Automatic skin repair device for erhu cylinder

A kind of piano tube and automatic technology, which is applied in the direction of grinding drive device, machine tool suitable for grinding the edge of workpiece, and parts of grinding machine tool, etc., which can solve the problems of hand burden and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

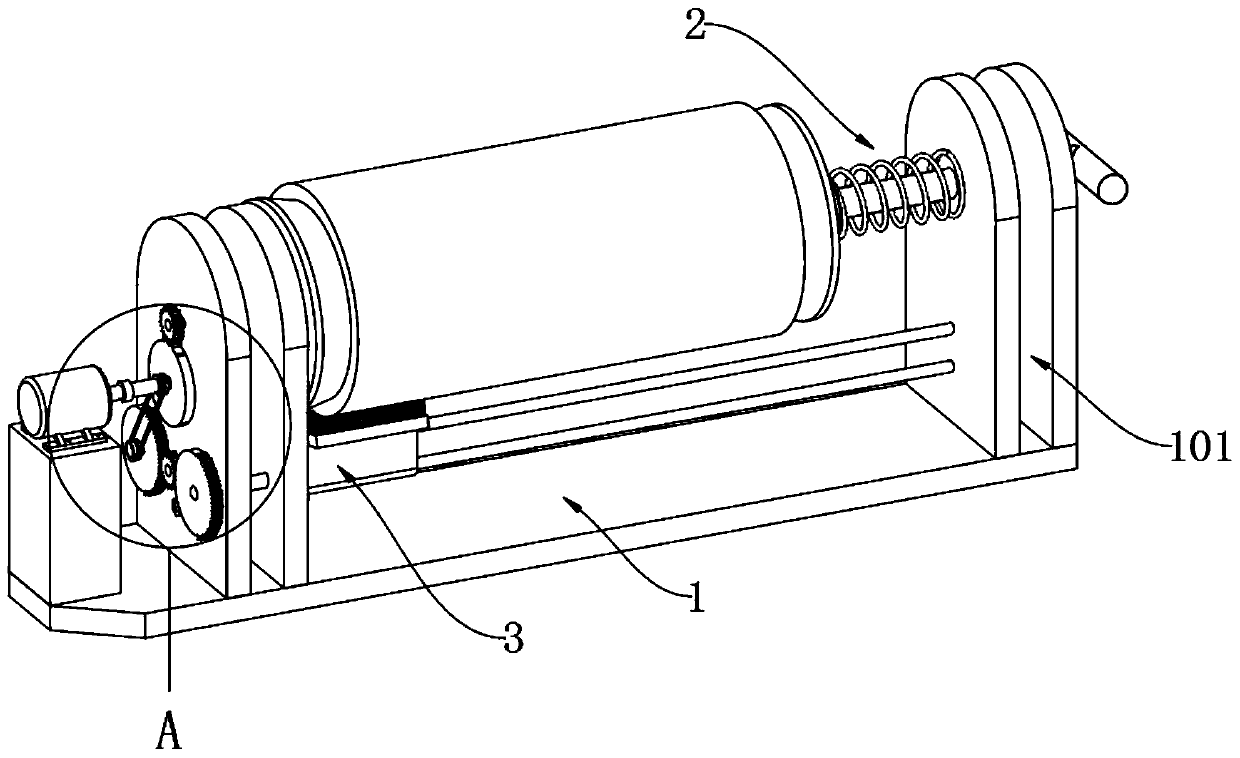

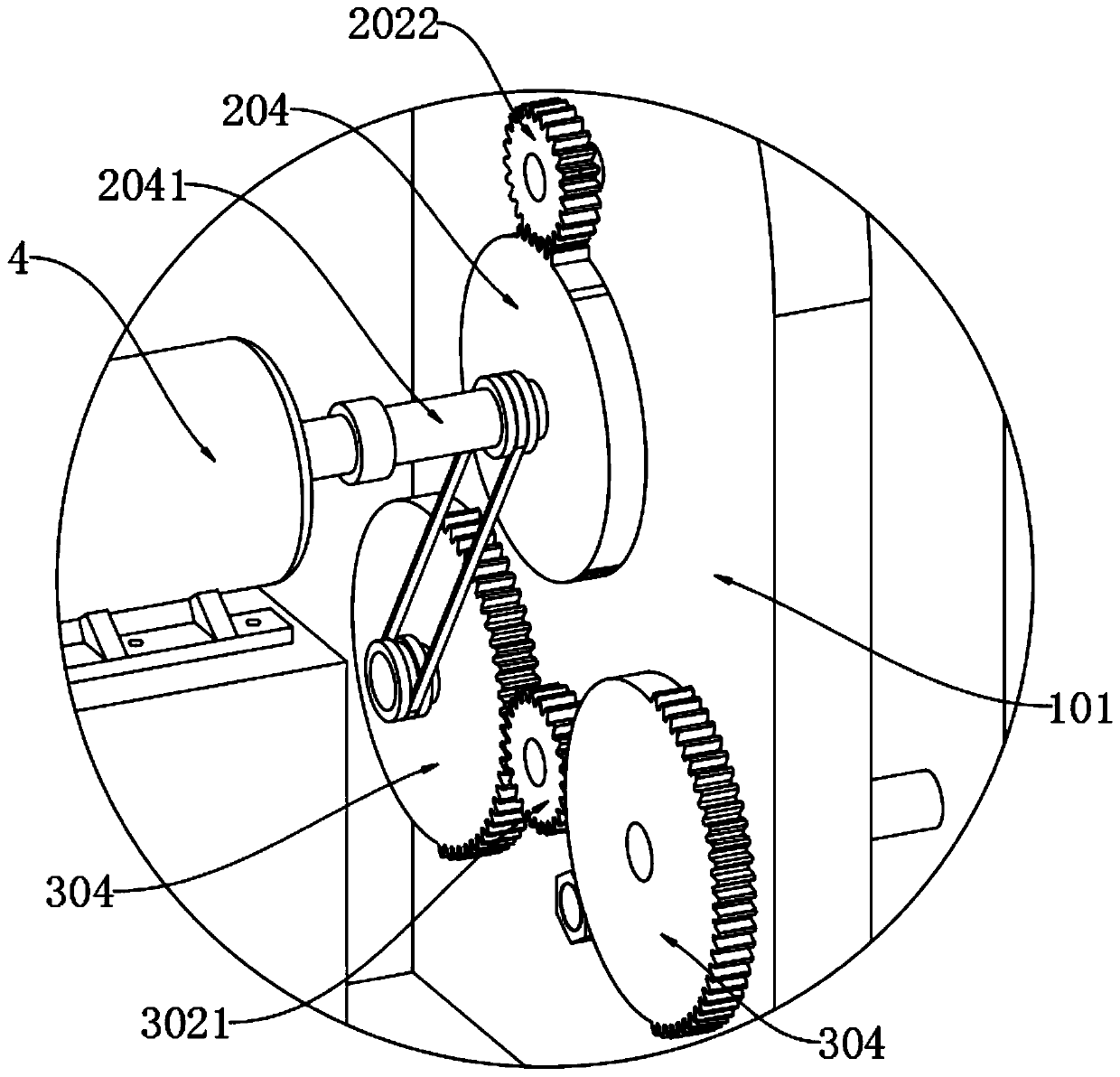

[0033] as attached figure 1 , attached Figure 3-4 , attached Figure 6 And attached Figure 9 Shown:

[0034]The present invention provides an automatic skin repairing device for the erhu qin tube, which includes a qin tube locking and rotating mechanism 2; Vertically connected to the base 1, one side of the support plate 101 is also equipped with a skin repairing mechanism 3, and the skin repairing mechanism 3 is linked with the piano tube clamping rotation mechanism 2, and the piano tube clamping rotation mechanism 2 is also connected with the driving motor 4 There is transmission connection between them, wherein, the piano tube clamping rotation mechanism 2 is composed of an adjustable rotating part and a fixed rotating part, and the adjustable rotating part includes a first wooden plug 201, a card slot 2011, a push-pull rod 203 and a clamping plate 2031, the first wooden plug 201 is a truncated cone structure and is rotatably connected to the front end of the push-pul...

Embodiment 2

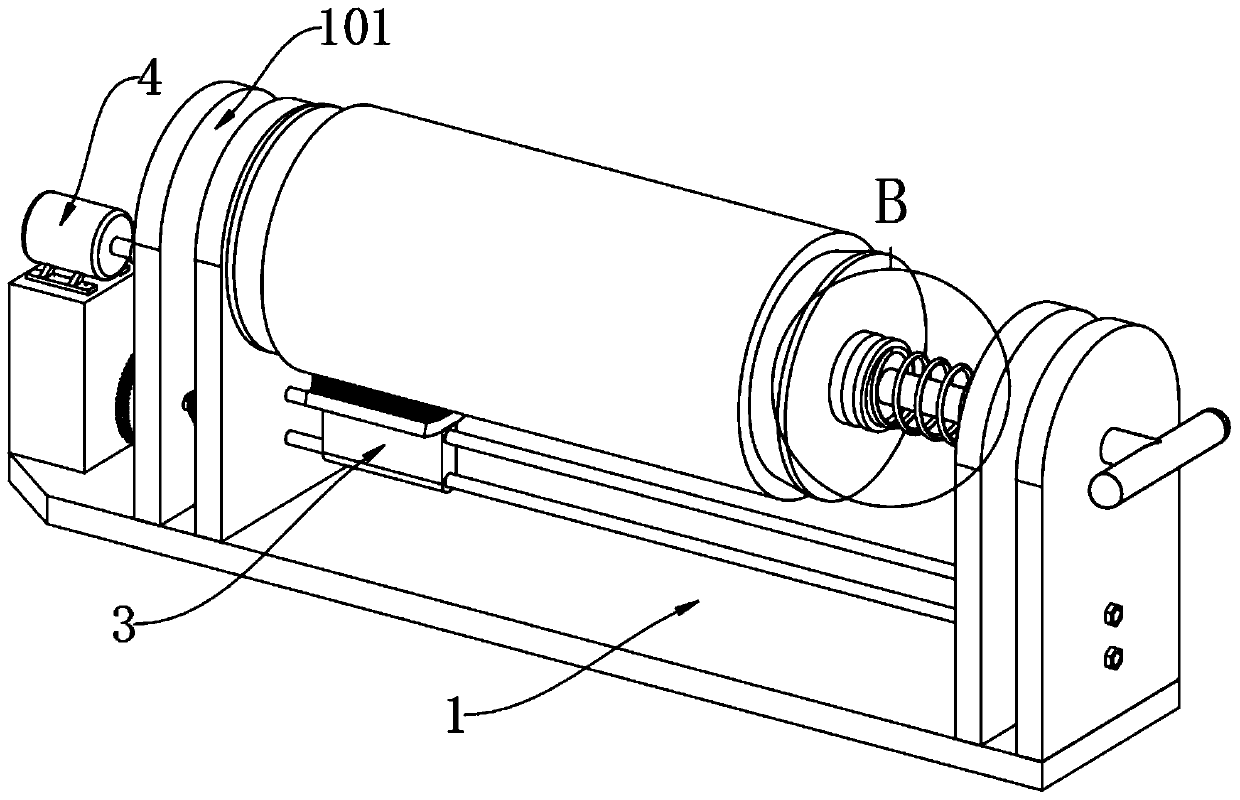

[0036] as attached figure 2 , attached Figure 5 And attached Figure 7-8 Shown:

[0037] The present invention provides a kind of automatic skinning device that is used for erhuqin tube, skinning mechanism 3 comprises steel wire scrub brush 301, slide seat 3011, threaded rod 302, lower drive gear 3021 and guide bar 303, the bottom side of steel wire scrub brush 301 is connected with Sliding seat 3011, and the sliding seat 3011 is slidably connected to the screw rod 302 through the threaded hole. One end of the screw rod 302 passes through the support plate 101 and is fitted with the lower driving gear 3021. The other end passes through the support plate 101 and is clamped by a nut. The sliding seat 3011 The lower end of the guide rod 303 is also interspersed with a guide rod 303, and the two ends of the guide rod 303 pass through the support plate 101 and are fixed by nuts, wherein the steel wire brush 301 is an arc-shaped structure, which can make the steel wire and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com