Giant salamander breeding pond

A technology for breeding ponds and giant salamanders, applied in animal husbandry, etc., can solve the problems of accelerating external oxygen, improper, fertilized eggs gather together and collide with each other, and achieve the effect of avoiding movement interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is further described in detail through specific implementation methods:

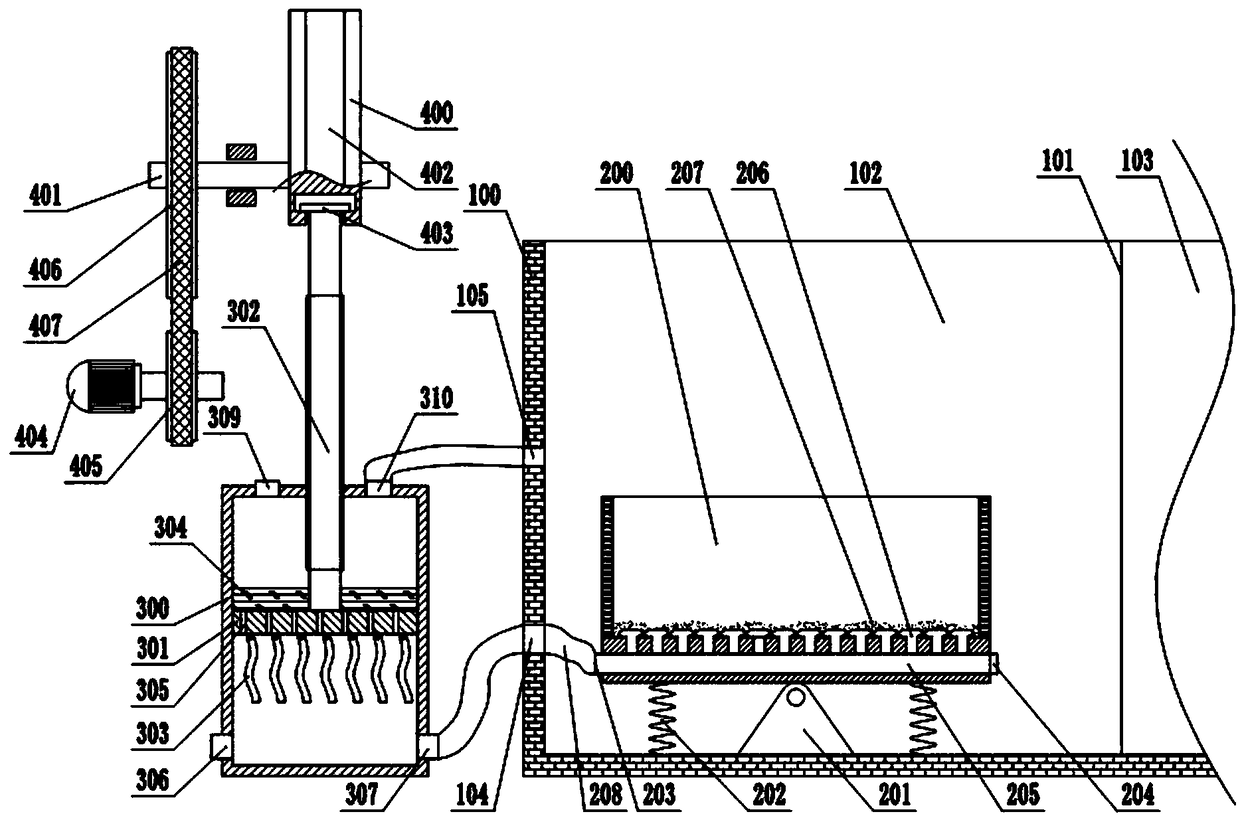

[0031] The reference numerals in the drawings of the description include: the culture pond body 100, the partition net 101, the hatching area 102, the growing area 103, the first water inlet 104, the first water outlet 105, the hatching bucket 200, the mounting seat 201, the spring 202, Second water inlet 203, second water outlet 204, drain pipe 205, air bag 206, fine sand 207, bellows 208, mixing bucket 300, piston 301, piston rod 302, mixing belt 303, water purification layer 304, through hole 305 , Intake check valve 306, water outlet check valve 307, air outlet check valve 309, water inlet check valve 310, cam 400, horizontal shaft 401, "T" groove 402, positioning block 403, motor 404, driving belt Wheel 405, driven pulley 406, belt 407.

[0032] The embodiment is basically as figure 1 Shown:

[0033] A giant salamander culture pond, comprising a culture pond body 100, a parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com