Thin film packaging structure and preparation method and application thereof

A technology of thin-film packaging and packaging structure, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., to achieve good stress release space, improved heat insulation performance, and better flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

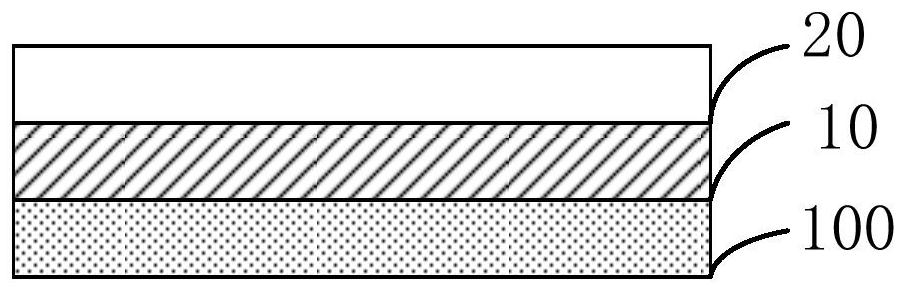

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing the thin film encapsulation structure, comprising the following steps:

[0038] S10, providing the modified layered two-dimensional material, and mixing the modified layered two-dimensional material and the nanocellulose to obtain a first mixture, dissolving the first mixture in a solvent to form a the ink of the first mixture, and inkjet printing the ink containing the first mixture on the structure to be encapsulated to form a first encapsulation layer;

[0039] S20, mixing the modified layered two-dimensional material and the polymer water-repelling oxygen film-forming material to obtain a second mixture, dissolving the first mixture in a solvent to form an ink containing the second mixture, Inkjet printing an ink containing the second mixture on the first encapsulation layer to form a second encapsulation layer.

[0040] The modified layered two-dimensional material can be prepared by exfoliating the layere...

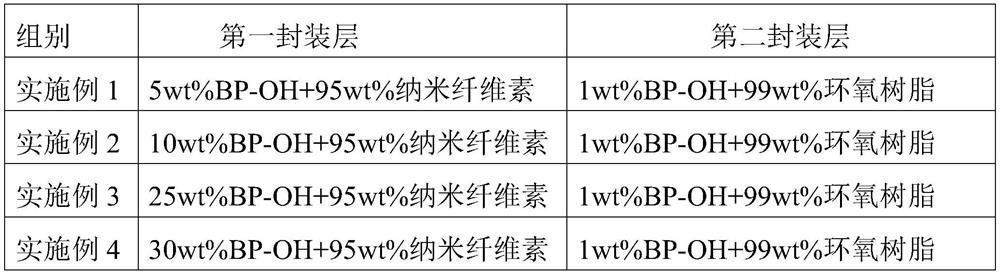

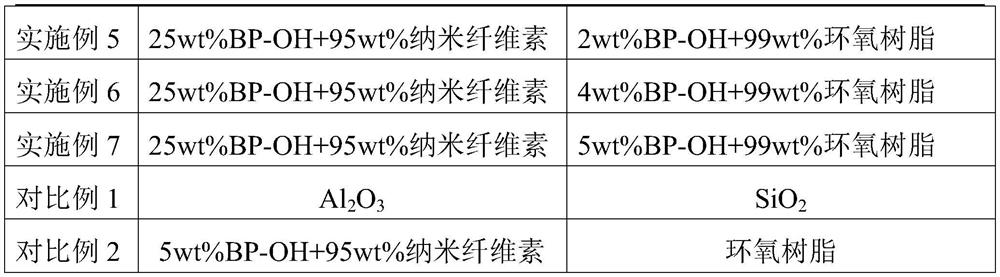

Embodiment 1

[0055] A QLED device, including an anode and a cathode, an organic functional layer between the anode and the cathode, and a thin-film packaging structure covering the cathode, specifically: ITO substrate / PEDOT:PSS(50nm) / poly-TPD(30nm) / Quantum dot light-emitting layer (20nm) / ZnO(30nm) / silver (70nm) / thin film encapsulation structure (540nm), wherein the thin film encapsulation structure is composed of the first encapsulation layer and the second encapsulation layer, the first encapsulation layer is BP-OH / The NFC composite film has a thickness of 260nm, and the second packaging layer is a BP-OH / epoxy resin composite film with a thickness of 280nm. BP-OH is modified black phosphorus with hydroxyl groups on the surface, and NFC is nanocellulose. The specific preparation method of the thin film encapsulation structure is as follows:

[0056] (1) Preparation of BP-OH: The two-dimensional material BP was peeled off by ball milling with the assistance of LiOH. The ball milling spee...

Embodiment 2

[0060] A QLED device, including an anode and a cathode, an organic functional layer between the anode and the cathode, and a thin-film packaging structure covering the cathode, specifically: ITO substrate / PEDOT:PSS(50nm) / poly-TPD(30nm) / Quantum dot light-emitting layer (20nm) / ZnO(30nm) / silver (70nm) / thin film encapsulation structure (540nm), wherein the thin film encapsulation structure is composed of the first encapsulation layer and the second encapsulation layer, the first encapsulation layer is BP-OH / The NFC composite film has a thickness of 260nm, and the second packaging layer is a BP-OH / epoxy resin composite film with a thickness of 280nm. BP-OH is modified black phosphorus with hydroxyl groups on the surface, and NFC is nanocellulose. The specific preparation method of the thin film encapsulation structure is as follows:

[0061] (1) Preparation of BP-OH: The two-dimensional material BP was peeled off by ball milling with the assistance of LiOH. The ball milling spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com