Quantum dot film, backlight unit and display device

A quantum dot film and quantum dot technology, applied in the display field, can solve the problem of large invalid side of the quantum dot layer, achieve the effect of alleviating the problem of invalid side, reducing cost, and improving water and oxygen barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

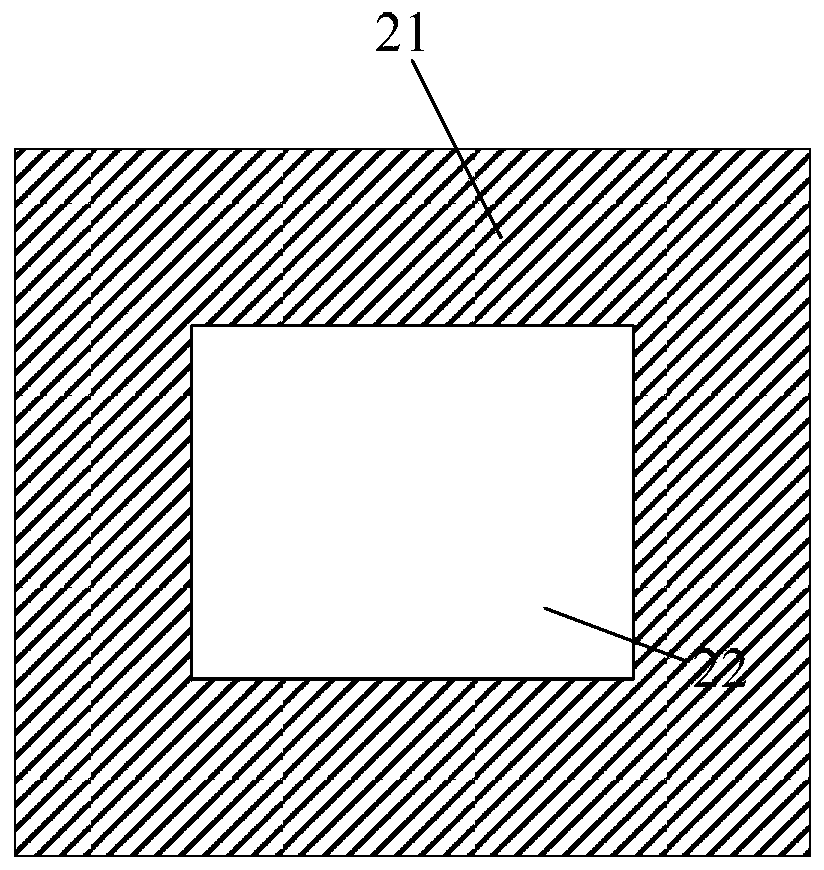

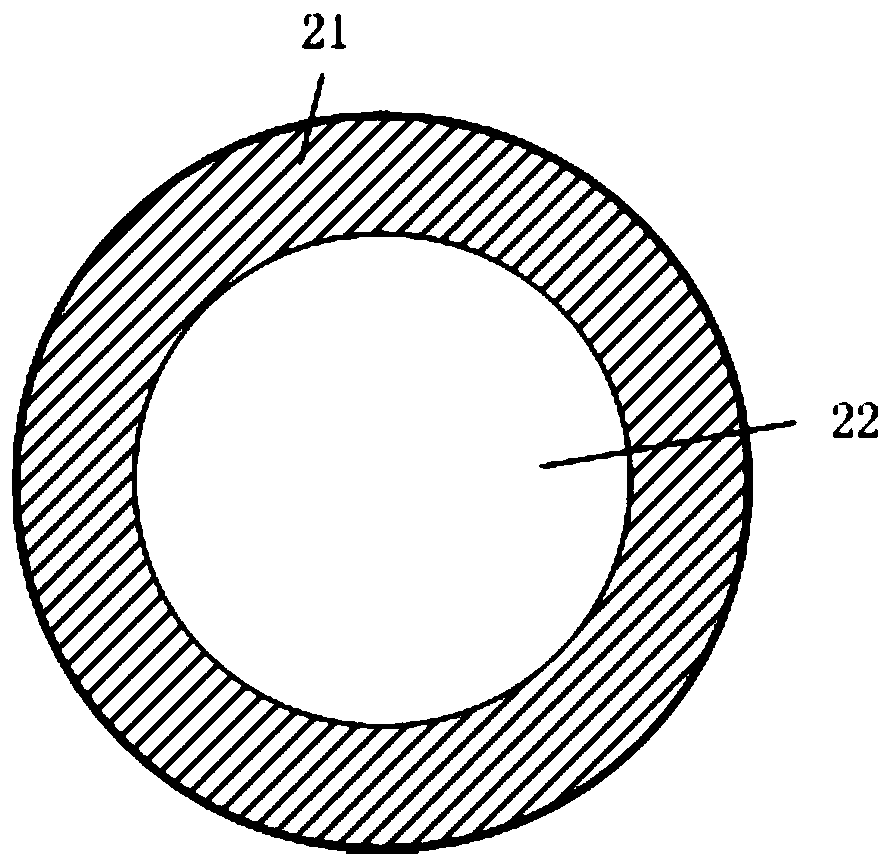

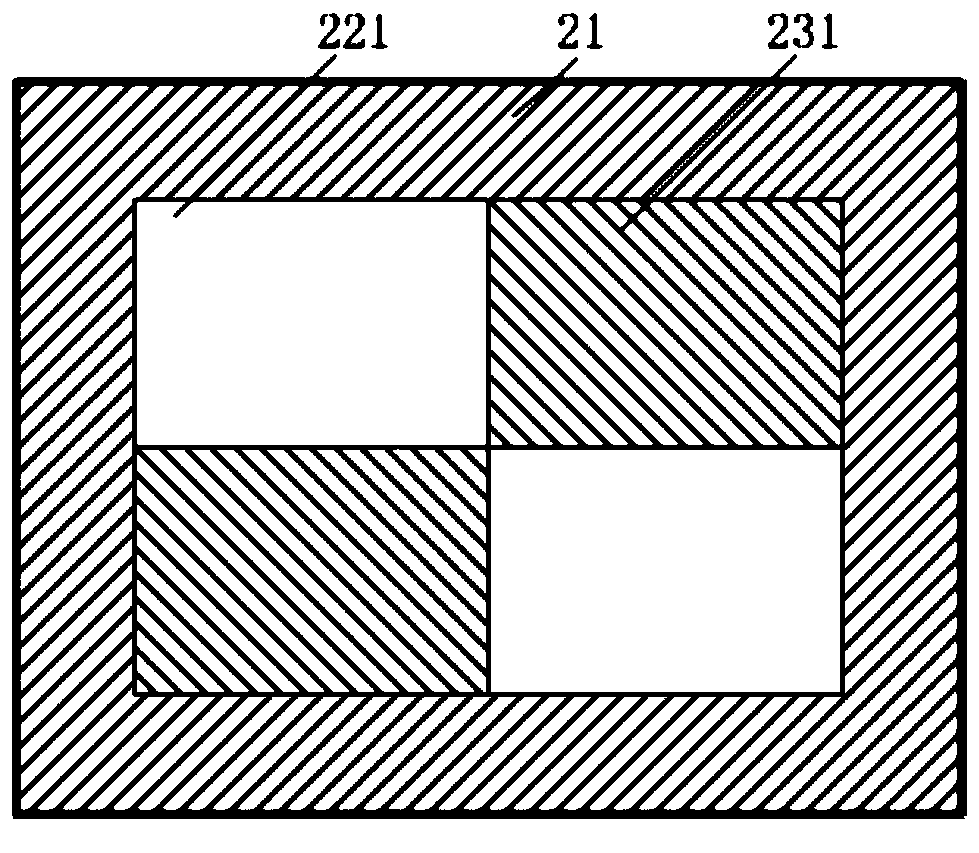

[0057] The quantum dot film includes a quantum dot layer, the quantum dot layer, such as figure 1 As shown, the quantum dot layer includes a first red quantum dot region 21 and a green quantum dot region 22 . Wherein, the first red quantum dot region 21 is the first red quantum dot region, and the first red quantum dot region is formed by red quantum dot resin, and the red quantum dot resin includes red quantum dots, a first matrix, an additive and a thermosetting agent, Among them, the red quantum dot has a CdSe / CdS core-shell structure, the diameter of the CdSe core is 4nm, and the ligand is oleate. The matrix is bisphenol A epoxy resin, and its weight percentage is 98.8%; the additive is spherical titanium dioxide diffusion particles with a particle size of 10 μm, and its weight percentage is 0.2%; the thermosetting agent is ethylenediamine, and its weight percentage is 0.9%. Green quantum dot area 22 is formed by green quantum dot resin, and above-mentioned green quantu...

Embodiment 2

[0059] The difference from Example 1 is that the quantum dot film also includes a first barrier film 10 and a second barrier film 30, and the specific structure is as Figure 6 As shown, the first barrier film 10 and the second barrier film 30 are both alumina barrier films, and their water permeability is 0.1g / m 2 ·day, its oxygen permeability is 0.01cc / m 2 day.

Embodiment 3

[0061] The difference from Example 2 is that the first matrix is polymethacrylate resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com