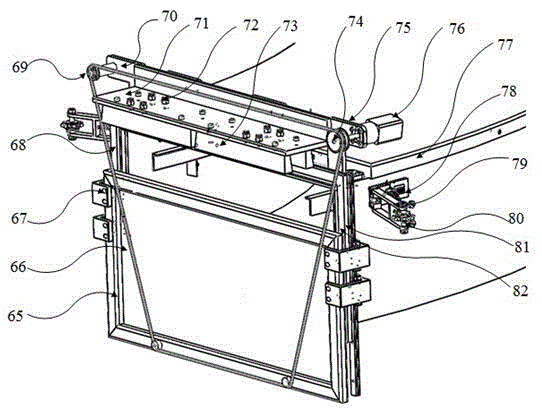

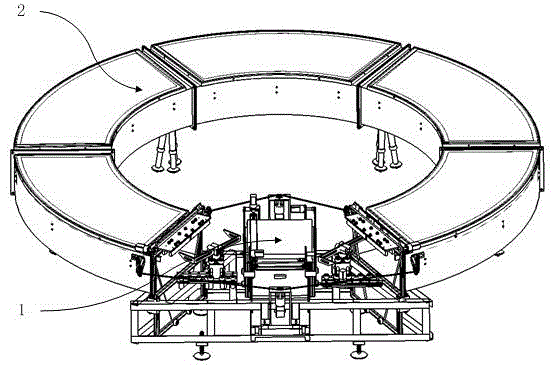

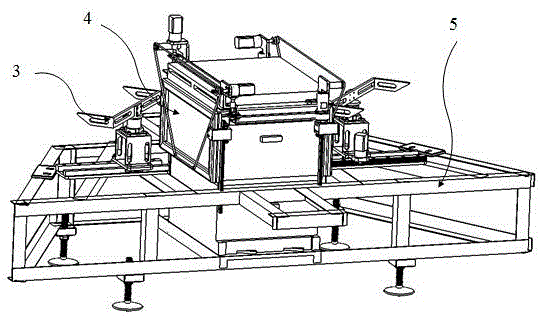

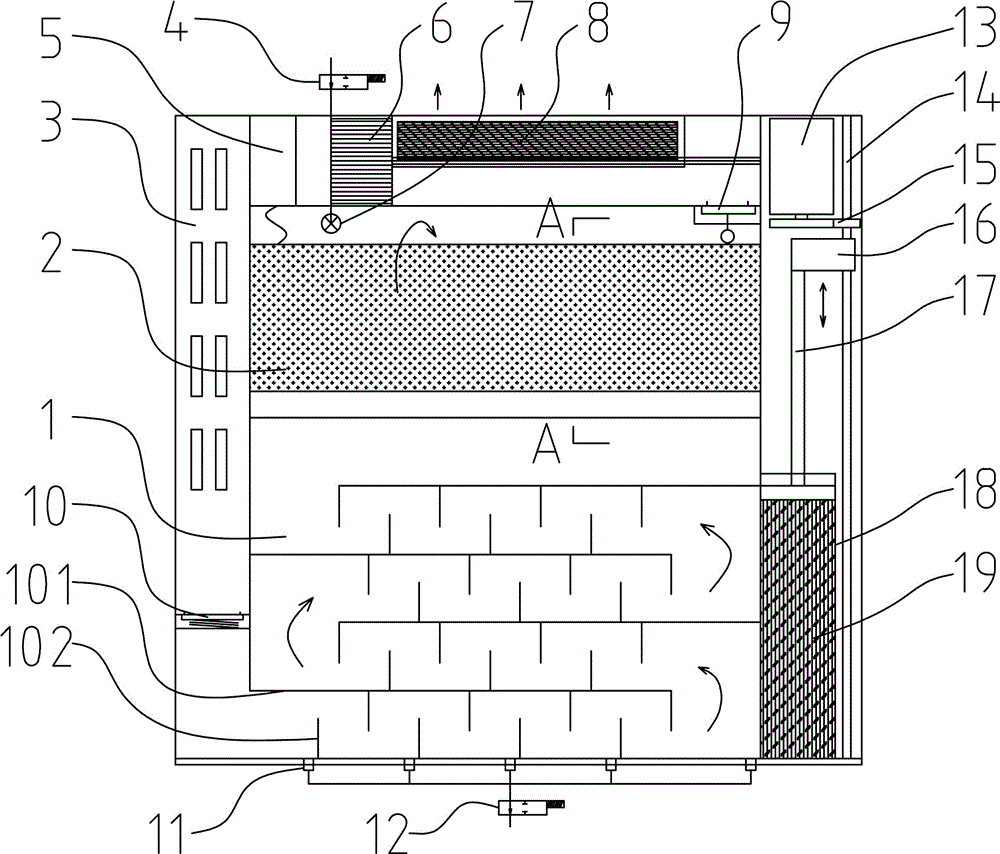

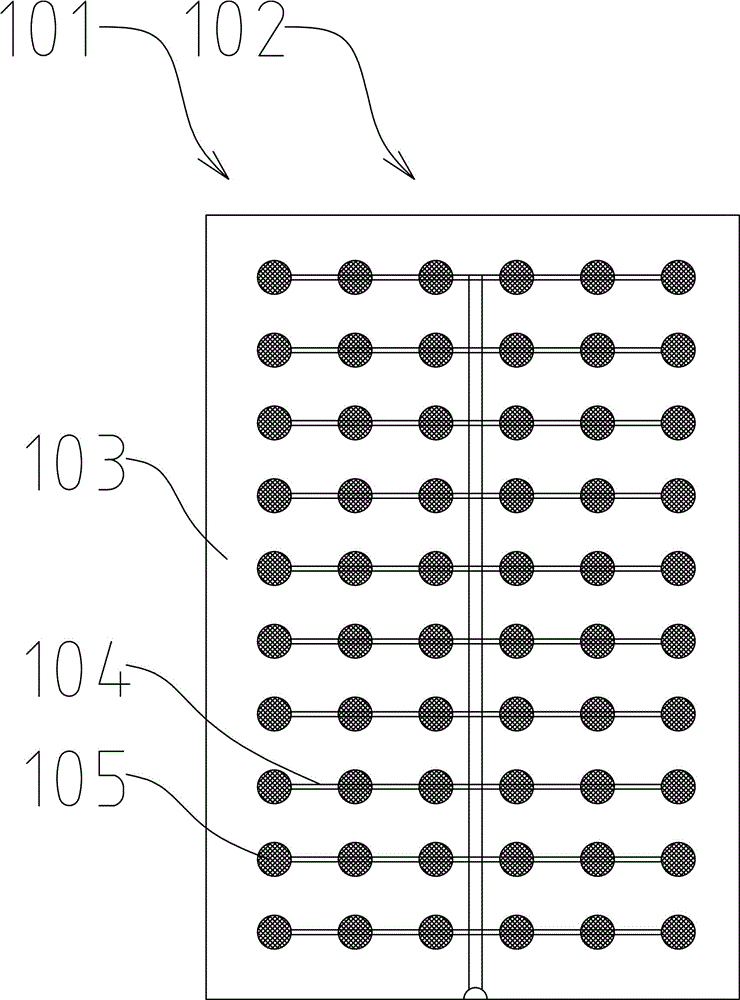

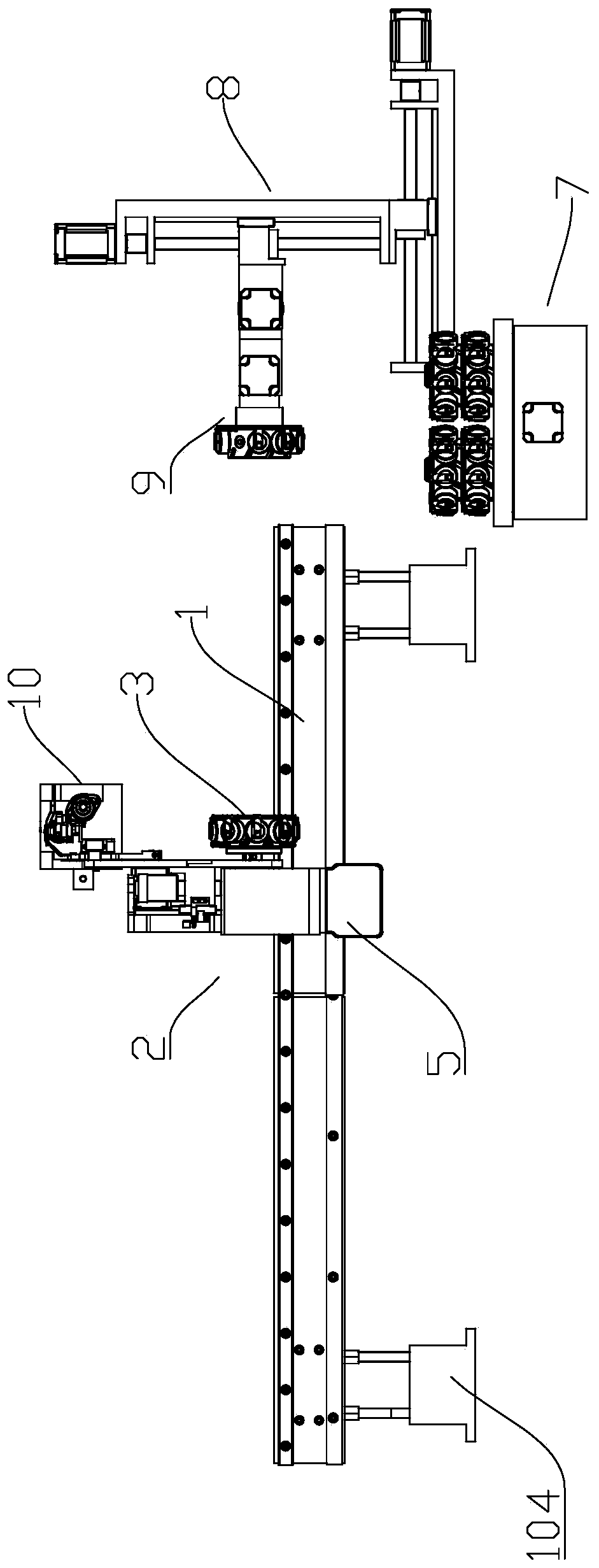

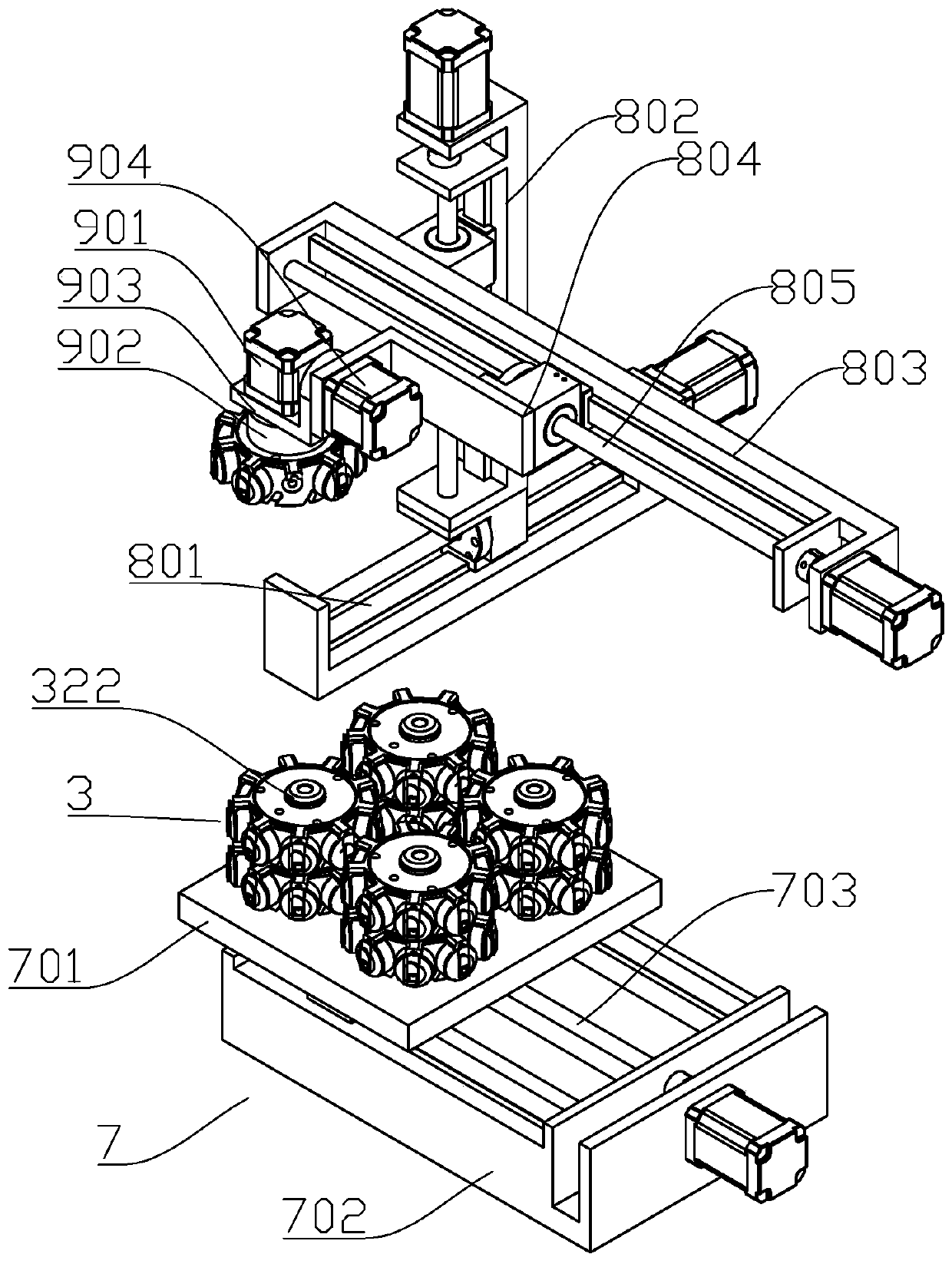

Full-automatic-feeding multi-station embroidery machine bottom thread changing system and method

InactiveCN110158248AExtend the intervalReduce the difficulty of operationAuxillary devicesAutomotive engineering

The invention provides a full-automatic-feeding multi-station embroidery machine bottom thread changing system and method. By the full-automatic-feeding multi-station embroidery machine bottom threadchanging system and method, automatic shuttle shell replacement can be achieved while spare shuttle shell automatic supplementing and replaced shuttle shell recycling can be achieved, full-automatic and rapid shuttle shell replacement can be achieved, and shuttle shell replacement efficiency can be improved greatly to finally improve the production efficiency of a computerized embroidery machine.The system comprises a horizontal guiding mechanism, a translation drive device, a shuttle shell replacement device, rotating storage plates and an automatic storage plate replacement device; the translation drive device is slidably connected with the horizontal guiding mechanism, the shuttle shell replacement device is arranged on the translation drive device, and the shuttle shell replacement device is driven by the translation drive device to move among multiple stations of the embroidery machine; the rotating storage plates are detachably connected with the shuttle shell replacement deviceand are used for storing multiple spare shuttle shells; the automatic storage plate replacement device is located at one end of the horizontal guiding mechanism and is used for demounting and replacing the rotating storage plates.

Owner:ZHUJI LIGHT IND TIMES ROBOT TECH CO LTD

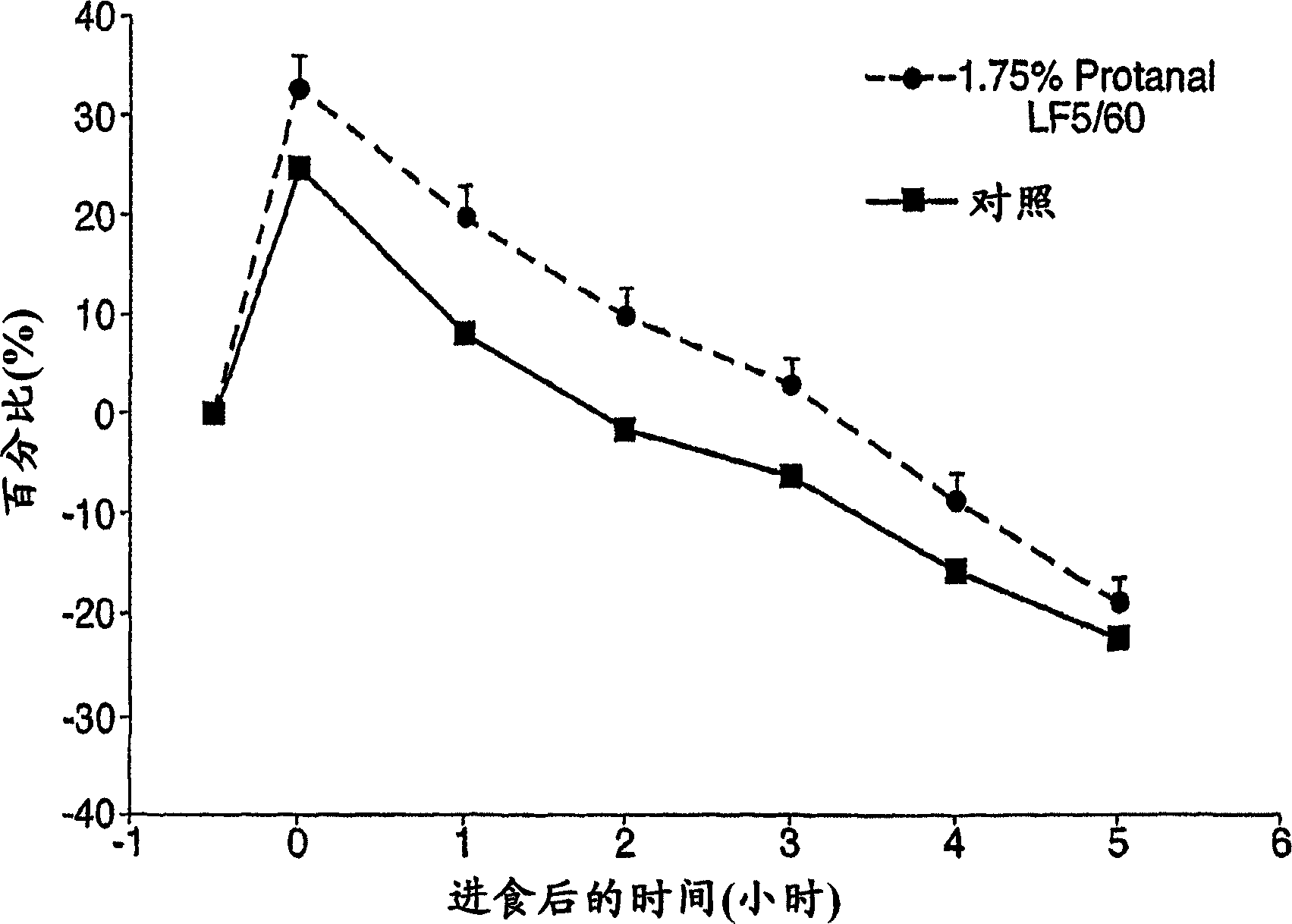

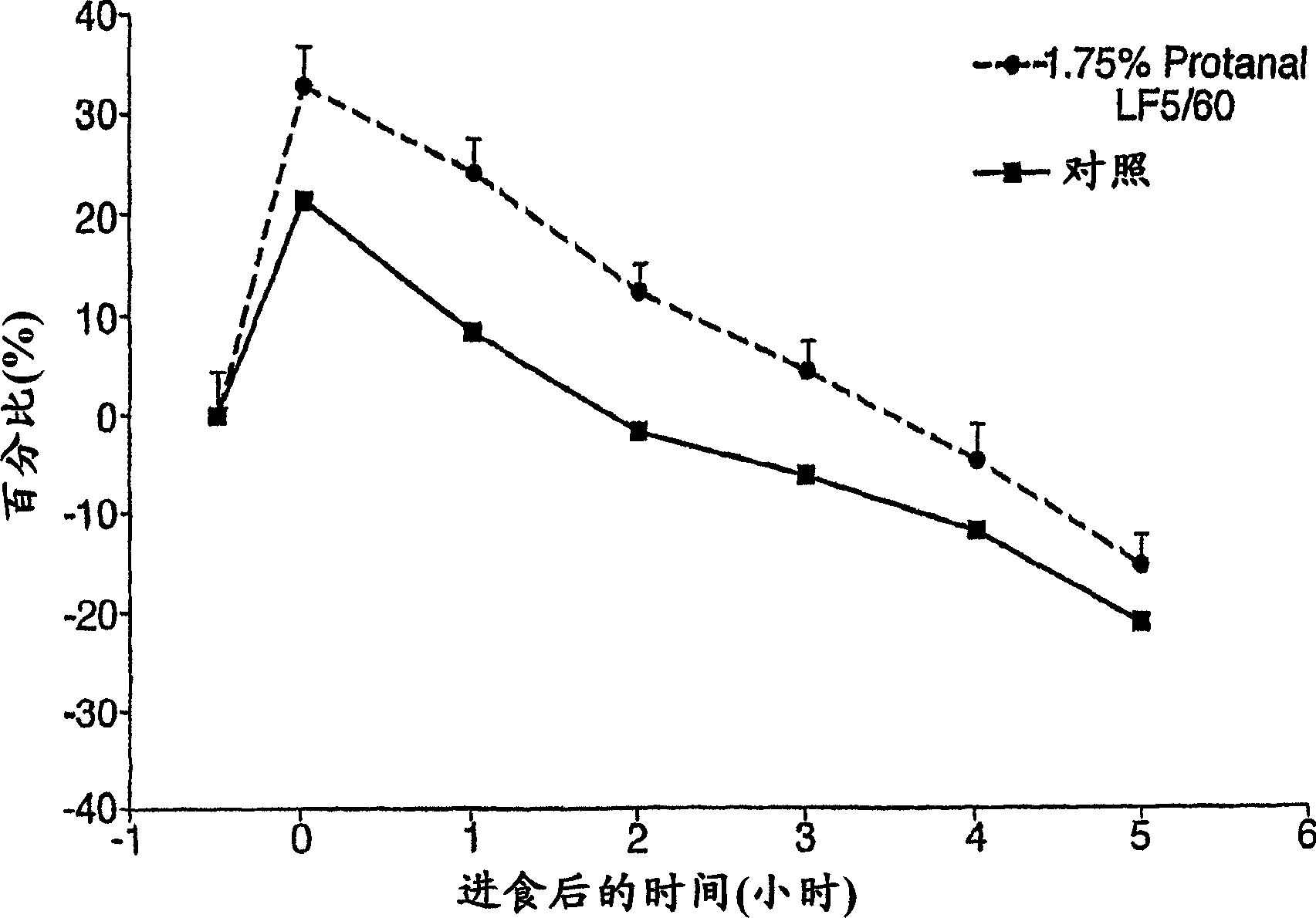

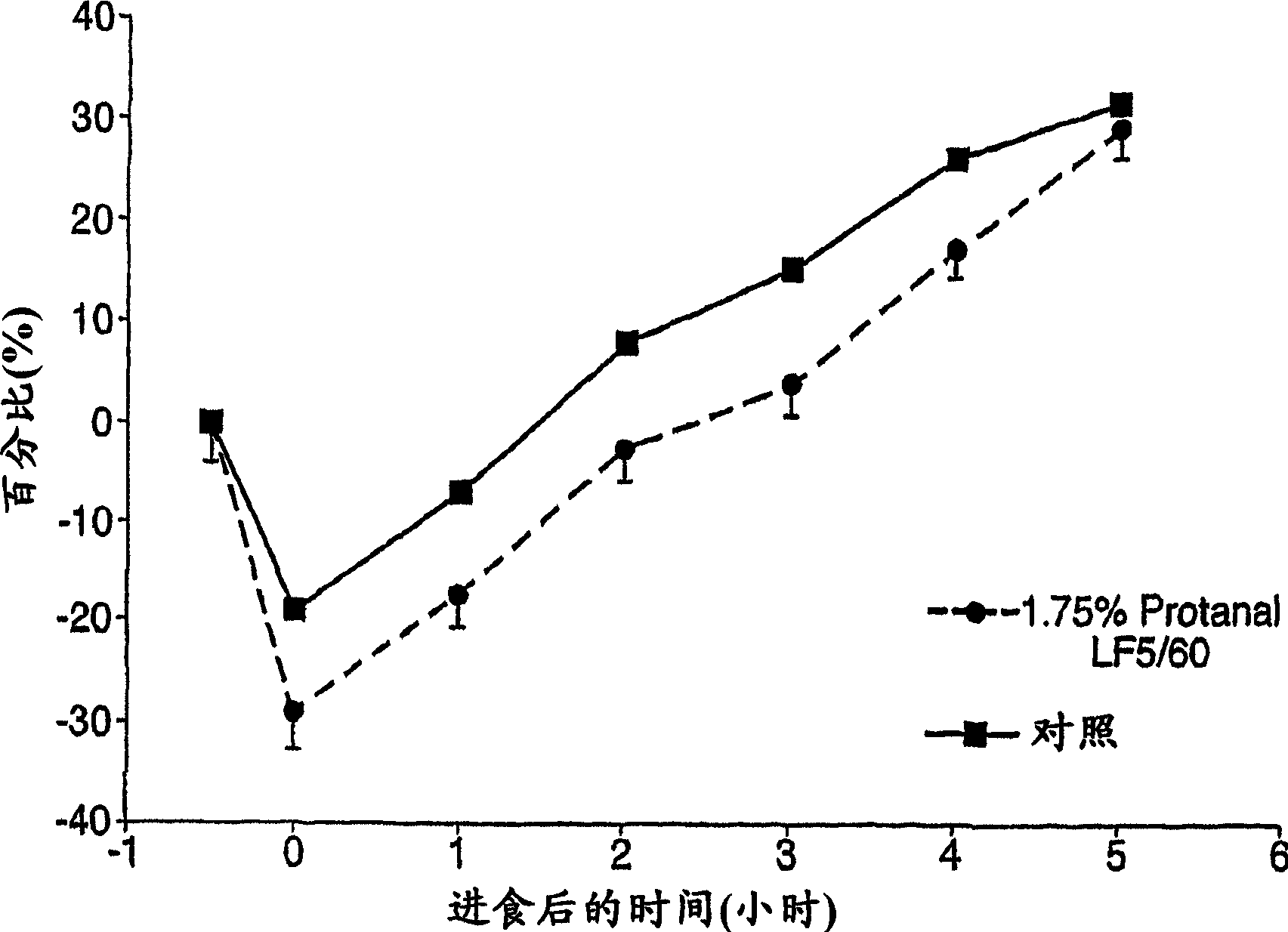

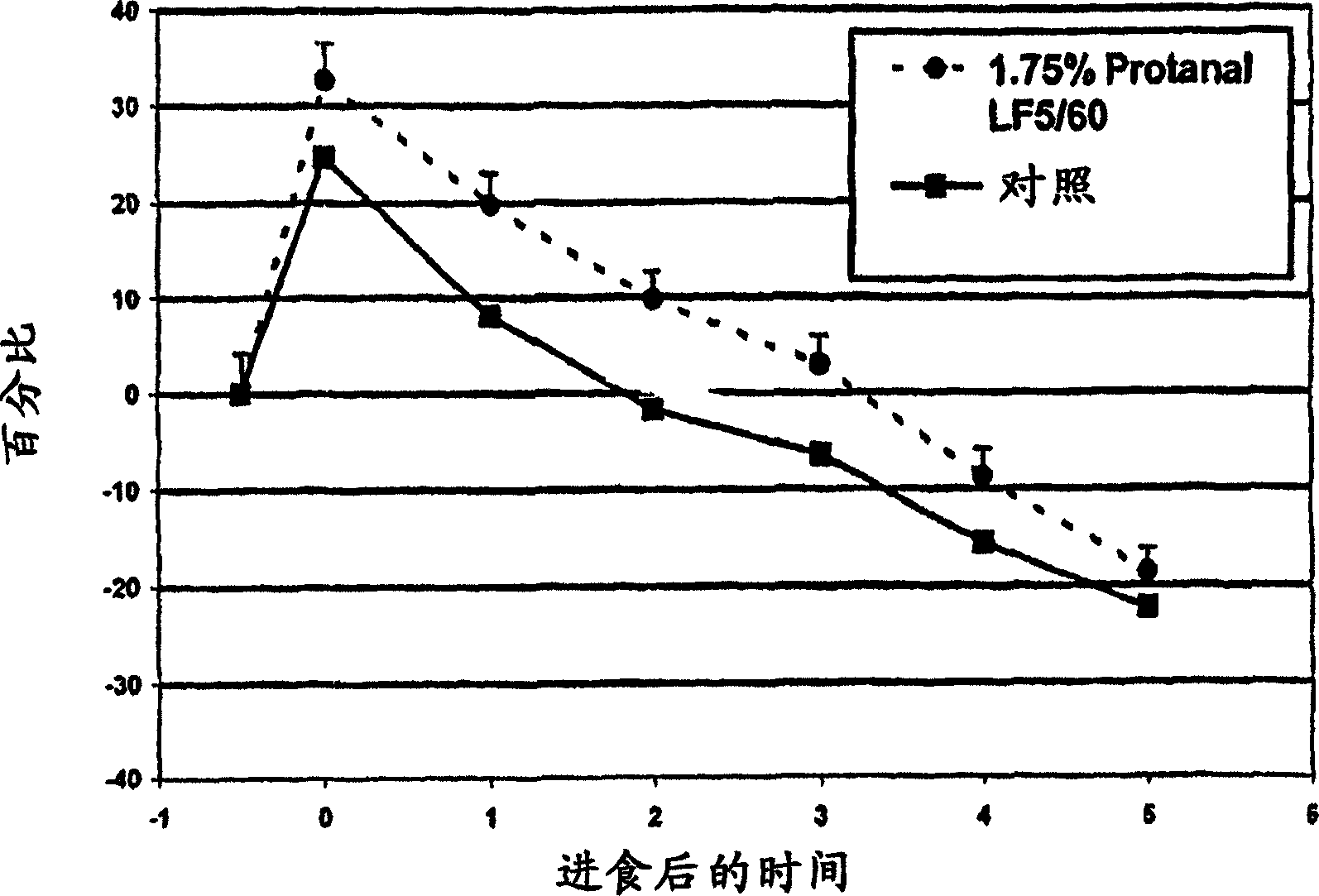

Satiety enhancing food compositions

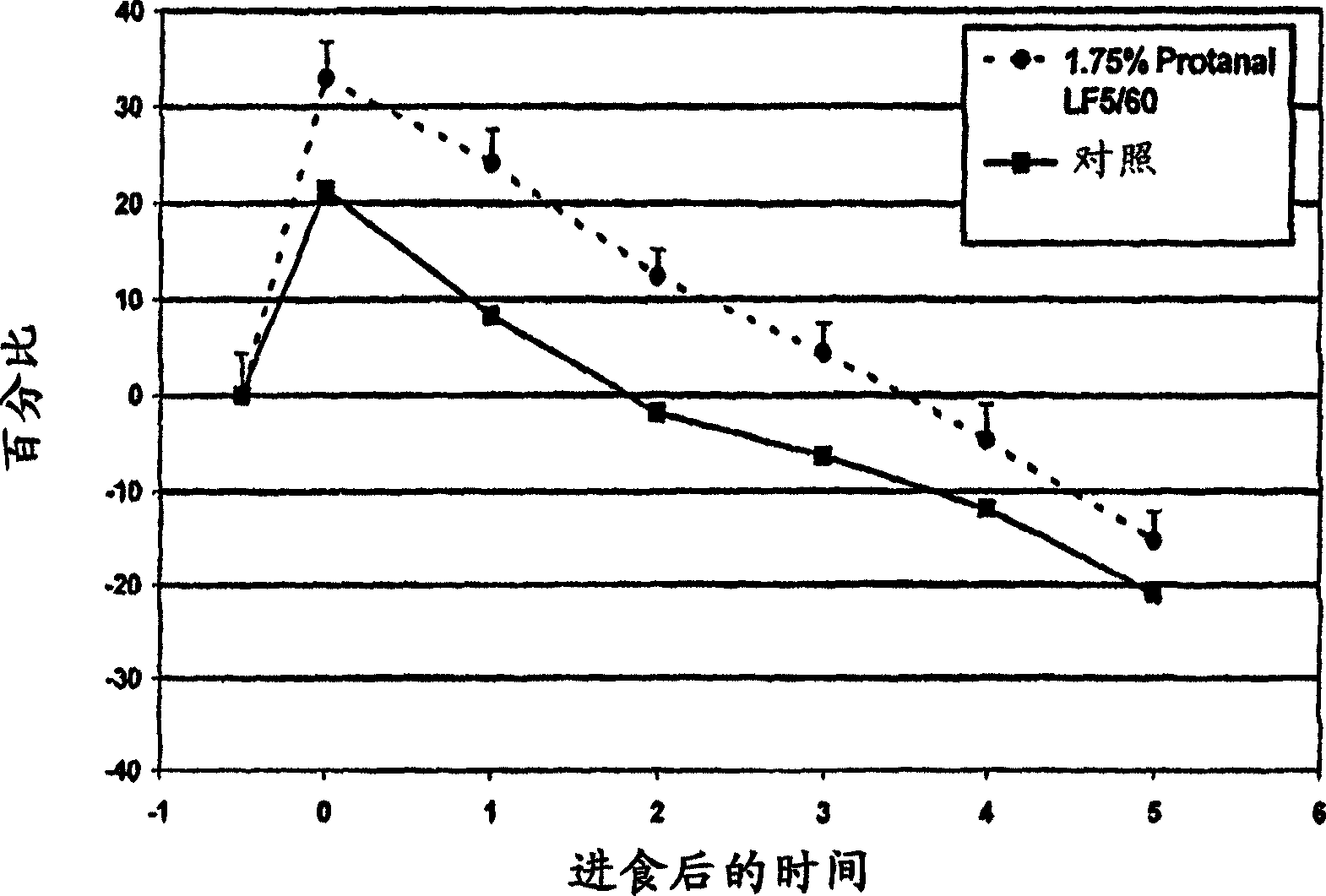

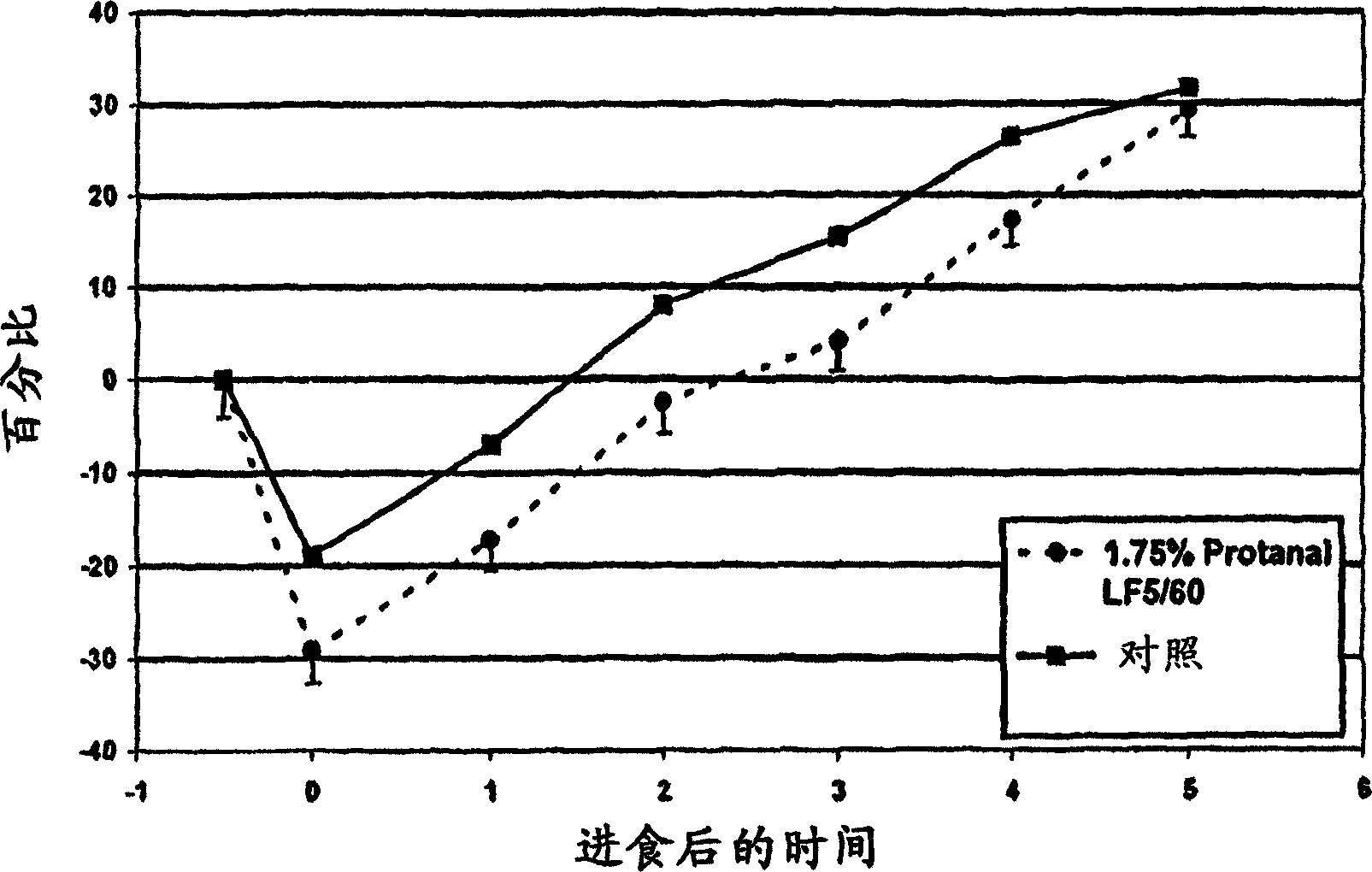

InactiveCN1874691AGood satiety effectReduce manufacturing costMetabolism disorderFood ingredientsBiopolymerFood composition data

The present invention provides an aqueous liquid or spoonable edible composition comprising at least 1%wt protein and from 0.1 to 5%wt of a biopolymer thickening agent which is not denatured or hydrolysed between pH 2 and 4, and wherein the composition has a gastric viscosity at 0.1 s<-1> and 37 DEG C of at least 20 Pa.s and further wherein the gastric viscosity is greater than the viscosity of the composition. The compositions of the invention have good satiety effects and are beneficial for use in weight control plans and may be used for the prevention and / or treatment of being overweight or obese. The edible composition may be a food composition intended for use in a weight loss or weight control plan such as a meal replacer food product.

Owner:UNILEVER NV

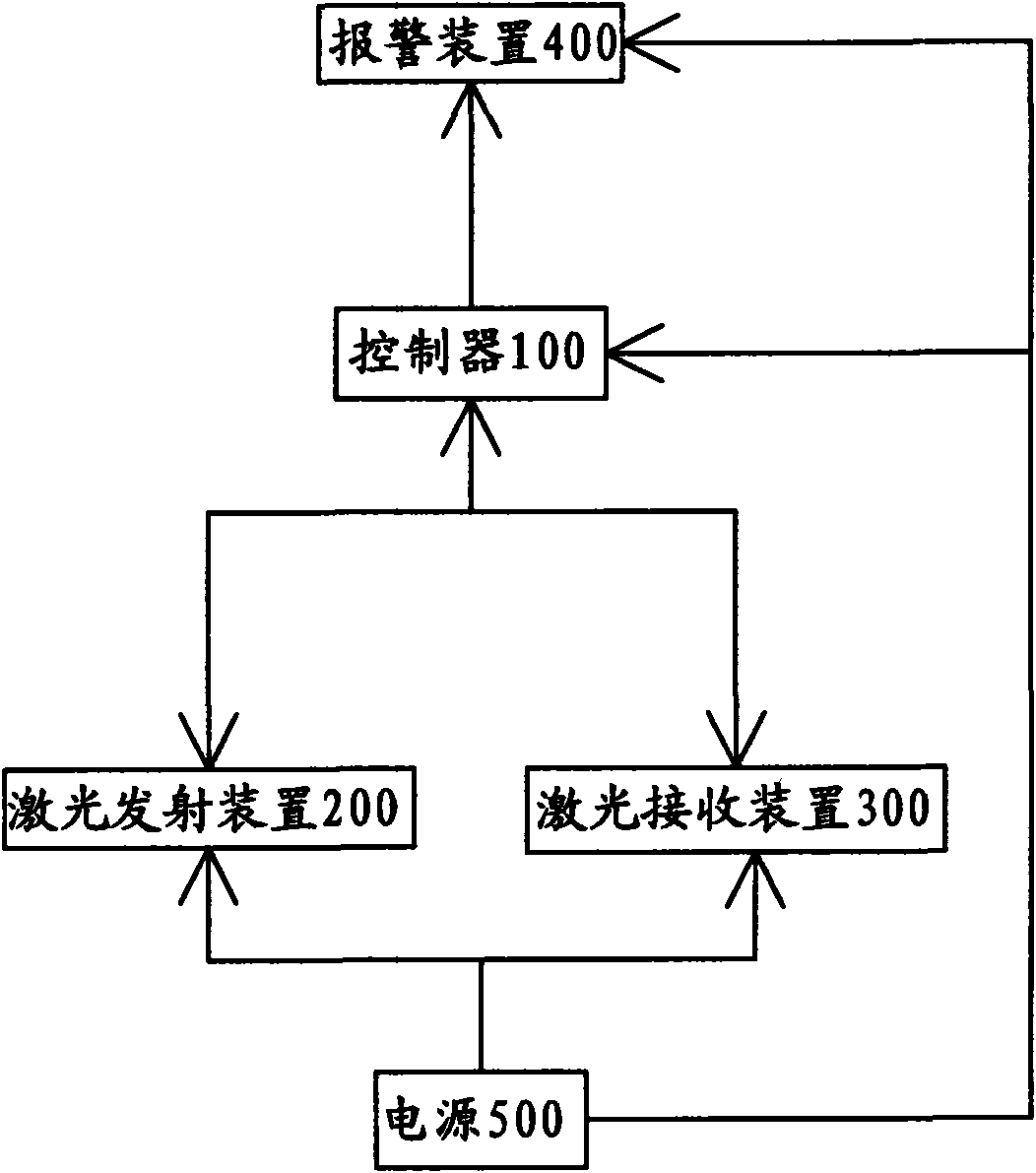

Laser detecting alarming method and apparatus

InactiveCN101551933AImprove anti-interference abilityImprove confidentialityOptical detectionBurglar alarmReal-time dataConfidentiality

The invention discloses a laser detecting alarming method and apparatus. The method includes: Step 1, starting up the laser emission device; Step 2, collecting real-time data, which is a numerical value of the user operations parameter self-recorded by the laser emission apparatus; step 3, setting the real-time data as cipher key of encryption algorithm, calculating a calculated data by using encryption algorithm, calculating the pulse interval time delta T [n] by calculated data, setting the delta T [n] as the pulse interval time of the laser emission apparatus; Step 4, determining whether the laser receiver is intended to receive to the laser signal, if so, it is safe, otherwise, the alarm signal is sent to the alarm device, and performing the step 5; Step 5, the alarm device emiting alarm. The alarm method and strong has strong interference immunity and strong confidentiality.

Owner:XIAMEN STELCOM INFORMATION & TECH

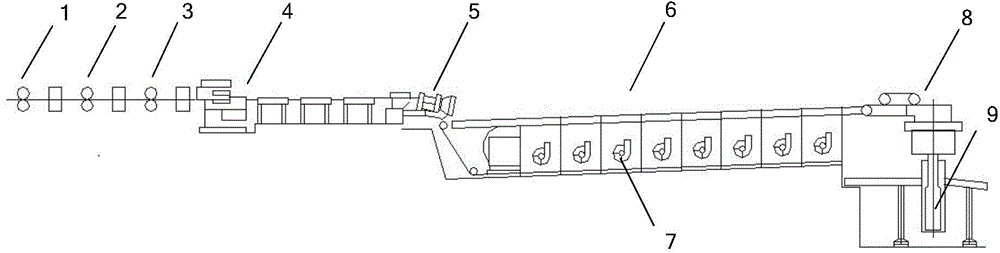

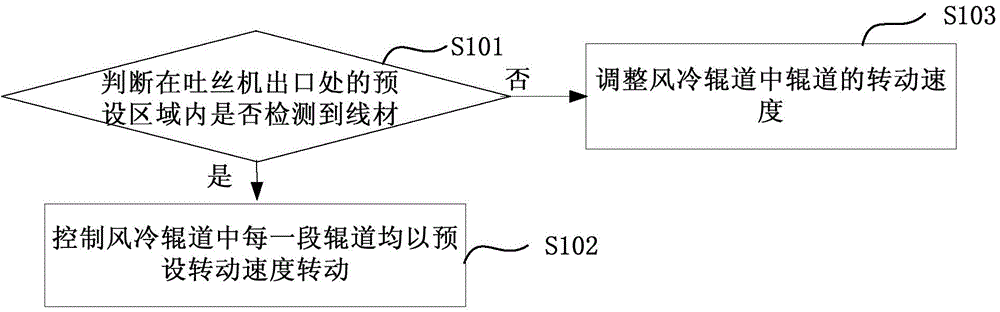

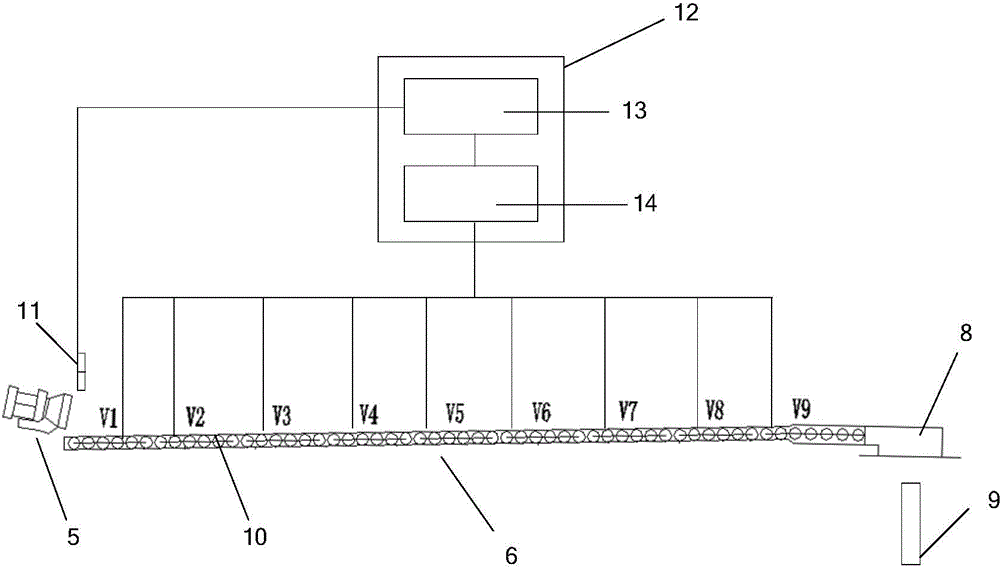

Wire rod rolling controlling method and system

InactiveCN104607469AExtend the intervalShorten production intervalsRoll mill control devicesMetal rolling arrangementsWire rodEngineering

The embodiment of the invention discloses a wire rod controlling method and a system. By judging whether wire rod is detected in a preset area at an outlet of a wire drawing machine, the rotating speed of every section of roller bed in an air-cooled roller bed is adjusted, when the wire rod is detected in the preset area at the outlet of the wire drawing machine, every section of the roller bed in the air-cooled roller bed is controlled to rotate at a preset rotating speed; when the wire rod is not detected in the preset area at the outlet of the wire drawing machine, it shows that the wire drawing machine does not draw the wire rod to the air-cooled roller bed at the moment, the rotating speed of the roller bed in the air-cooled roller bed is adjusted, so that the wire rod on the air-cooled roller bed is transferred faster, until the wire rod is detected in the preset area at the outlet of the wire drawing machine, namely the wire drawing machine starts to draw the wire rod to the air-cooled roller bed again, and every section of the roller bed of the air-cooled roller bed rotates at the preset rotating speed again.

Owner:ELECTRON CO LTD

Grinding device for automobile accessories

ActiveCN108500770AReduce the difficulty of turningImprove grinding efficiencyEdge grinding machinesGrinding carriagesEngineeringHardness

The invention discloses a grinding device for automobile accessories. The grinding device comprises a frame. A support plate is arranged below a workbench. A circular ring tube is fixed on the supportplate. A rotating shaft is rotationally connected in the inner circle of the circular ring tube. A through hole is formed in the rotating shaft. An open hole is formed in the circular ring tube. A grinding head is fixed on the rotating shaft. Radiating holes are formed in the grinding head. The through hole is communicated with the radiating holes. A connecting pipe is connected to the circular ring tube. A collecting box is fixed on the frame. Collecting holes are uniformly distributed in the collecting box. A rotating rod is rotationally connected to the collecting box. A fixing seat is fixed on the rotating rod. A negative-pressure pump is fixed on the frame. The negative-pressure pump is communicated with the collecting box. The negative-pressure pump is communicated with a gas outletpipe. A driving mechanism is arranged on the frame. Compared with the prior art, by the adoption of the scheme, the gas output by the negative-pressure pump can carry heat generated by the grinding accessories out of the grinding head, the hardness of the grinding head cannot be reduced, and therefore the grinding quality is ensured; and through the driving mechanism, the accessories rotate intermittently, and the grinding efficiency is greatly improved.

Owner:宁波隆锐机械制造有限公司

Giant salamander breeding pond

The invention relates to the technical field of breeding devices and particularly discloses a giant salamander breeding pond. The giant salamander breeding pond comprises a breeding pond body, whereina separation net is arranged in the middle of the breeding pond and divides the breeding pond into a hatching zone and a growth zone, a hatching bucket is arranged in the hatching zone, the bottom ofthe hatching bucket is hinged to a mounting base, a water draining pipe horizontally penetrates through the bottom wall of the hatching bucket, and air bags are uniformly distributed in the hatchingbucket. The giant salamander breeding pond also comprises a stirring bucket, wherein a piston is slidingly connected in the stirring bucket, a through hole is vertically formed in the piston, a pistonrod is connected to the top of the piston, the piston rod is in threaded connection with the top of the stirring bucket, and the end, extending out of the stirring bucket, of the piston rod is connected with a transmission mechanism. The bottom of the piston is connected with a flexible stirring belt. An air inlet one-way valve and a water outlet one-way valve are arranged on the side wall of thestirring bucket, an air outlet one-way valve and a water intlet one-way valve are arranged at the top of the stirring bucket, the water outlet one-way valve is communicated with the water draining pipe, and the water inlet one-way valve is communicated with the breeding pond. By adopting the giant salamander breeding pond, no direct impact is produced on fertilized ovum of giant salamanders, andthe oxygen content demand in water can be met.

Owner:正安县鲵食养殖有限公司

Use of biological cellulose gel as potted plant soil substitute

InactiveCN103483050AGood water holding performanceExtend the intervalCultivating equipmentsSoilless cultivationNutrientChemistry

The invention relates to new use of biological cellulose gel as a potted plant soil substitute, roots of a potted plant are in contact with the biological cellulose gel, and moisture, nutrients and the like are provided to the plant through the biological cellulose gel. The biological cellulose gel is granular biological cellulose gel. Through replacement of potted plant soil with biological cellulose gel granules, watering time interval is obviously prolonged due to better water holding capacity of the biological cellulose gel granules; when the moisture in the biological cellulose gel granules is absorbed by the plant, the biological cellulose gel granules may shrink, and the volume is reduced, so that if watering is needed can be determined according to the size of the biological cellulose gel granule volume accounting for a flowerpot volume.

Owner:钟春燕

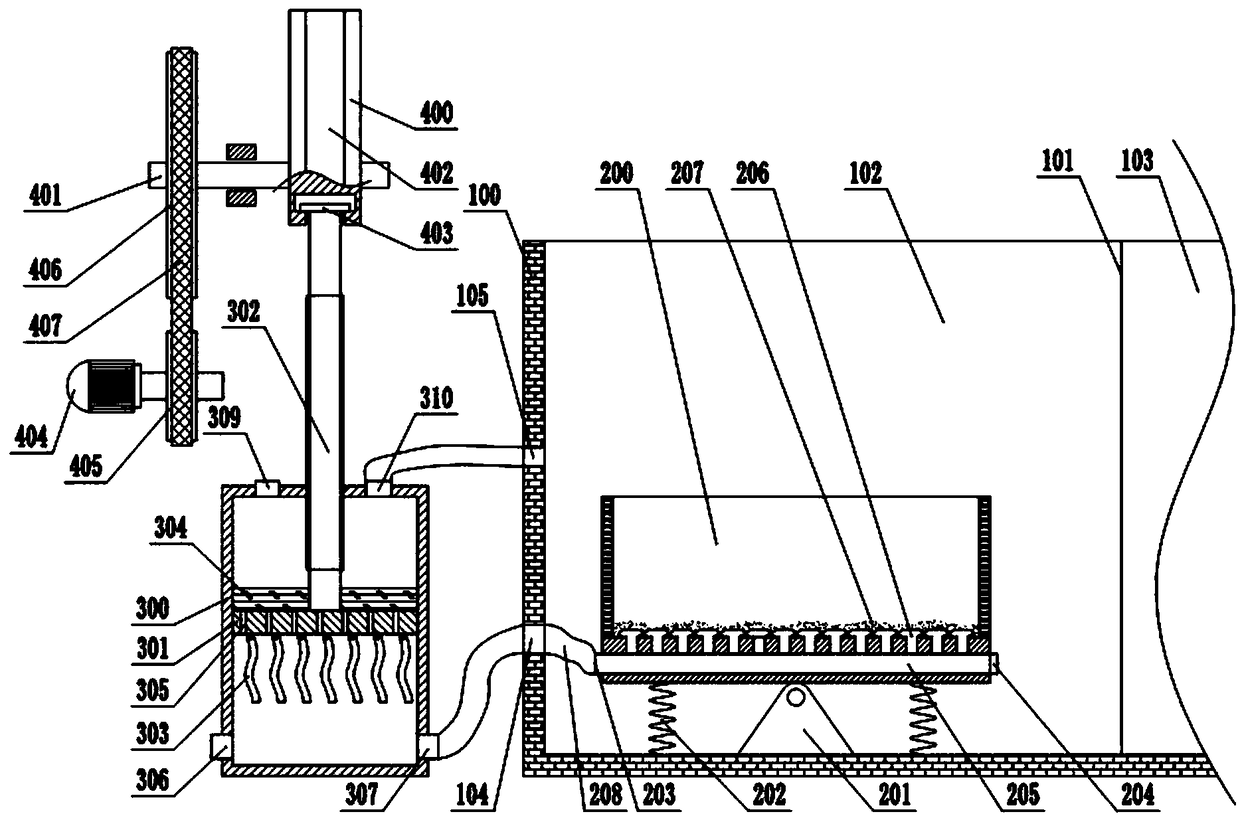

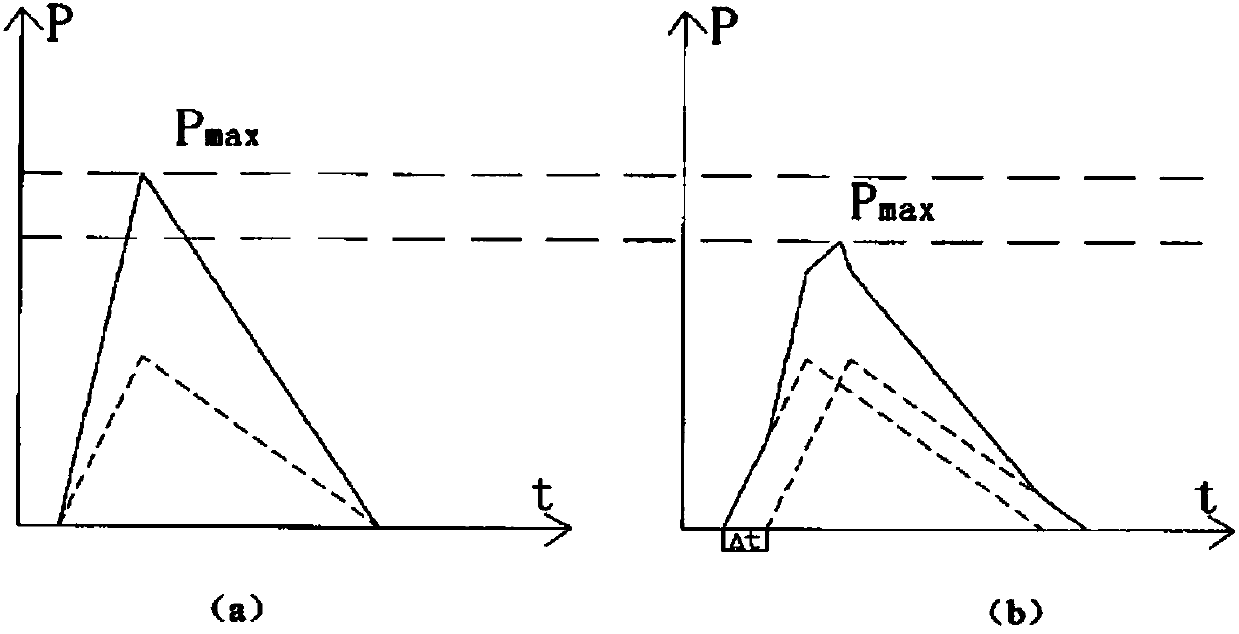

Tunneling blasting method comprehensively utilizing detonator short time difference and empty hole vibration reduction technique

InactiveCN108592725AGuaranteed blasting effectAvoid the disadvantage of large blasting vibrationBlastingDetonatorEngineering

The invention discloses a tunneling blasting method comprehensively utilizing the detonator short time difference and an empty hole vibration reduction technique. The center line of a tunnel face of ablasted tunnel serves as the boundary, and the blasted area is divided into a left region and a right region, wherein the left region and the right region are symmetrical to each other; the two sidesof the center line are provided with a plurality of slotting holes, auxiliary holes and peripheral holes correspondingly, wherein the slotting holes, the auxiliary holes and the peripheral holes aresymmetrical to one another, a vibration reduction hole linear array is arranged on the ground between the blasted area and a building, and in the implementation process, the same row of holes are blasted hole by hole in a symmetrical and delayed manner. Hole-by-hole sequential blasting is performed through electronic detonators, and targeted to different types of blastholes, through the setting ofthe optimal delay time of the electronic detonators, vibration waves transferred to the ground interfere with one another and are counteracted partially; and meanwhile, vibration reduction holes of optimized design are formed on the ground, and 50% of blasting vibration can be effectively lowered. Through the combined measure, the blasting effect of a constructed smooth surface can be guaranteed,the defect that traditional smooth surface blasting is large in vibration can also be overcome, and finally influences on the surface buildings are reduced.

Owner:厦门爆破工程有限公司 +1

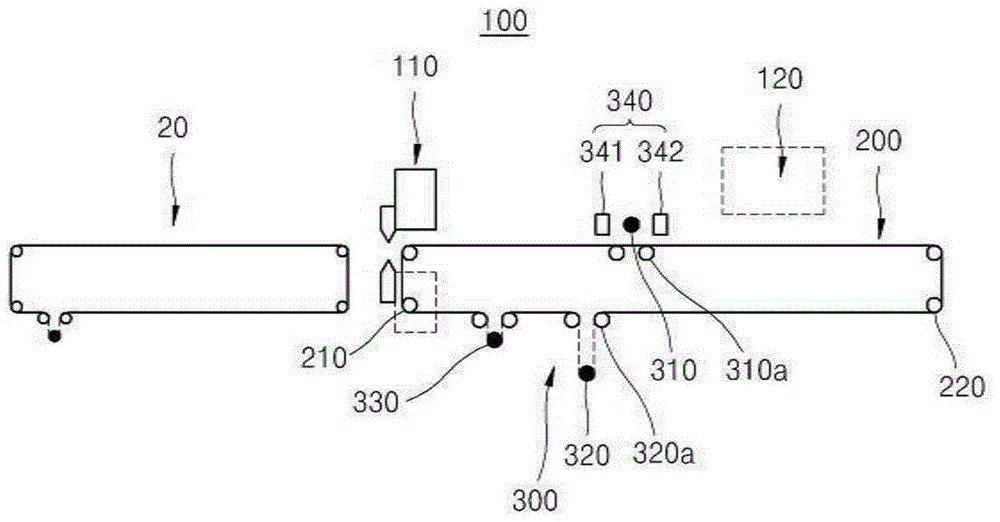

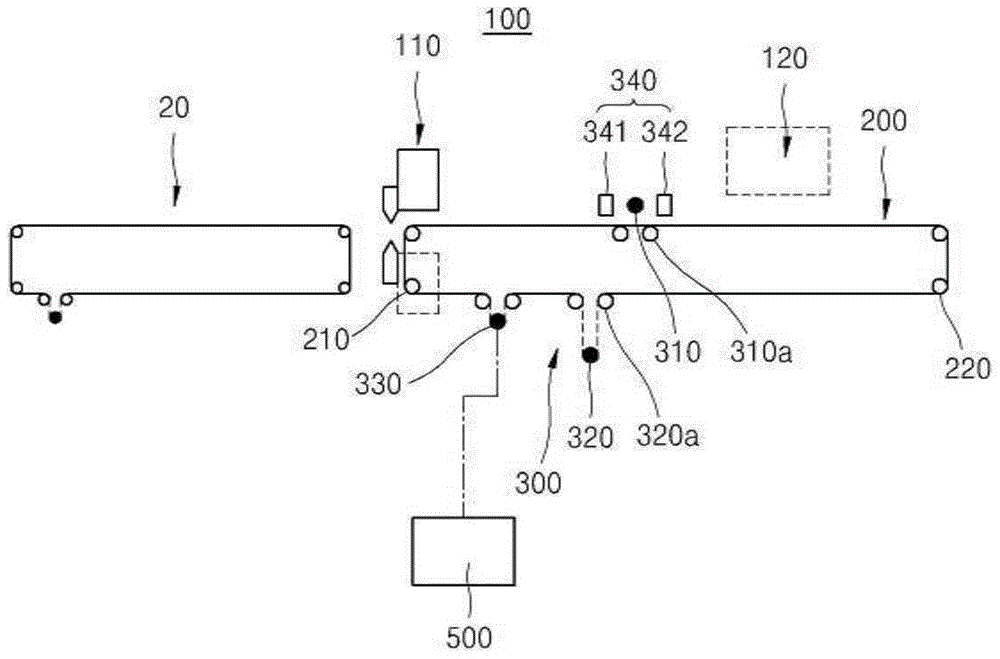

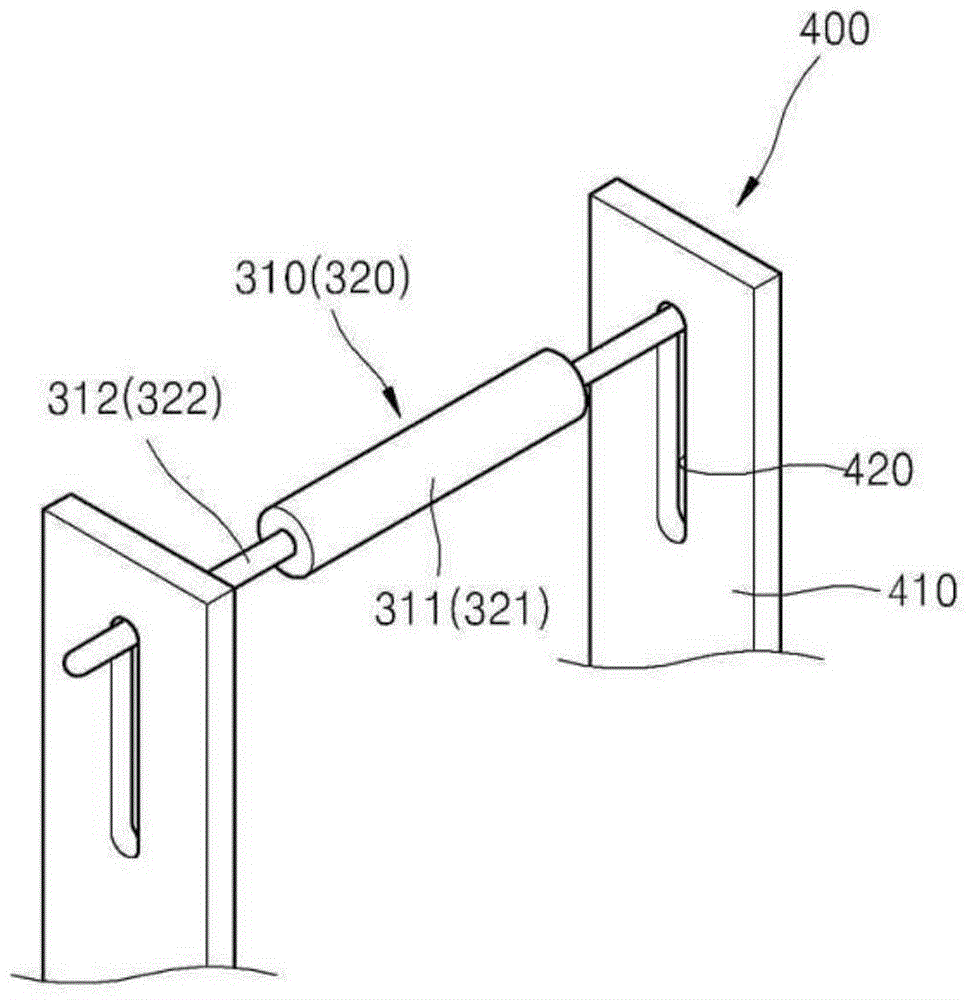

Scribing device and scribing method

InactiveCN104628246AExtend the intervalGuaranteed flatnessGlass severing apparatusMechanical engineeringProcess control

The present invention provides a scribing device, which comprises a conveyer belt used for receiving substrates for the continuous scribing operation and conveying the substrates; and a process control unit used for changing the movement direction of the conveyer belt so as to continuously conduct the subsequent process of the above substrates. The invention further provides a scribing method.

Owner:TOP ENG CO LTD

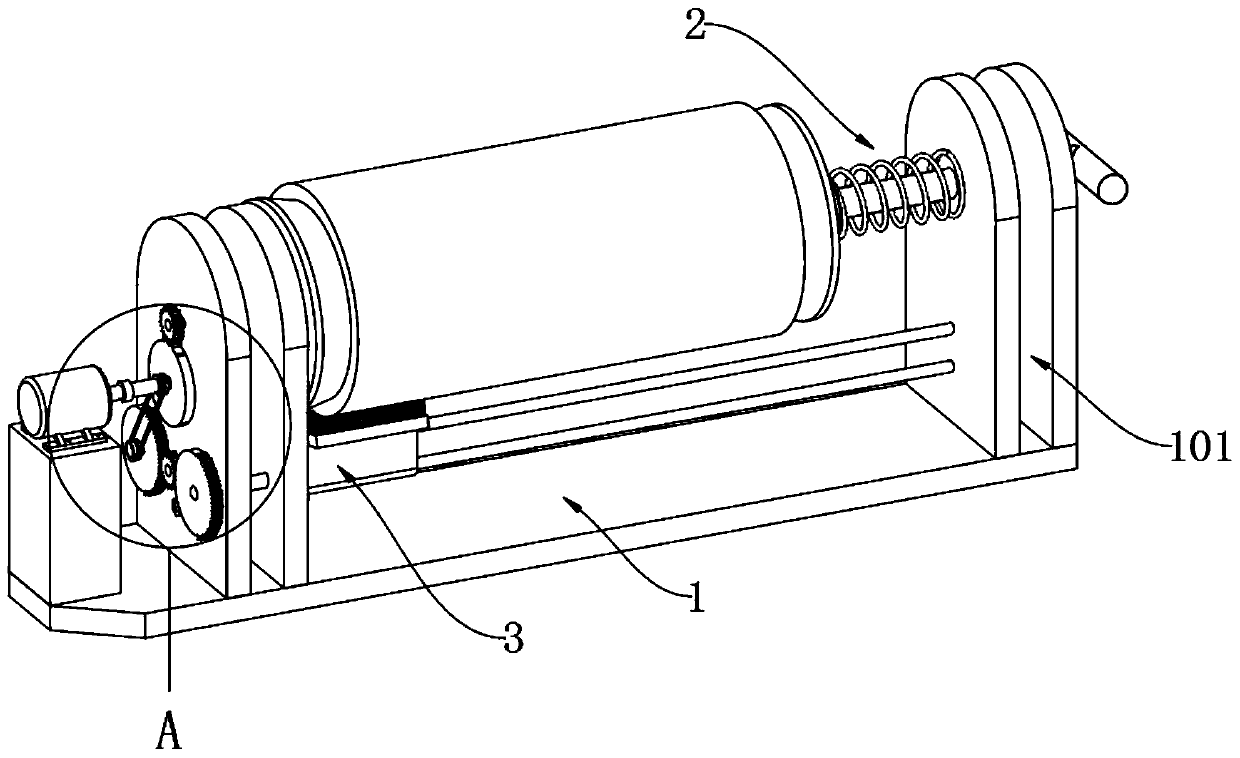

Automatic skin repair device for erhu cylinder

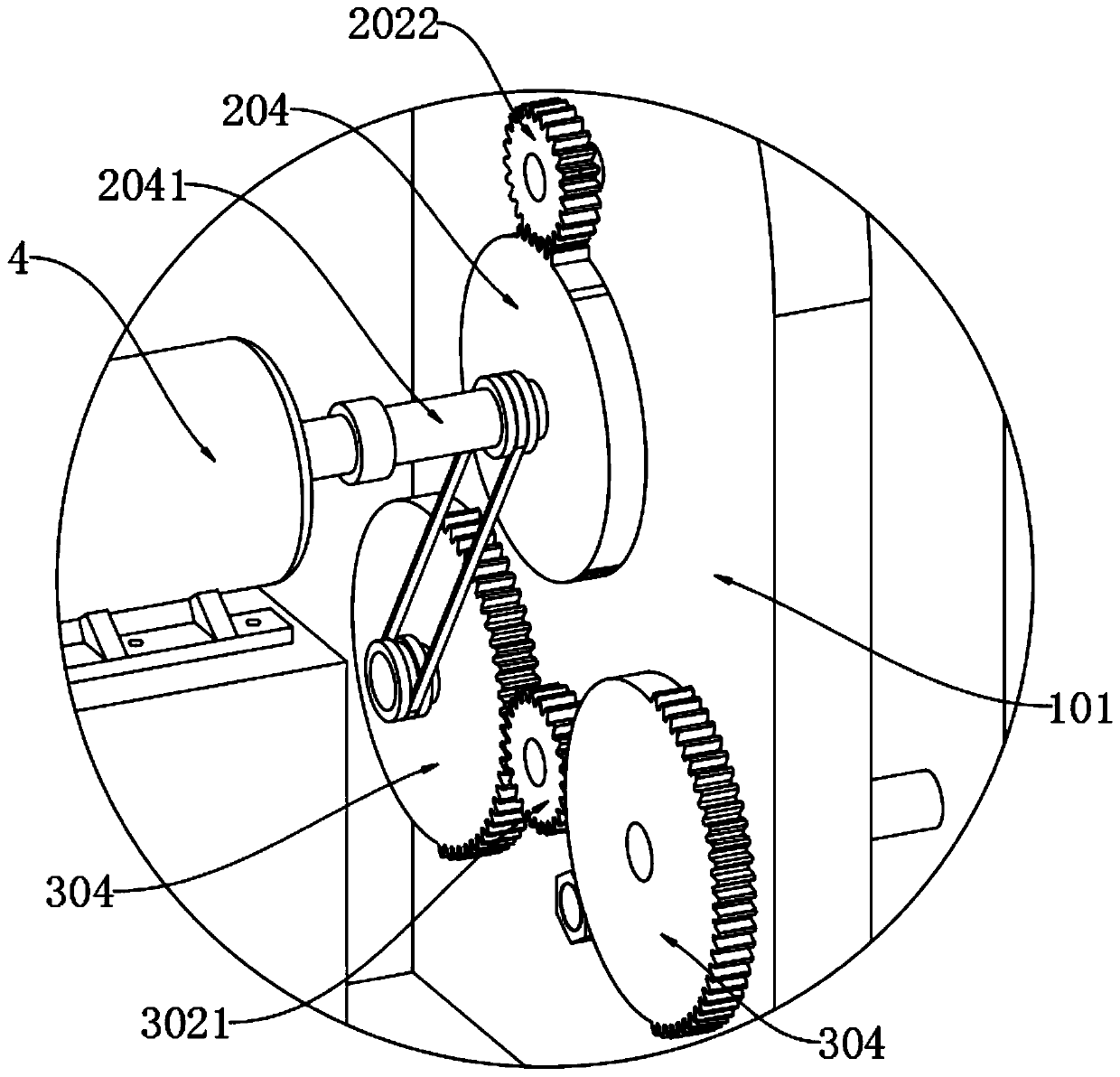

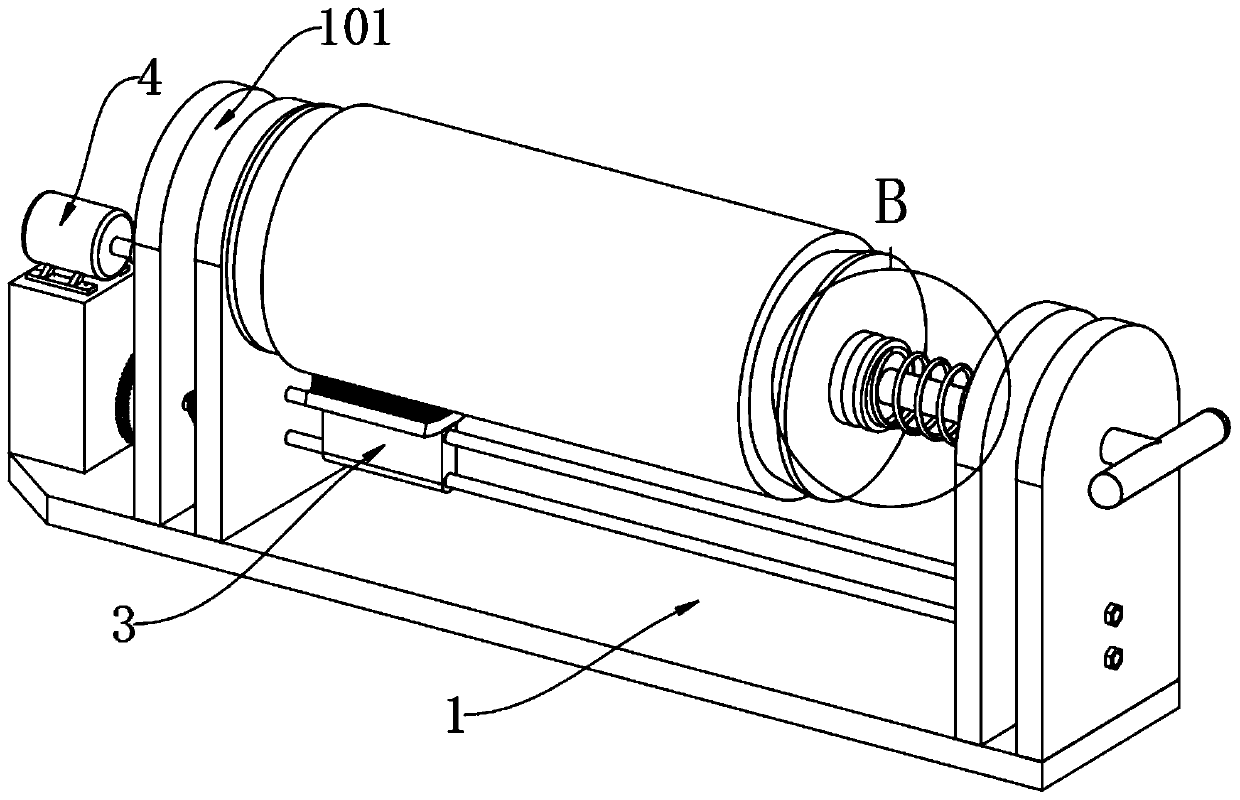

ActiveCN111438611AExtend the intervalIncrease speedEdge grinding machinesRevolution surface grinding machinesGear wheelSkin repair

The invention provides an automatic skin repair device for an erhu cylinder, belongs to the technical field of cylinder polishing and aims to solve the problems that manual fixation and rotation are needed, high strength needs to be consumed, and hands are prone to burden. The device comprises a cylinder-clamping rotating mechanism, wherein the cylinder-clamping rotating mechanism is mounted on asupporting plate in a rotating mode, a skin repair mechanism is further mounted at one side of the supporting plate, the skin repair mechanism is in linkage with the cylinder-clamping rotating mechanism, and the cylinder-clamping rotating mechanism is also in transmission connection with a driving motor. According to the device, elastic force of a clamping spring is utilized to drive a first wooden clamping plug into one end of the cylinder so as to clamp and fix the cylinder, the driving motor is utilized to drive an intermittent gear A to rotate and drive an upper driving gear to rotate intermittently, and parts of clamping teeth on an intermittent gear B are utilized to drive a lower driving gear to rotate, so that a steel wire plate brush moves on a threaded rod to repair skin of the cylinder.

Owner:义乌市倩飞科技有限公司

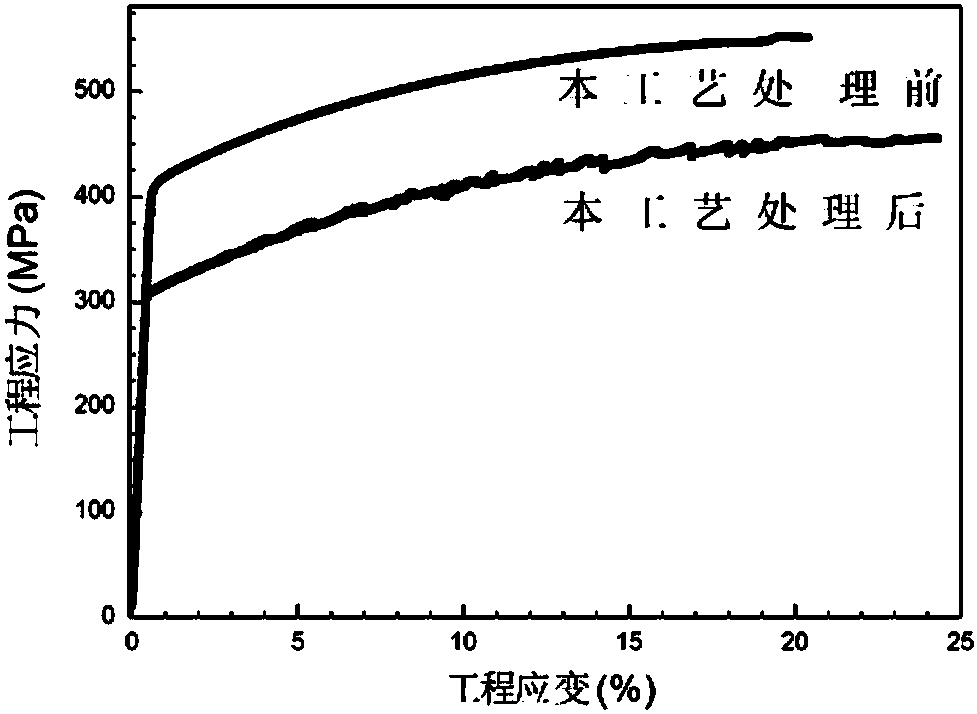

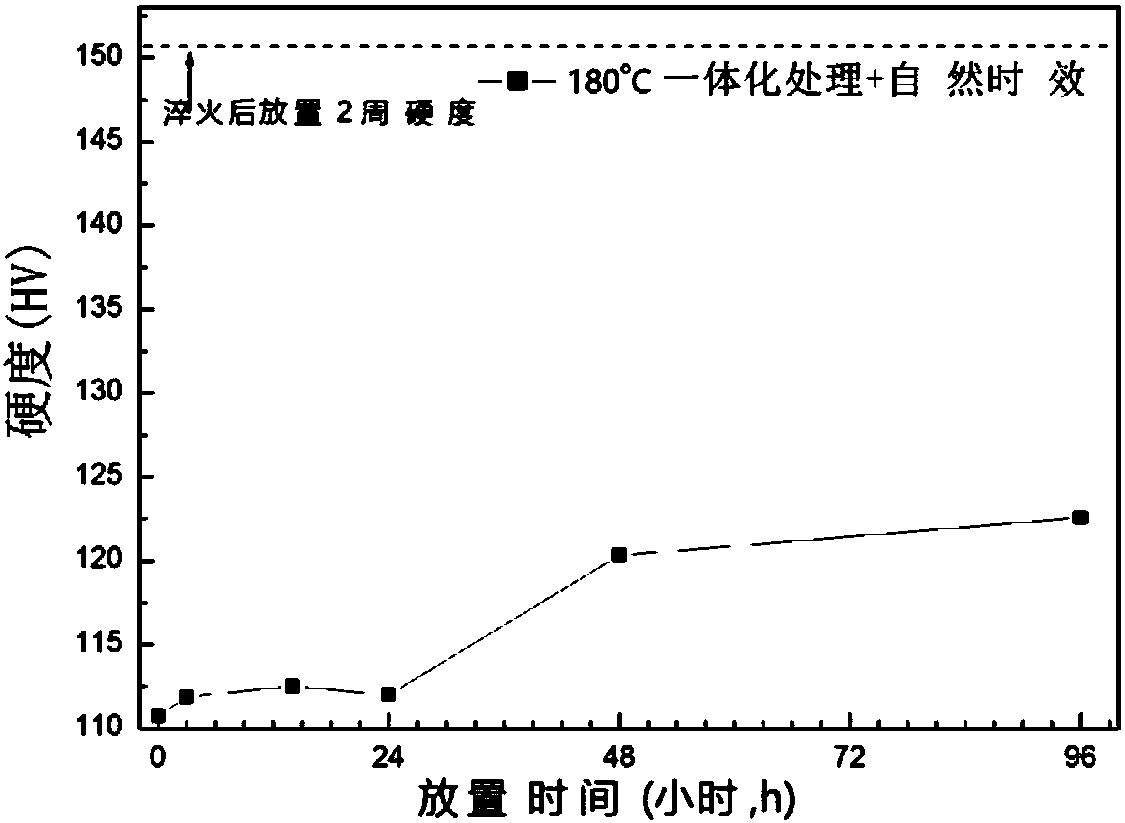

Quenching state restoring-forming integrated process for aluminum alloy

The invention provides a quenching state restoring-forming integrated process for an aluminum alloy. An aluminum alloy plate placed at room temperature is subjected to non-isothermal heating with theheating speed larger than 15 DEG C / min to be heated to 150-210 DEG C, and then is immediately transferred onto a forming device within 1-2 min, and a formed component is subjected to aging heat treatment reinforcement within 1 day. By means of the process, the aluminum alloy stored at room temperature for a long time can restore to the state close to the quenching state, strength is remarkably lowered, the forming capacity is improved, and the integrated process is favorable for coordinated control of the high-strength aluminum alloy.

Owner:CENT SOUTH UNIV

Liquid drug delivery micropump

ActiveCN1871040AThe process is easy to realizeHigh pump accuracyMedical devicesPressure infusionMicropumpDrug delivery

Owner:SENSILE PAT AG

Satiety enhancing food compositions

InactiveCN1874690AGood satiety effectReduce manufacturing costMetabolism disorderFood ingredientsBiopolymerFood composition data

The present invention provides an aqueous liquid or spoonable edible composition comprising at least 1% wt protein and from 0.1 to 5% wt of a biopolymer thickening agent which is not denatured or hydrolysed between pH 2 and 4, and wherein the composition has a gel strength at 37 DEG C and pH 2 of at least 10 KPa. The compositions of the invention have good satiety effects and are beneficial for use in weight control plans.

Owner:UNILEVER NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com