Magnesium metal plate capable of being quickly rolled and formed and rolling method of magnesium metal plate

A magnesium metal and rapid technology, which is applied to the rolling forming process of magnesium alloy alloy sheets and the field of metal material manufacturing, to achieve the effects of strong forming ability, simple processing method and fast deformation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

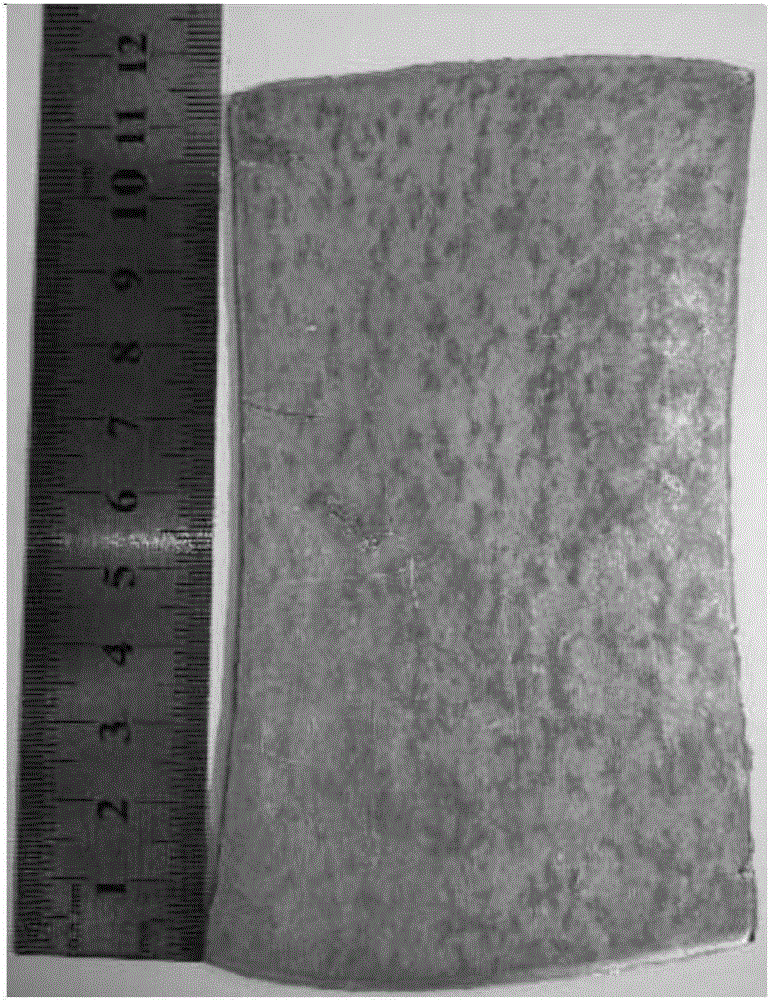

[0028] The Mg-0.5Zn-0.5Er alloy obtained by ordinary casting is solution-treated, and then cut and milled to obtain a rolling blank, and the blank is placed in a holding furnace for treatment, and the temperature of the holding furnace is 400°C. Set rolling speed to 2.0m / s. First, the rolling temperature is 400°C, the deformation in the first pass is 30%, and then the second rolling is carried out, the deformation is 25%, and the above rolling direction is 0°; then the alloy Place it in a 345°C holding furnace for heat preservation for 15 minutes, and then roll the alloy in a low-temperature stage at a rolling temperature of 345°C, with a single-pass deformation of 10% and a rolling direction of 90°. 2 passes; then place the alloy in a holding furnace for heat preservation, the heat preservation temperature is 300°C, and the heat preservation time is 30 minutes, and the heat-preserved alloy continues to be rolled at a low temperature stage, the rolling temperature is 300°C, an...

Embodiment 2

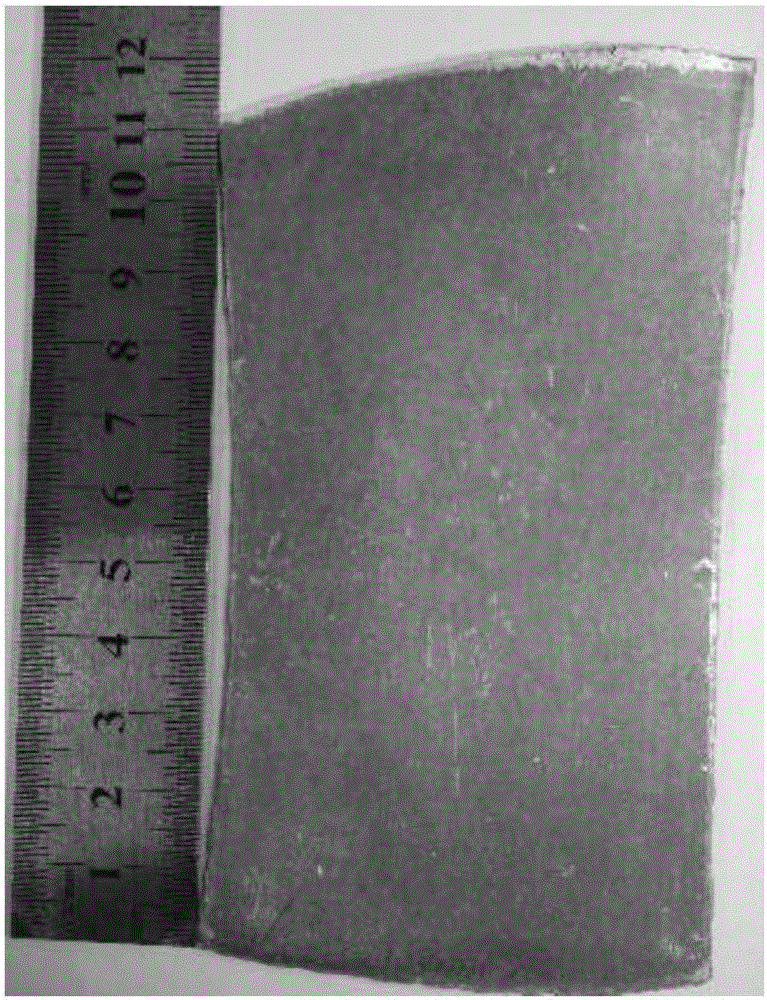

[0030] The Mg-1.0Zn-0.5Er alloy obtained by ordinary casting is solution-treated, and then cut and milled to obtain a rolling blank, and the blank is placed in a holding furnace for treatment, and the temperature of the holding furnace is 450°C. Set rolling speed to 2.5m / s. Firstly, the rolling temperature is 450°C, the deformation per pass is 25%, the above rolling direction is 0°, and the rolling is 1 pass; then the rolling temperature is lowered to 400°C, and the sample is kept at this temperature for 15 minutes, and each The amount of deformation per pass is 30%, the rolling direction above is 90°, and one pass is rolled; then low-temperature stage rolling is carried out, and the rolling temperature is set at 300°C, and then the alloy is placed in a holding furnace for heat preservation. The holding temperature is 300°C, the holding time is 30min, and the heat-preserved alloy is continued to be rolled at the low temperature stage, the rolling temperature is 300°C, the sing...

Embodiment 3

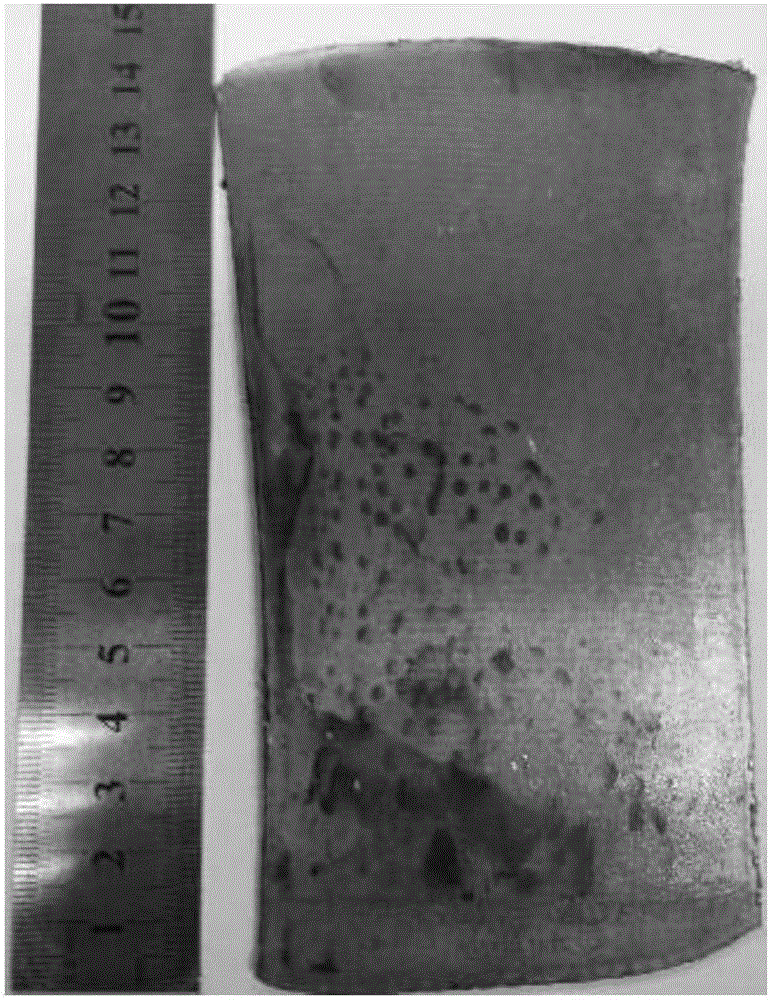

[0032] The Mg-1.5Zn-1.0Er alloy obtained by ordinary casting is solution-treated, and then cut and milled to obtain a rolling blank, and the blank is placed in a holding furnace for treatment, and the temperature of the holding furnace is 400°C. Set rolling speed to 2.5m / s. The rolling temperature is 400°C, the deformation of each pass is 35%, the pass is 1 pass, and the rolling direction is 0°; then the alloy is placed in a holding furnace at 475°C for 15 minutes, and then The alloy is rolled at a low temperature stage, the rolling temperature is 475°C, the deformation in a single pass is 25%, the rolling direction is 90°, and a total of 1 pass is rolled; then the alloy is placed in a holding furnace for heat preservation, heat preservation The temperature is 350°C, and the holding time is 30 minutes. Then lower the furnace temperature to 250°C, keep it warm for 15 minutes, and continue rolling the heat-preserved alloy at a low temperature stage. The rolling temperature is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com