Metallic glass composite material ultrasound-assisted 3D cold printing device and method

A printing device and ultrasonic-assisted technology, applied in the field of additive manufacturing, can solve problems such as difficulty in manufacturing metal glass parts, and achieve the effects of not easy to crack, good mechanical properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

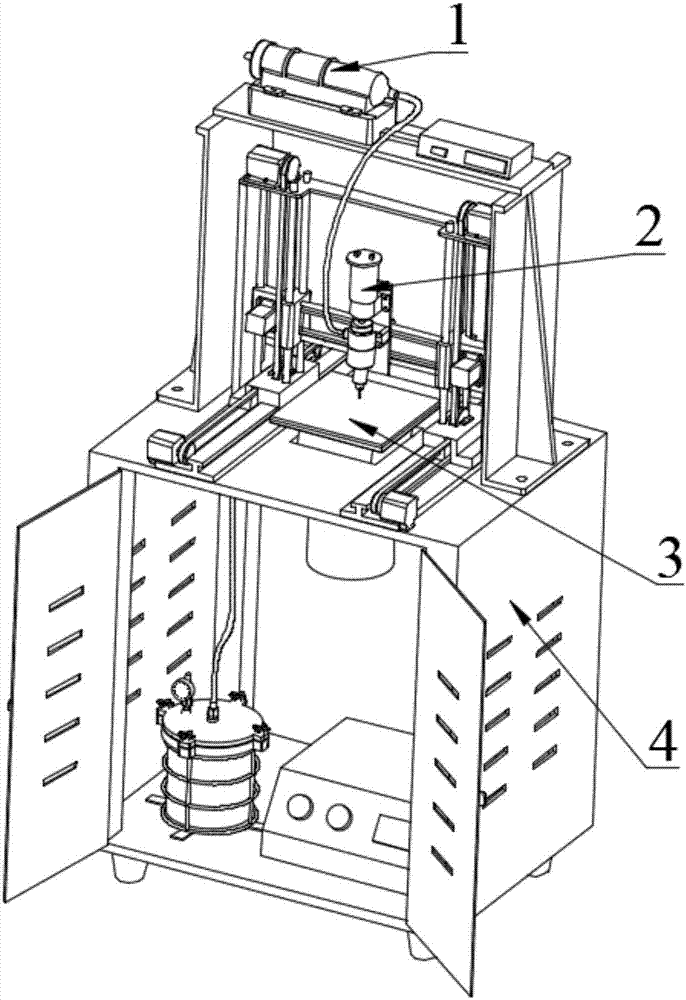

[0063] An ultrasonic-assisted 3D cold printing device for metallic glass composite materials, consisting of an ultrasonic vibrating barrel 1, a three-axis cold printing device 2, an ultrasonic vibrating substrate 3, and a base case 4, and the ultrasonic vibrating barrel 1 is fixed on the base case 4 Above, the three-axis cold printing device 2 is fixed on the base case 4 and located under the ultrasonic vibration cylinder 1 , and the ultrasonic vibration substrate 3 is fixed on the base case 4 and located under the three-axis cold printing device 2 .

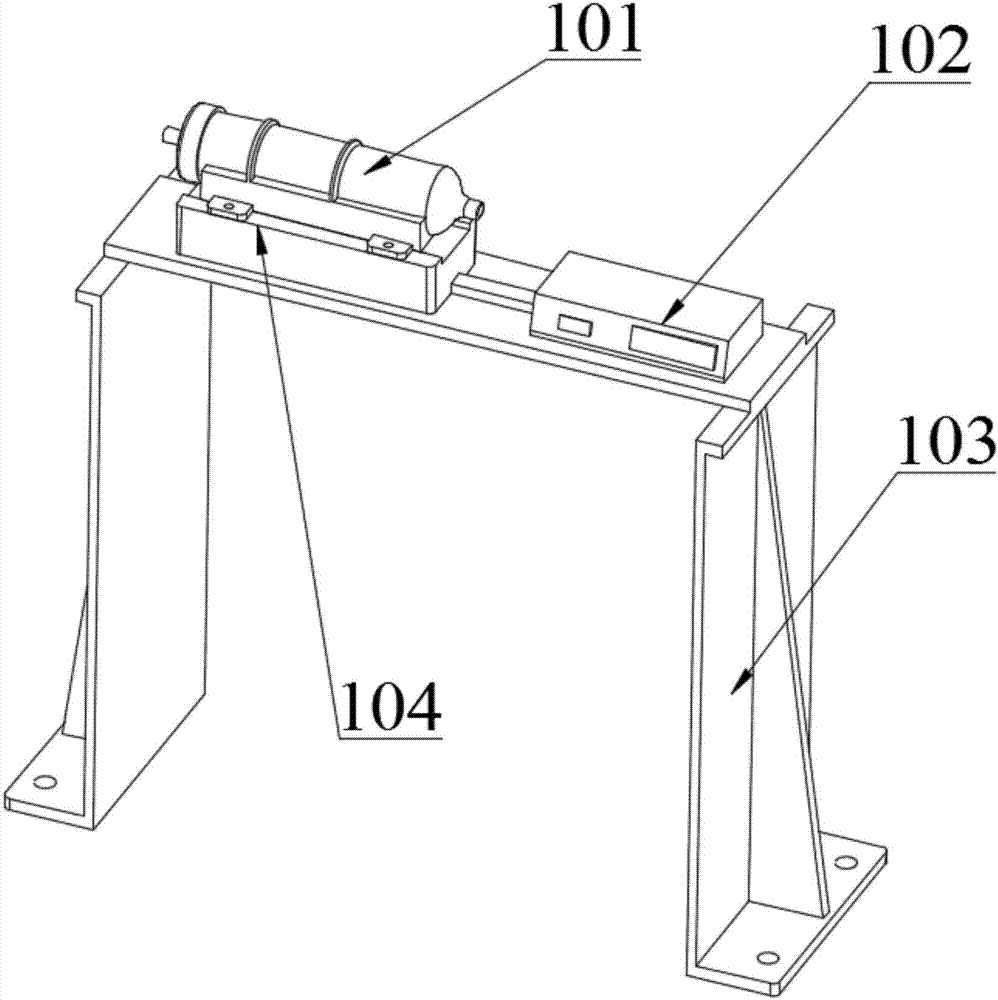

[0064] The ultrasonic vibration barrel 1 of the present invention is composed of a barrel 101, an ultrasonic power supply 102, a barrel support 103, and an ultrasonic vibrator 104. The barrel 101 is fixed on the ultrasonic vibrator 104, and the ultrasonic vibrator 104 is fixed on the material On the cylinder support 103, the ultrasonic power supply 102 is fixed on the cylinder support 103.

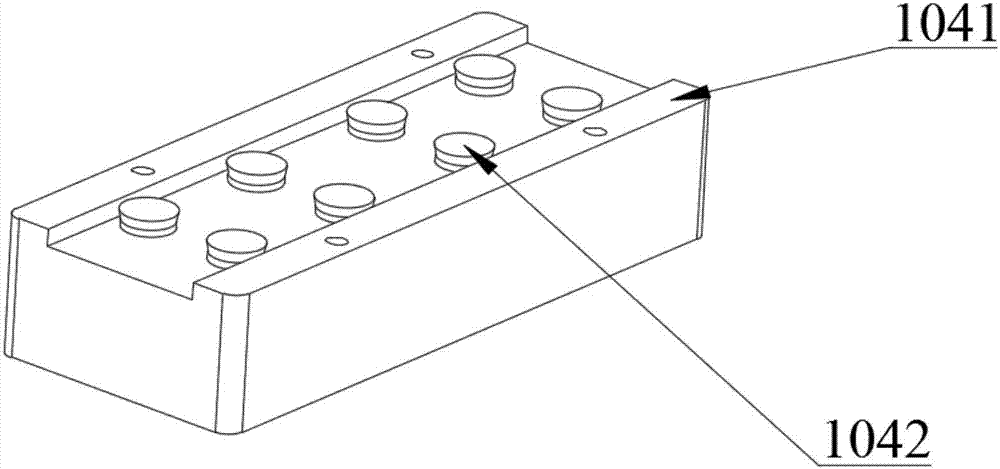

[0065] The ultrasonic vibrator 104 of...

Embodiment 2

[0072] A metal-glass composite material ultrasonic-assisted 3D cold printing method, comprising the following steps:

[0073] (1) Slurry ratio

[0074] It is composed of the following raw materials in parts by mass:

[0075] Metallic glass powder, particle size 30μm, 120 parts,

[0076] Fine ceramic powder, particle size is 5μm, 30 parts,

[0077] 35 parts of deionized water,

[0078] 4 parts of monomer methacrylamide,

[0079] 1 part of crosslinking agent N,N-methylenebisacrylamide,

[0080] Dispersant polyphenyl polyoxyethylene ether 0.5 part,

[0081] 0.2 parts of initiator ammonium persulfate,

[0082] Catalyst tetramethylethylenediamine 0.3 part;

[0083] The metallic glass powder is made of iron-based amorphous alloy

[0084] (2) Slurry preparation

[0085] Weigh monomer methacrylamide and cross-linking agent N,N-methylenebisacrylamide and dissolve in deionized water, add dispersant polyphenyl polyoxyethylene ether, after the above raw materials are completely d...

Embodiment 3

[0099] A metal-glass composite material ultrasonic-assisted 3D cold printing method, comprising the following steps:

[0100] (1) Slurry ratio

[0101] It is composed of the following raw materials in parts by mass:

[0102] Metallic glass powder with a particle size of 40 μm, 135 parts,

[0103] Fine ceramic powder, particle size is 7μm, 35 parts,

[0104] 40 parts of deionized water,

[0105] 6 parts of monomer methacrylamide,

[0106] 2.5 parts of crosslinking agent N,N-methylenebisacrylamide,

[0107] Dispersant polyphenyl polyoxyethylene ether 0.8 part,

[0108] 0.3 parts of initiator ammonium persulfate,

[0109] Catalyst tetramethylethylenediamine 0.4 part;

[0110] The metallic glass powder is made of iron-based amorphous alloy

[0111] (2) Slurry preparation

[0112] Weigh monomer methacrylamide and cross-linking agent N,N-methylenebisacrylamide and dissolve in deionized water, add dispersant polyphenyl polyoxyethylene ether, after the above raw materials are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com