Quenching state restoring-forming integrated process for aluminum alloy

A technology of aluminum alloy and aluminum alloy sheet, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems that complex component processing cannot be practically applied, and achieves the convenience of shape and property collaborative control, low heating temperature, and improved quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

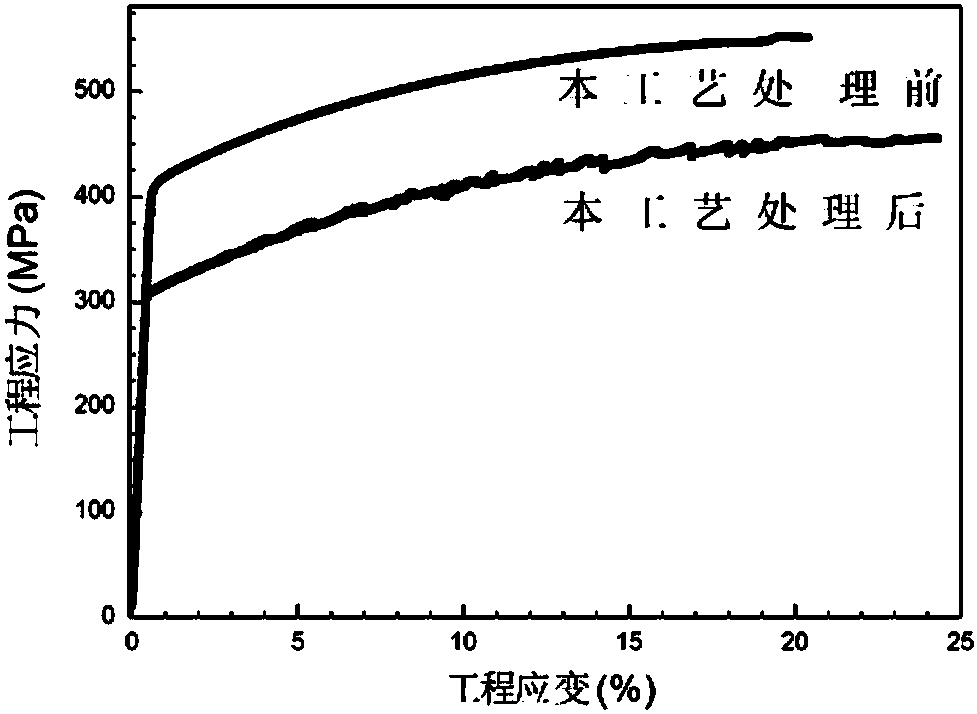

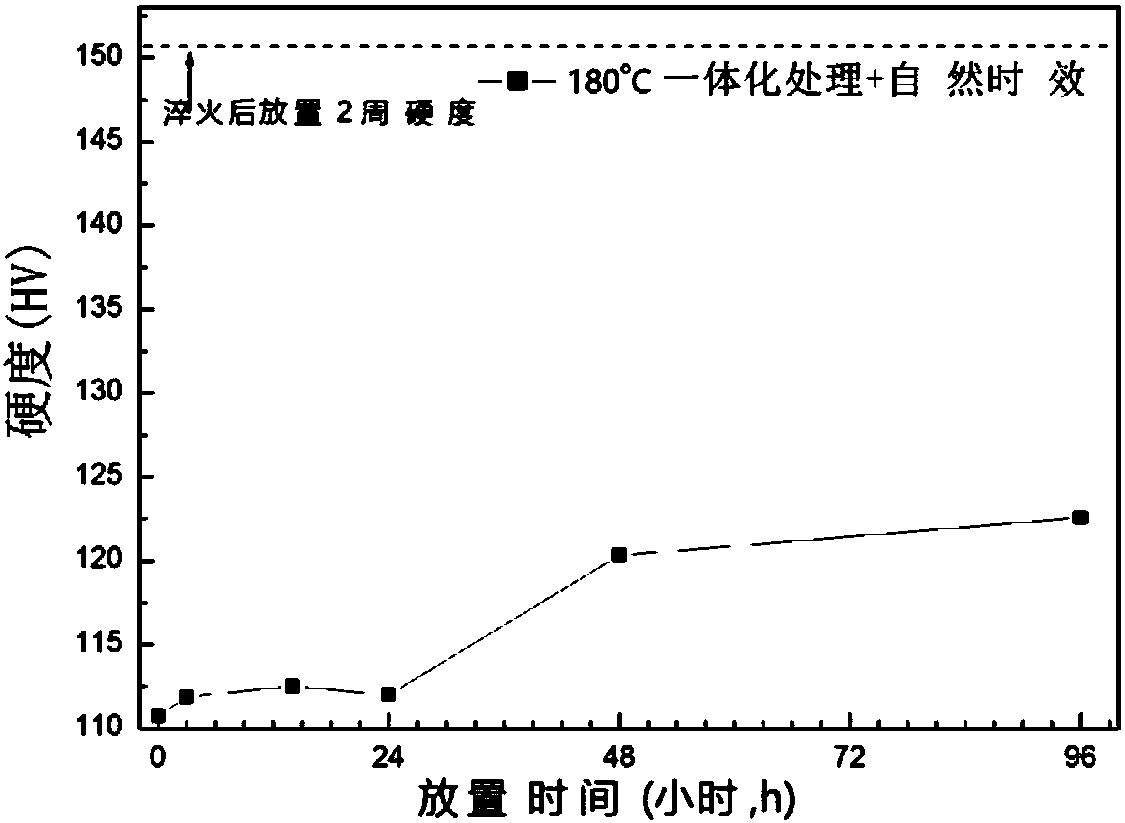

[0028] The 7B04 aluminum alloy is solid-solution treated and water-quenched in an air circulation resistance furnace to obtain an aluminum alloy sheet; then parked at room temperature for 2 weeks, and then non-isothermally heated to 150°C at 15°C / min in an aging furnace, and the plate is taken out to room temperature Carry out hardness test and tensile test after cooling.

Embodiment 2

[0030] 7B04 aluminum alloy is solid solution treated in an air circulation resistance furnace and water quenched to obtain aluminum alloy plate; then parked at room temperature for 2 weeks, and then non-isothermally heated to 180°C at 15°C / min in an aging furnace, and the plate is taken out to room temperature Carry out hardness test and tensile test after cooling.

Embodiment 3

[0032] The 7B04 aluminum alloy is solid-solution treated and water-quenched in an air circulation resistance furnace to obtain an aluminum alloy plate; then parked at room temperature for 2 weeks, and then non-isothermally heated to 210°C at 15°C / min in an aging furnace, and the plate is taken out to room temperature Carry out hardness test and tensile test after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com