Patents

Literature

39results about How to "Improve forming ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

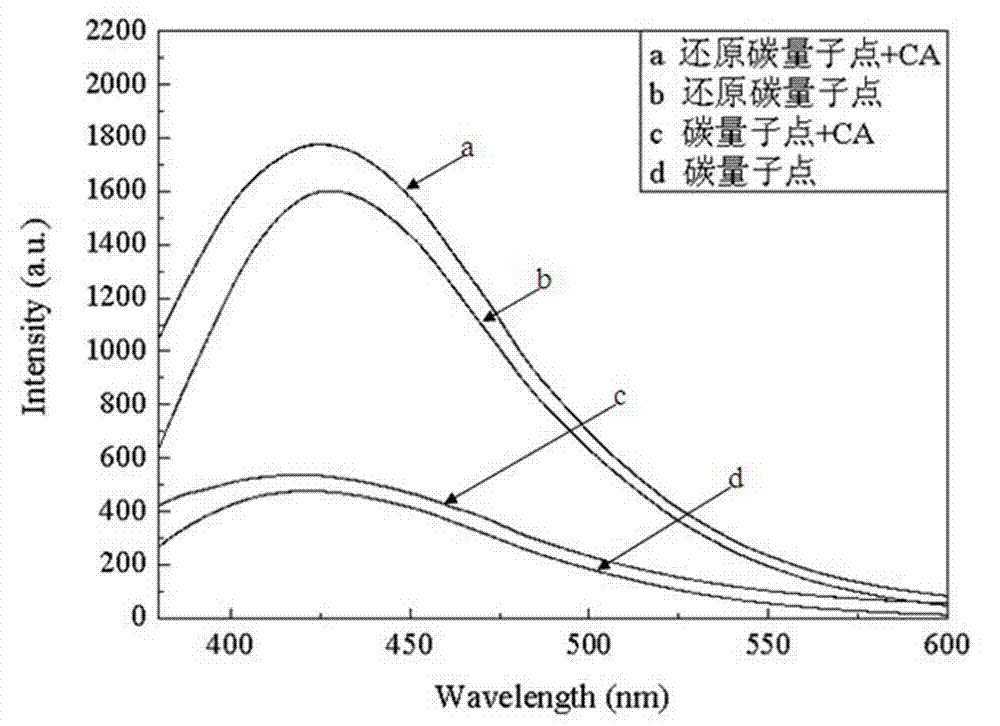

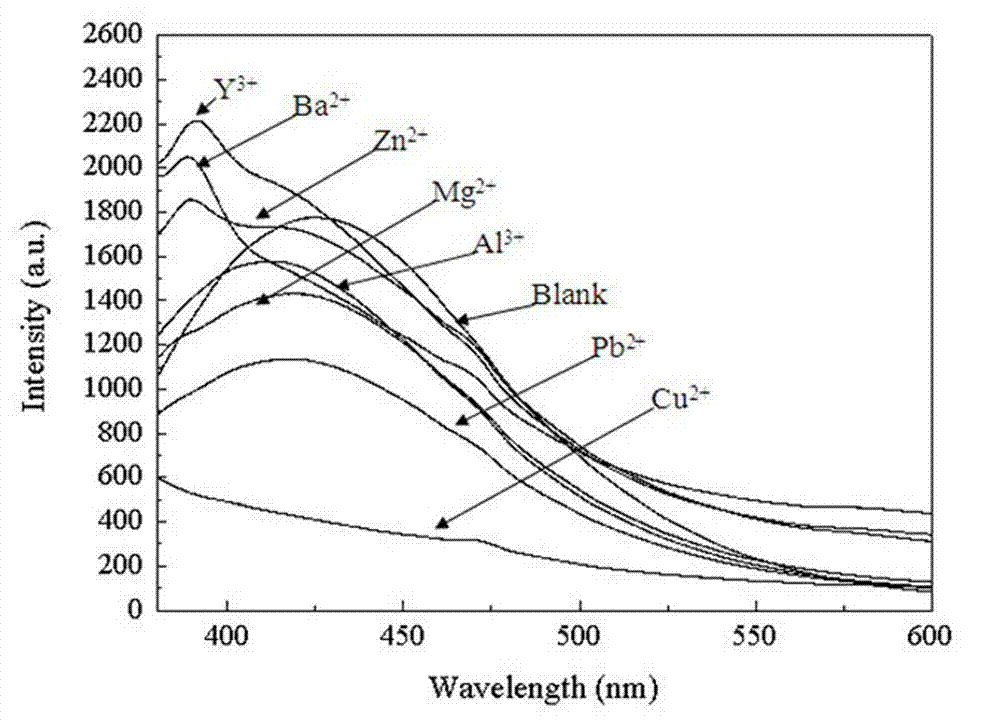

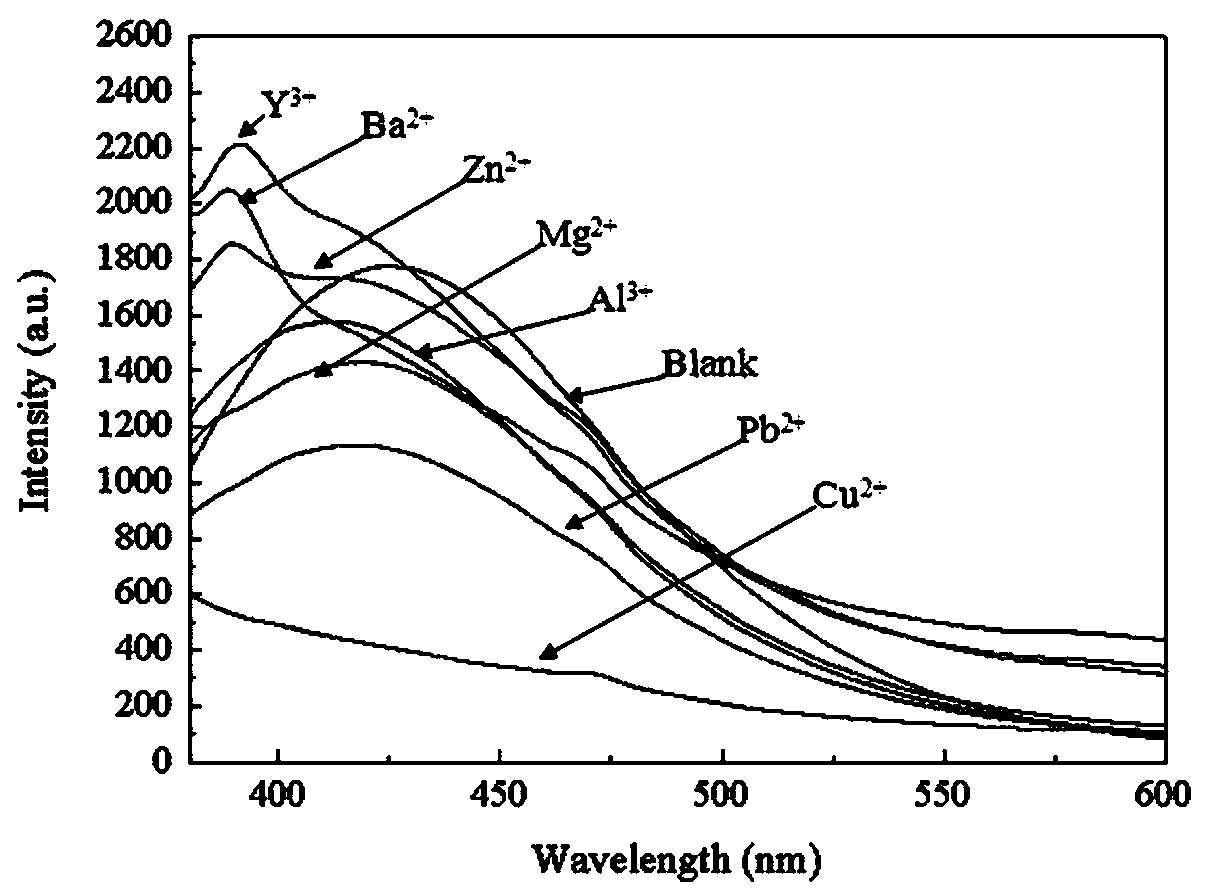

Preparation method of carbon quantum dot containing calcium alginate gel for detecting copper ions

InactiveCN102964608ACause secondary pollutionStrong forming abilityFluorescence/phosphorescenceLuminescent compositionsAtherion elymusPhysical chemistry

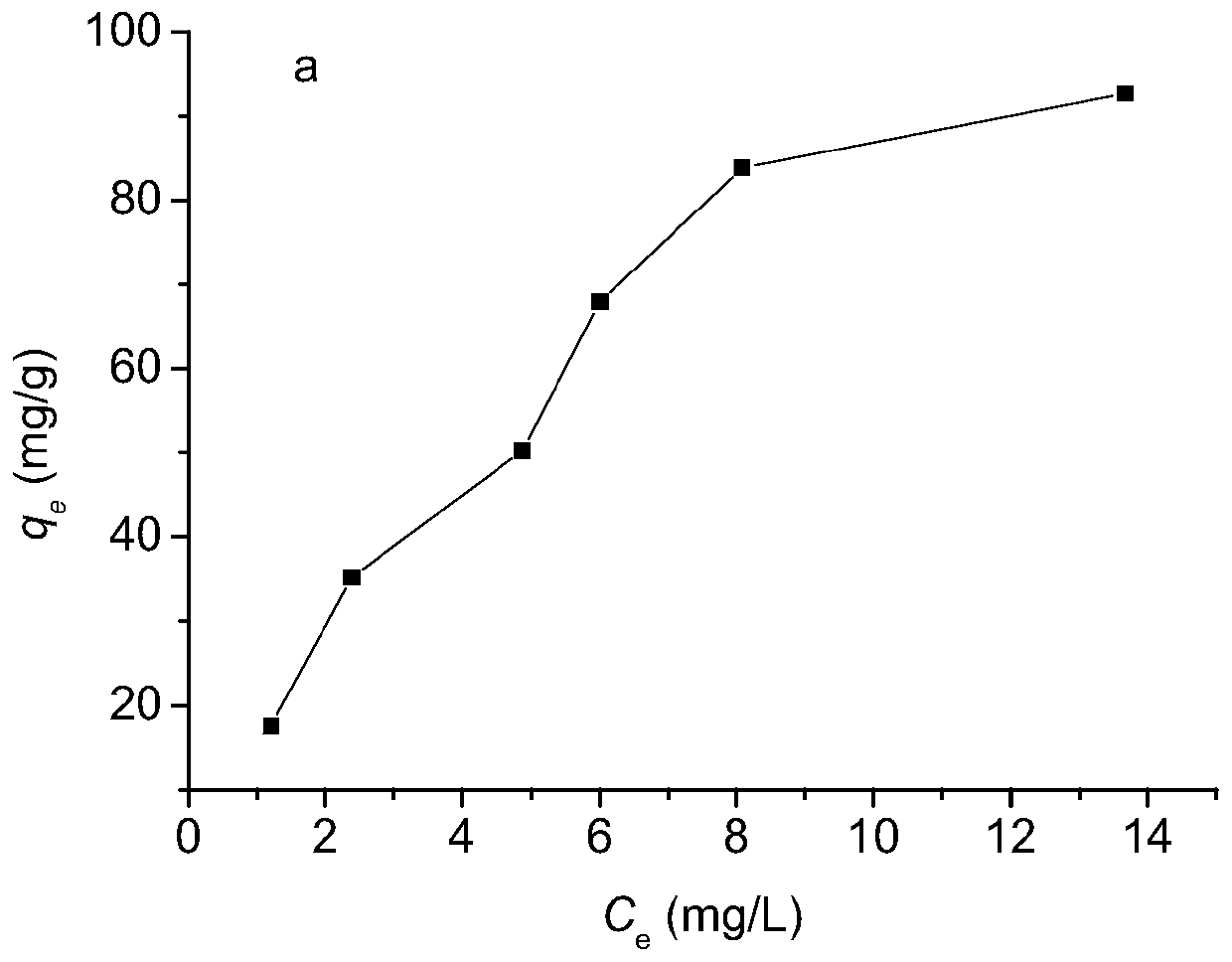

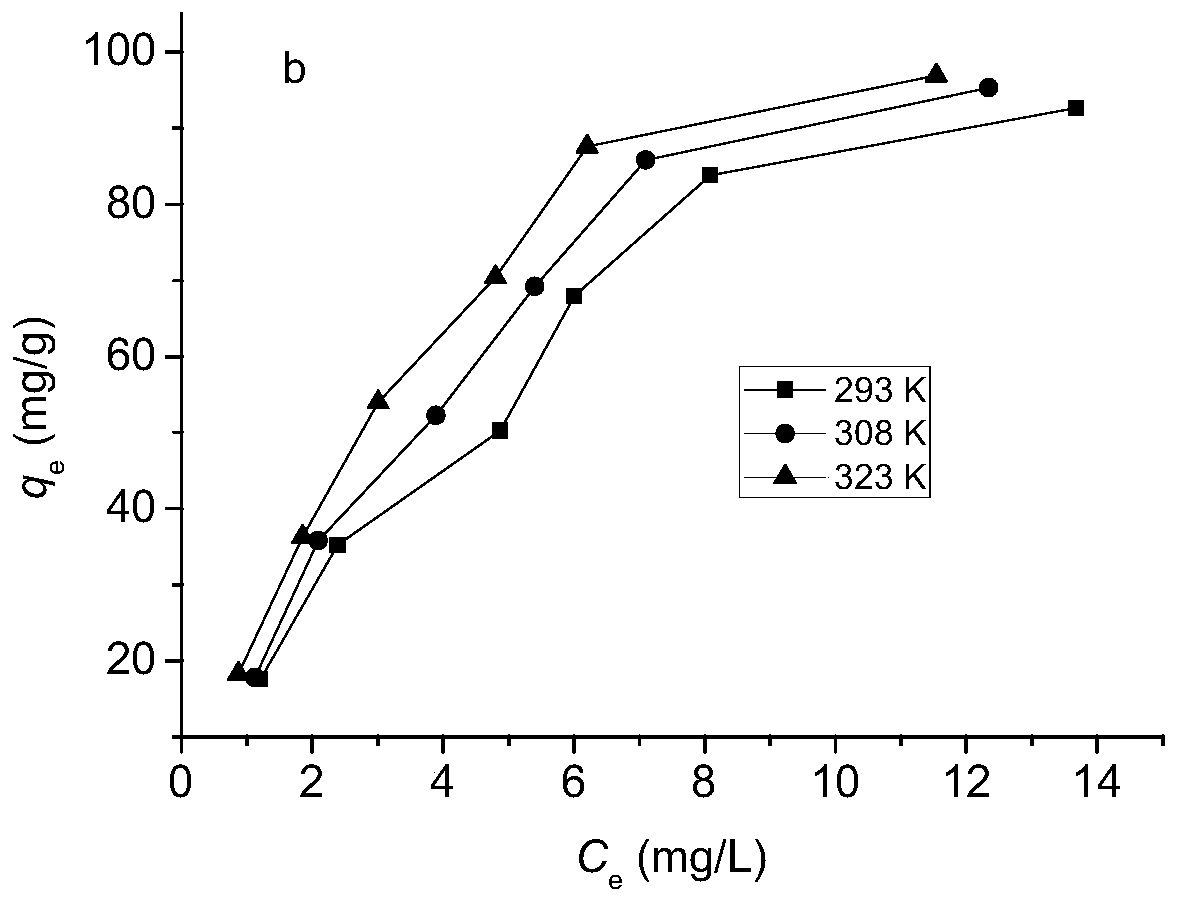

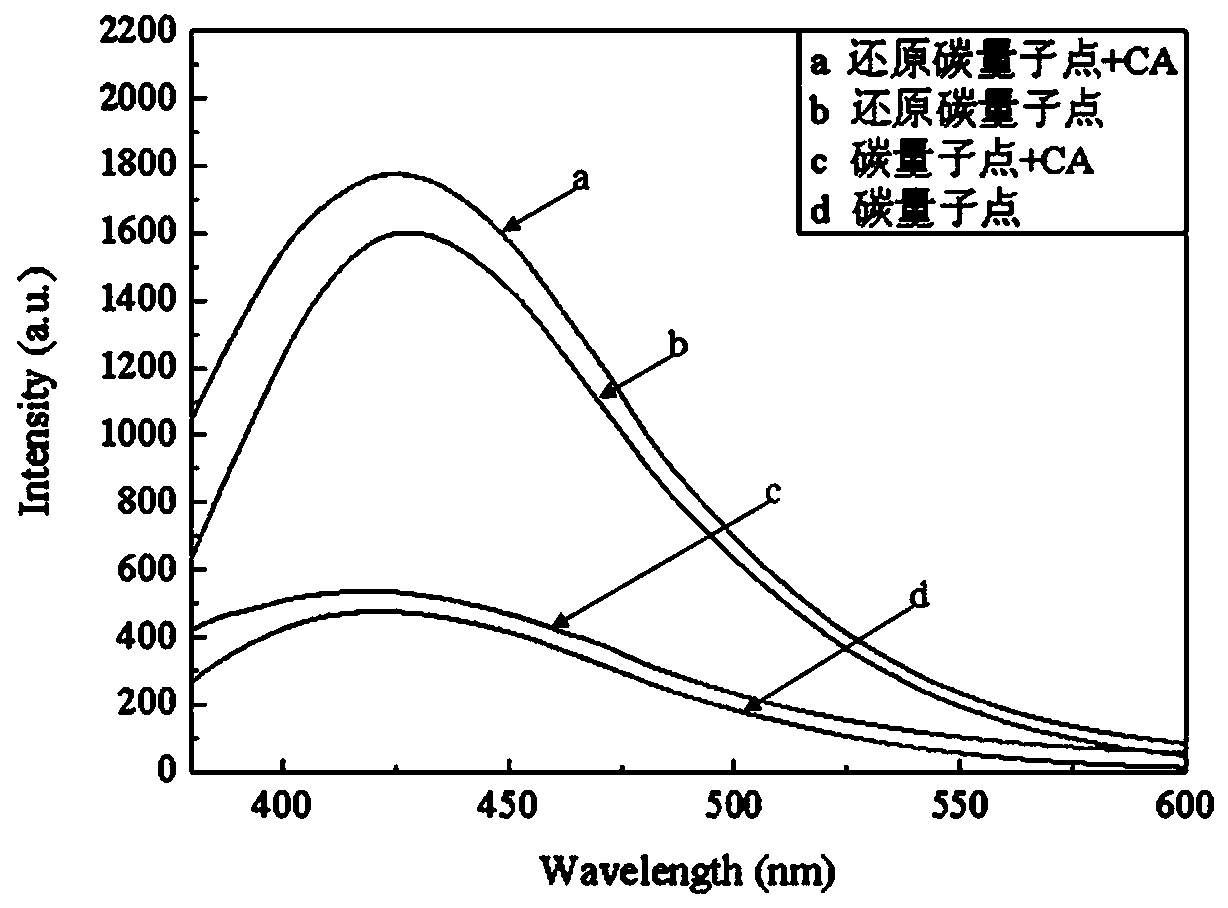

The invention relates to a detection technology of copper ions, and in particular relates to a preparation method of a reduced carbon quantum dot containing calcium alginate gel for detecting copper ions. The preparation method of the carbon quantum dot containing calcium alginate gel for detecting the copper ions comprises the following steps of: preparing fluorescent carbon quantum dots; neutralizing the fluorescent carbon quantum dots, adding sodium borohydride into the neutralized fluorescent carbon quantum dots to perform reduction; mixing deionized water with the neutralized fluorescent carbon quantum dots at equal volume, and adding sodium alginate into the mixture to obtain a sodium alginate sol; and spraying a calcium ion solution to the surface of the sol or soaking the sol into the calcium ion solution to perform crosslinking, and drying to obtain the calcium alginate gel. By using the characteristics that the carbon quantum dots have fluorescent characteristics, the fluorescence of the carbon quantum dots is enhanced after reduction, and the calcium alginate can enhance the fluorescent characteristics of the carbon quantum dots, when the copper ions are detected, the cost of an adopted fluorospectro photometer is low, the sample preparation and treatment steps are simple and easy to operate, and the detection sensitivity is high, so that the calcium alginate gel can be widely used for detecting the copper ions.

Owner:ZHONGBEI UNIV

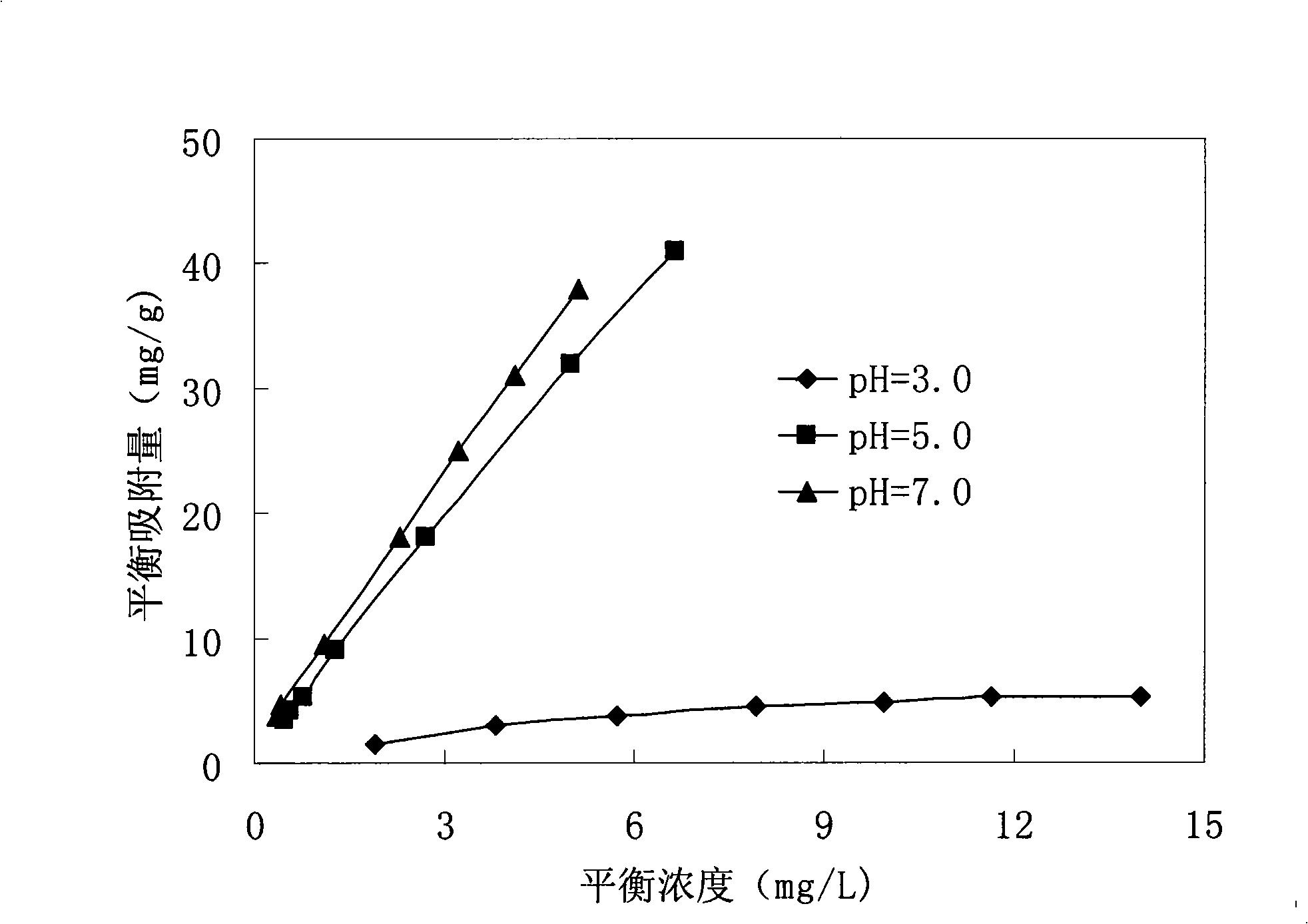

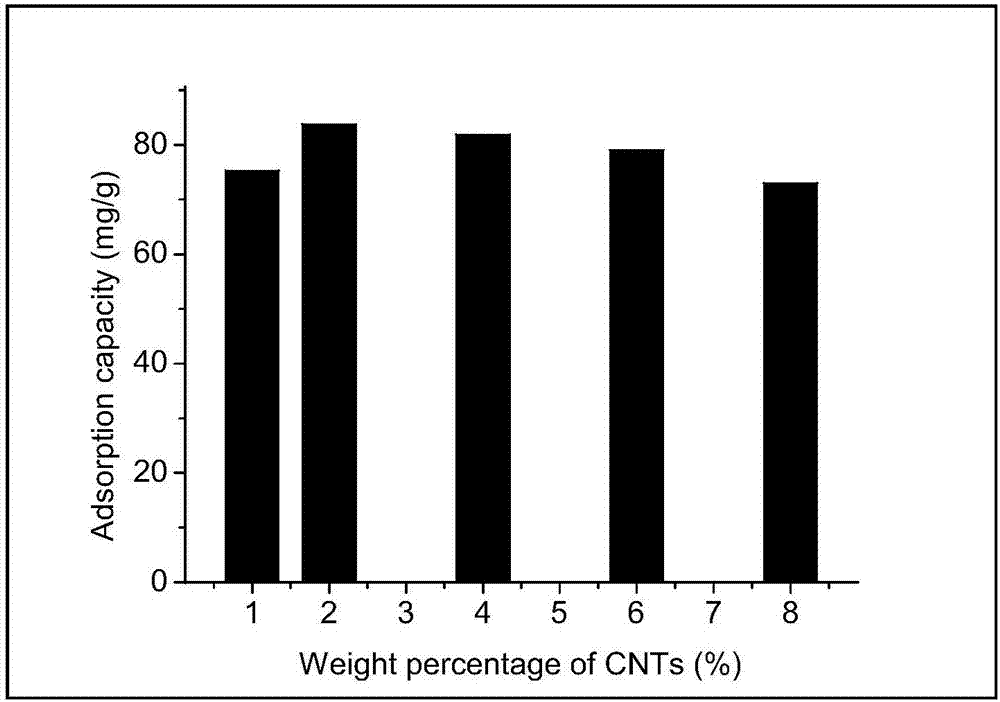

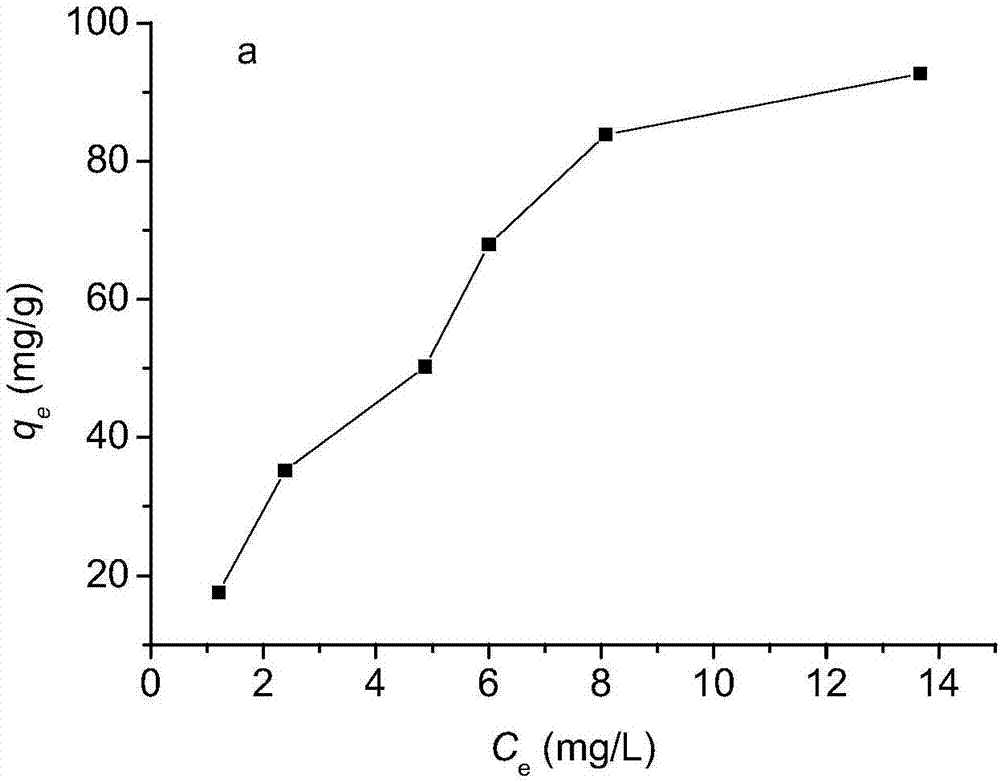

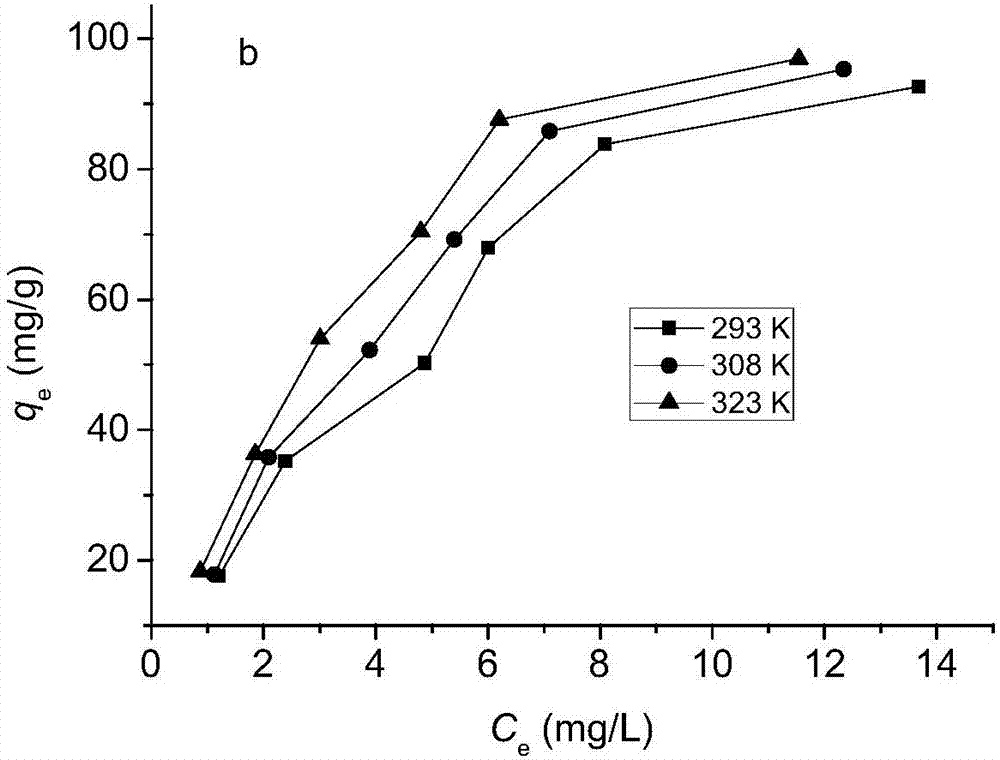

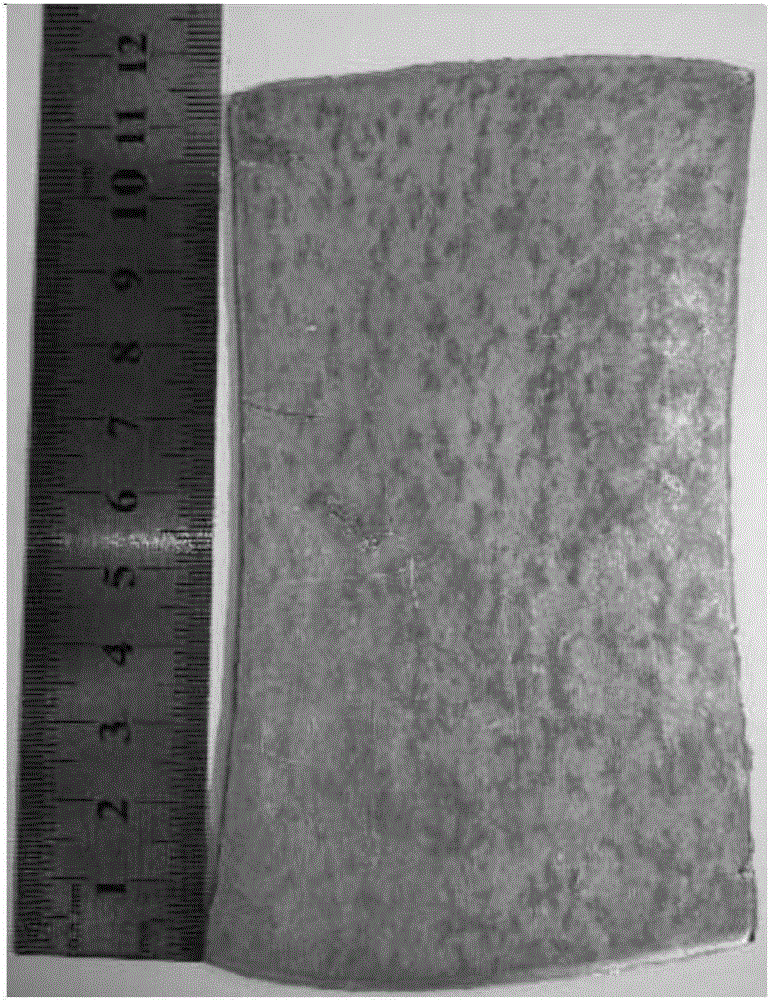

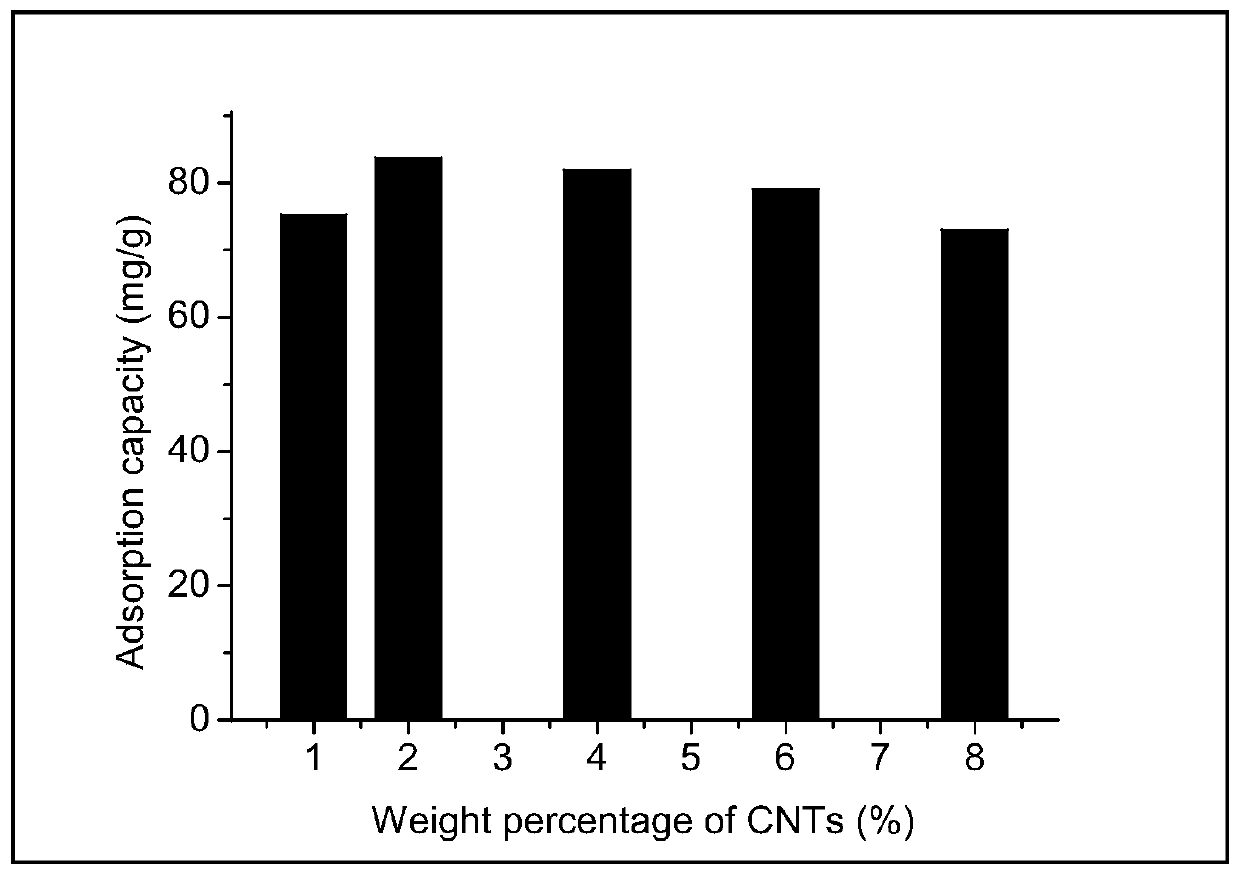

Environment-friendly carbon nanotube/sodium alginate heavy metal ion sorbing material and preparation method thereof

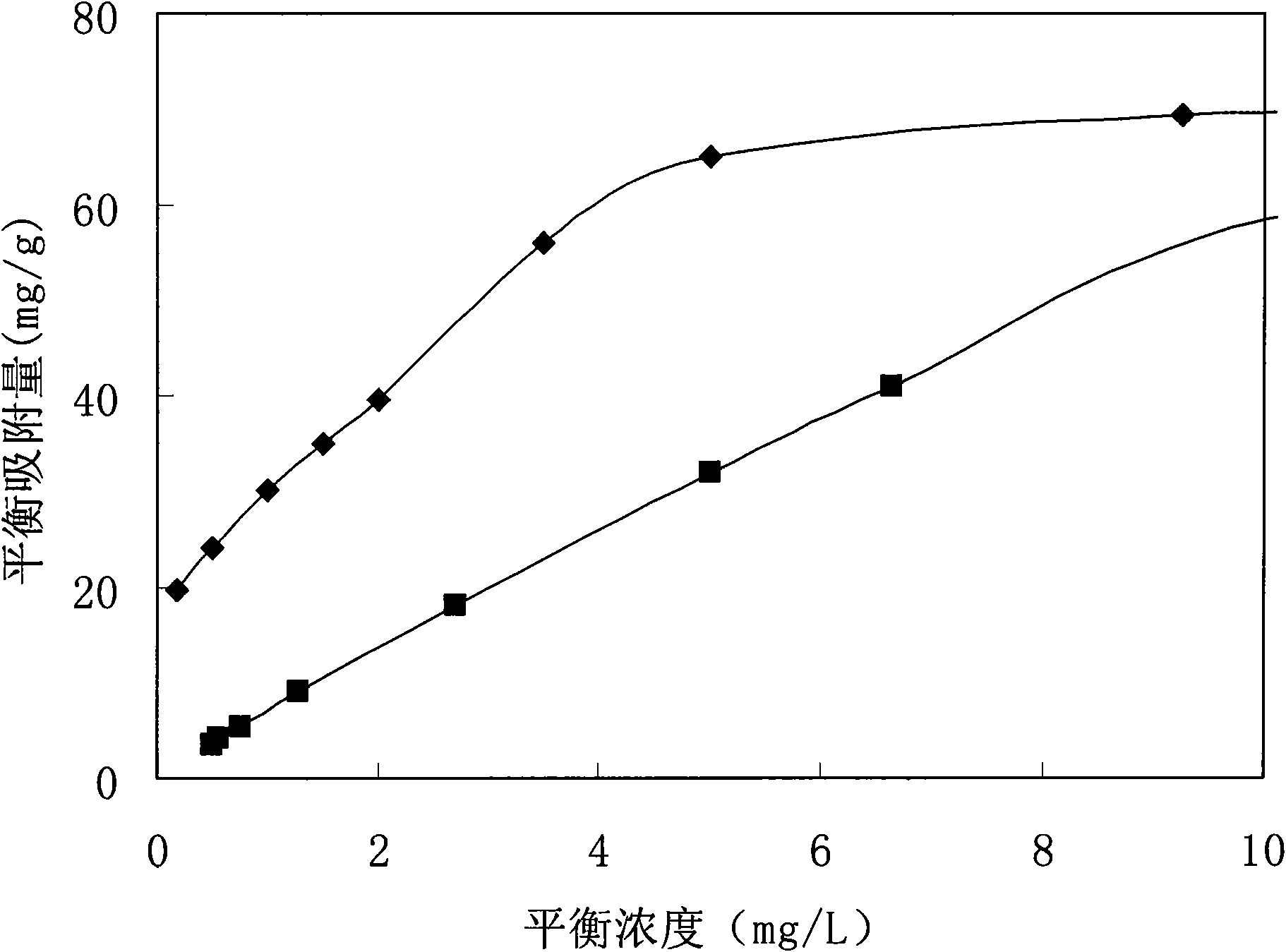

InactiveCN101574641AImprove adsorption capacityPlay non-toxicOther chemical processesWater/sewage treatment by sorptionSorbentCarbon nanotube

An environment-friendly carbon nanotube / sodium alginate heavy metal ion sorbing material and a preparation method thereof belong to the technical field of new nano material and environmental protection. Aiming at solving the problem that the carbon nanotube with microsize is likely to cause secondary pollution to water quality while being used as sorbent, the invention uses nontoxicity, good adsorptive capacity and excellent formability of sodium alginate, and prepares carbon nanotube / sodium alginate granular composite material by sol-gel method. The carbon nanotube / sodium alginate granular composite material has good adsorptive capacity on heavy metal ion in sewage. The method has simple preparation process and controllable condition, is suitable for mass production, reduces secondary pollution to water by the carbon nanotube with microsize, and prepares the environment-friendly carbon nanotube / sodium alginate composite sorbing material.

Owner:QINGDAO UNIV

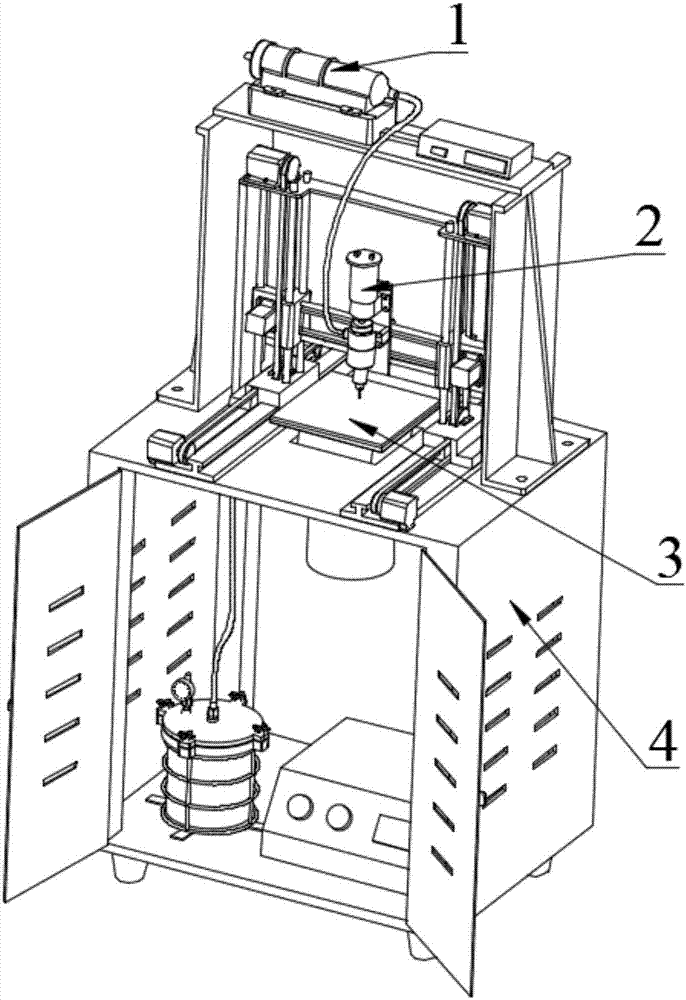

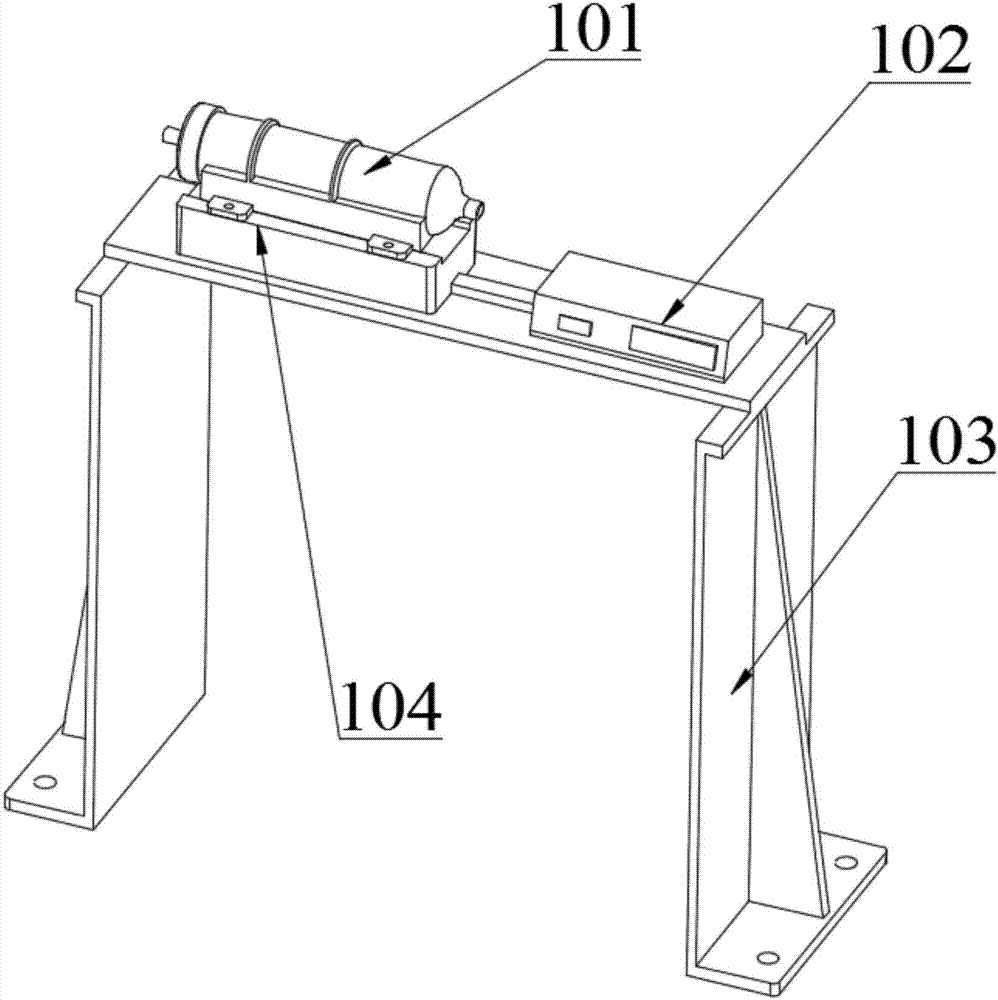

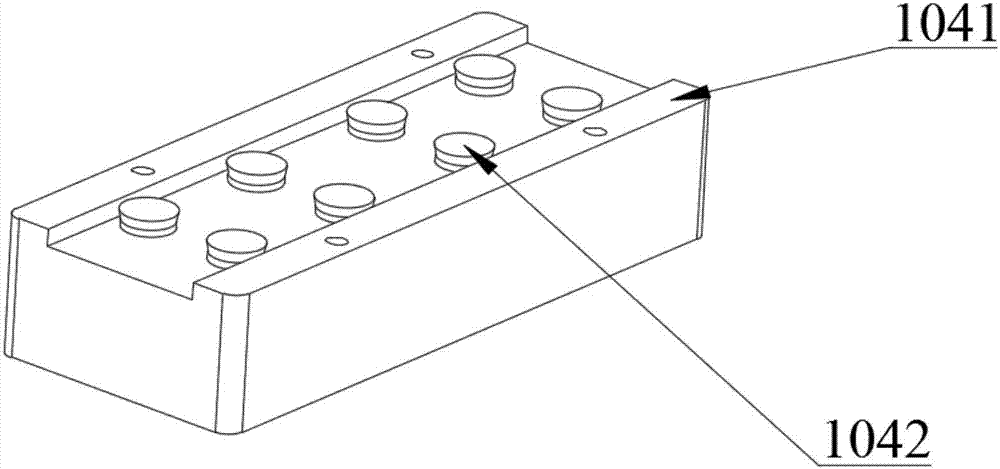

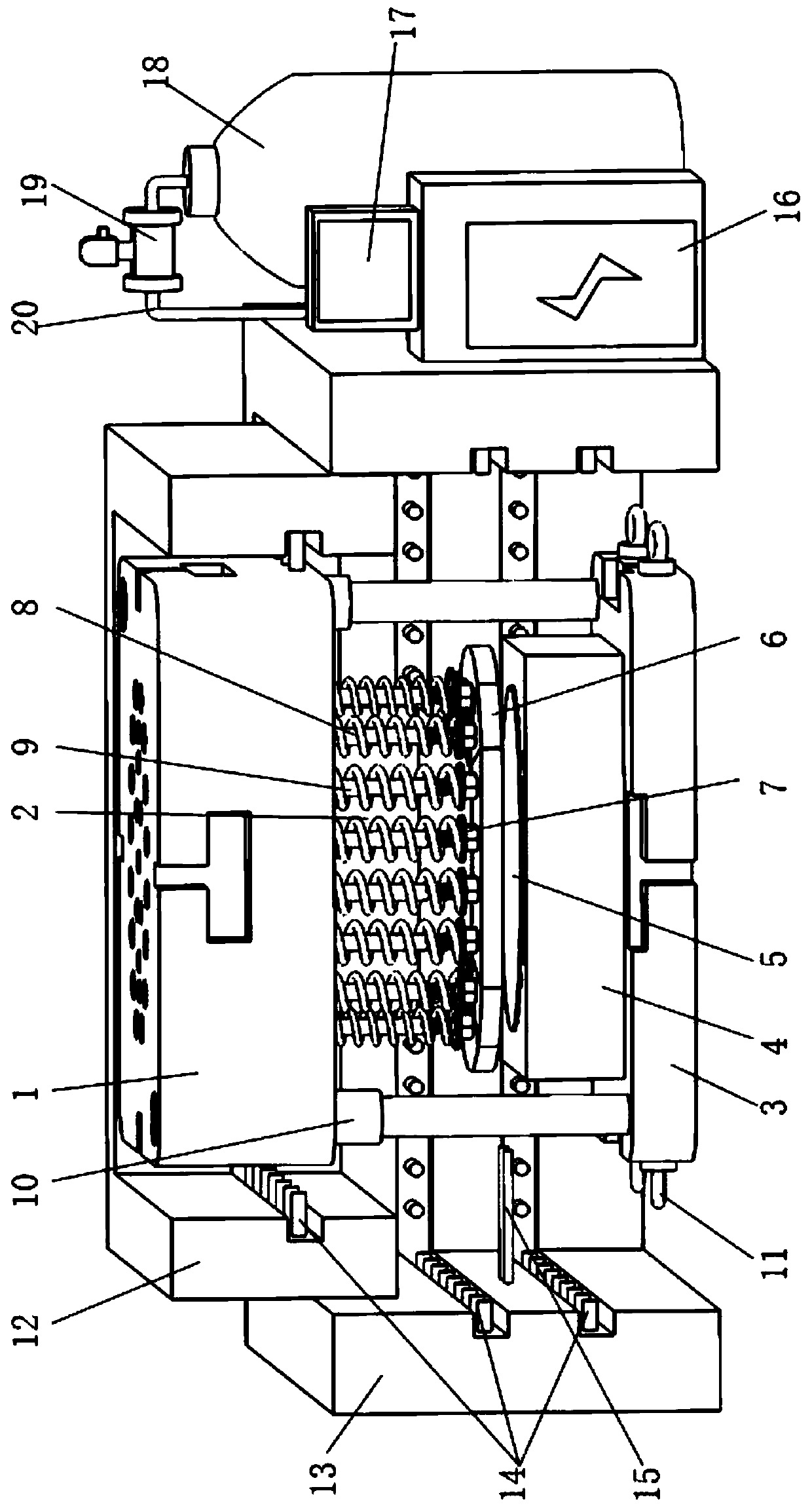

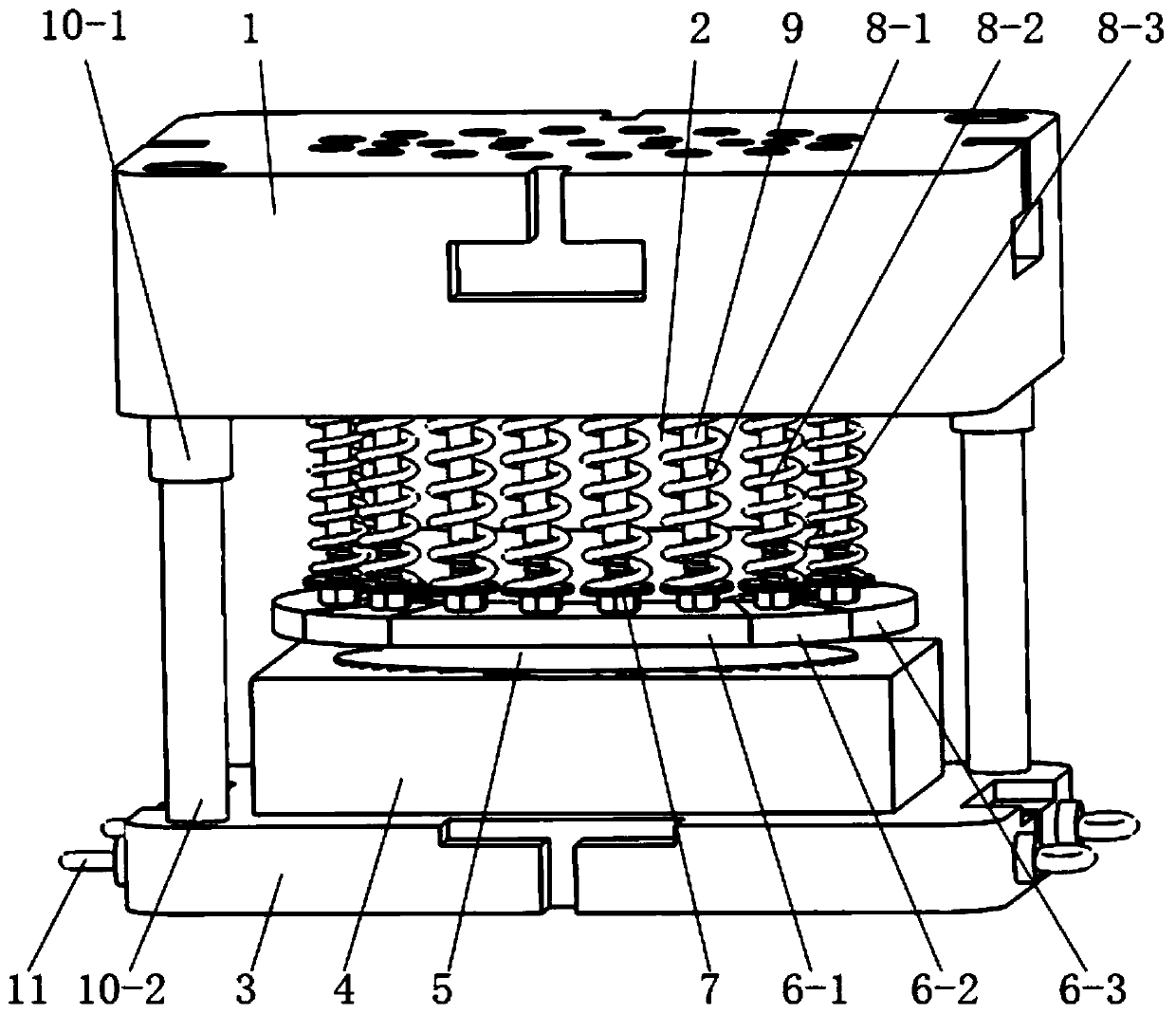

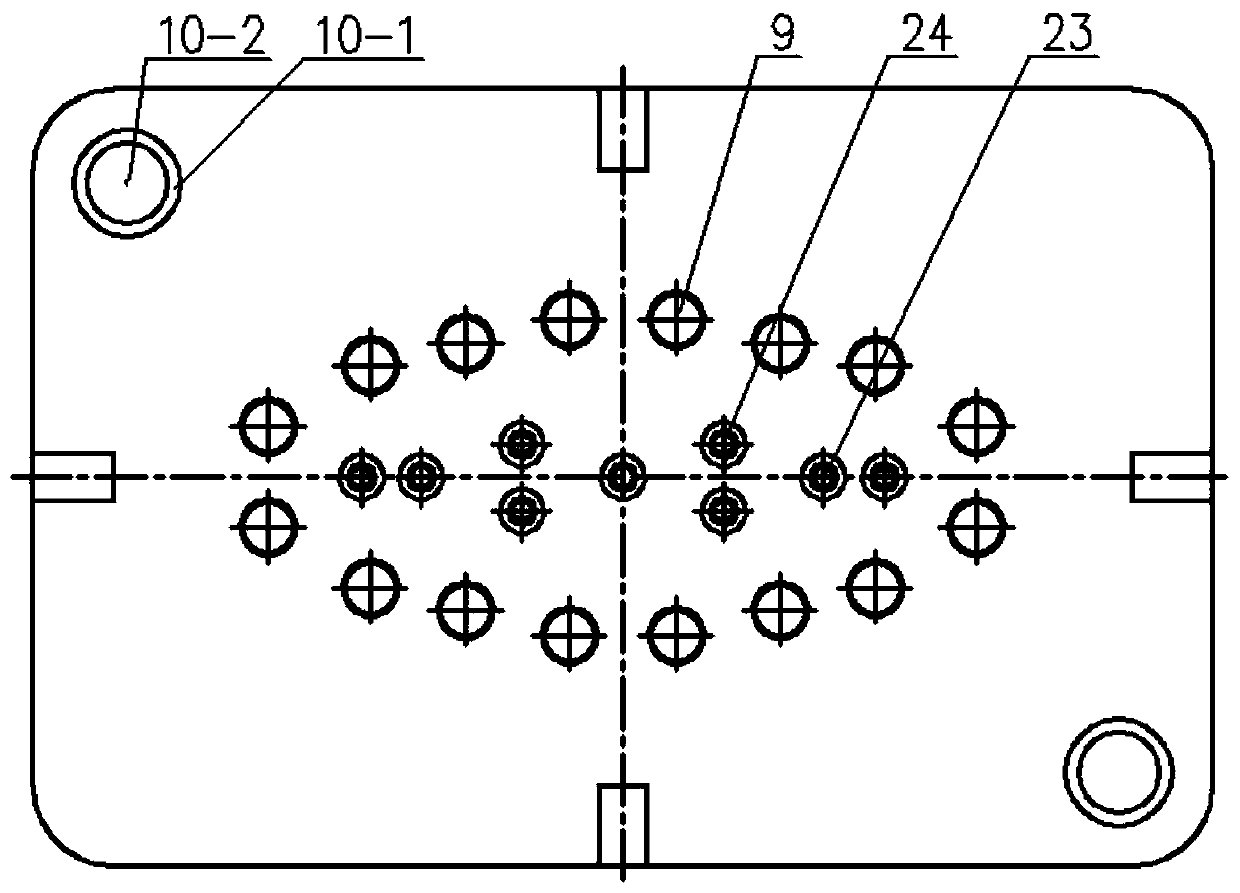

Metallic glass composite material ultrasound-assisted 3D cold printing device and method

ActiveCN107470627ALow costStrong forming abilityAdditive manufacturing apparatusTransportation and packagingGlass compositesUltrasound assisted

The invention provides a metallic glass composite material ultrasound-assisted 3D cold printing device and method, and belongs to the field of additive manufacturing. The metallic glass composite material ultrasound-assisted 3D cold printing device comprises an ultrasonic vibration material cylinder, a three-axis cold printing device, an ultrasonic vibration base plate and a base machine box. According to the metallic glass composite material ultrasound-assisted 3D cold printing device, the 3D cold printing technology, the ultrasonic vibration technology and the superfine-particle reinforced metal matrix composite material technology are combined, the ultrasonic vibration material cylinder is fixedly arranged on the base machine box, the three-axis cold printing device is fixedly arranged on the base machine box, and the ultrasonic vibration base plate is fixedly arranged on the base machine box. According to the metallic glass composite material ultrasound-assisted 3D cold printing device and method, superfine reinforced particles are added to a metallic particle solution, so that the mechanical property of a material is enhanced; the distribution uniformity of the superfine particles in the metallic particle solution is improved by the use of ultrasonic vibration; and a three-dimensional metallic glass composite material part is directly formed through the 3D cold printing technology, the forming speed is high, the part strength is high, the density is uniform, the cost is low, and no special requirements for the working environment exist.

Owner:JILIN UNIV

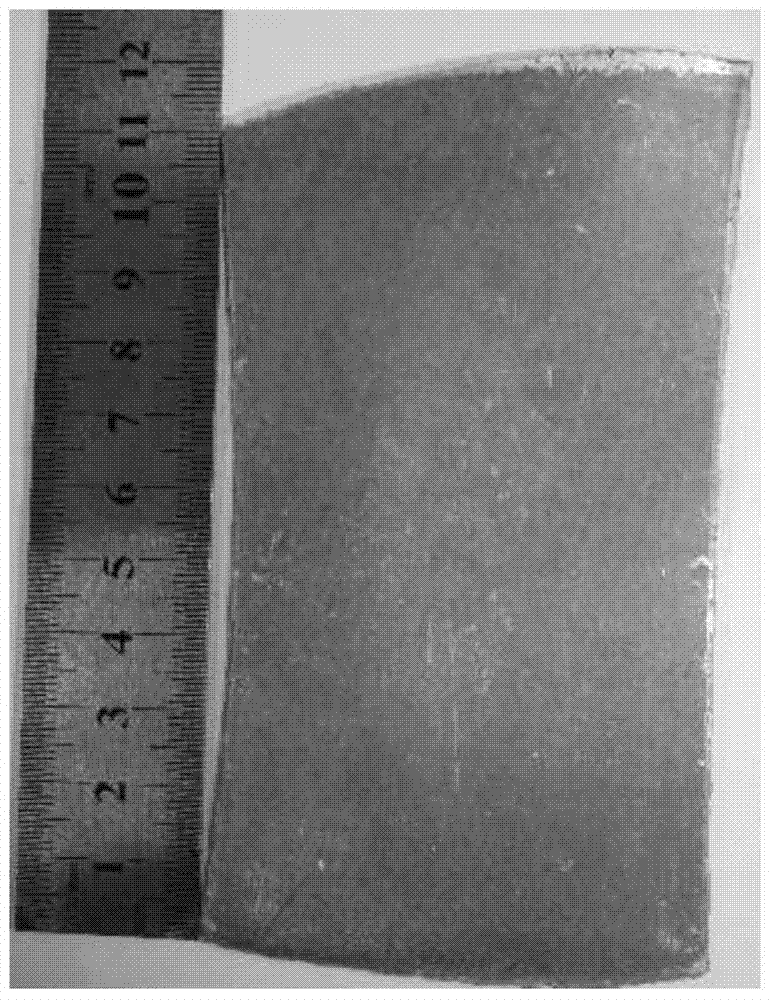

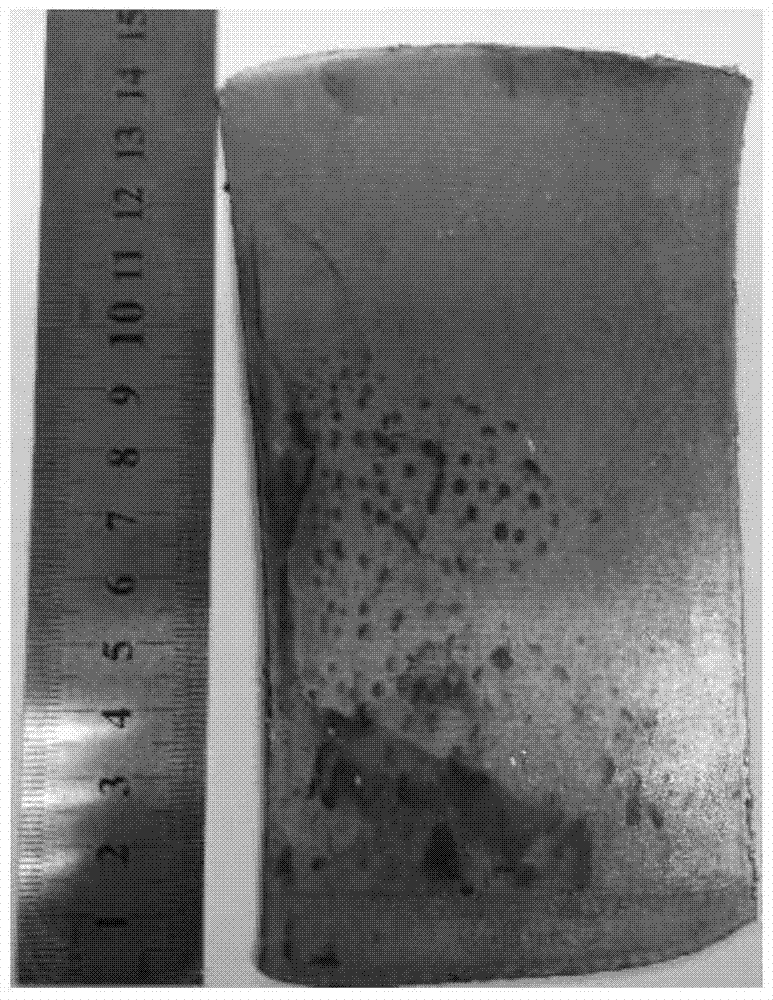

Method for producing high-strength steel with yield strength of 600MPa level

InactiveCN101538680ASimple metallurgical compositionReduce alloy costTemperature control deviceThin slabLaminar cooling

The invention belongs to the technical field of high-strength steel production, and relates to a method for producing high-strength steel with yield strength of 600MPa level. The high-strength steel is smelted by a converter or an electric furnace; and after the molten steel components are qualified, the molten steel components are delivered to an LF furnace to carry out refining for the molten steel and fine adjustment for the components, wherein the steel comprises the following components in percentage by mass: 0.03 to 0.08 percent of C, 0.20 to 0.50 percent of Si, 1.0 to 1.5 percent of Mn, 0.06 to 0.10 percent of Ti, 0.02 to 0.08 percent of Nb, 0.02 to 0.06 percent of Al, less than or equal to 0.008 percent of limited element S, less than or equal to 0.008 percent of N, less than or equal to 0.04 percent of P, and the balance of Fe. The method adopts a thin slab blank to continuously cast the steel, the charging temperature of a casting blank is between 950 and 1,050 DEG C, the heating temperature is more than or equal to 1,150 DEG C, the discharging temperature is between 1,080 and 1,160 DEG C, the final rolling temperature is between 820 and 920 DEG C, and after laminar cooling, the rolling temperature is between 550 and 650 DEG C. The yield strength of the high-strength steel produced by the method is in a range of 590MPa to 660MPa, the high-strength steel has good forming property and welding property at the same time, and the thickness of a plate is in a range of 1.4 to 9.0 millimeters. By applying the method, the metallurgical components of the steel are simple, the alloying cost is low, and the process is simple and easy to control.

Owner:湖南华菱涟源钢铁有限公司 +1

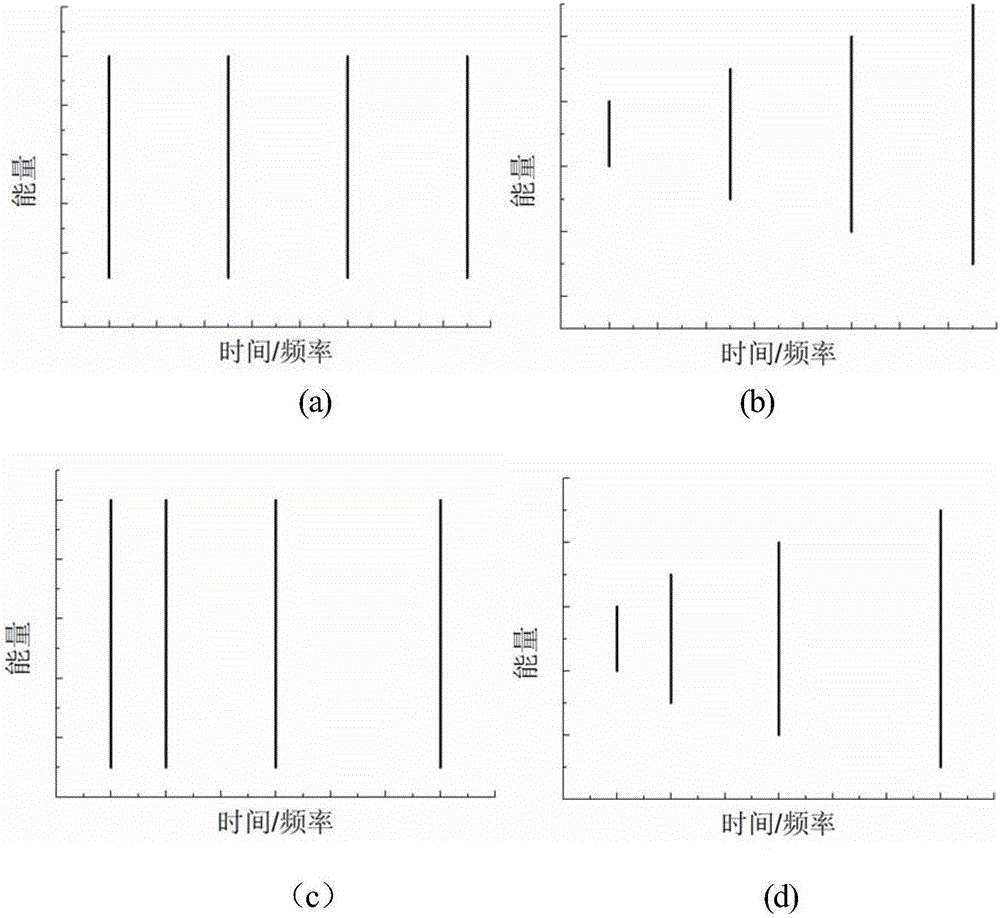

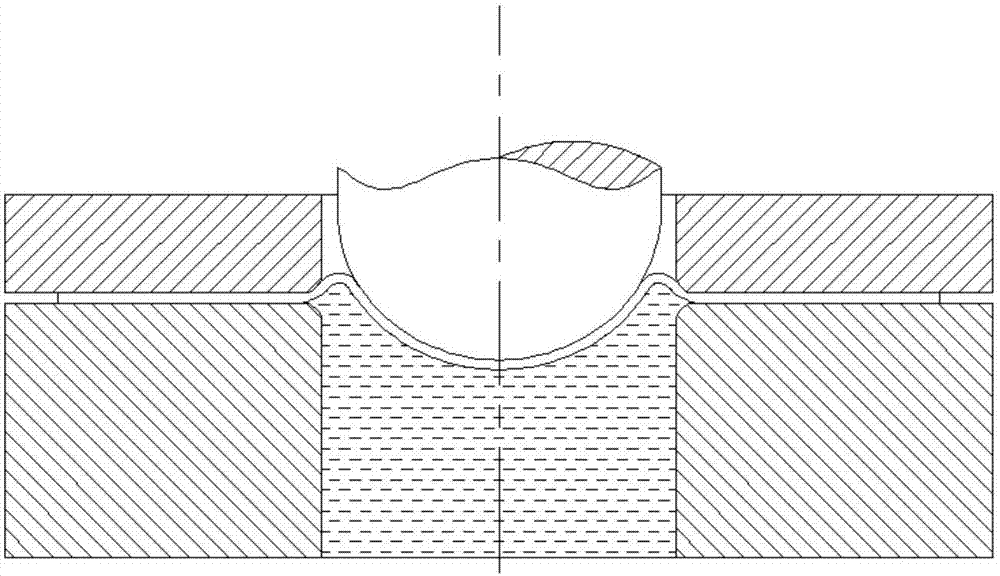

High-energy-rate pulse impact hydraulic-forming method

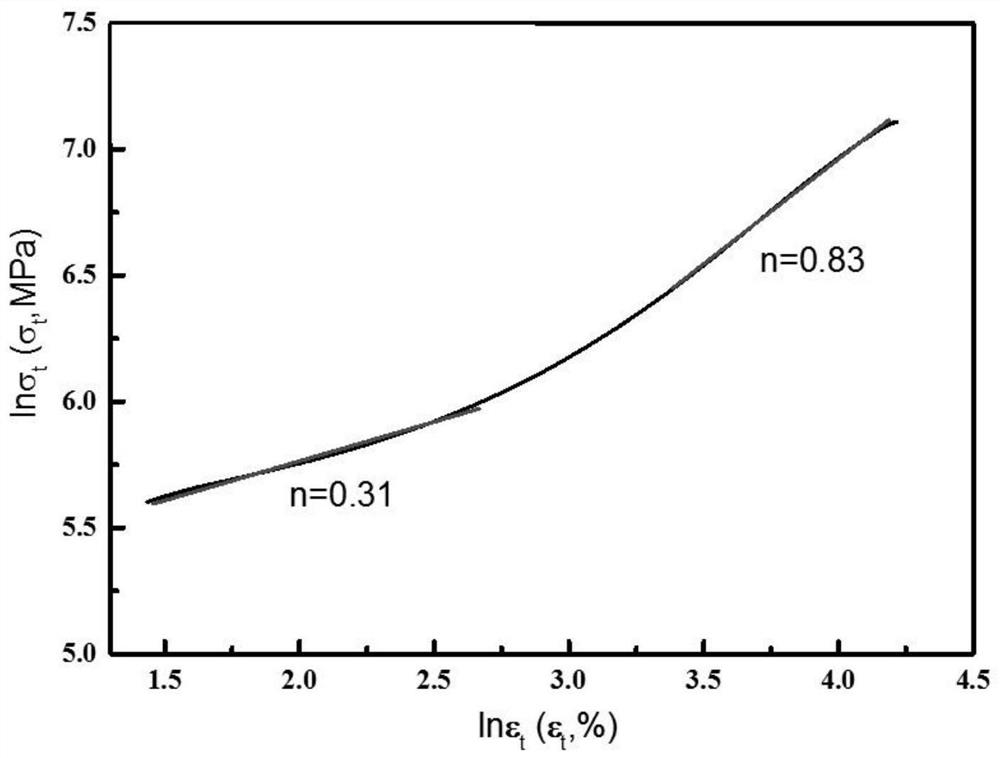

The invention discloses a high-energy-rate pulse impact hydraulic-forming method and belongs to the field of high-speed formation of materials. According to the high-energy-rate pulse impact hydraulic-forming method, the advantages of high-speed impact forming and the advantages of pulse hydraulic forming are combined, and an impact body which moves at a high speed impacts liquid media repeatedly to complete incremental forming of a part. According to the process of each time of impacting, an impact power source drives the impact body to move at a high speed, the impact body which moves at a high speed impacts the liquid media, the kinetic energy of the impact body is instantly converted into the pressure energy of the liquid media, and thus rapid deformation of a workpiece is completed. According to the method, the overall output energy can be controlled accurately, so that the energy transmission rate, namely energy used for workpiece forming, is controlled accurately, and the required part shape is obtained through multiple times of pulse impact; the deformation of each pass can be controlled accurately, the forming time is short, the strain rate of materials is high (10<3>s<1->-10<4>s<-1>), the forming limit of the materials can be increased, and the mold attaching effect is good; and the high-energy-rate pulse impact hydraulic-forming method can be used for precise formation of magnesium alloy, aluminum alloy, titanium alloy and other alloys difficult to deform.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

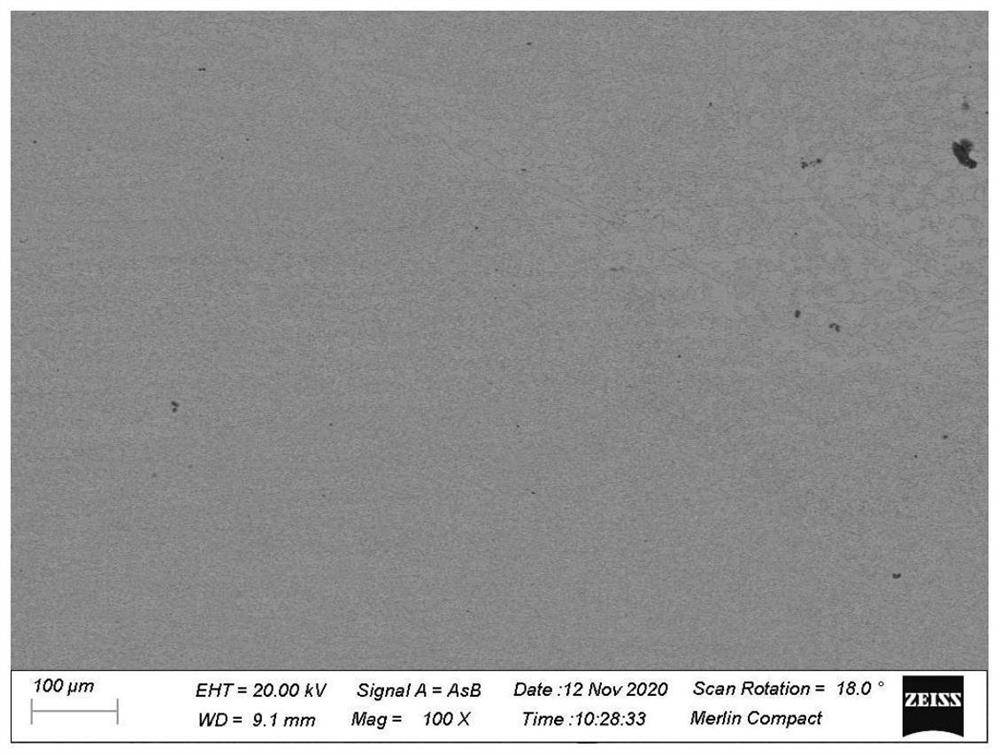

Densification formation type preparation method of nickel-based alloy powder

InactiveCN105921762AOvercome the problem of poor forming and densification abilityStrong forming abilityWater bathsTungstate

The invention discloses a densification formation type preparation method of nickel-based alloy powder. The method is characterized by comprising the following steps: weighting the following components in percentage by mass: 34.3 to 39.4% of nickelous nitrate hexahydrate, 23.9 to 26.9% of chromic nitrate nonahydrate, 1.7 to 2.2% of iron nitrate nonahydrate, 2.5 to 3.1% of ammonium tungstate monohydrate, and 30.7 to 35.4% of oxalic acid; preparing a 300mol solution through nickelous nitrate hexahydrate, chromic nitrate nonahydrate, and ammonium tungstate monohydrate, then heating to reach the temperature of 60 to 85 DEG C, and uniformly stirring; adding 2ml ammonium hydroxide, and stirring for a few minutes; adding iron nitrate nonahydrate and oxalic acid to the solution; maintaining the temperature in a water bath, and uniformly stirring; moving out the solution; naturally cooling to reach the room temperature; filtering and precipitating; drying, filtering and grinding the precipitate; placing the grinded powder into a corundum boat-shaped container; transferring the corundum boat-shaped container into a hydrogenation furnace to reduce at the temperature of 750 DEG C, so as to obtain high-temperature nickel-based alloy powder.

Owner:SHAANXI UNIV OF TECH

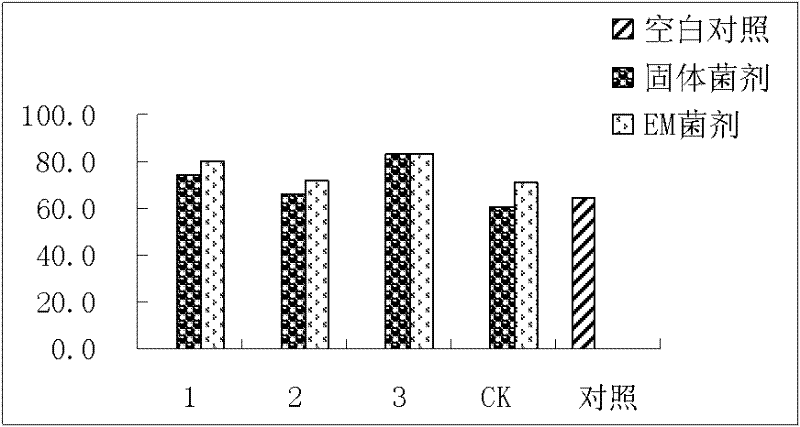

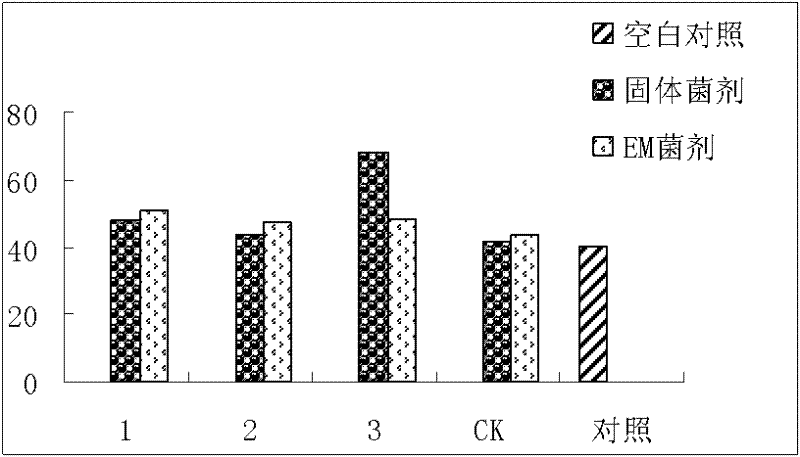

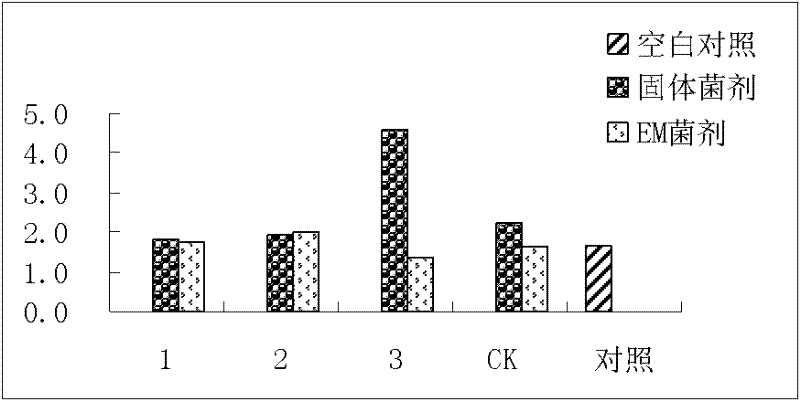

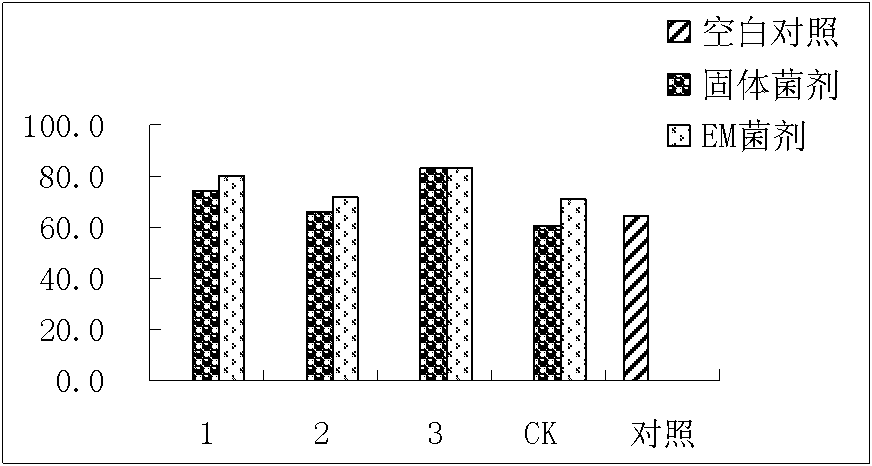

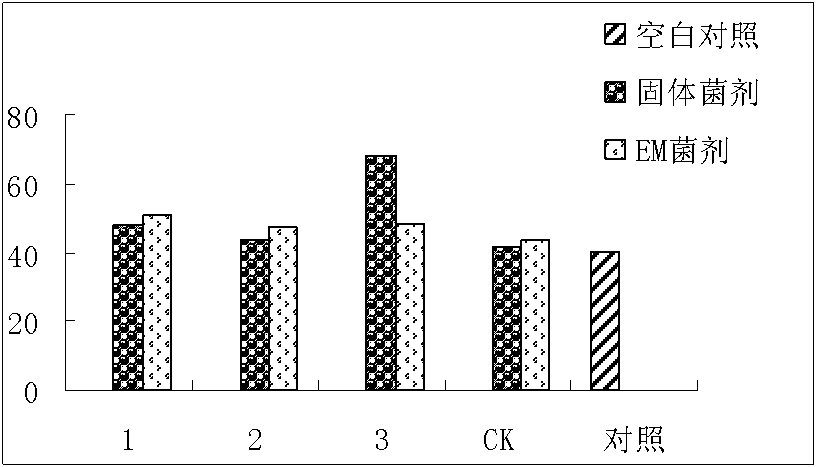

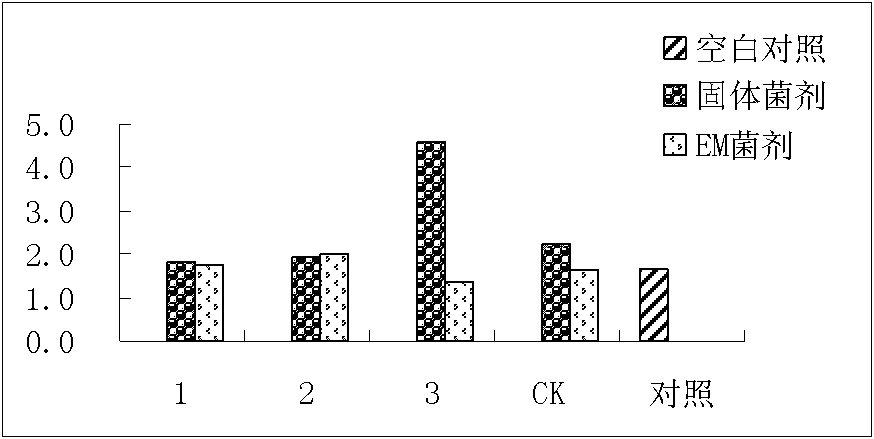

Method for promoting crop straw to become efficiently decomposed by use of alkaline residues and application thereof

InactiveCN102249748ARipe and efficientImprove the value of agricultural useOrganic fertilisersDecompositionNitrogen

A method for promoting crop straw to become efficiently decomposed by the use of alkaline residues and an application thereof. The method provided by the invention comprises the following steps of: crushing the straw and adjusting the water content to 60-70 wt%, adding inocula with uniformly mixing, adjusting the carbon / nitrogen ratio to 20-30 by the use of urea, adding alkaline residues which account for 5-15 wt% of the above mixture, culturing the materials in airtight condition for 50-60 days, ventilating once three days for 5-15 minutes each time, and adjusting the water content within 60-70 wt% during the period. According to the test, peanuts and rice straw are used as raw materials, two inocula are selected, and different levels of alkaline residues are respectively added; the promotion effect of adding different levels of alkaline residues under the condition of constant temperature incubation on the efficient decomposition of straw is studied, so as to provide an appropriate chemical additive for the aerobic composting of straw and raise the agricultural utilization value of straw.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

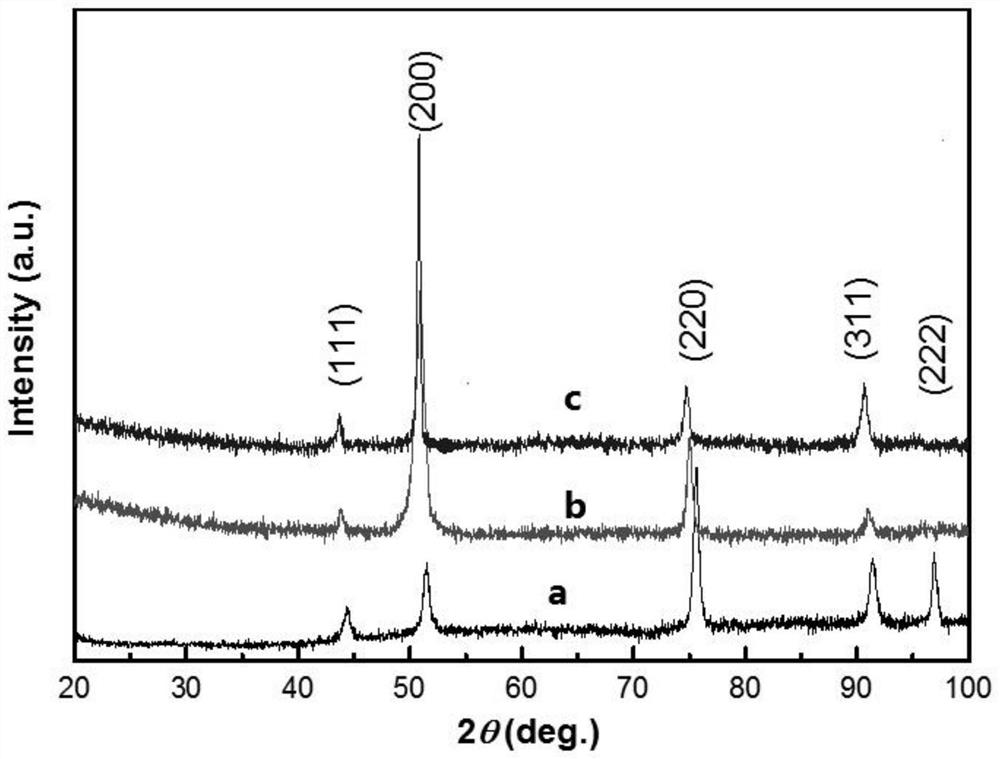

CoCrFeNiMox high-entropy alloy with non-equal atomic ratio and preparation method of CoCrFeNiMox high-entropy alloy

The invention discloses a CoCrFeNiMox high-entropy alloy with a non-equal atomic ratio and a preparation method of the CoCrFeNiMox high-entropy alloy, and relates to the CoCrFeNiMox high-entropy alloy with the non-equal atomic ratio and the preparation method of the CoCrFeNiMox high-entropy alloy. The invention aims to solve the problem that the plasticity of the existing high-entropy alloy is poor, as a result, plastic processing is restricted. The alloy expression is CoCrFeNiMox, x is 0, 2 or 4, and the alloy is prepared from the following raw material components in atomic percent: 0%-20% of Mo, 10%-40% of Co, 10%-40% of Cr, 10%-25% of Fe and 10%-25% of Ni, and the sum of the atomic percent of the components is 100%. CoCrFeNiMox high-entropy alloy is applied to the field of high-entropy alloys.

Owner:HARBIN INST OF TECH

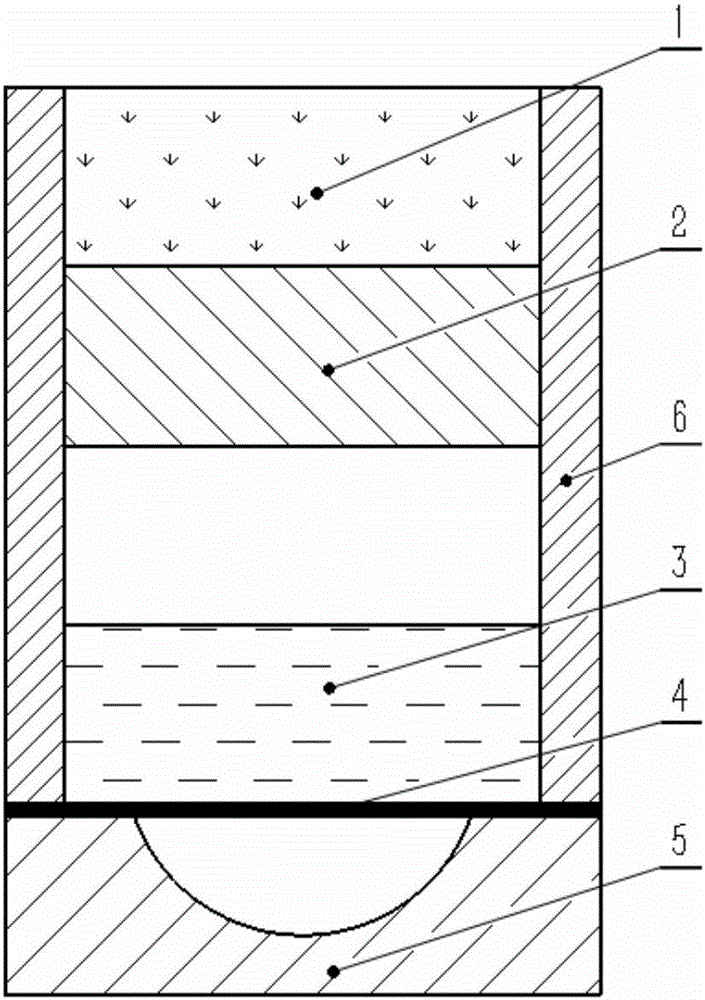

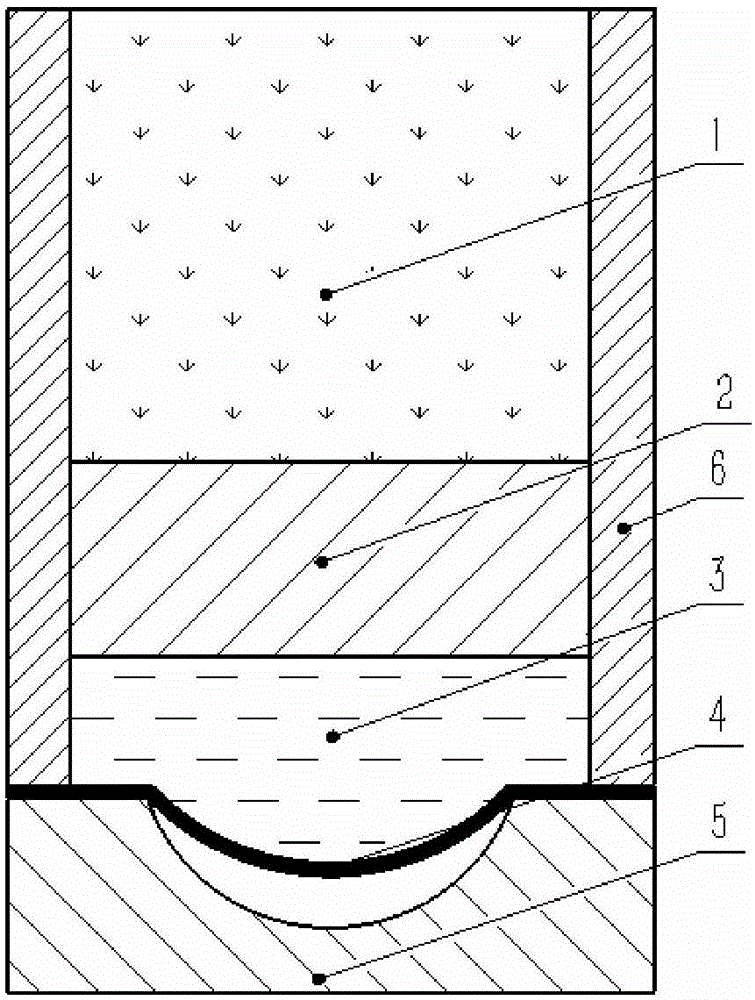

Ultralow-temperature moulding device and method for aluminum and lithium alloy complex curved-surface thin-walled components

PendingCN110722043AImprove forming abilityUniform deformationShaping toolsMoulding deviceThin walled

The invention discloses an ultralow-temperature moulding device and method for aluminum and lithium alloy complex curved-surface thin-walled components. The moulding device comprises a copious coolingtank, a control cabinet, a liquid nitrogen container, a solenoid valve group, a male mould, a female mould, a temperature detector and an edge pressing device; the male mould, the female mould, the temperature detector and the edge pressing device are arranged in the copious cooling tank; the solenoid valve group is arranged on a pipeline which connects the liquid nitrogen container and the copious cooling tank; the solenoid valve group and the temperature detector are both electrically connected to the control cabinet; the edge pressing device is arranged to be capable of pressing a plate blank between the male mould and the female mould; and a tank door is arranged on the copious cooling tank. By adopting a cooling device of the ultralow-temperature moulding device, temperature can be maintained unchanged at any temperature between 0 DEG C to minus 180 DEG C during a moulding process; an ultralow-temperature energy field is provided for the moulding process, so that moulding capability of aluminum and lithium alloy thin plates is greatly improved; deforming is more uniform; thinning and partial corrugating during the moulding process are reduced; and breakage of the components during the moulding process is avoided.

Owner:CENT SOUTH UNIV

Preparation method of new nanometer composite adsorption material

InactiveCN106938191AImprove adsorption capacityStrong forming abilityOther chemical processesWater contaminantsRefrigerated temperaturePollution

The invention discloses a preparation method of a new nanometer composite adsorption material. The preparation method comprises the specific steps of, adding a certain amount of concentrated sulfuric acid in a beaker of 500 mL, in an ice-bath condition, slowly adding potassium permanganate and sodium nitrate, performing full stirring to dissolve potassium permanganate and sodium nitrate, adding expandable graphite while performing uniform stirring, and keeping the beaker in a refrigerator at 273 K for 24 h; and heating the beaker in an oil-bath pot to 308 K, maintaining the temperature while performing stirring for 30 min, slowly dropwise adding deionized water while performing stirring and raising the temperature to 371 K, and maintaining the temperature at 371 K while performing stirring for 15 min. According to the preparation method, agar is taken as a carrier to prepare active carbon / oxidized graphene / agar aerosol. Efficient adsorptive property of active carbon and oxidized graphene is fully developed, easy agglomeration of oxidized graphene is prevented, oxidized graphene with small size is hard to remove from a water body, and the problem of secondary micro-pollution to the water environment is solved.

Owner:QINGDAO UNIV

Magnesium metal plate capable of being quickly rolled and formed and rolling method of magnesium metal plate

The invention belongs to the manufacturing technology of metal materials, and relates to a magnesium metal plate capable of being quickly rolled and formed and a rolling method of the magnesium metal plate. Zn and Er are selected as main alloying elements, the additive amount of Zn is 0-5.0 wt%, the additive amount of Er is 0-1.0 wt%, the sum of the mass percents of Zn and Er is not smaller than 0.5% and not larger than 5.0%, and Mg serves as the balance. The high-temperature rolling temperature interval ranges from 350 to 500 DEG C, and deformation of each pass is 25%-35%. The low-temperature rolling temperature interval ranges from 250 to 350 DEG C and does not include 350 DEG C, and deformation of each pass is 10%-25%. The accumulated deformation of high-temperature rolling and low-temperature rolling is not smaller than 80%. The plate is smooth in surface and edge and free of cracking, and is a metal material of the plate capable of being quickly rolled and formed.

Owner:BEIJING UNIV OF TECH

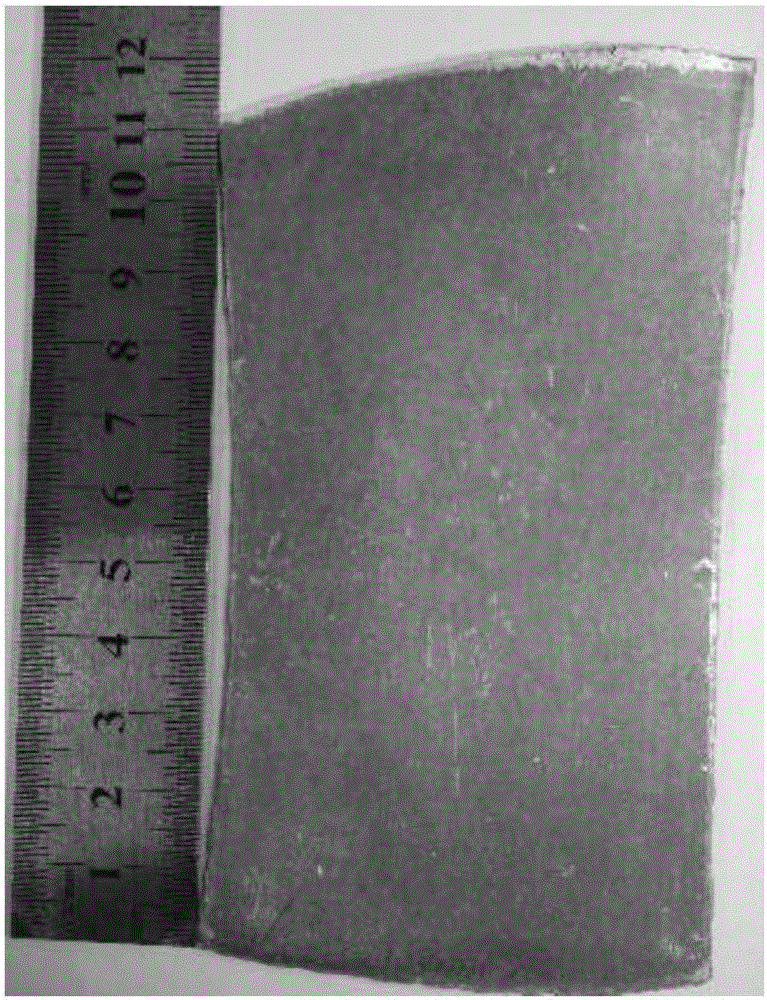

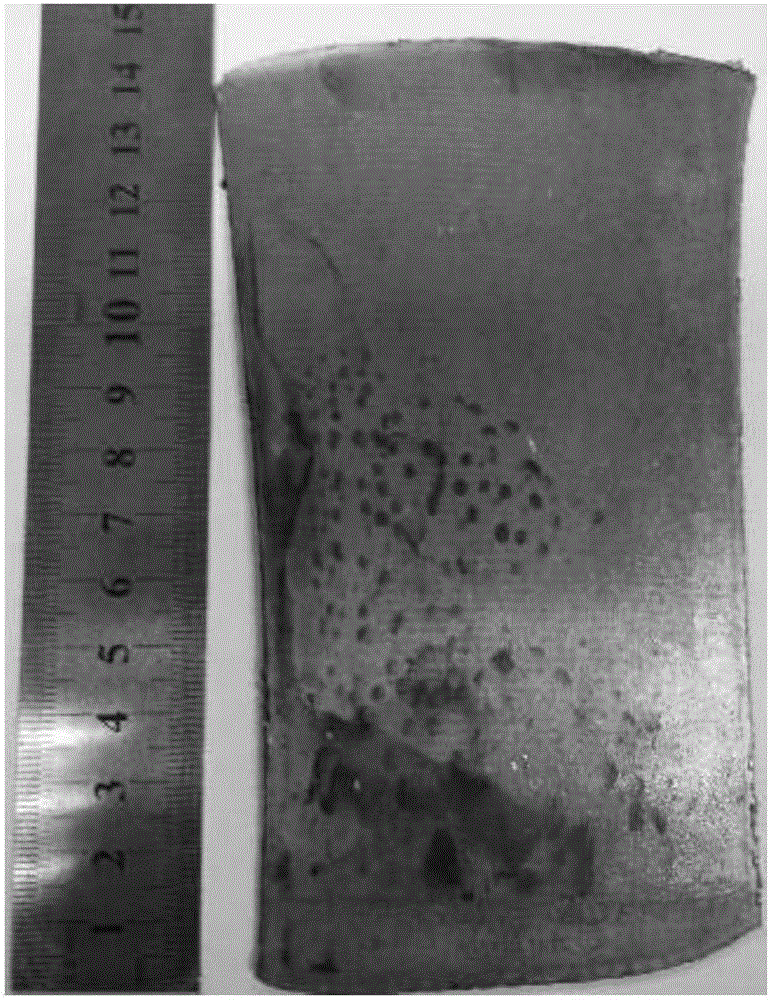

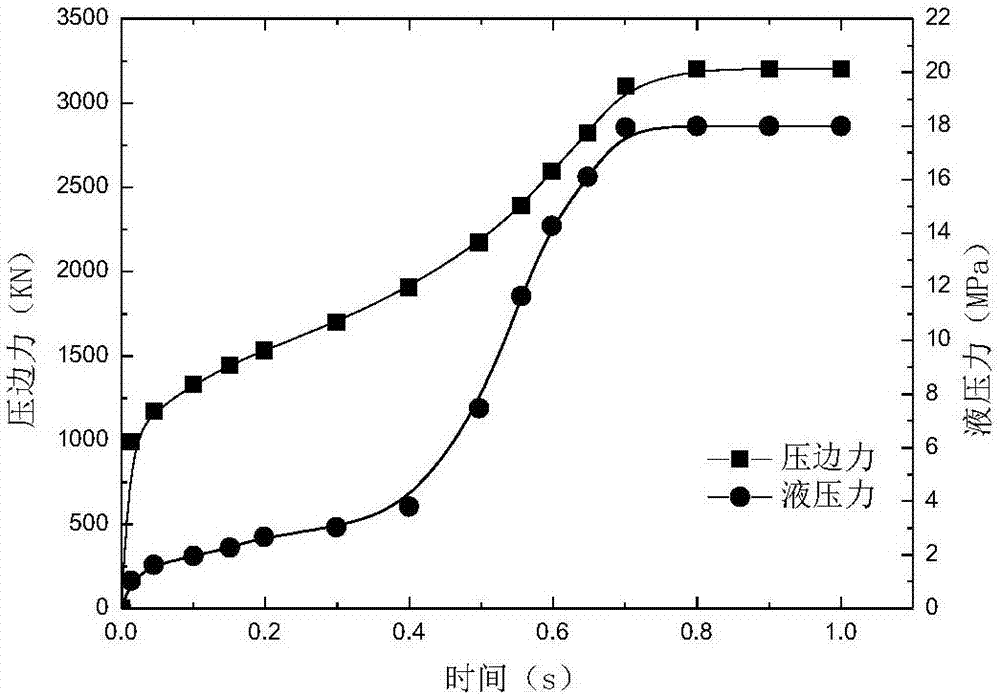

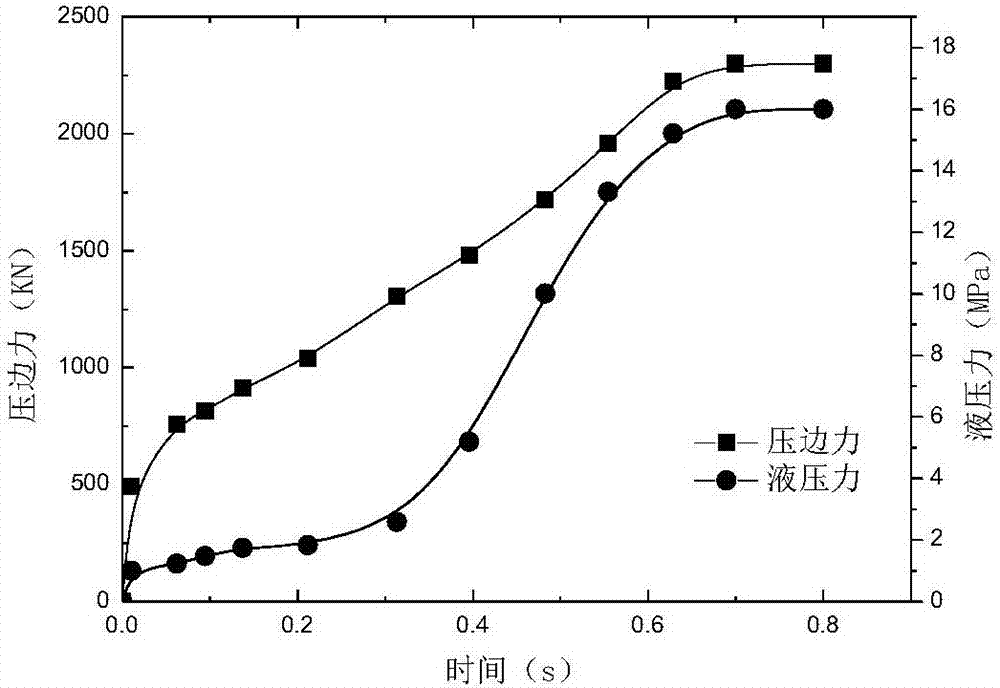

Super-large thin-plate curved-surface part numerical-control hydro-mechanical deep-drawing forming method

The invention relates to a numerically controlled liquid-filled deep-drawing forming method for ultra-large thin plate curved surface parts. According to the different characteristics of each forming stage of liquid-filled deep-drawing, the plate is subjected to liquid-filled drawing by means of an optimized combination of variable blank-holding force and variable hydraulic pressure. deep. Since the sheet metal is very prone to wrinkling and cracking when the relative thickness is very small, because the blank-holding force and hydraulic pressure required for the sheet metal in the forming stage are not the same, this method is used to analyze the blank-holding force and hydraulic pressure at different forming stages. The hydraulic pressure is controlled to avoid wrinkling and cracking during the forming process of the ultra-large sheet. This method greatly improves the forming ability of ultra-large thin plates and the forming quality of parts. And through optimization, the optimal variable blank holder force and variable hydraulic pressure loading curves are obtained. Thereby, the liquid-filled deep drawing process of the ultra-large thin plate is completed.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

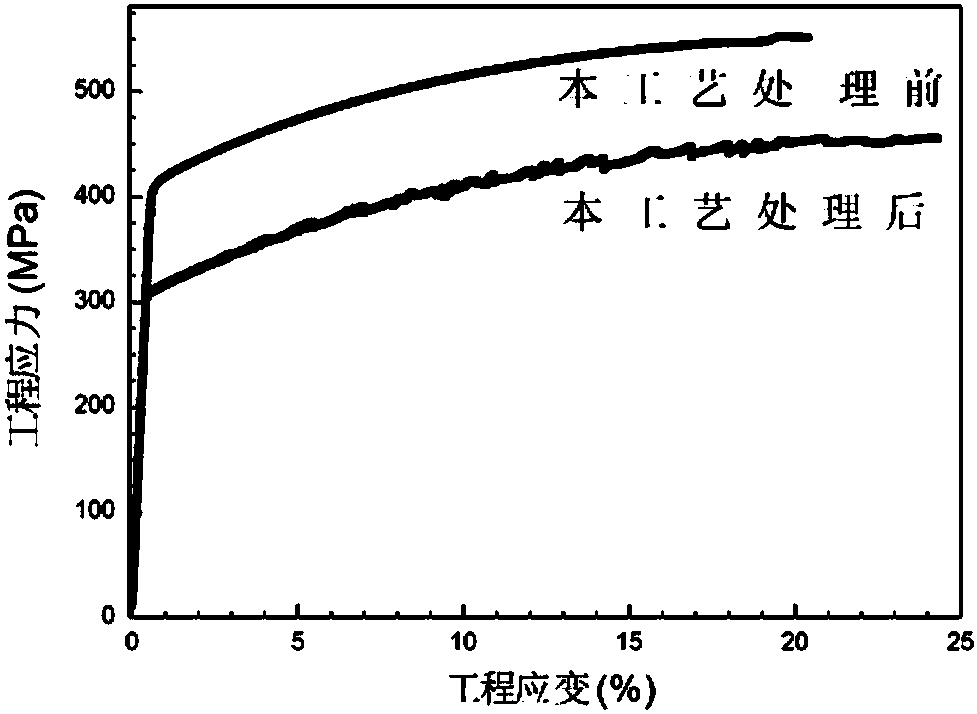

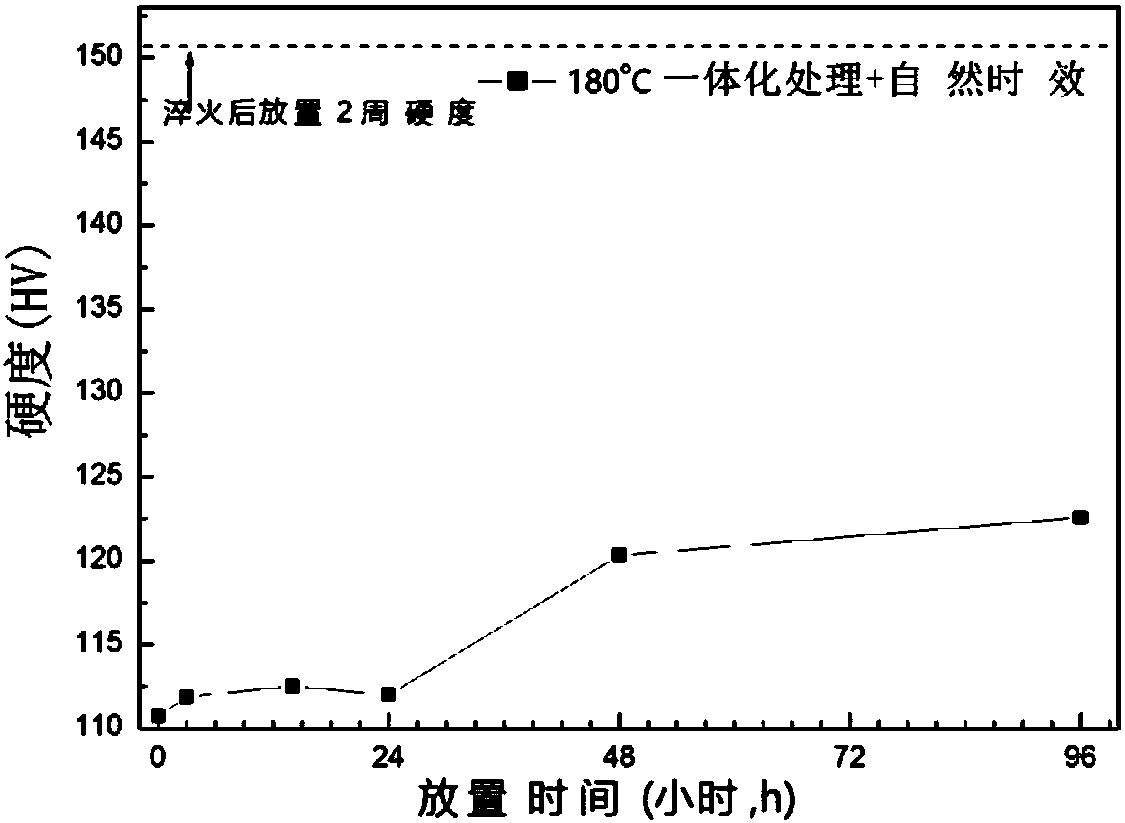

Quenching state restoring-forming integrated process for aluminum alloy

The invention provides a quenching state restoring-forming integrated process for an aluminum alloy. An aluminum alloy plate placed at room temperature is subjected to non-isothermal heating with theheating speed larger than 15 DEG C / min to be heated to 150-210 DEG C, and then is immediately transferred onto a forming device within 1-2 min, and a formed component is subjected to aging heat treatment reinforcement within 1 day. By means of the process, the aluminum alloy stored at room temperature for a long time can restore to the state close to the quenching state, strength is remarkably lowered, the forming capacity is improved, and the integrated process is favorable for coordinated control of the high-strength aluminum alloy.

Owner:CENT SOUTH UNIV

Non-equal-atomic-ratio high-entropy alloy and method for preparing wire by using same

The invention belongs to the technical field of high-entropy alloy wires and preparation, and discloses a non-equal-atomic-ratio high-entropy alloy, a wire and a preparation method thereof. The preparation raw materials are Fe, Mn, Cr and Ni metal particles, and the preparation method comprises the steps that the metal particles are weighed according to the set proportion and melted and poured in a vacuum induction melting furnace, and a non-equal-atomic-ratio high-entropy alloy ingot is prepared; and homogenization heat treatment is carried out on an as-cast non-equal-atomic-ratio high-entropy alloy ingot prepared at an initial stage, then hot rotary swaging is carried out to form a bar, then rolling is carried out through an end rolling machine, and high-temperature annealing and multi-pass drawing are carried out to obtain the wire. The preparation process of the non-equal-atomic-ratio high-entropy alloy wire prepared through the method is simple, any intermediate annealing treatment and surface treatment do not need to be interspersed in the wire drawing process, and the production process of the wire is greatly simplified.

Owner:SOUTHEAST UNIV

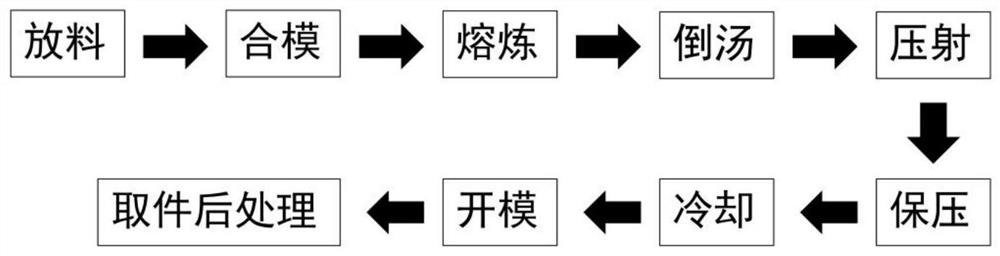

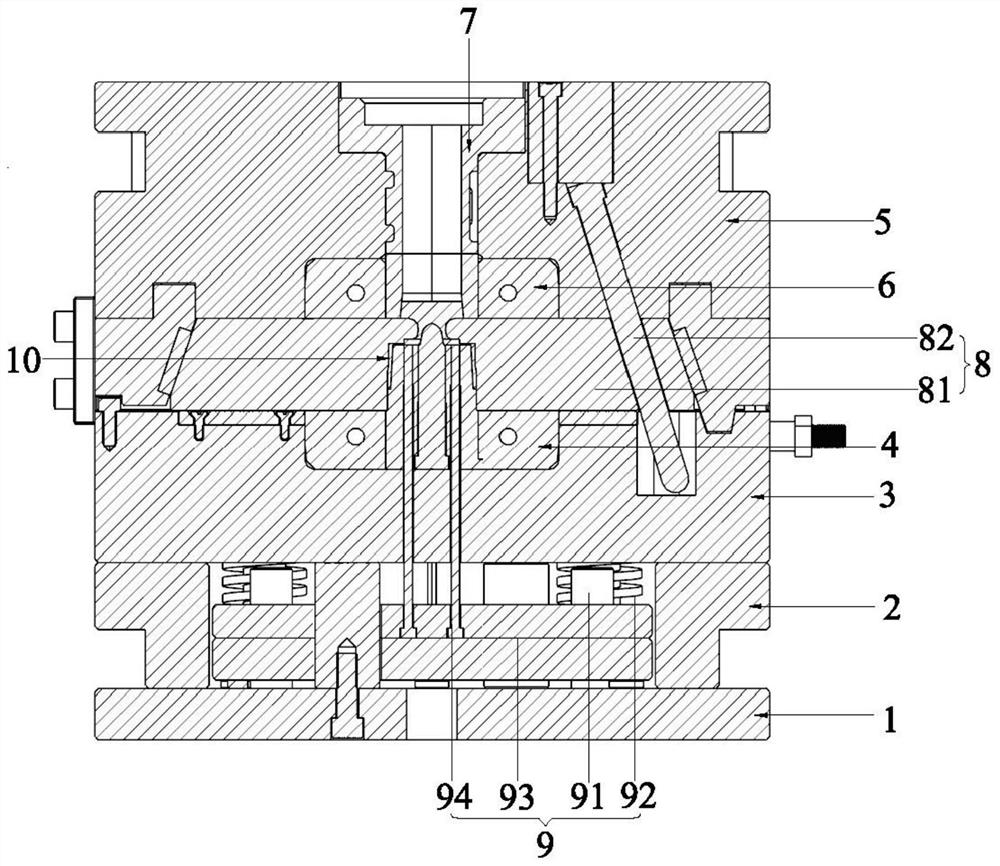

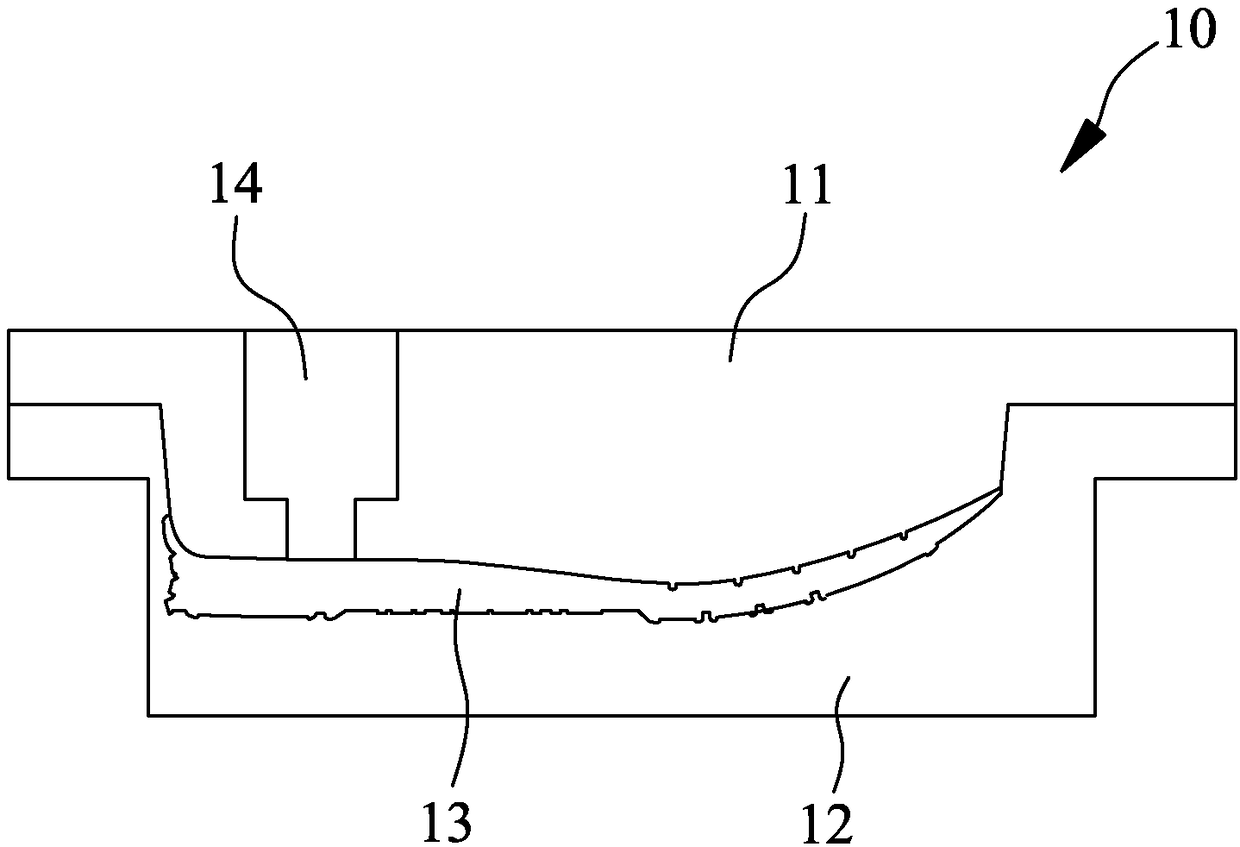

Vacuum die-casting die and method for amorphous alloy flexible gear of harmonic reducer

The invention discloses a vacuum die-casting die and method for an amorphous alloy flexible gear of a harmonic reducer. The vacuum die-casting die comprises a vacuum box, a bottom plate, square iron,a male die plate, a male die core, a female die plate, a female die core, a sprue bush, a core-pulling assembly and an ejection mechanism, wherein the bottom plate, the square iron, the male die plate, the male die core, the female die plate, the female die core, the sprue bush, the core-pulling assembly and the ejection mechanism are arranged in the vacuum box body. The vacuum die-casting methodis simple in step and easy to achieve; an amorphous alloy material of a Zr-based system is reasonably selected for die casting, fluidity is good, the pouring temperature is low, and the forming capacity is high; and the whole die is placed in a vacuum environment in a matched manner, and it is effectively guaranteed that the amorphous alloy material cannot be easily oxidized or crystallized in thedie casting process. The vacuum die-casting die is reasonable in structure, the manufactured flexible gear has better surface smoothness and dimensional precision, only a small number of post-processing procedures are needed in the subsequent process, the production period is greatly shortened, the machining cost is reduced, in addition, the yield strength and fatigue strength are higher, and theservice life is long.

Owner:SONGSHAN LAKE MATERIALS LAB +1

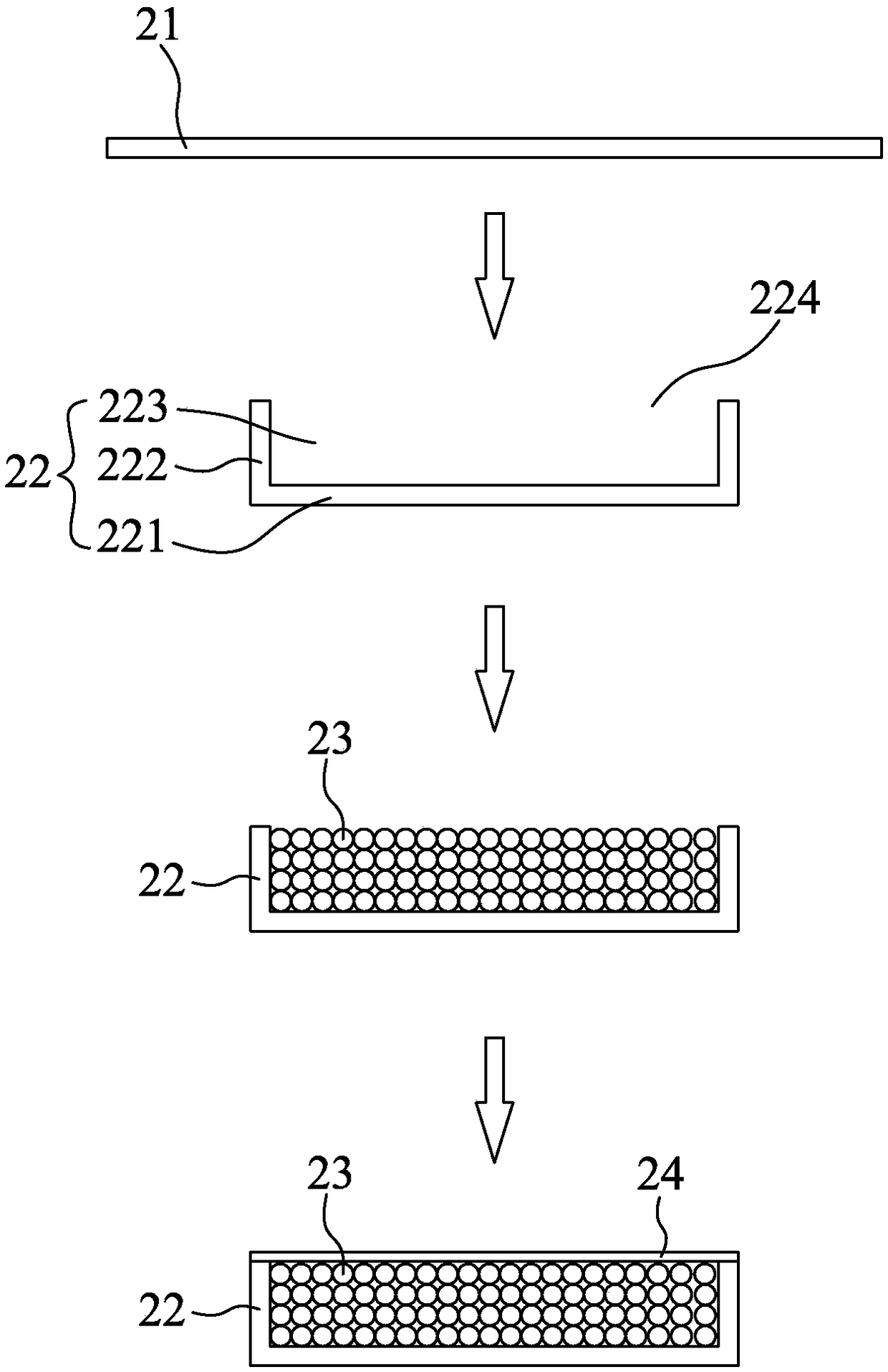

Plastic sucking moulding process for damping insole

InactiveCN108544775AImprove molding efficiencyImprove forming abilityDomestic footwearHardnessMechanical engineering

The invention discloses a plastic sucking moulding process for a damping insole, the plastic sucking moulding process comprises the following steps: 1, processing a TPU film with a thickness of 1.0 mmto 4.0 mm from a TPU material having a Shore hardness of 55 A to 75 A; 2, heating and softening the TPU film, placing the TPU film in a plastic sucking machine for plastic sucking moulding, cooling and shaping to obtain a TPU container having a bottom wall and a side wall, wherein the TPU container has an upper opening, and the bottom wall and the side wall form a cavity; 3, fully adding ETPU particles into the cavity of the TPU container; and 4, covering the upper opening of the TPU container with the TPU film with a thickness of 0.03 mm to 0.1 mm, and connecting the TPU film with the side wall of the TPU container to form the damping insole. Compared with the prior art, the plastic sucking moulding process is applied to the field of shoemaking, and greatly improves the forming efficiency.

Owner:FUJIAN XINGXUN NEW MATERIALS TECH CO LTD

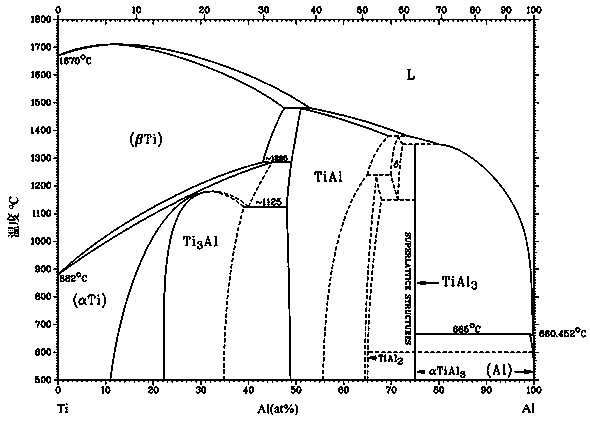

Ti-Al-based alloy with good additive manufacturing forming property and application thereof

InactiveCN107723517ASmall liquid-solid regionIncrease the amount of controlAdditive manufacturing apparatusManufactured formManufacturing technology

The invention discloses Ti-Al-based alloy with the good additive manufacturing forming property and application of the Ti-Al-based alloy, and belongs to the technical field of metal additive manufacturing. The ingredients of the Ti-Al-based alloy are originated from a two-cluster alloy ingredient design model, the alloy element atomic percent (at.%) expression is shown in the description, whereinthe single or mixture total content of Ti, V, Nb, Ta, Zr, Hf and Mo elements is 2.9+ / -0.5 at.%, the single or mixture total content of Al and Sn elements is 11.8+ / -1.0 at.%, the total content of otherelements is controlled within 1 at.%, the main alloying element of the alloy is the Al element, the oxidation resistance and melt stability of alloy melt and flowability can be improved, and the alloy has good melt and solid structure consistency, and can be used for additive manufacturing forming.

Owner:DALIAN UNIV OF TECH

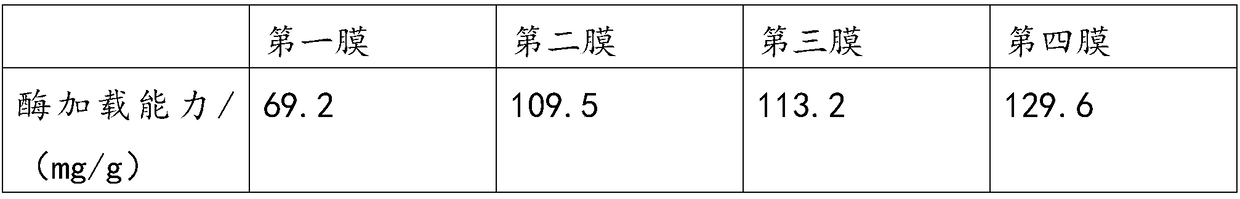

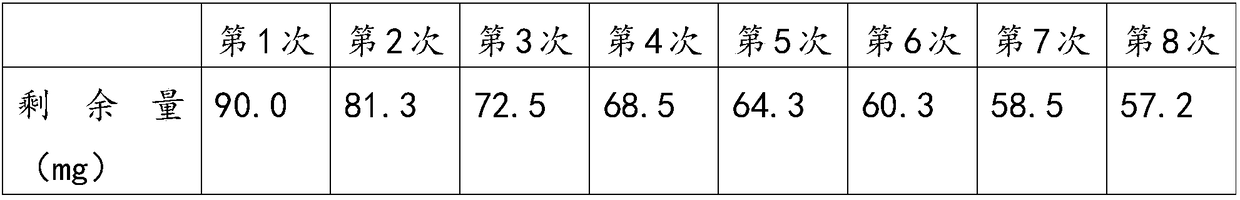

Preparation method of composite nanofiber membrane, composite nanofiber membrane, application of composite nanofiber membrane to enzyme immobilization and immobilized enzyme

ActiveCN108754871AImprove the nano effectGood enzyme loading capacityElectro-spinningOn/in organic carrierComposite nanofibersNanofiber

The invention belongs to the field of nanofiber membranes, and particularly relates to a preparation method of a composite nanofiber membrane, the composite nanofiber membrane, application of the composite nanofiber membrane to enzyme immobilization and an immobilized enzyme. An electrostatic spinning solution containing chitosan is adopted for preparing the nanofiber membrane, and the membrane has a good film-forming property and an enzyme-immobilizing function; meanwhile, polypeptide nanofibers are adopted and loaded onto the membrane, in this way, the property of the membrane is further improved, and the enzyme-immobilizing property of the membrane is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

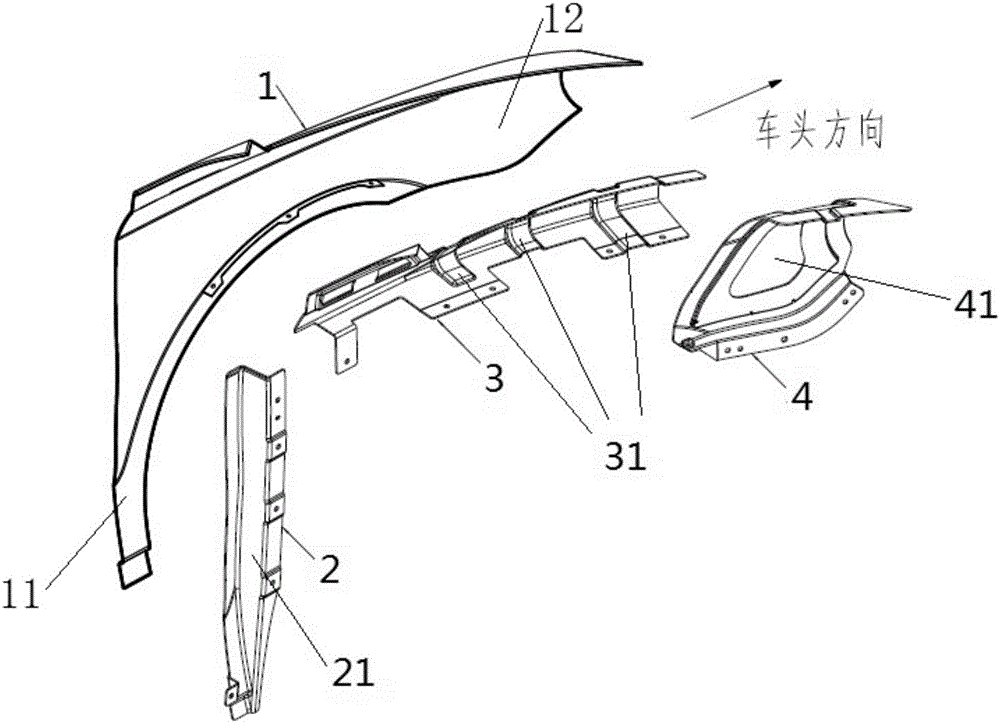

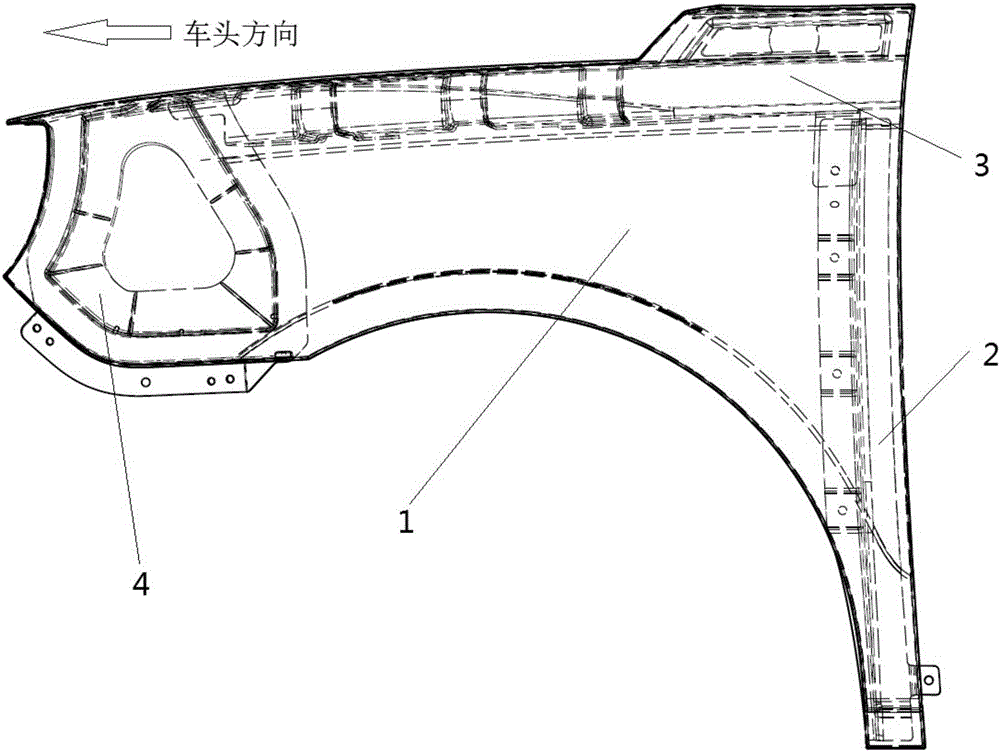

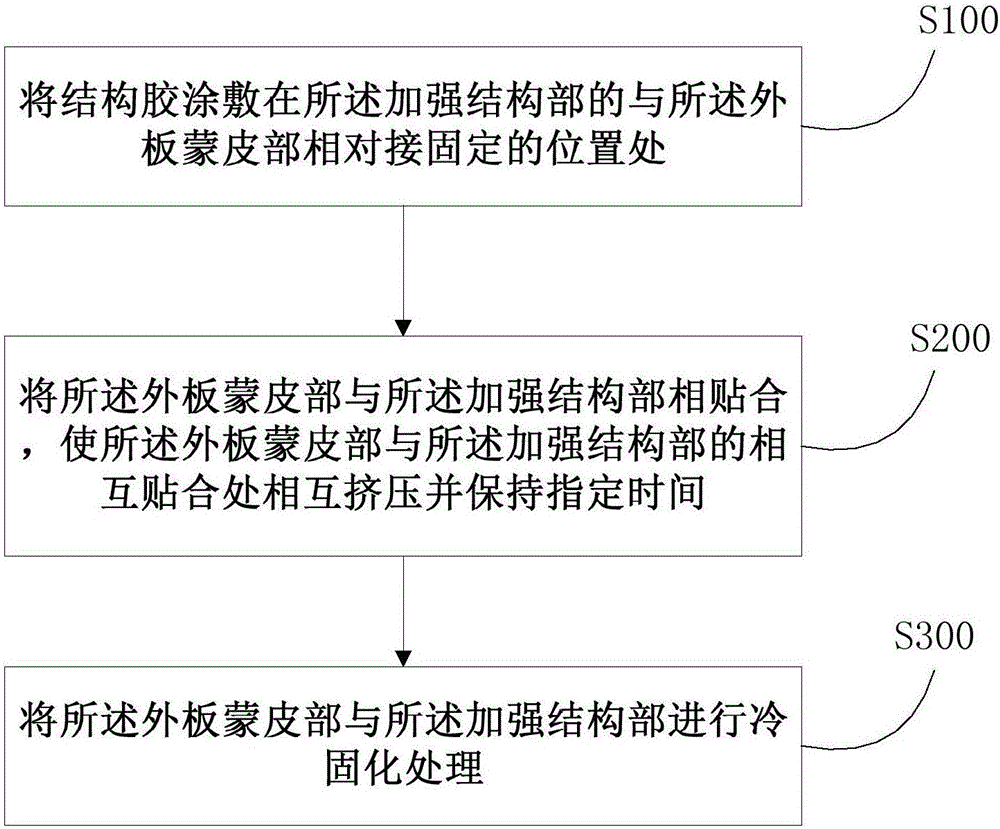

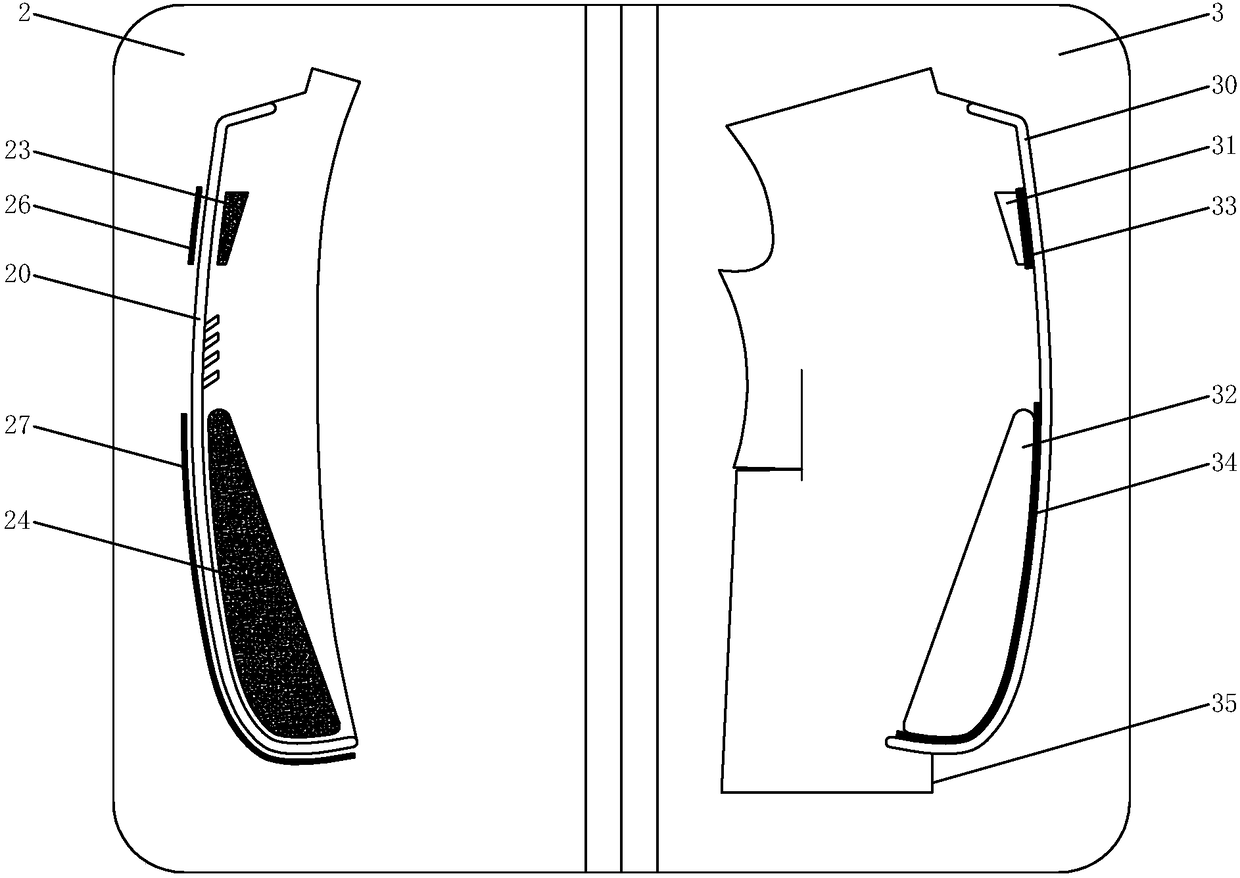

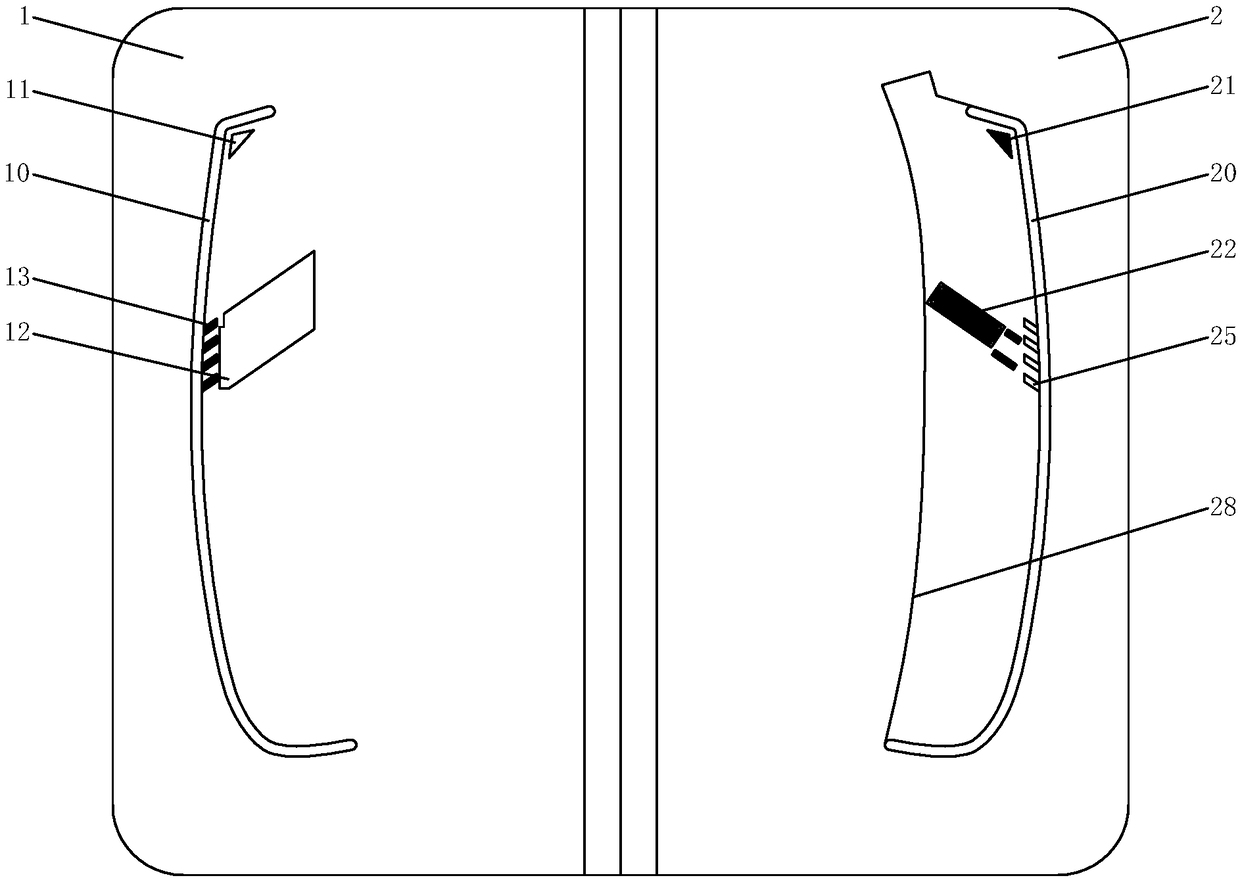

Fender structure for vehicle and assembling method thereof

ActiveCN106364573AReduce development investmentImprove forming abilitySuperstructure subunitsFenderMechanical property

The invention provides a fender structure for a vehicle and an assembling method thereof, and relates to the fender structure. The fender structure comprises an outer plate skin part and a reinforcing structure part, wherein the outer plate skin part is used for shielding a wheel of the vehicle and made of SMC materials through mold pressing; and the reinforcing structure part is used for enhancing the mechanical property of the outer plate skin part and formed on the inner side, facing a vehicle body, of the outer plate skin part, and the reinforcing structure part is made of SMC materials through mold pressing. Compared with a fender made of steel in the prior art, a fender composed of the outer plate skin part and the reinforcing structure part both made of the SMC materials is lower in weight, the weight is relatively reduced by 15%-20%, and thus the weight of the vehicle body is greatly lowered; and the mold-pressing process is adopted, the mold development investment is reduced by about 65% compared with steel molds.

Owner:ZHEJIANG GEELY NEW ENERGY COMML VEHICLES CO LTD +1

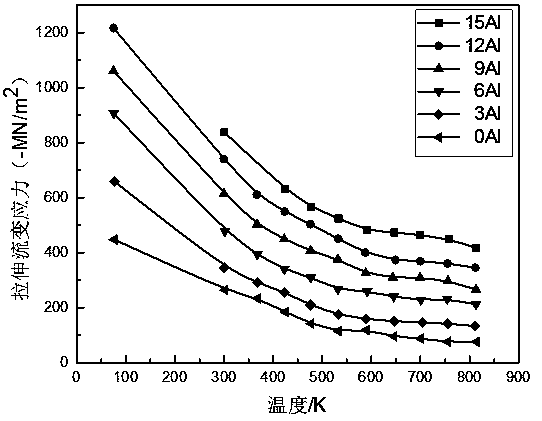

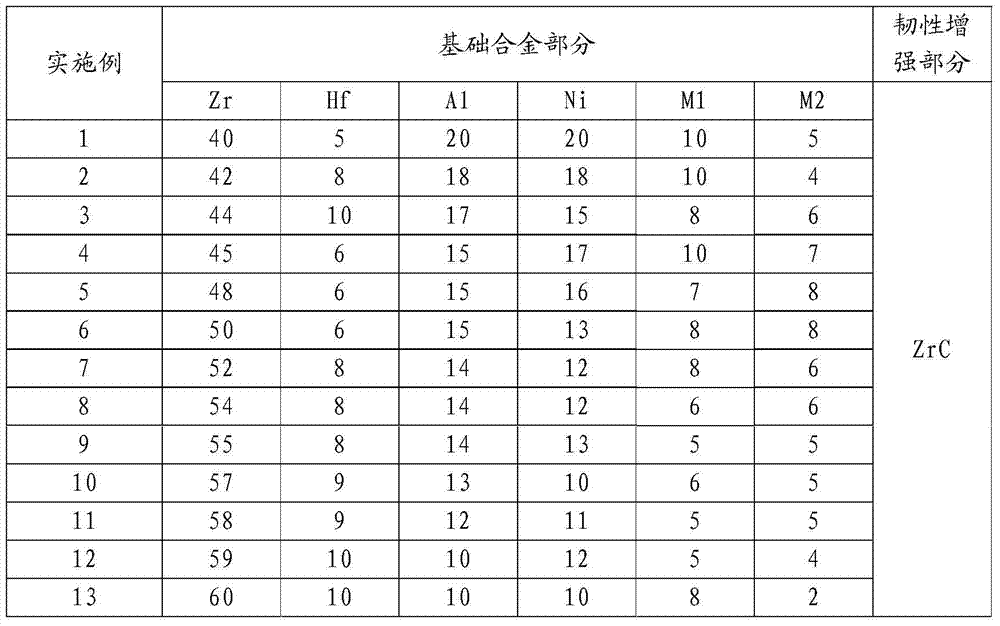

A kind of high toughness amorphous composite material and its preparation method and application

The invention discloses a high-toughness amorphous composite material and its preparation method and application. The amorphous composite material is prepared from a base alloy part and a toughness enhancing part; the element composition and atomic mole percentage of the base alloy part are: Zr: 45‑65%, Hf: 5‑15%, Al: 10‑20%, Ni: 10‑20%, M1 component: 5‑10%, M2 component: 2‑8%; the M1 group Divided into one or more of Sn, Bi, Si, Cu elements; the M2 component is one or two of Ag, Pd elements; the purity of each element in the basic alloy part is greater than 99.9%; the toughness enhancement part is One or more of WC, SiC, TiC, TiN, ZrC nano-powders, the amount added is 2-10% of the volume of the above-mentioned base alloy. The amorphous composite material in the invention has good impact toughness, and has high toughness and impact resistance without mechanical processing.

Owner:DONGGUAN EONTEC CO LTD +1

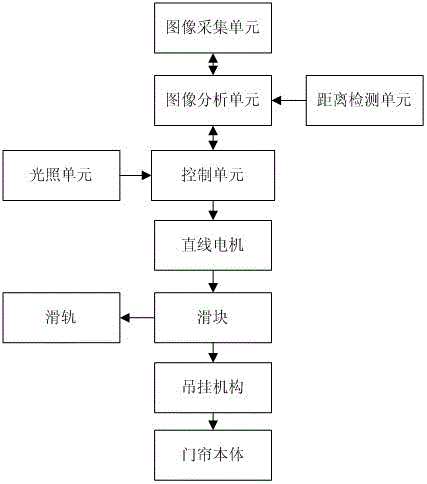

A door curtain automatic control push system based on image acquisition

ActiveCN104323690BImprove the effect of air barrierImprove stabilityCurtain accessoriesAutomatic controlControl unit

Owner:WUXI WISEN INNOVATION TECH

Preparation method of nickel-based alloy powder capable of densification and forming

InactiveCN105921762BOvercome the problem of poor forming and densification abilityShorten the interatomic distanceWater bathsTungstate

The invention discloses a densification formation type preparation method of nickel-based alloy powder. The method is characterized by comprising the following steps: weighting the following components in percentage by mass: 34.3 to 39.4% of nickelous nitrate hexahydrate, 23.9 to 26.9% of chromic nitrate nonahydrate, 1.7 to 2.2% of iron nitrate nonahydrate, 2.5 to 3.1% of ammonium tungstate monohydrate, and 30.7 to 35.4% of oxalic acid; preparing a 300mol solution through nickelous nitrate hexahydrate, chromic nitrate nonahydrate, and ammonium tungstate monohydrate, then heating to reach the temperature of 60 to 85 DEG C, and uniformly stirring; adding 2ml ammonium hydroxide, and stirring for a few minutes; adding iron nitrate nonahydrate and oxalic acid to the solution; maintaining the temperature in a water bath, and uniformly stirring; moving out the solution; naturally cooling to reach the room temperature; filtering and precipitating; drying, filtering and grinding the precipitate; placing the grinded powder into a corundum boat-shaped container; transferring the corundum boat-shaped container into a hydrogenation furnace to reduce at the temperature of 750 DEG C, so as to obtain high-temperature nickel-based alloy powder.

Owner:SHAANXI UNIV OF TECH

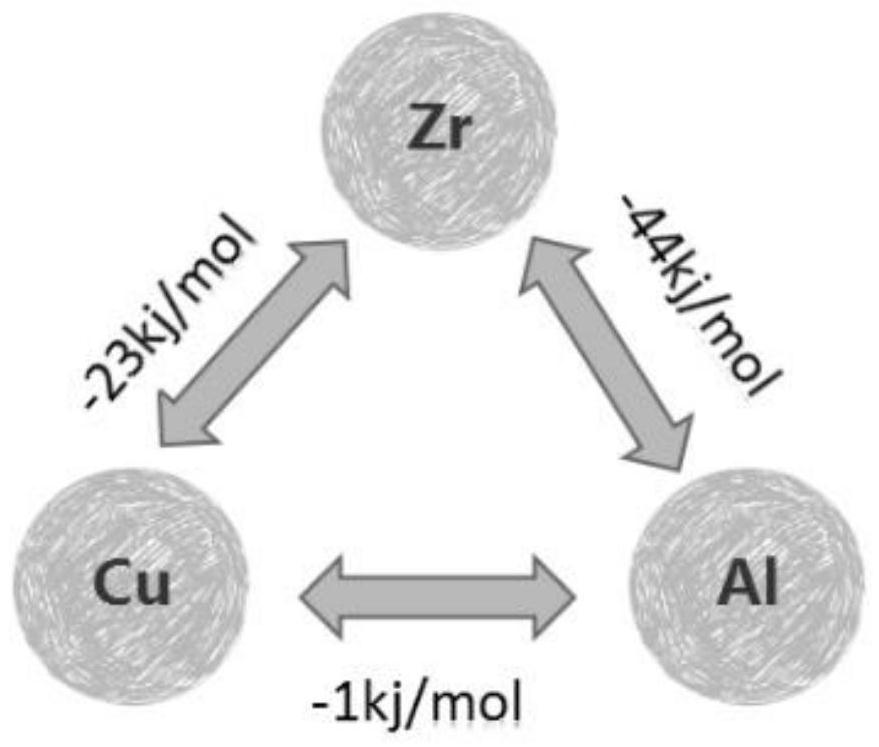

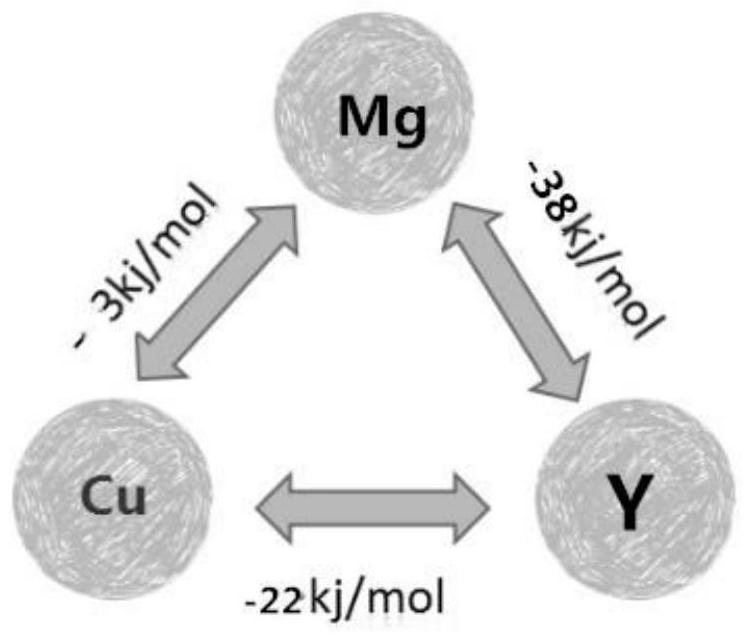

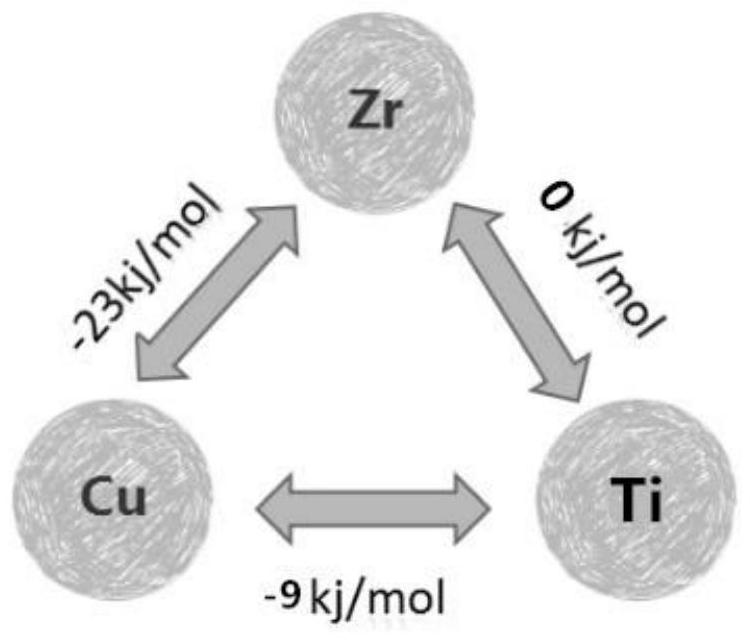

A Calculation Method of Maximum Negative Mixing Enthalpy of Ternary Amorphous Alloy

ActiveCN108985004BAvoid wastingImprove forming abilityChemical processes analysis/designChemical physicsPhysical chemistry

Owner:GUANGDONG UNIV OF TECH

A kind of preparation method of nanocomposite adsorption material

InactiveCN106938191BImprove adsorption capacityImprove forming abilityOther chemical processesWater contaminantsActivated carbonAdhesive

Owner:QINGDAO UNIV

Preparation method of carbon quantum dot containing calcium alginate gel for detecting copper ions

InactiveCN102964608BCause secondary pollutionImprove forming abilityFluorescence/phosphorescenceLuminescent compositionsAtherion elymusPhysical chemistry

Owner:ZHONGBEI UNIV

Non-equiatomic ratio high-entropy alloy and method for preparing wire using the same

The invention belongs to the technical field of high-entropy alloy wire and its preparation, and discloses a non-isoatomic ratio high-entropy alloy, wire and a preparation method thereof. The preparation raw materials are Fe, Mn, Cr, and Ni metal particles, and the preparation method is as follows: The above-mentioned metal particles are weighed according to the set ratio, melted and poured in a vacuum induction melting furnace, and prepared into a non-isoatomic ratio high-entropy alloy ingot; Then it is hot swiveled into a rod, then rolled by an end mill, annealed at high temperature, and drawn in multiple passes to obtain a wire. The preparation process of the non-isoatomic ratio high-entropy alloy wire prepared by the invention is simple, and no intermediate annealing treatment and surface treatment are interspersed in the wire drawing process, which greatly simplifies the production process of the wire.

Owner:SOUTHEAST UNIV

A kind of rapid rolling formable magnesium metal plate and its rolling method

The invention belongs to the manufacturing technology of metal materials, and relates to a magnesium metal plate capable of being quickly rolled and formed and a rolling method of the magnesium metal plate. Zn and Er are selected as main alloying elements, the additive amount of Zn is 0-5.0 wt%, the additive amount of Er is 0-1.0 wt%, the sum of the mass percents of Zn and Er is not smaller than 0.5% and not larger than 5.0%, and Mg serves as the balance. The high-temperature rolling temperature interval ranges from 350 to 500 DEG C, and deformation of each pass is 25%-35%. The low-temperature rolling temperature interval ranges from 250 to 350 DEG C and does not include 350 DEG C, and deformation of each pass is 10%-25%. The accumulated deformation of high-temperature rolling and low-temperature rolling is not smaller than 80%. The plate is smooth in surface and edge and free of cracking, and is a metal material of the plate capable of being quickly rolled and formed.

Owner:BEIJING UNIV OF TECH

Western-style clothes front shirt and liner molding die and manufacturing method thereof

PendingCN108577001AGuaranteed flatnessGuaranteed fitJacketsClothes making applicancesEngineeringMechanical engineering

Owner:FUJIAN SEVEN FASHION TECH CO LTD

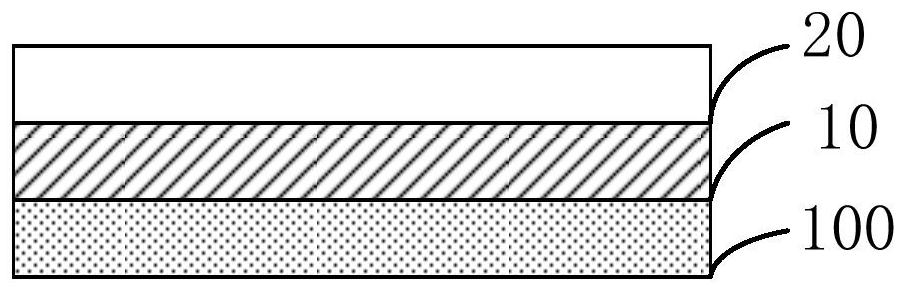

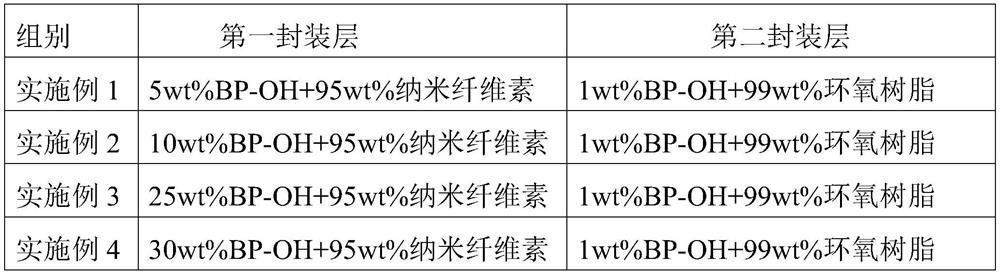

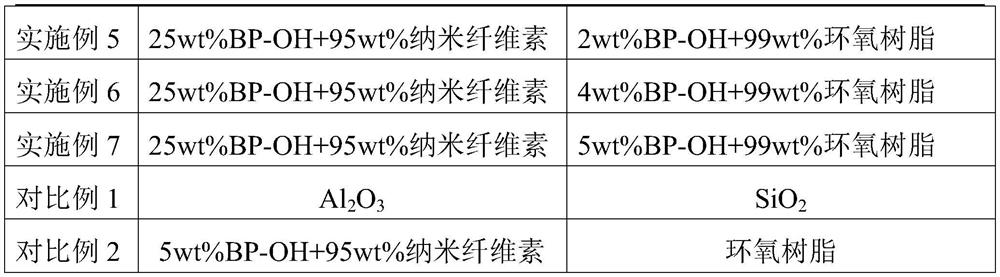

Thin film packaging structure and preparation method and application thereof

PendingCN114122280AHigh water and oxygen barrierEvenly dispersedSolid-state devicesSemiconductor/solid-state device manufacturingPolymer scienceThin membrane

The invention provides a thin film packaging structure. The thin film packaging structure comprises a first packaging layer used for covering a structure to be packaged; the second packaging layer is formed on the first packaging layer; wherein the first packaging layer comprises a modified layered two-dimensional material and nanocellulose, the second packaging layer comprises a modified layered two-dimensional material and a polymer water-blocking oxygen film-forming material, and the surface of the modified layered two-dimensional material contains hydroxyl or amino. And the content of the modified layered two-dimensional material in the first packaging layer is greater than or equal to that of the modified layered two-dimensional material in the second packaging layer. The invention also provides a preparation method of the thin film packaging structure. The invention further provides a light-emitting device which comprises the thin film packaging structure.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

Method for promoting crop straw to become efficiently decomposed by use of alkaline residues and application thereof

InactiveCN102249748BRipe and efficientImprove the value of agricultural useOrganic fertilisersAgricultural engineeringAgricultural crops

A method for promoting crop straw to become efficiently decomposed by the use of alkaline residues and an application thereof. The method provided by the invention comprises the following steps of: crushing the straw and adjusting the water content to 60-70 wt%, adding inocula with uniformly mixing, adjusting the carbon / nitrogen ratio to 20-30 by the use of urea, adding alkaline residues which account for 5-15 wt% of the above mixture, culturing the materials in airtight condition for 50-60 days, ventilating once three days for 5-15 minutes each time, and adjusting the water content within 60-70 wt% during the period. According to the test, peanuts and rice straw are used as raw materials, two inocula are selected, and different levels of alkaline residues are respectively added; the promotion effect of adding different levels of alkaline residues under the condition of constant temperature incubation on the efficient decomposition of straw is studied, so as to provide an appropriate chemical additive for the aerobic composting of straw and raise the agricultural utilization value of straw.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com