A kind of organic optoelectronic device packaging film and preparation method thereof

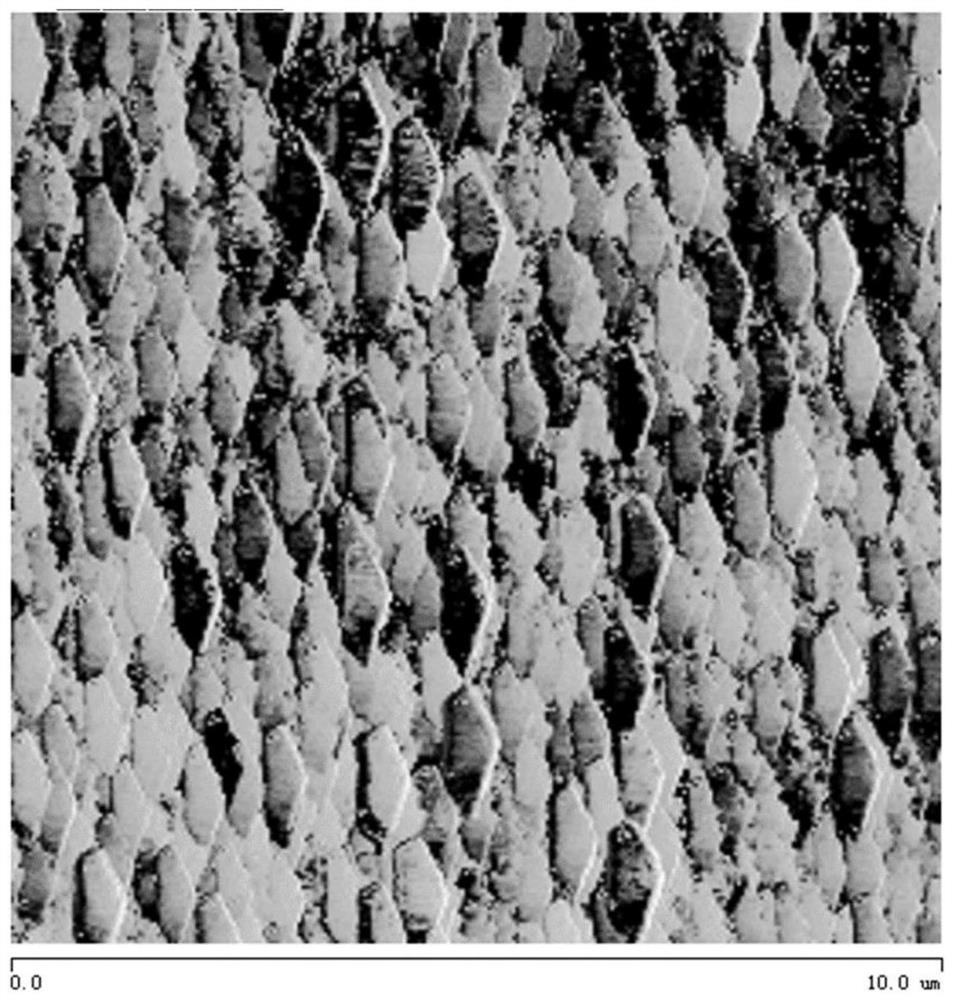

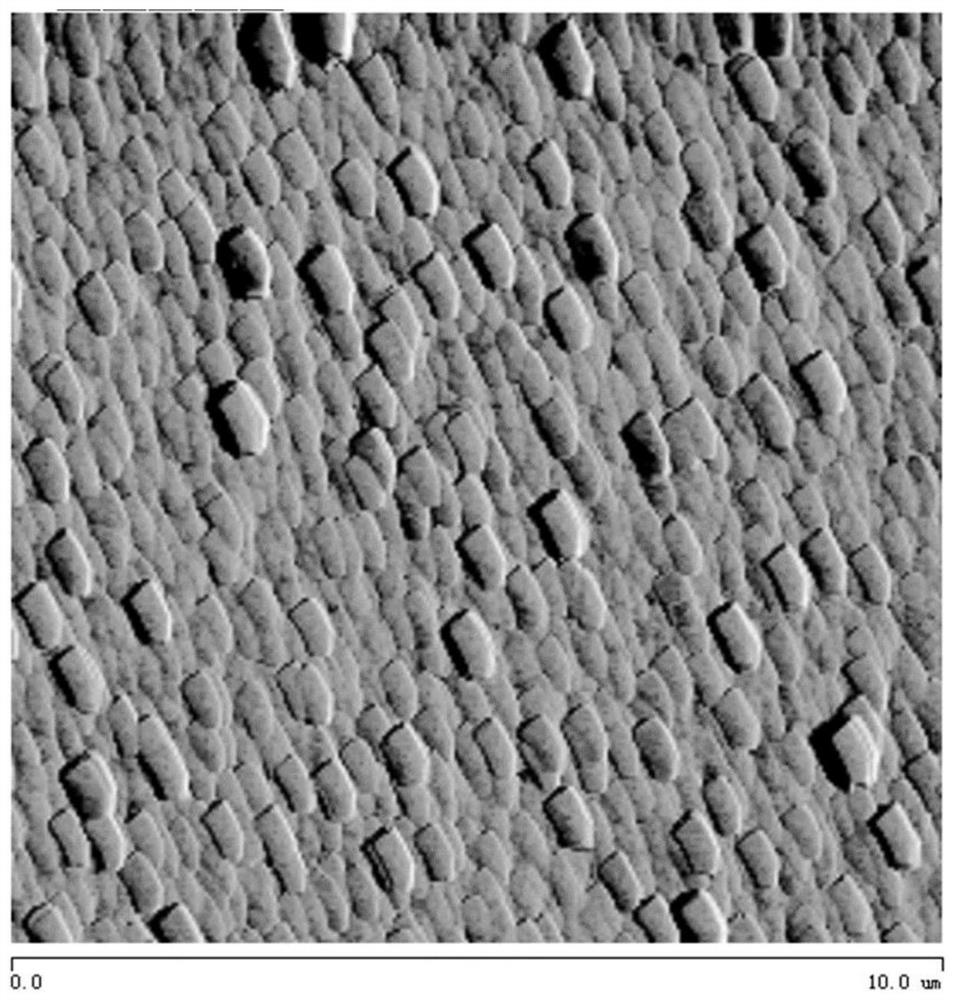

A technology for optoelectronic devices and encapsulation films, which is applied in the field of organic optoelectronic device encapsulation films and its preparation, can solve problems such as inability to effectively block water and oxygen, large surface roughness, and poor compactness, and achieve improved visible light transmittance and reduced defects The effect of increasing the number and improving the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

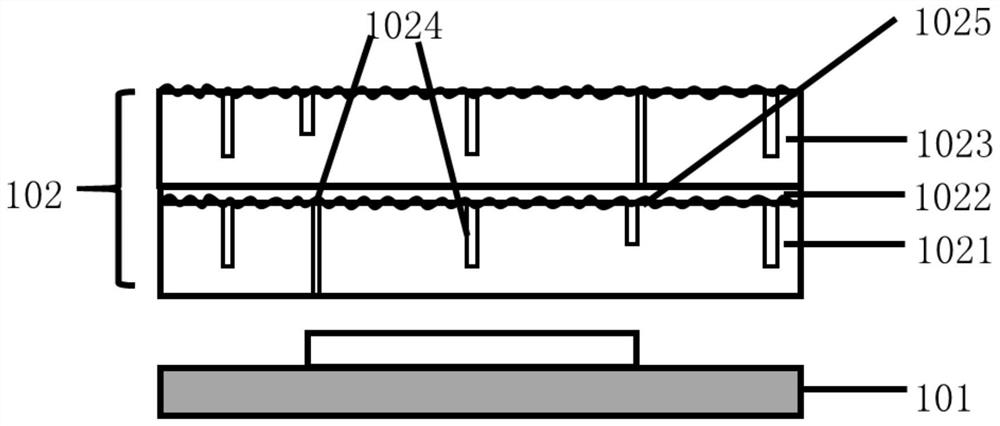

[0032] An embodiment of the present invention provides a method for manufacturing an encapsulation film, including:

[0033] (1) The structure to be packaged is ITO / MoO by inductively coupled plasma enhanced chemical vapor deposition process x (2nm) / m-MTDATA(30nm) / NPB(20nm) / Alq(50nm) / LiF(0.5nm) / Al(100nm) organic optoelectronic devices grow the first encapsulation layer: inductively coupled plasma before passing reactive gas Volume-enhanced chemical vapor deposition equipment (low temperature ICP-PECVD system, model: ICP-PECVD-150) the vacuum in the chamber is 3 × 10 -5 Torr. With hexamethyldisiloxane (HMDSO) as the reaction precursor, the flow rate is 0.08g / min; with argon (Ar) as the auxiliary reaction gas, the flow rate is 30sccm, with O 2 For the reaction gas, the flow rate is 158 sccm. During the process, the vacuum degree is 273mTorr, the reaction temperature is 77°C, and the radio frequency power is 100W. The reaction produces silicon oxide (SiO x ) is the first enc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com