Patents

Literature

284results about How to "Not prone to cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction method of anti-plastering putty for concrete structure wall

InactiveCN101363269AThin thickness and small weightLight weightCovering/liningsResource consumptionPutty

The invention discloses a construction method of a wall putty of a plaster-free concrete structure. The construction method comprises the following steps: construction preparation, base course treatment, concave-convex line construction, a first full application of wall putty, flattening, a second full application of wall putty and flattening. The construction method has the advantages of less workload, short construction time, little resource consumption, no hollow drum and crack of the floated coat, no crack at the joint of the primary structure and the secondary structure.

Owner:中建五局第三建设有限公司 +1

Starch bonding agent, and preparation method and use thereof

InactiveCN101962518AStrong adhesionStrong bondMechanical working/deformationStarch derivtive adhesivesHardnessSodium hypochlorite

The invention provides a preparation method for a starch bonding agent, which comprises the following steps of: performing crosslinking treatment on starch by adopting a crosslinker to form modified starch A, performing oxidation with sodium hypochlorite, esterification with butanedioic anhydride and treatment with a cationic etherifying agent on the starch to form modified starch B, and mixing the modified starch A and the modified starch B according to a certain proportion to form the modified starch bonding agent. The preparation method has the advantage of ensuring higher bonding power, firm bonding, high hardness of bonded paper products, high drying speed, low viscosity of paste, high flowability and wettability, convenience of coating, high storage stability and difficulty in gel production.

Owner:内蒙古奈伦农业科技股份有限公司

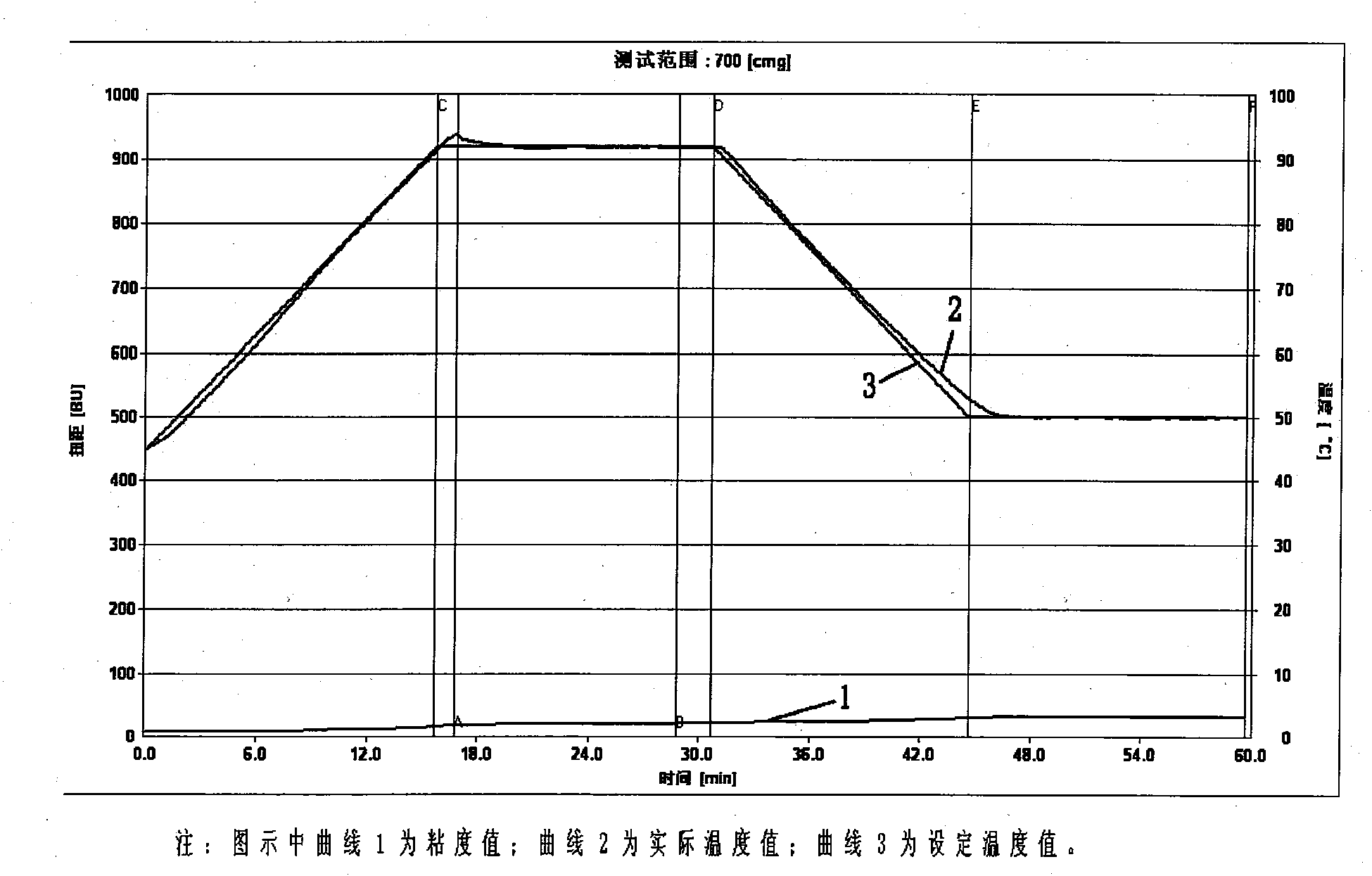

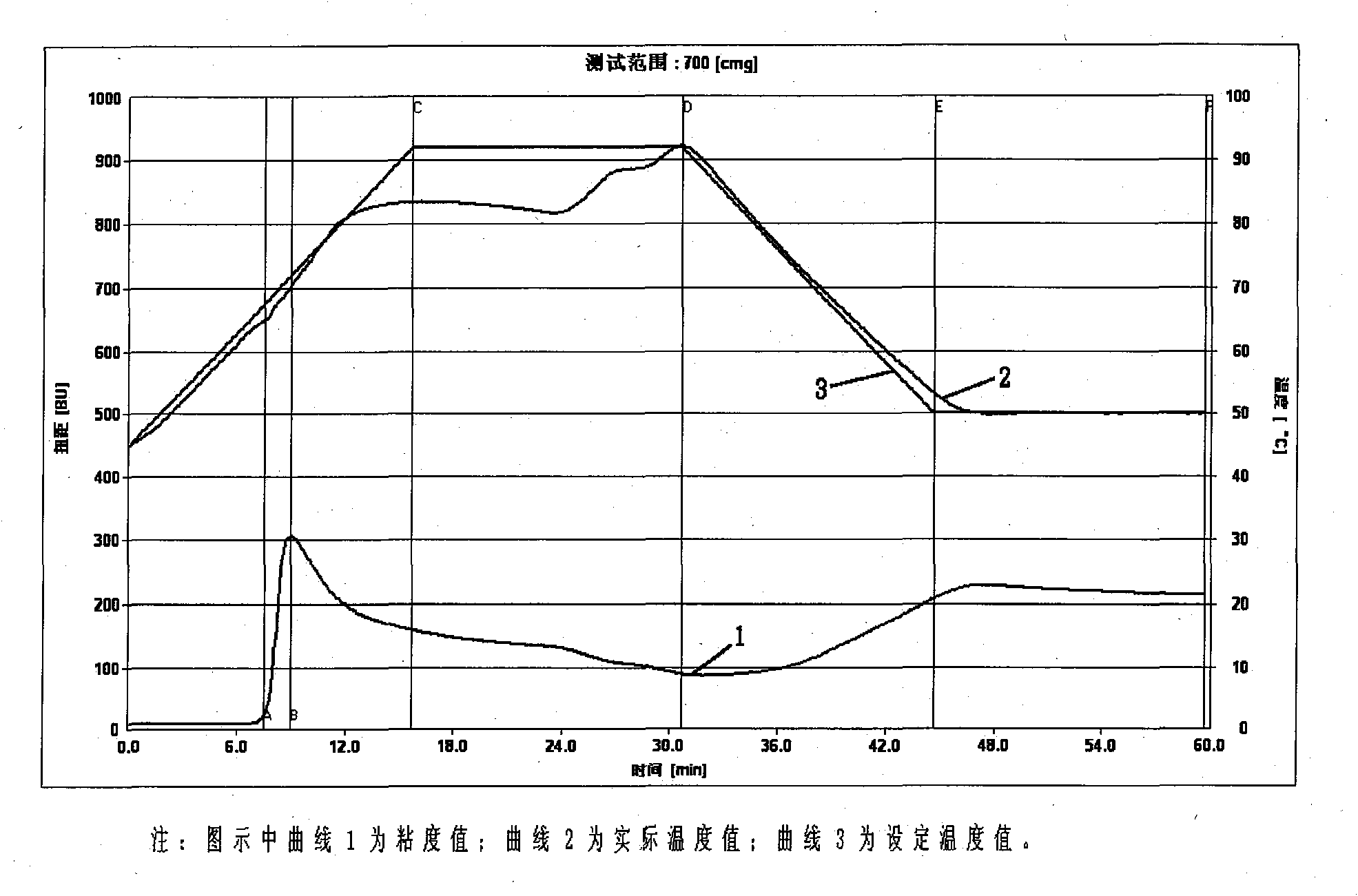

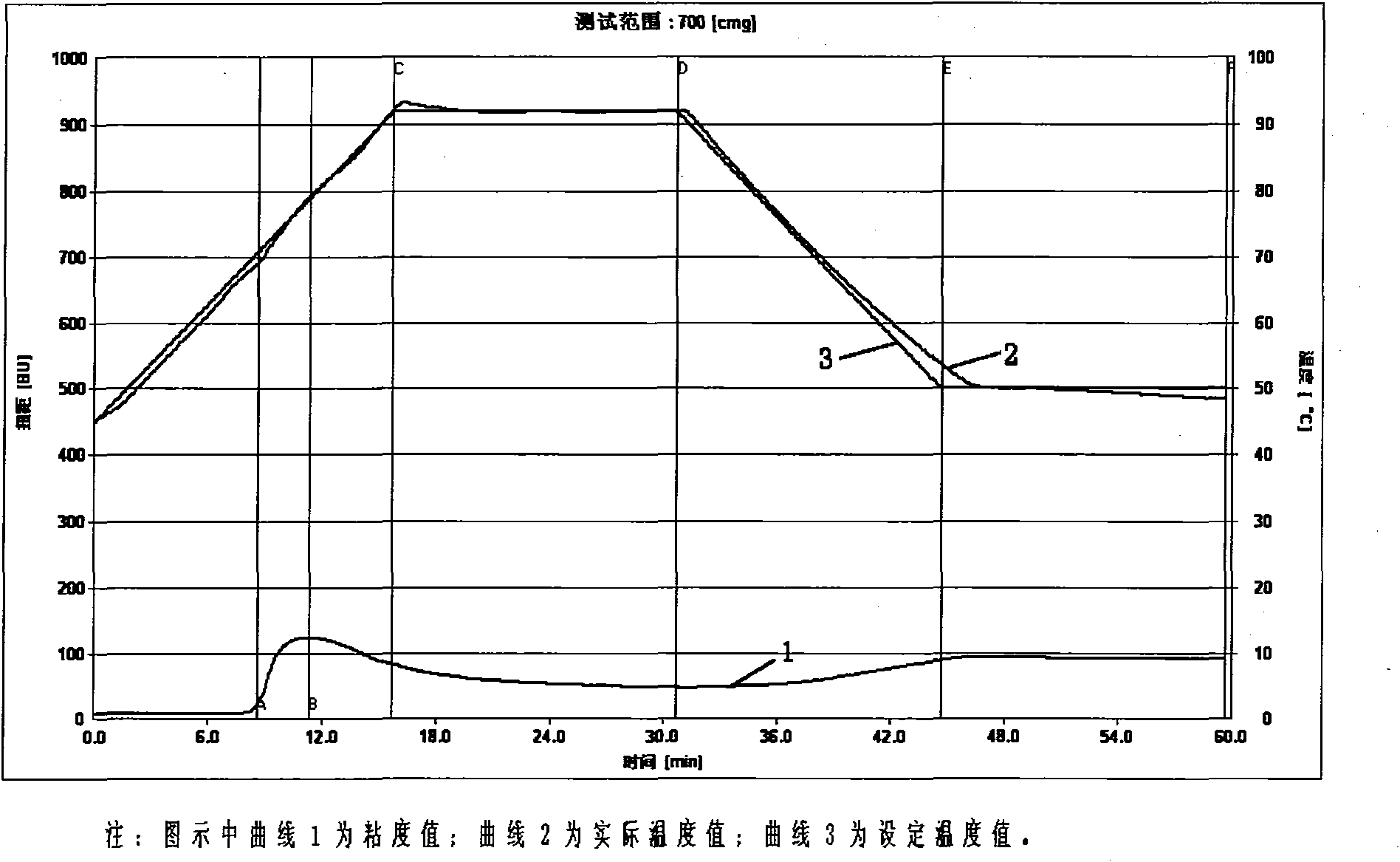

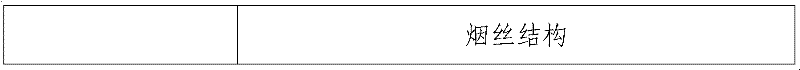

Tobacco shred drying method

InactiveCN102511913AGood quality characteristicsImprove stabilityTobacco preparationDrying timeVacuum chamber

The invention discloses a tobacco shred drying method. The moisture content of cut tobacco shreds is balanced to 20-24%, and the temperature is balanced to 10-30 DEG C. The balanced tobacco shreds are quickly frozen to be under the temperature of -40 DEG C to -35 DEG C at a cooling rate of -0.06 DEG C / min to -1.0 DEG C / min and maintained for 1-4 hours. Pre-frozen tobacco shreds are placed into a vacuum chamber to be dried, wherein absolute pressure in the vacuum chamber is 50-70 Pa, the temperature of a heating plate is 20-40 DEG C, and drying time is 0.5-4 hours. Finally, the moisture content of tobacco shreds is regained to 11-13%. By means of the method, quality characteristics and original shape of raw materials can be maintained well, and the phenomena including surface hardening, fragrance loss and the like caused by surface precipitation of soluble matter contained in the tobacco shreds are avoided. The method is simple and low in energy consumption, can improve smoking quality of the tobacco shreds remarkably, and has good application prospect.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

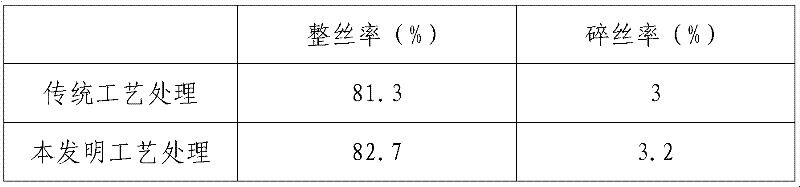

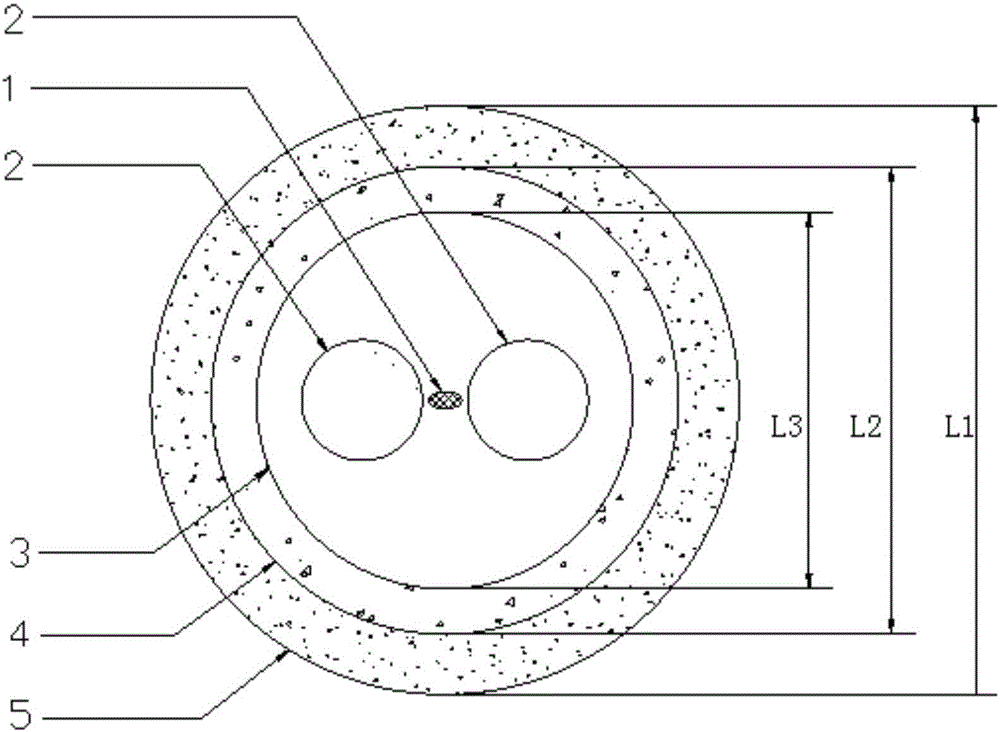

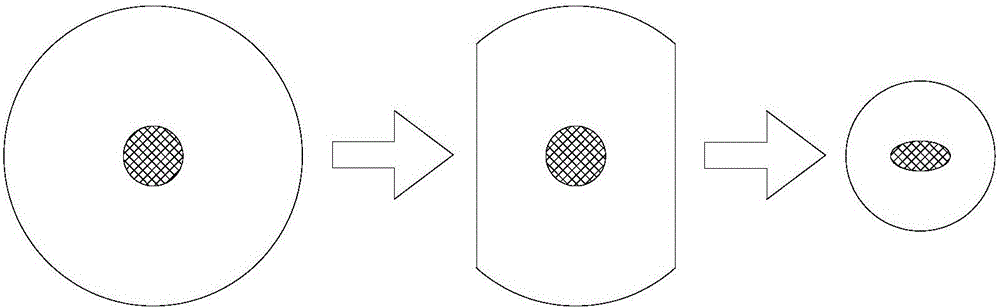

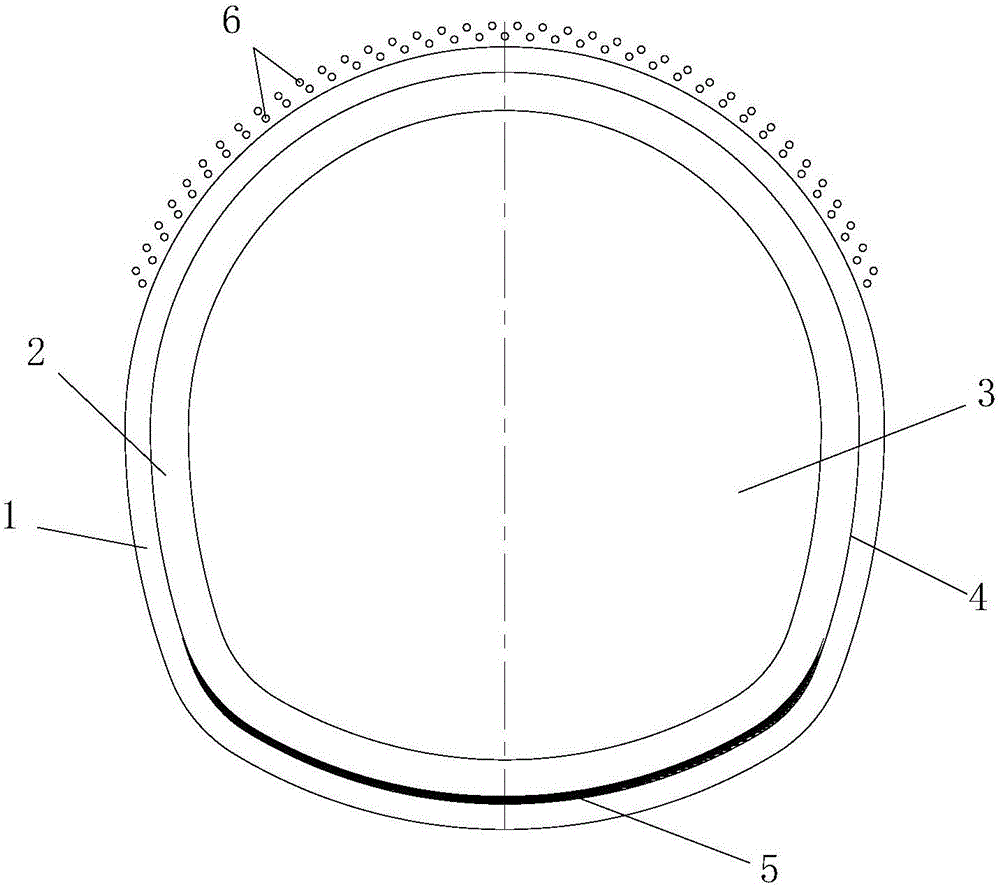

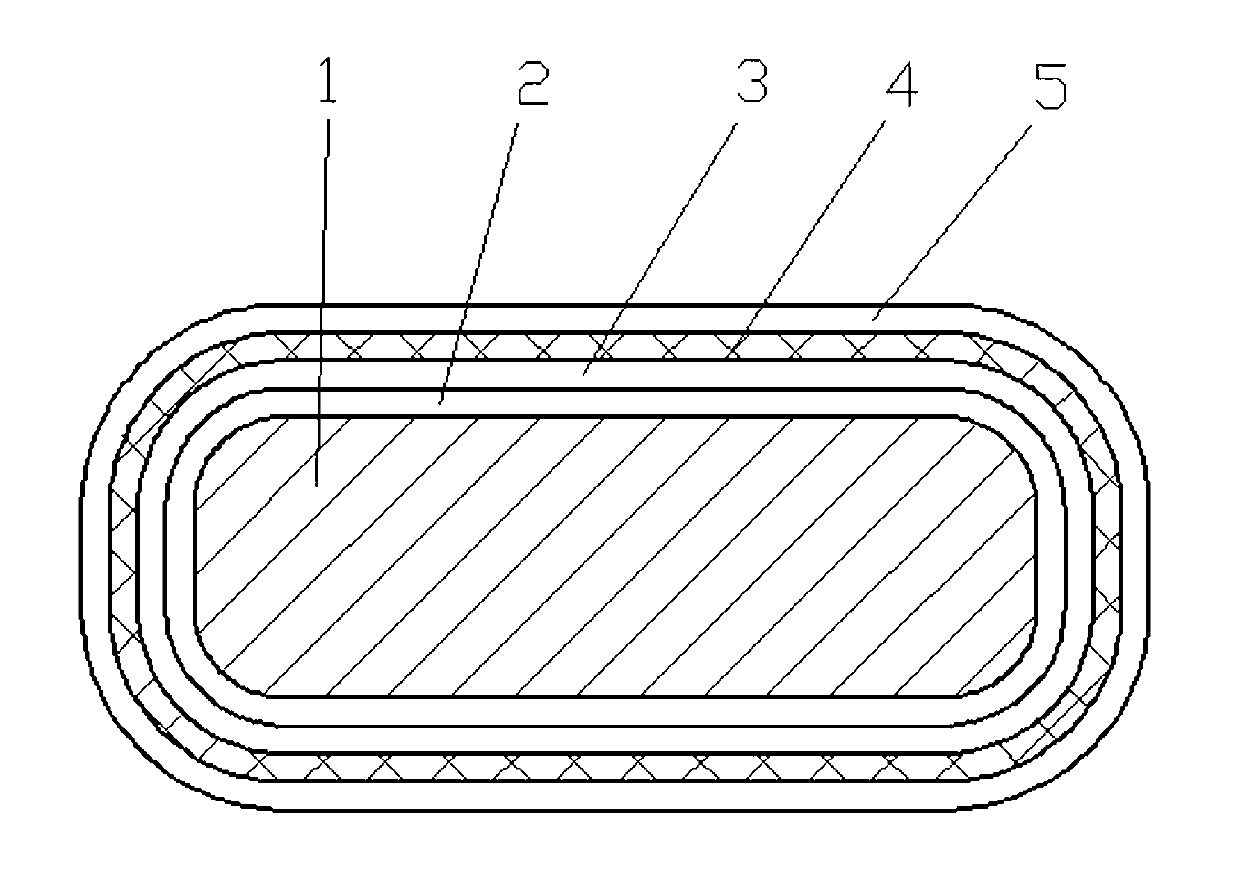

Ellipse core panda type polarization maintaining optical fiber and manufacturing method thereof

InactiveCN106199827AReduce lossLittle influence of temperatureOptical waveguide light guideHigh numerical apertureEllipse

The invention discloses an ellipse core panda type polarization maintaining optical fiber and a manufacturing method thereof. The polarization maintaining optical fiber comprises a fiber core, stress areas, cladding and an outer coating. The cross section of the fiber core is oval, the fiber core is arranged in the centre of the cladding, the position of the central point of the cross section of the fiber core coincides with the position of the central point of the cross section of the optical fiber, the two stress areas are symmetrically distributed on the two sides of the fiber core in the long axis direction and arranged in the cladding, and the outer coating is arranged on the outer side of the cladding. The manufacturing method comprises the steps that a core rod is prepared through a CVD method, and a core rod with the large core diameter and the high numerical aperture is prepare; the core rod is subjected to flat grinding and stretching the core rod is finished into an ellipse core rod, a hole is formed in the long axis direction, and finishing is carried out in the short axis direction; two stress rods are prepared; an optical fiber preform is formed through the core rod, the stress rods and the pure silicon cladding, and finally RIT wire drawing is carried out on the optical fiber preform, and the ellipse core panda type polarization maintaining optical fiber is manufactured. The optical fiber is low in loss, high in double refraction performance and good in temperature performance, and grinding performance is improved while polarization performance is kept.

Owner:武汉长盈通光电技术股份有限公司

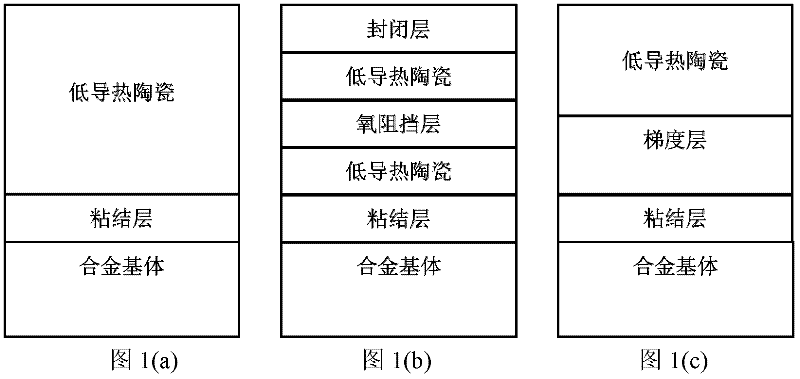

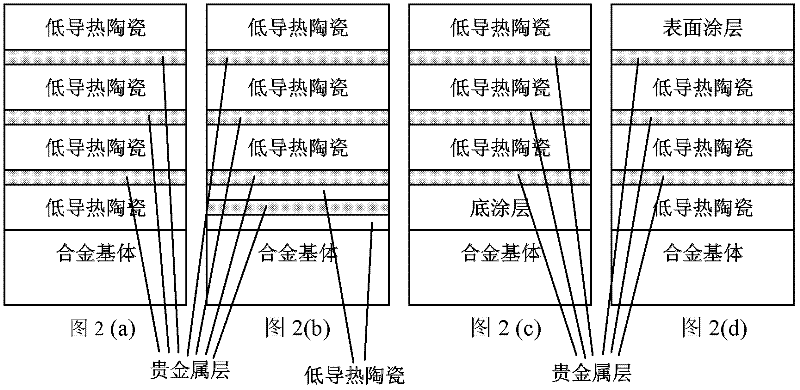

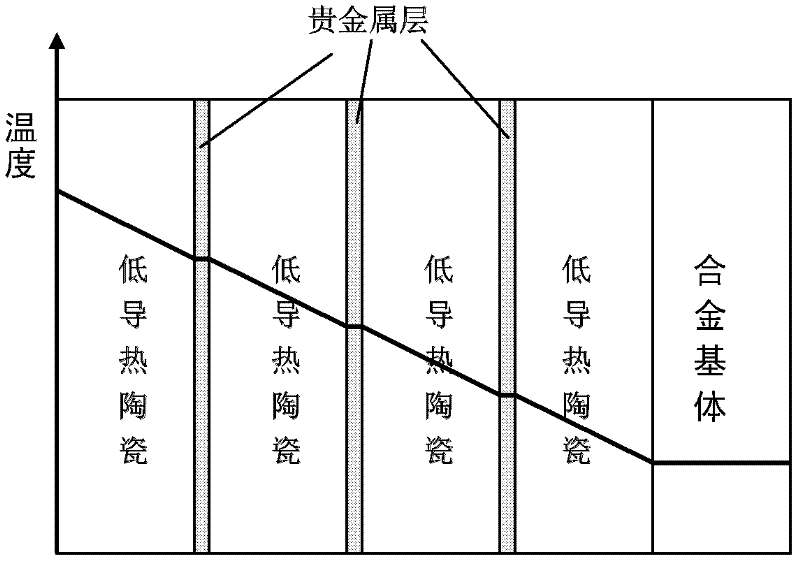

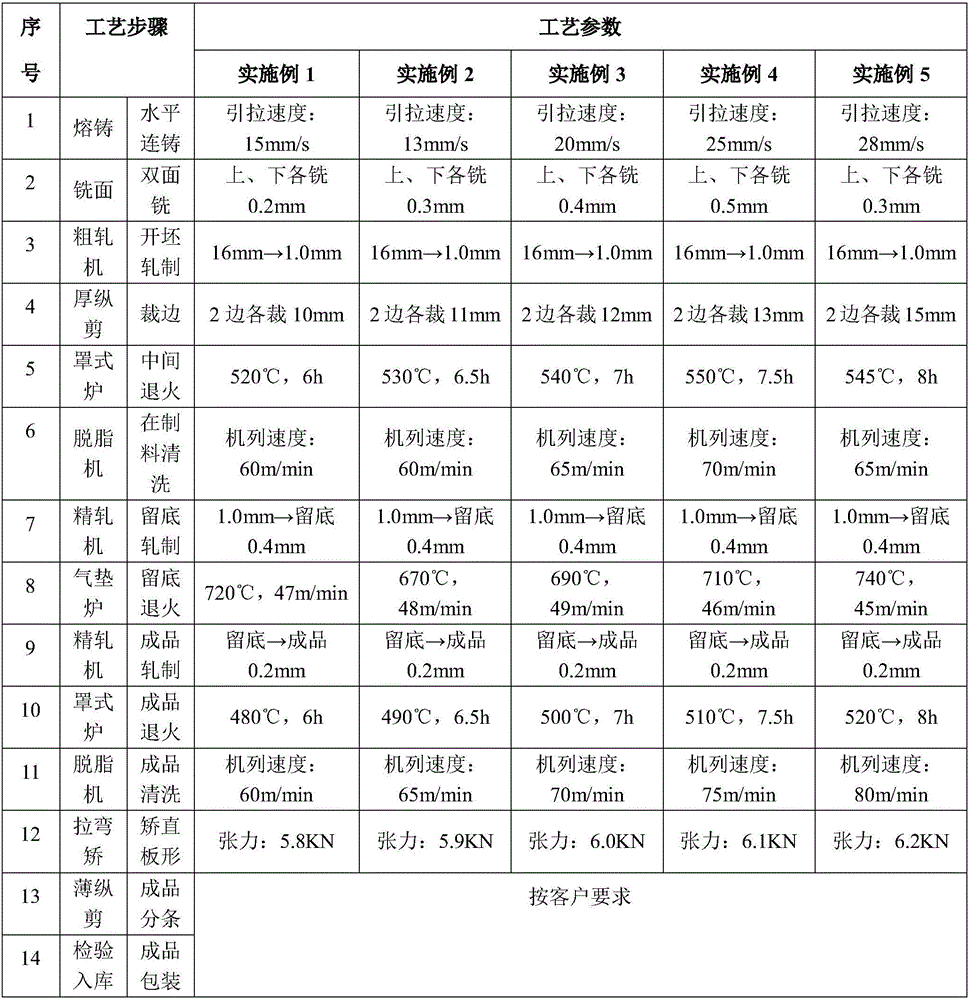

Multipurpose low-conductivity ceramic/noble metal lamellar composite thermal barrier coating

InactiveCN102345122AGood heat insulationNo insulationBlade accessoriesEfficient propulsion technologiesAviationThermal insulation

The invention discloses a multipurpose low-conductivity ceramic / noble metal lamellar composite thermal barrier coating, relating a composite material and coating technology. The coating is divided into four types: (1) regularly and alternatively depositing low-conductivity ceramic layers and noble metal layers; (2) irregularly and alternatively depositing low-conductivity ceramic layers and noblemetal layers; (3) exerting low-conductivity ceramic and noble metal lamellar composite thermal barrier coatings on antioxidant protection layers deposited on the surface of a basic alloy; and (4) depositing other functional coatings on the outer surface of the low-conductivity ceramic / noble metal lamellar composite thermal barrier coating. According to the invention, the lamellar composite thermal barrier coating formed by alternatively depositing the low-conductivity ceramic layers and the noble metal layers has the advantages of excellent thermal insulation performance and thermal shock resistance, stable coating structure and long service life and can be applied to the high temperature protection of hot end components of refractory alloys or high temperature alloys such as an aircraft engine, a marine engine, a ground gas turbine, a rocket engine, and the like.

Owner:UNIV OF SCI & TECH BEIJING

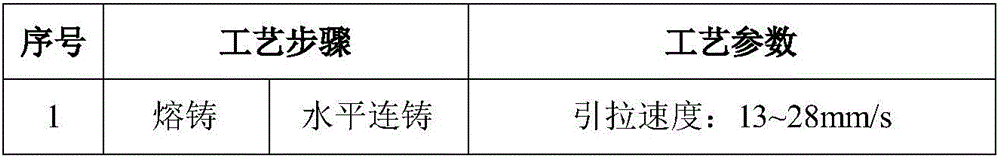

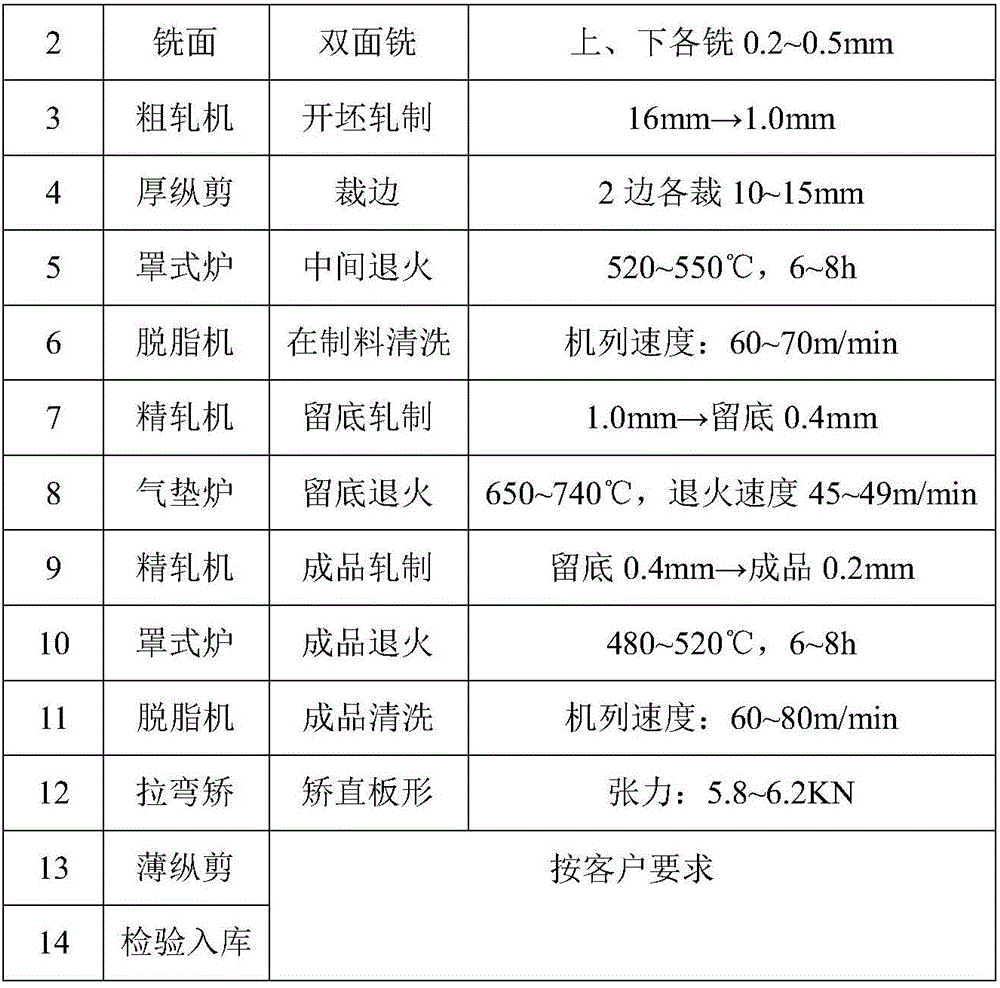

High-performance tin-phosphor bronze strip and production method thereof

The invention discloses a high-performance tin-phosphor bronze strip and a production method thereof. The high-performance tin-phosphor bronze strip comprises, by weight percent, 9% to 11% of Sn, 0.03% to 0.35% of P, not larger than 0.2% of Zn, not larger than 0.1% of Fe, not larger than 0.2% of Pb and the balance copper. Through the strict control over a casting technology, a rolling technology and an annealing technology of a tin-phosphor bronze alloy, a high-performance tin-phosphor bronze strip alloy product with the tin content ranging from 9% to 11% can be produced, and the application requirement of an IT industry and an electrommunication industry for a high-elasticity, high-strength and high-hardness copper alloy can be met.

Owner:安徽鑫科铜业有限公司

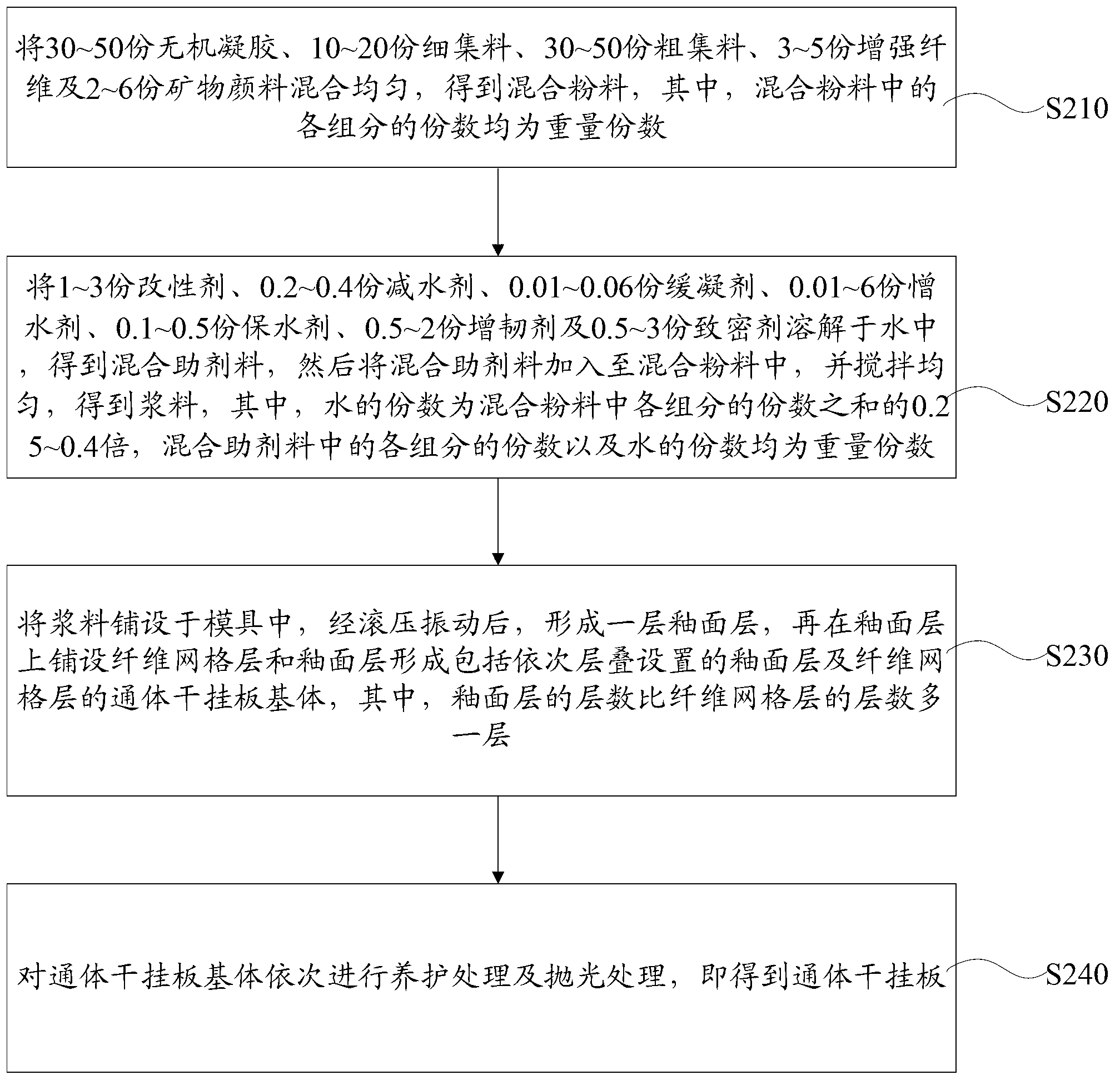

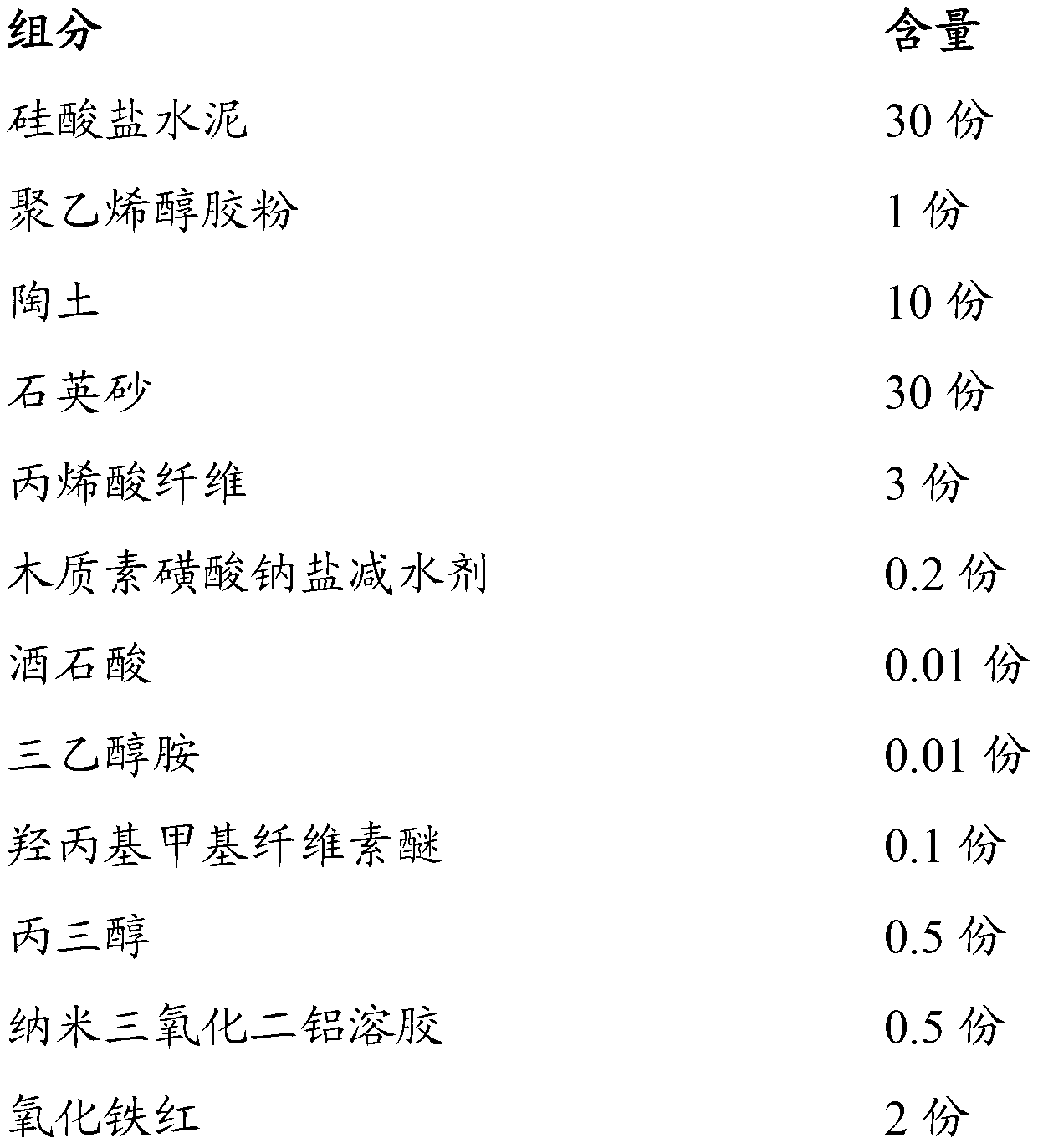

Full-body dry hanging plate and manufacturing method thereof

ActiveCN103255888AGood anti-delamination performanceExtended service lifeCovering/liningsFiberProcess conditions

The invention relates to a full-body dry hanging plate which comprises glaze layers and fiber grid layers, and the number of the glaze layers is one more than the number of the fiber grid layers. Each glaze layer comprises, by weight parts, 30-50 parts of inorganic gel, 1-3 parts of modifying agents, 10-20 parts of fine aggregate, 30-50 parts of coarse aggregate, 3-5 parts of reinforced fibers, 0.2-0.4 part of water reducer, 0.01-0.06 part of retarder, 0.01-6 parts of moisture repellent, 0.1-0.5 part of water-retaining agents, 0.5-2 parts of flexibilizer, 0.5-3 parts of densification agents and 2-6 parts of mineral pigment. The full-body dry hanging plate is good in layering resistant performance and splitting resistant performance. In addition, the invention provides a manufacturing method of the full-body dry hanging plate. The manufacturing method needs no procedure of high-temperature roasting, process conditions are relatively simple, and the full-body dry hanging plate is suitable for industrialized production.

Owner:深圳市爱思宝科技发展有限公司

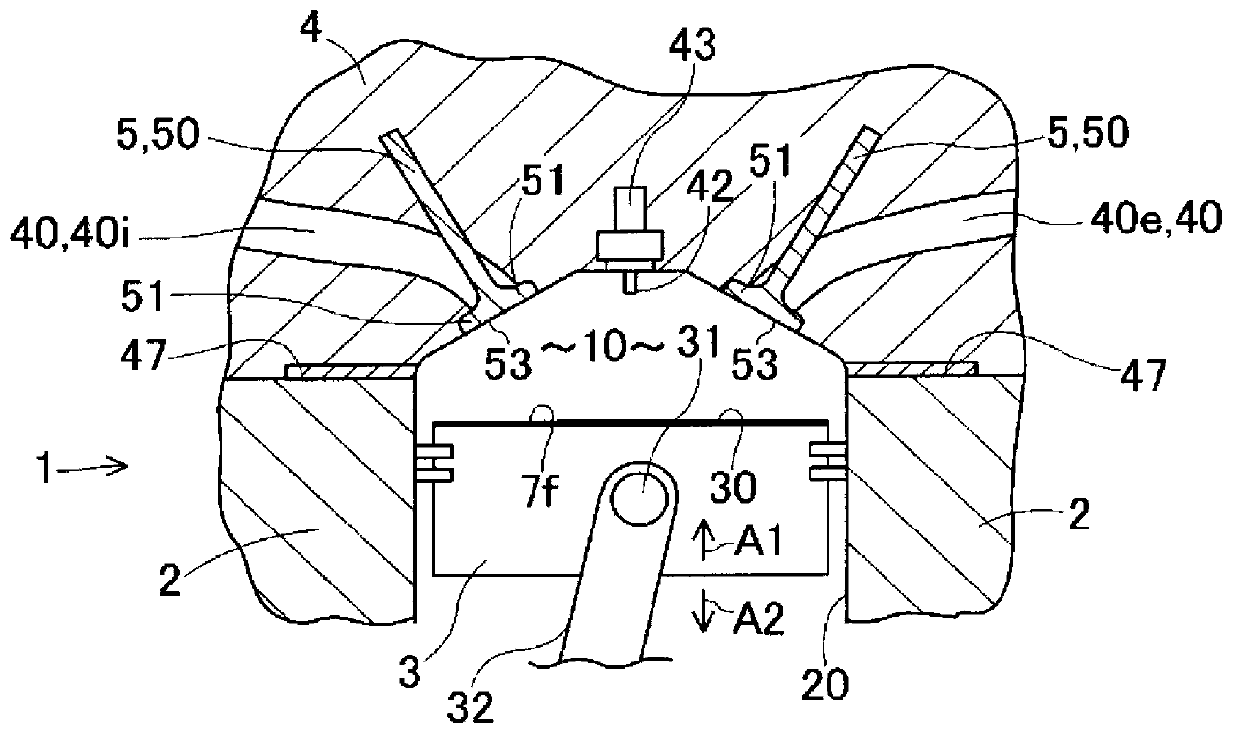

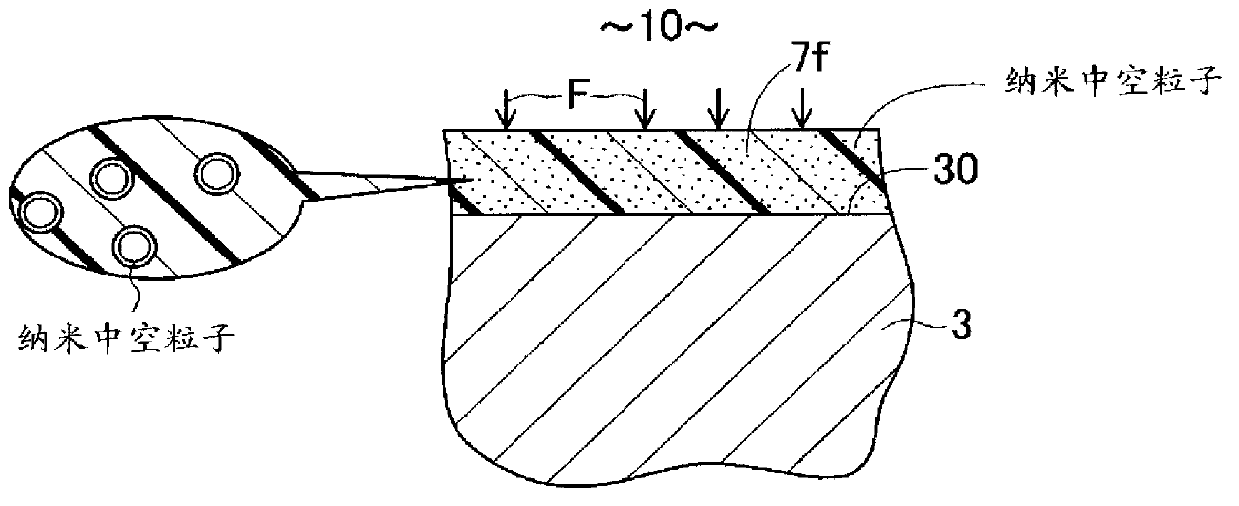

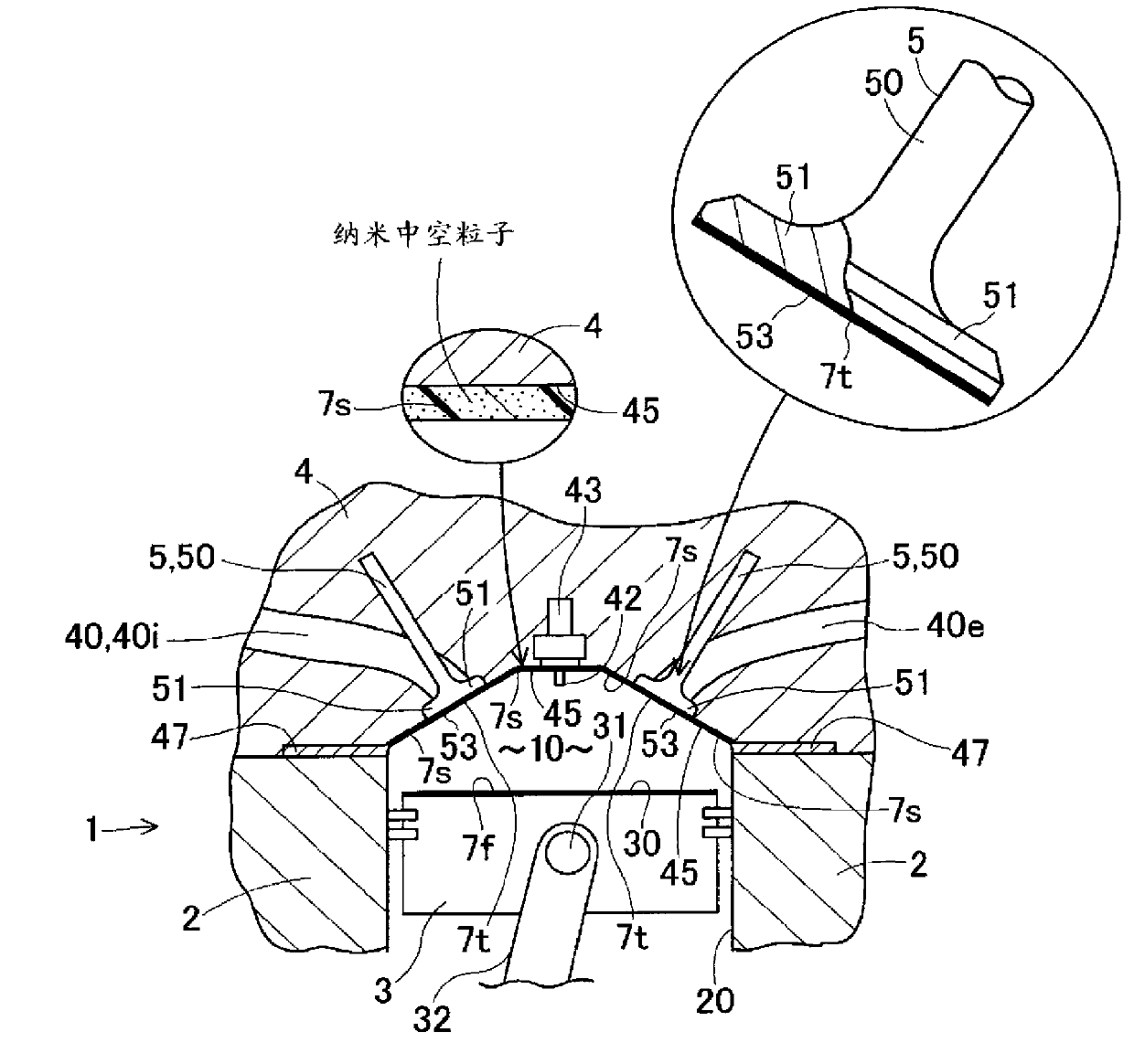

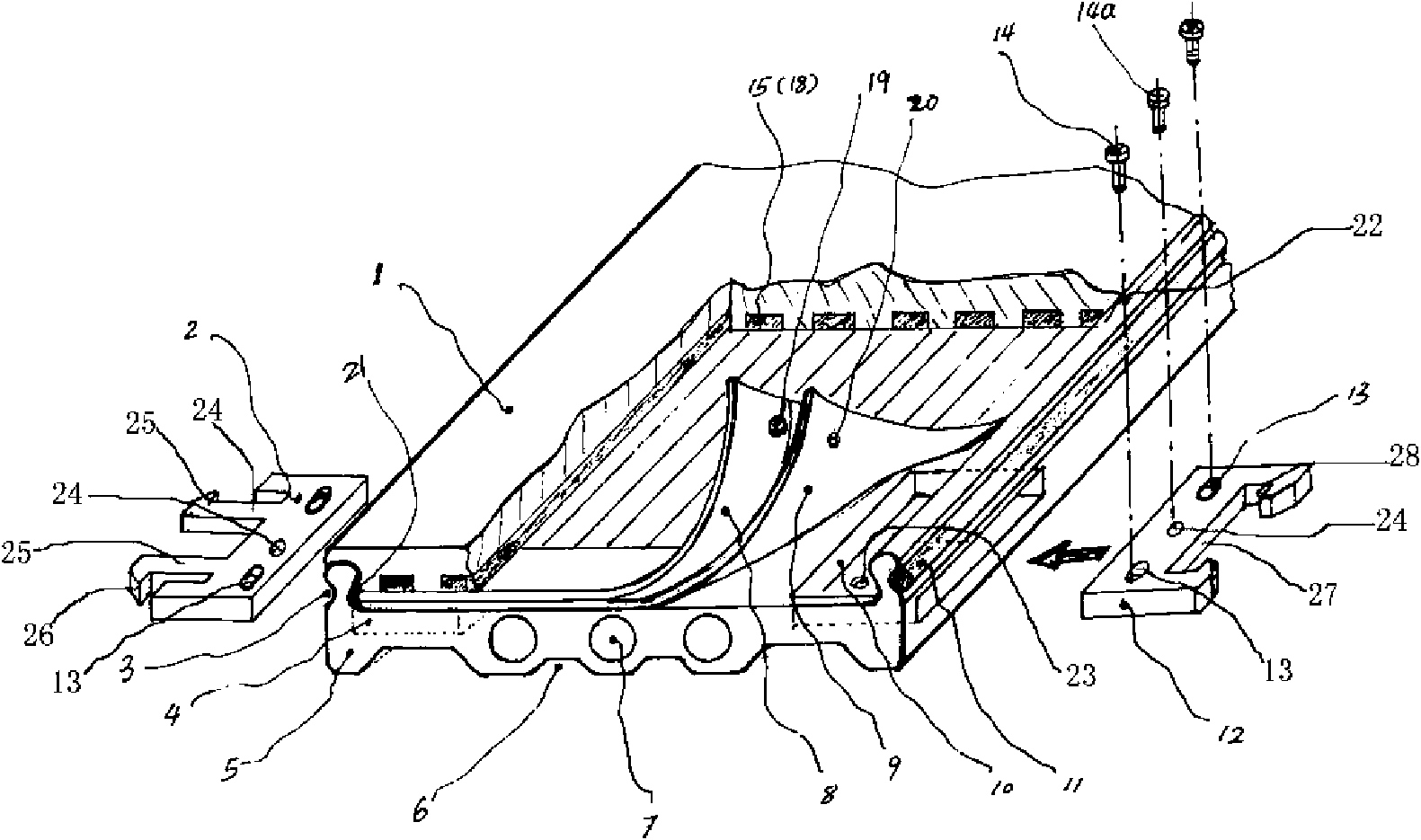

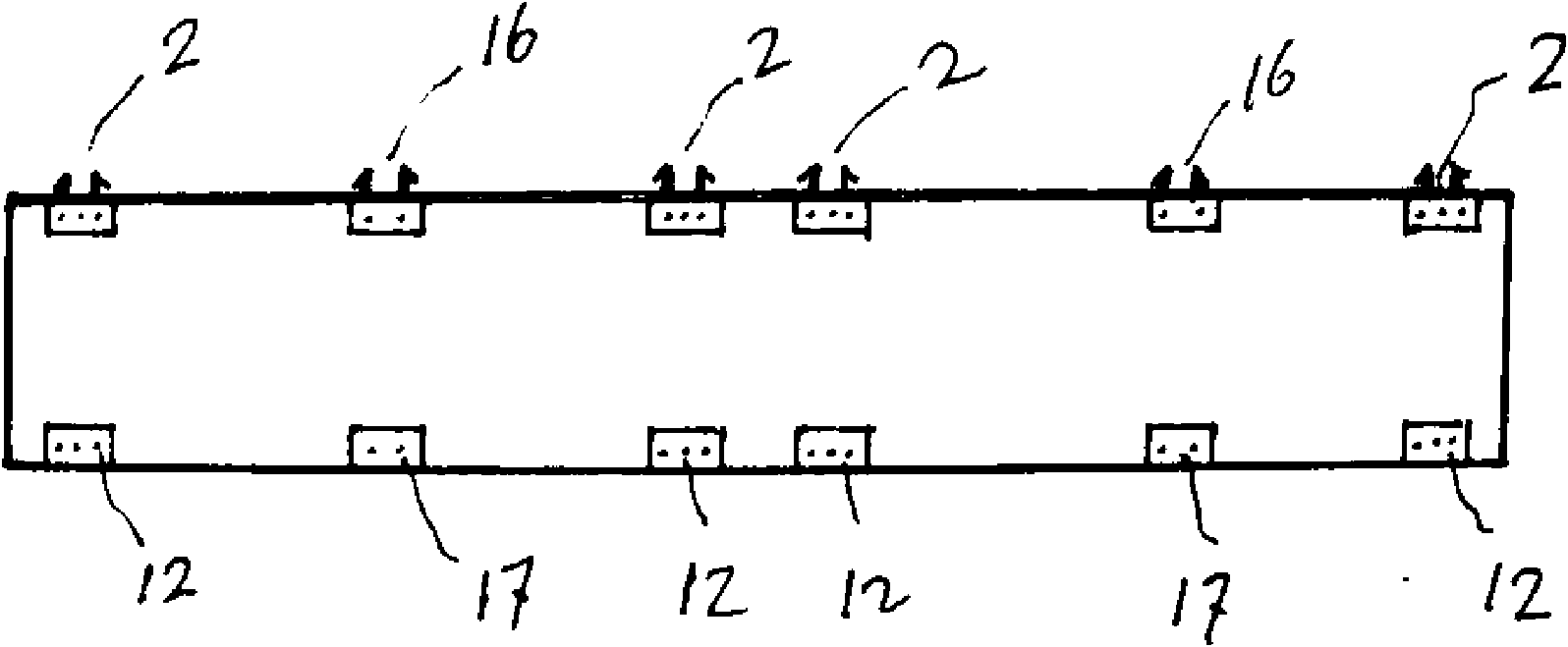

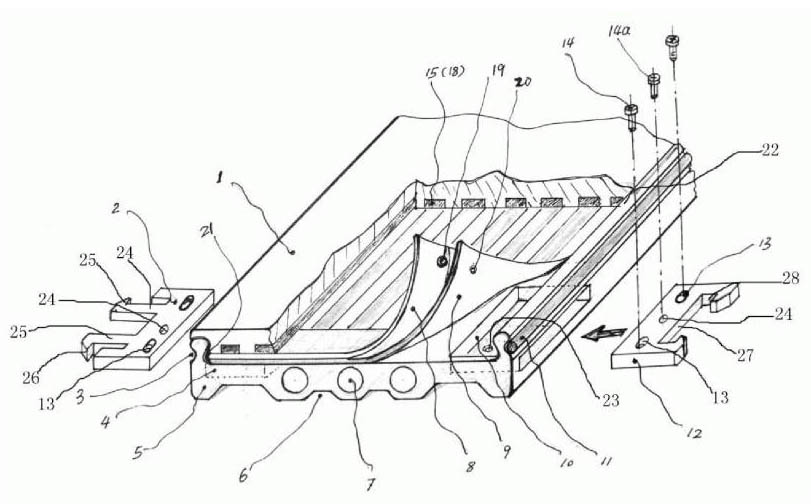

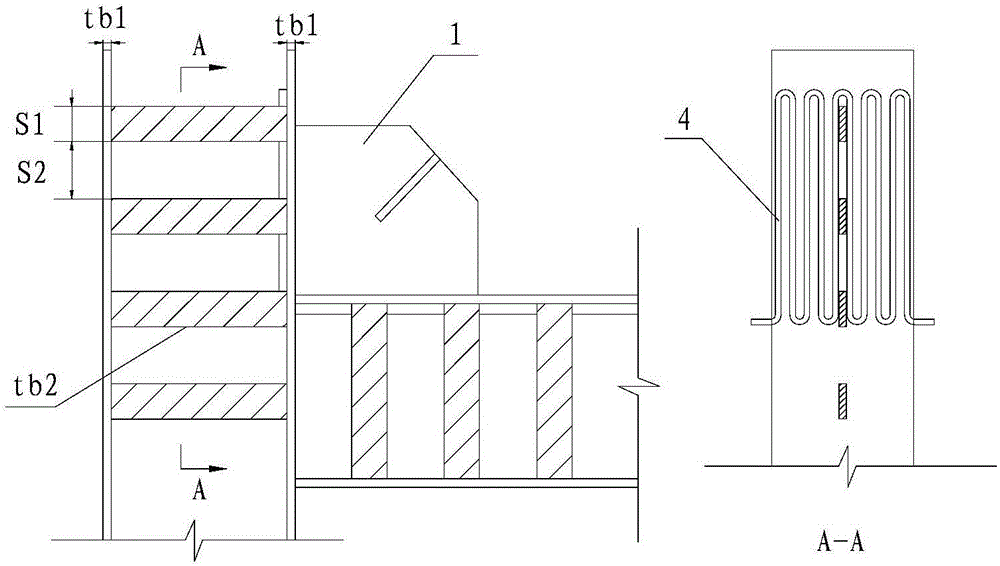

Engine and piston

InactiveCN103328797AAvoid crackingNot prone to crackingPlungersCylinder headsCombustion chamberCylinder head

Owner:AISIN SEIKI KK +1

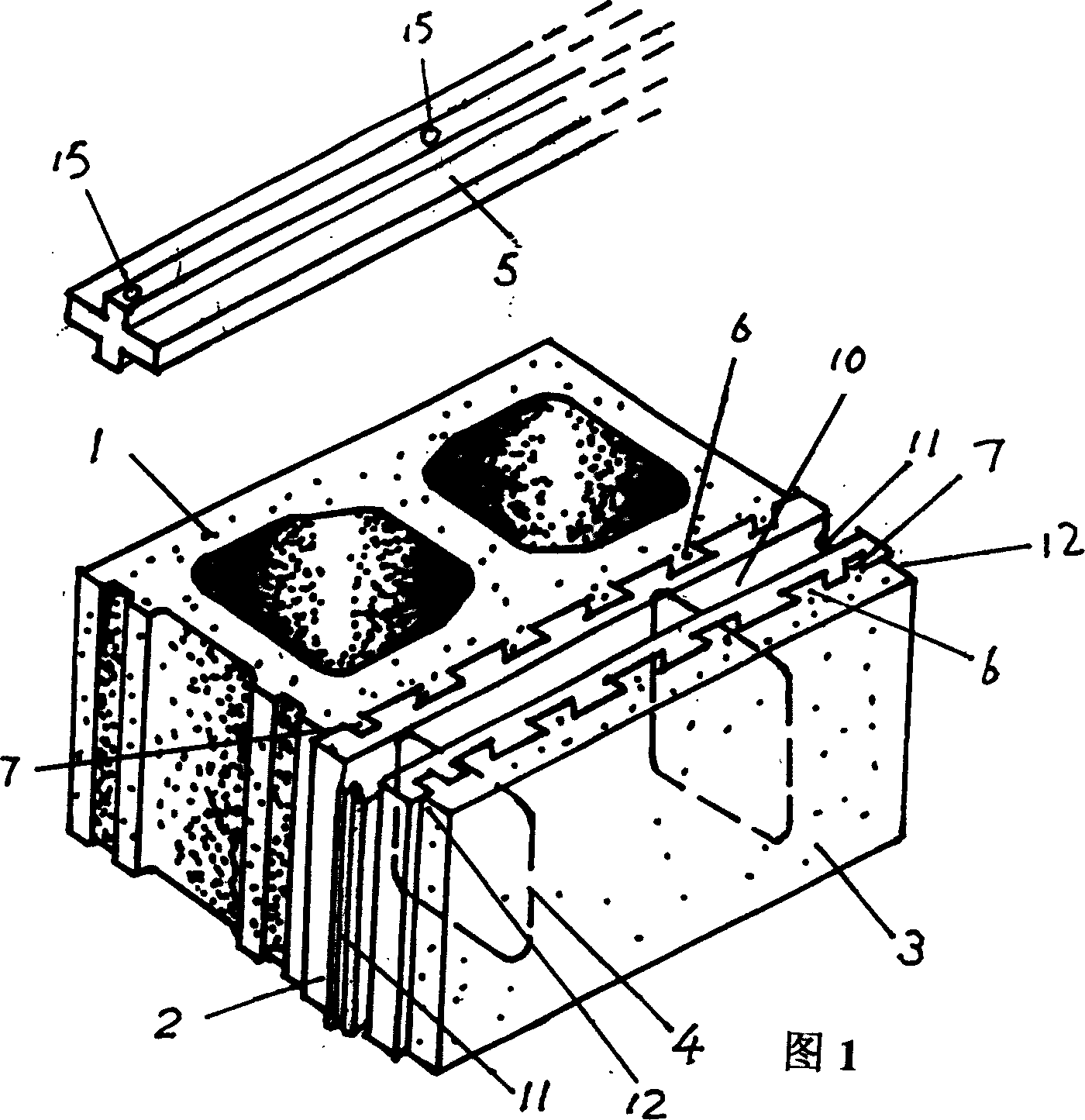

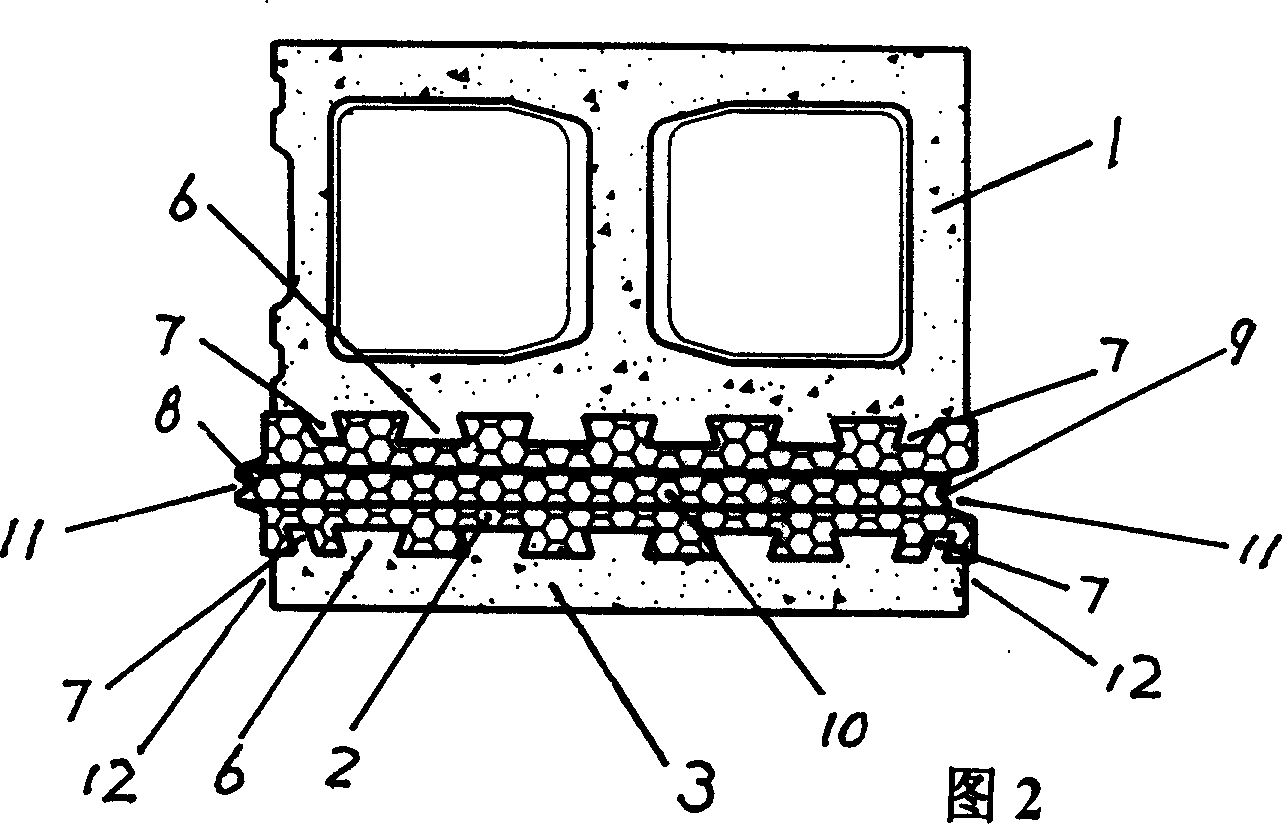

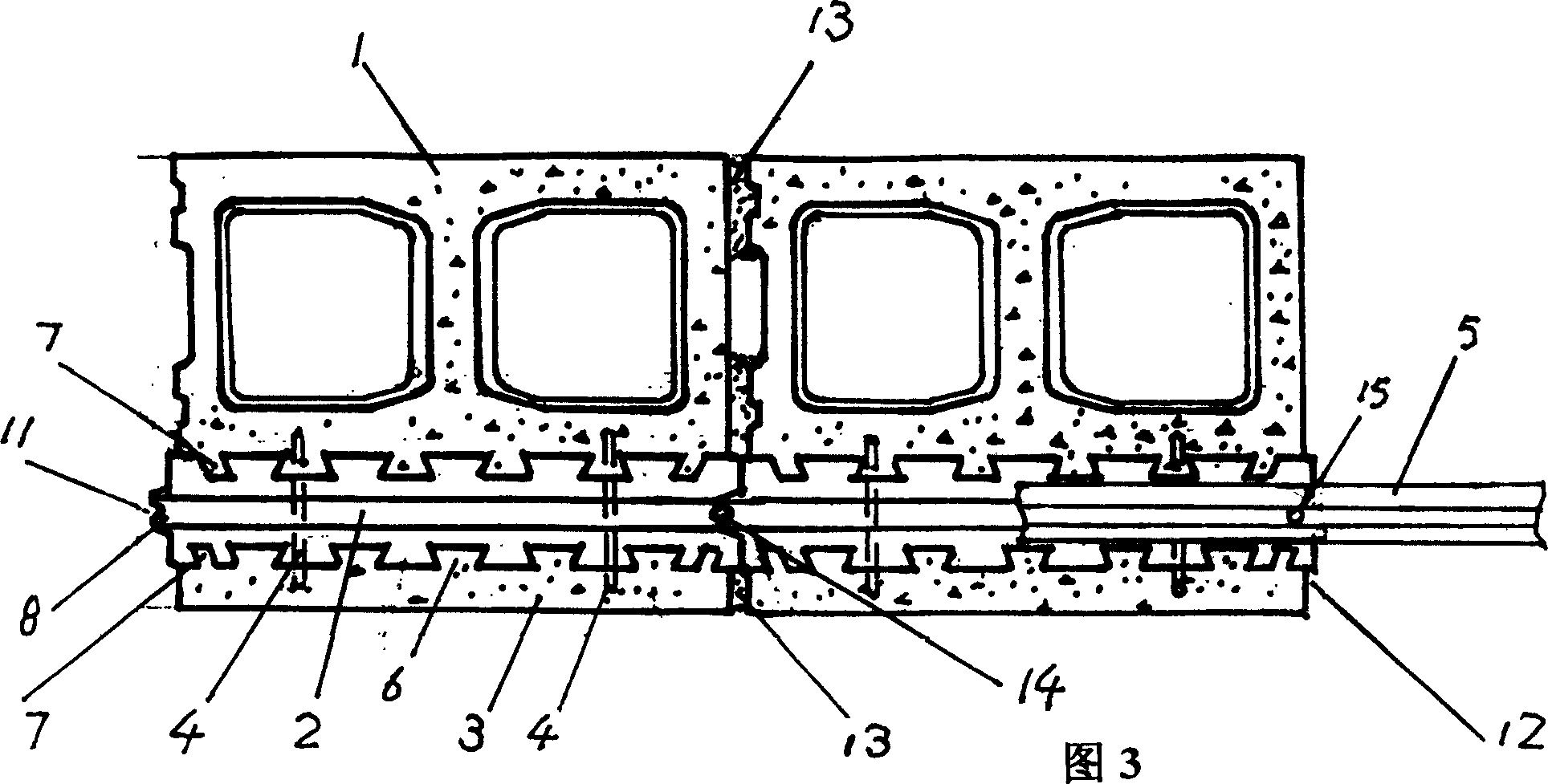

Composite energy saving building blocks and method for making same

InactiveCN1544775ASimple structureImprove insulation effectConstruction materialTectorial membraneSurface layer

The invention relates to a compound energy saving building block and its making method, at present compounded of bearing block, heat-preserving plate, lacing wire, surface layer, and so on. Two ends of the heat-preserving plate are made with inclined anticracking slots, there are air exhaust grooves made on the vertical concave and convex slot, there are cement seam pressure strips on the transverse groove, there are air exhaust holes made on the cement-seam pressure strips, and there are protective films on the lacing wires; and it is made by special techniques of screening antirust low conductive liquor, waterproofing agent and framework material, etc. It has simple and convenient construction, enhances constructing efficiency, has low engineering cost, short working cycle, etc. and it ensures the quality of architectural engineering.

Owner:怀方林

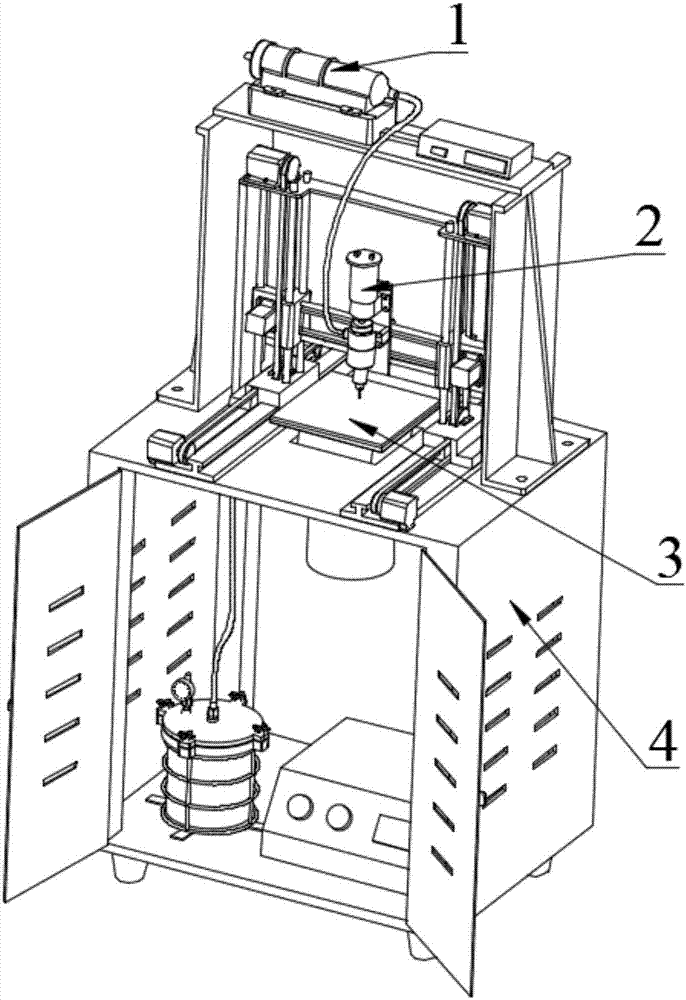

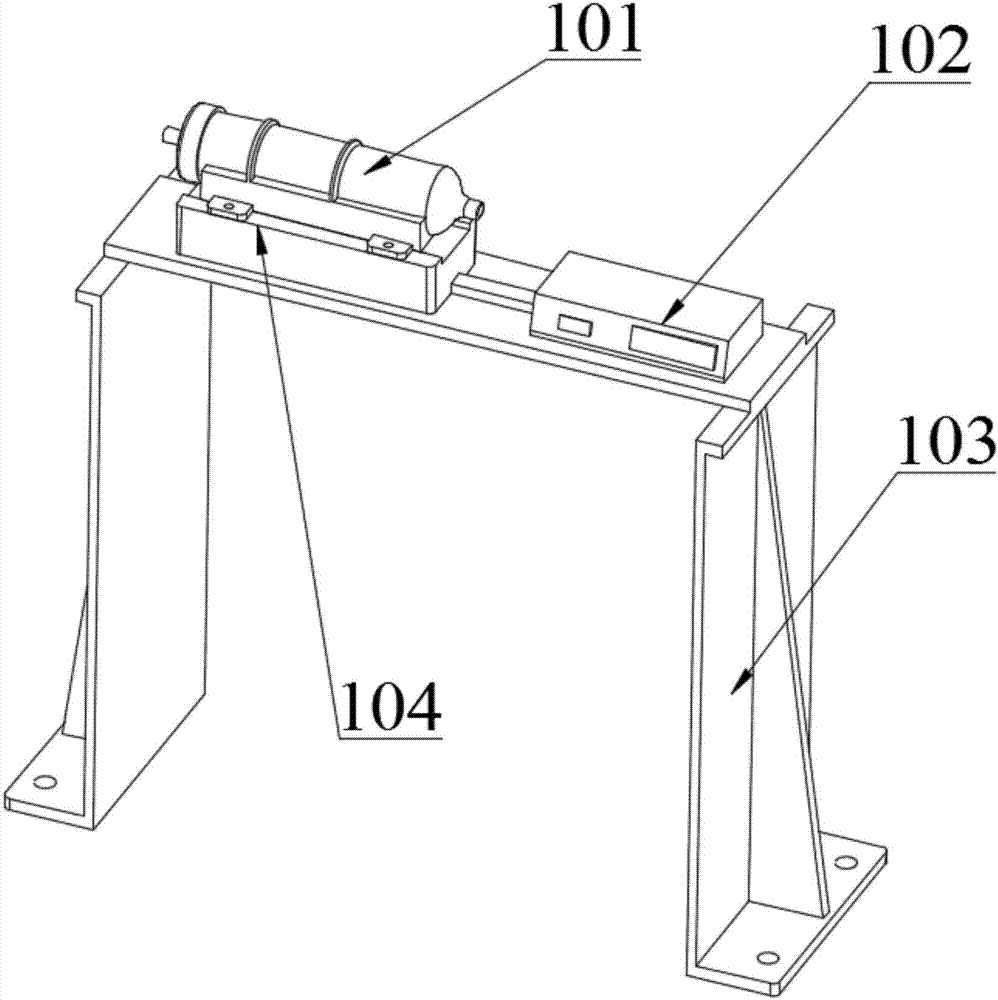

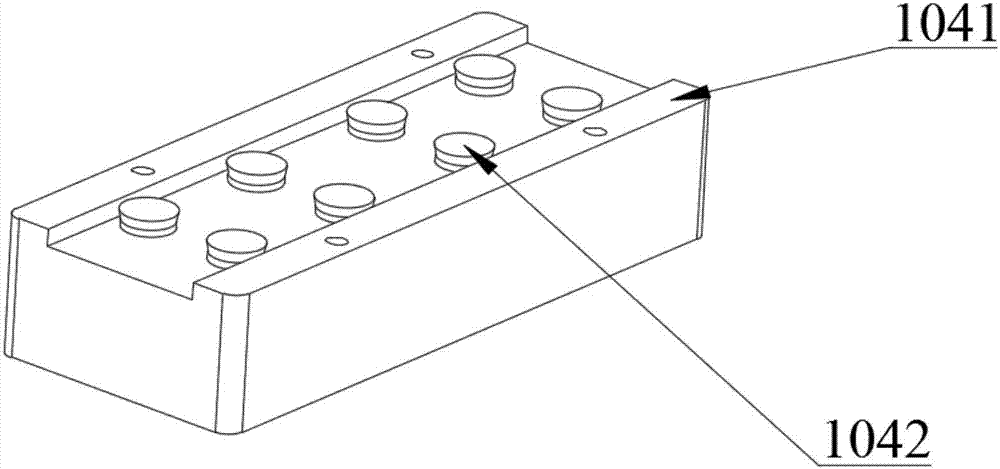

Metallic glass composite material ultrasound-assisted 3D cold printing device and method

ActiveCN107470627ALow costStrong forming abilityAdditive manufacturing apparatusTransportation and packagingGlass compositesUltrasound assisted

The invention provides a metallic glass composite material ultrasound-assisted 3D cold printing device and method, and belongs to the field of additive manufacturing. The metallic glass composite material ultrasound-assisted 3D cold printing device comprises an ultrasonic vibration material cylinder, a three-axis cold printing device, an ultrasonic vibration base plate and a base machine box. According to the metallic glass composite material ultrasound-assisted 3D cold printing device, the 3D cold printing technology, the ultrasonic vibration technology and the superfine-particle reinforced metal matrix composite material technology are combined, the ultrasonic vibration material cylinder is fixedly arranged on the base machine box, the three-axis cold printing device is fixedly arranged on the base machine box, and the ultrasonic vibration base plate is fixedly arranged on the base machine box. According to the metallic glass composite material ultrasound-assisted 3D cold printing device and method, superfine reinforced particles are added to a metallic particle solution, so that the mechanical property of a material is enhanced; the distribution uniformity of the superfine particles in the metallic particle solution is improved by the use of ultrasonic vibration; and a three-dimensional metallic glass composite material part is directly formed through the 3D cold printing technology, the forming speed is high, the part strength is high, the density is uniform, the cost is low, and no special requirements for the working environment exist.

Owner:JILIN UNIV

Coal mine underground coal bed waterproof paint

The invention provides a coal mine underground waterproof paint, which is characterized by comprising the following components in part by weight: 13 to 27 parts of re-dispersible latex powder, 30 to 40 parts of cement, 35 to 40 parts of quartz sand, 5 to 10 parts of graphite powder, 5 to 10 parts of fly ash, 4 to 6 parts of vermiculite powder, 4 to 6 parts of expanded perlite powder, 4 to 6 parts of aluminum hydroxide, 2 to 4 parts of magnesium hydroxide, 0.003 to 0.024 part of air entraining agent, and 0.02 to 0.09 part of water reducing agent. Compared with other waterproof paint, the coal mine underground waterproof paint has the advantages of good waterproofing quality, flame resistance, antistatic property, elasticity, good cohesive property with coal, light weight, environmental protection, nontoxicity, easy construction and the like, and is suitable for coal mine underground waterproofing.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

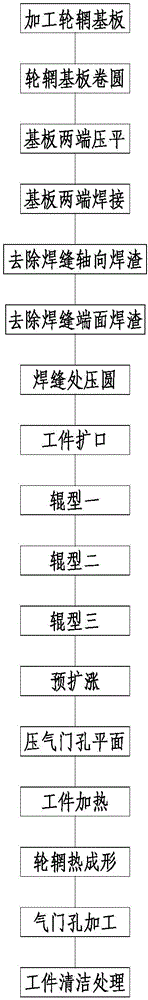

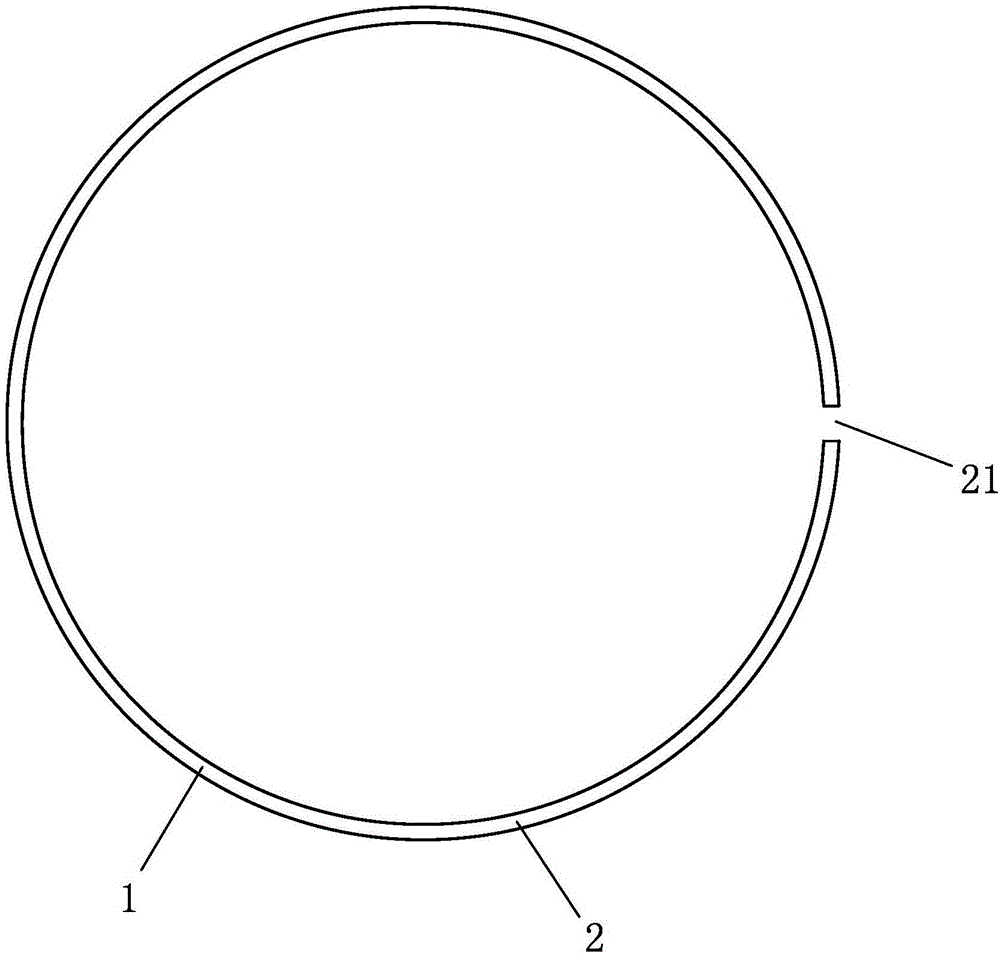

Manufacturing method of hot forming rim

ActiveCN106363353ANot prone to crackingAvoid deformationVehicle componentsEngineeringMechanical engineering

The invention relates to a manufacturing method of a hot forming rim. The manufacturing method comprises following manufacturing steps of A1, rim round pipe forming, wherein a metal plate is used for manufacturing a closed round pipe with the closed circumferential direction; A2, rim workblank forming, wherein the closed round pipe is manufactured into a rim workblank with the diameter smaller than the rim designed diameter; A3, rim workblank pre-expanding, wherein the rim workblank is subject to pre-expanding, and the diameter of the expanded rim reaches 99.5% to 99.9% of the designed diameter; A4, rim workblank heating, wherein the rim workblank is heated to the designed temperature; A5, expansion finishing, wherein through the expansion manner, the diameter of the workblank reaches the designed size; A6, stamping and hardening, wherein the strength of the rim workblank is improved to above 1300MPa. Before heating, pre-expanding is carried out, the expansion amount during hot forming is reduced, the size precision of the rim is improved, and the expanding traces are reduced; the precision of out-of-roundness of the rim is improved; after heating, the manner of expansion finishing and stamping and hardening is adopted, and the forming precision and the forming strength are more effectively improved.

Owner:ZHEJIANG JINGU CO LTD

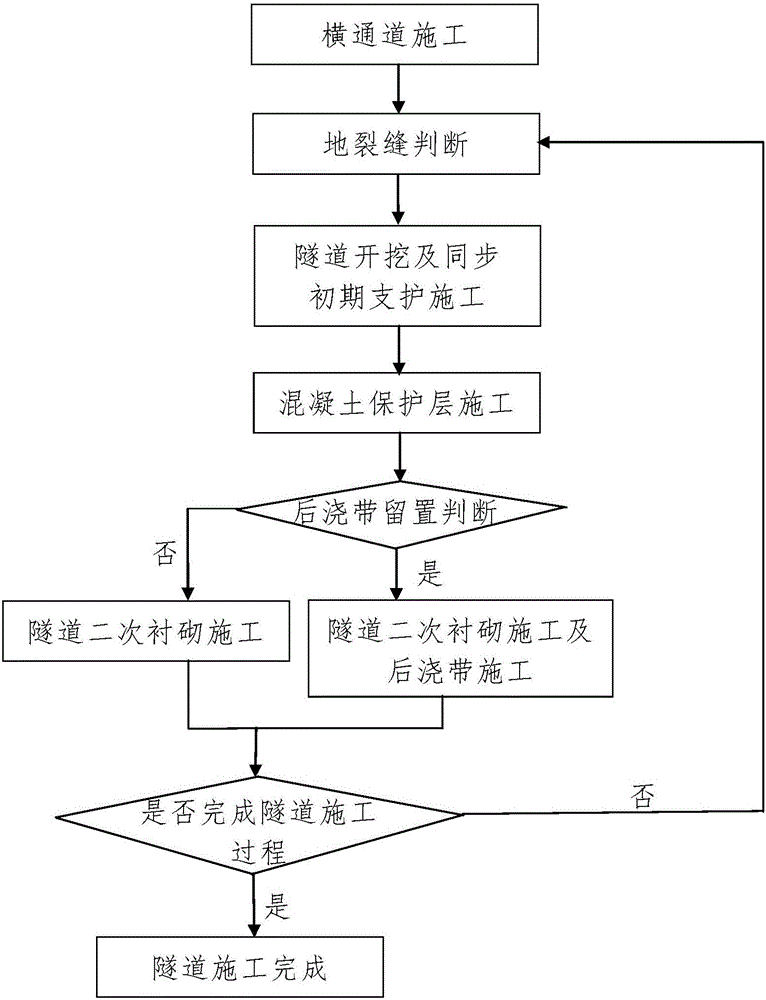

Ground fracture crushed zone passing construction method for shallow-buried tunnel excavation

ActiveCN106437726AThe method steps are simpleReasonable designUnderground chambersTunnel liningProtection layerTunnel construction

The invention discloses a ground fracture crushed zone passing construction method for shallow-buried tunnel excavation. A constructed shallow-buried excavation tunnel comprises a left line tunnel and a right line tunnel which are communicated through a transverse channel. During construction of the constructed shallow-buried excavation tunnel, the method comprises the steps that 1, transverse channel construction is performed; 2, tunnel construction is performed, wherein the two tunnel sections of the left line tunnel and the right line tunnel are constructed through the transverse channel, the construction is performed in the mode of multiple tunnel sections in the longitudinal extending direction of the tunnel from back to from during construction of any one tunnel section, and the construction of any one tunnel section includes the processes of ground fracture judgement, tunnel excavation and synchronous preliminary bracing construction, concrete protection layer construction, post-cast strip retention judgement, secondary tunnel lining construction and post-cast strip construction. The method includes simple steps and is reasonable in design, convenient to construct, good in construction effect, capable of simply and conveniently completing the shallow-buried tunnel excavation construction process of a ground fracture crushed zone and safe and reliable in construction process.

Owner:中铁二十局集团第五工程有限公司

Carbon-based composite building wave absorption and heat preservation material and preparation method thereof

The invention discloses a carbon-based composite building wave absorption and heat preservation material and a preparation method thereof. According to the preparation method, carbon-based wave absorbing agent, common silicate cement, expanded and vitrified small balls, re-dispersible latex powder, hydroxypropyl methyl cellulose, wood fiber, polypropylene fiber, surfactant, foam stabilizer, waterreducing agent, coupling agent, water and the like are adopted; and the material is obtained by adopting the steps of stirring, pouring molding, curing and the like. The material has the advantages of good wave absorption performance and heat insulation performance, low apparent density, low cost, high fire resistance, durability and the like, and is easy to construct. The material can be used for pouring roofs and walls of buildings, so that aims of electromagnetic radiation protection and energy conservation of the buildings are fulfilled.

Owner:CHONGQING UNIV

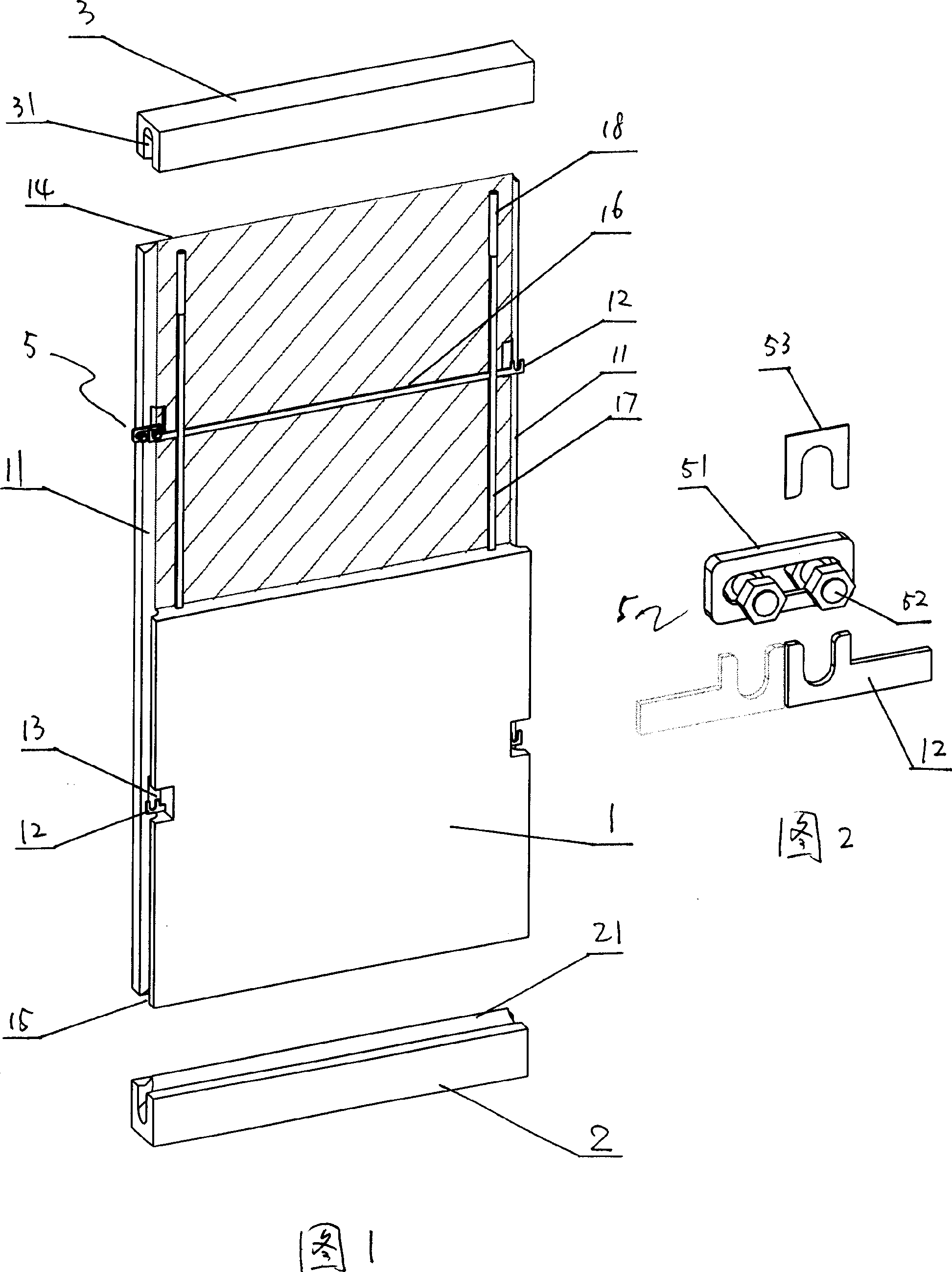

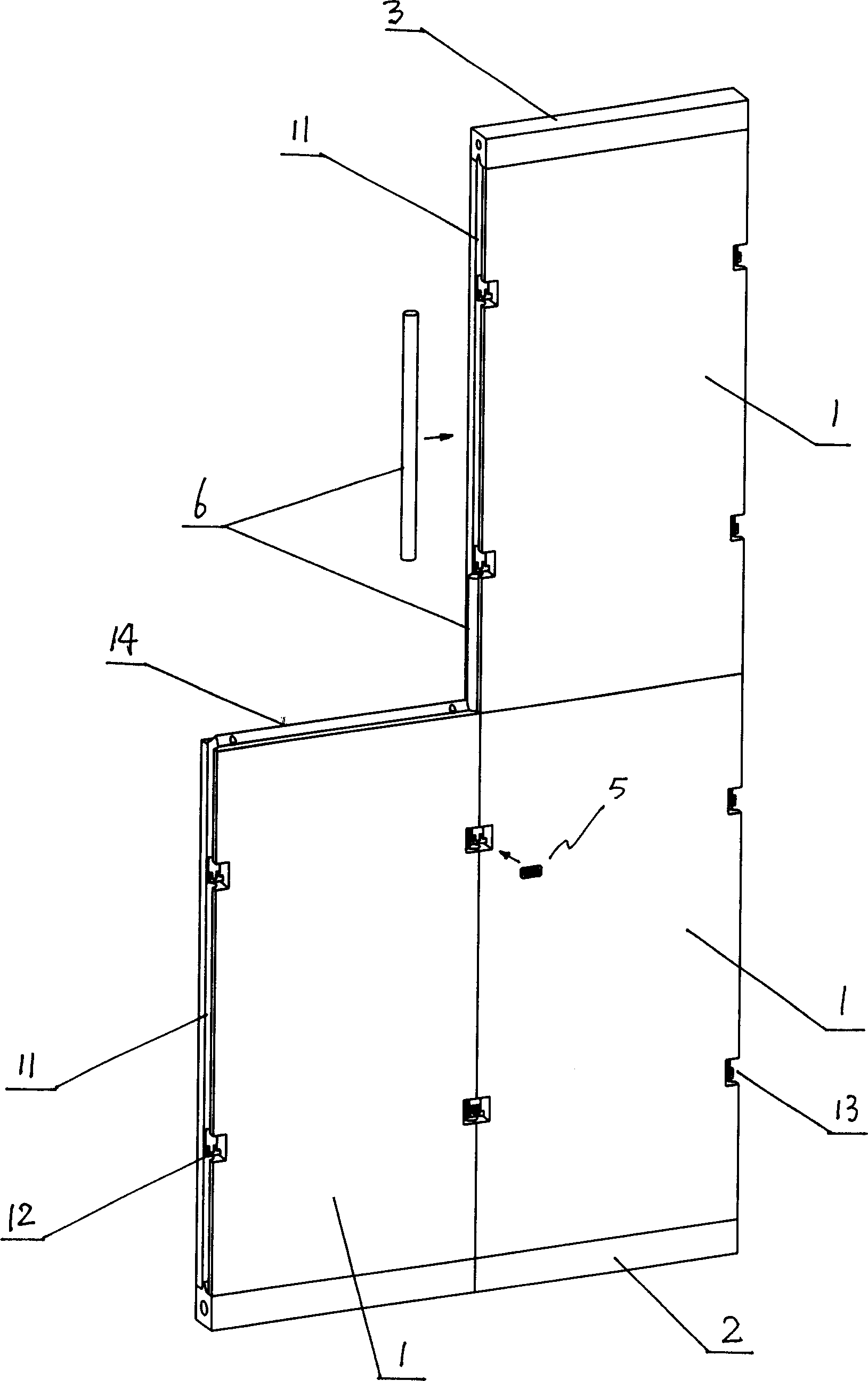

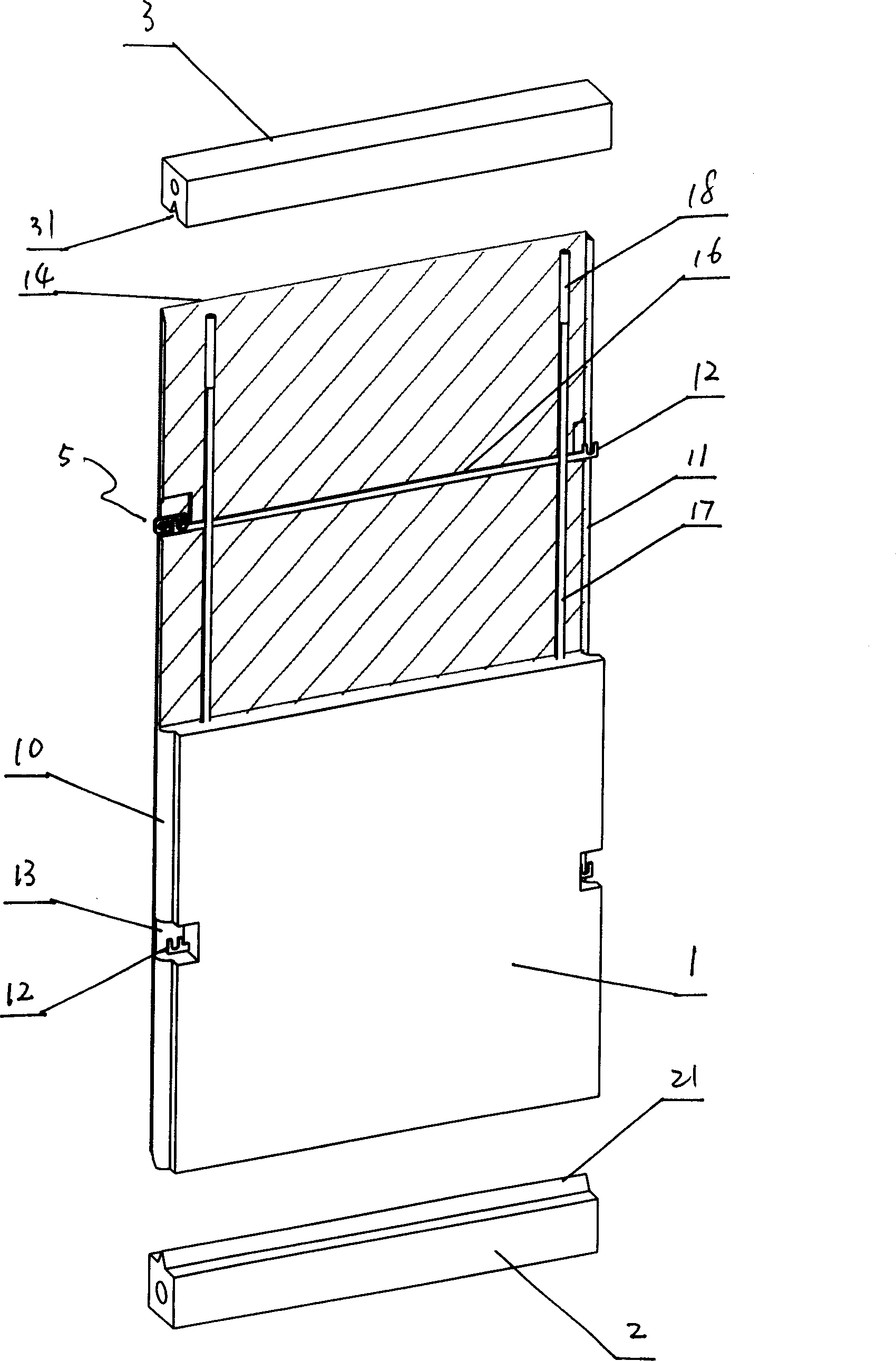

Assembled wall plate connected by metal connecting members

This invention relates to a sectioned wall plate associated by metal adapting piece, which comprises wall body, the selectable unit: lower bearing block and top block, characterized in that the vertical bilateral of the wall has symmetrical beard and metal adapting piece, and the upper and lower bilateral of the board has the intermeshing flange and beard; the wall has at least one horizontal reinforcement board used for connecting the metal adapting pieces in the two sides of the board, said adapting piece is U type clasp adapting piece, and the double bolt fastening assemblies are used to fit the adapting piece. When using, build up the wall as normal, and then use the connecting board assemblies to fasten the adapting pieces of two adjacent.

Owner:沈宪光

Green environment protection type raising-dust covering-agent and preparation process thereof

InactiveCN1450143AQuality improvementIncrease humusOrganic fertilisersSoil conditioning compositionsGreen environmentFree cooling

The present invention relates to an EEJL-1 green environment-protecting raise dust covering agent and its preparation method. Said covering agent is formed from water, straw, starch, lime powder and additive, their ratio is 100:2-10:0.5-8:0.1-0.6:0.1:-0.6 (weight ratio). Its preparation method includes the following steps: adding 2-10 portions of straw into 100 portions of water, stirring and heating to 30-50 deg.c, under the condition of continuously stirring adding 0.5-8 portions of starch, heating to 60-100 deg.C and adding 0.1-0.6 portion of lime powder and 0.1-0.6 portion of additive, then stirring for 20-40 min. and natural cooling so as to obtain the invented raise dust covering agent which has no pollution, is good in dust-suppressing effect and low in cost.

Owner:BEIJING UNIV OF TECH

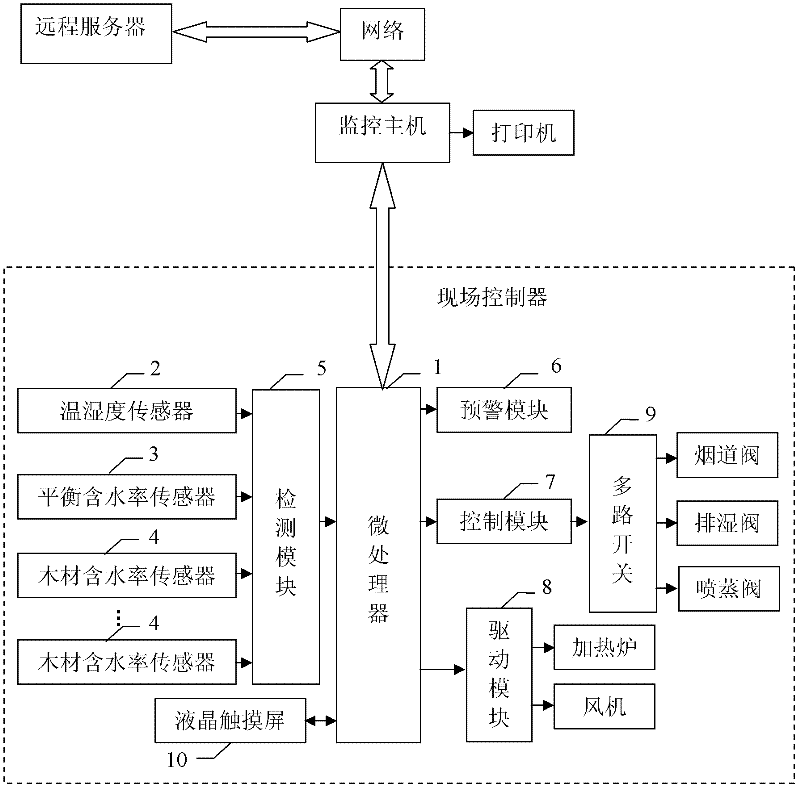

Wood drying remote monitoring system based on DSP (digital signal processor)

InactiveCN102564106AShort drying cycleImprove efficiencyDrying solid materialsDigital signal processingThe Internet

The invention discloses a wood drying remote monitoring system based on a DSP (digital signal processor), which relates to a wood drying remote monitoring system and solves problems of low drying efficiency and complication in operation of an existing wood drying remote monitoring system. The wood drying remote monitoring system comprises a remote server, a monitoring host and a field controller. The monitoring host and the field controller are in data transmission by a serial bus, the monitoring host and the remote server are in data transmission via an Internet according to the TCP (transmission control protocol), and the field controller can run independently, can also receive various commands from the remote server and the monitoring host via a network bus and the serial bus and feeds data back to the monitoring host after the commands are executed. The wood drying remote monitoring system is applicable to automatic wood drying places with middle and large-size drying kilns.

Owner:NORTHEAST FORESTRY UNIVERSITY

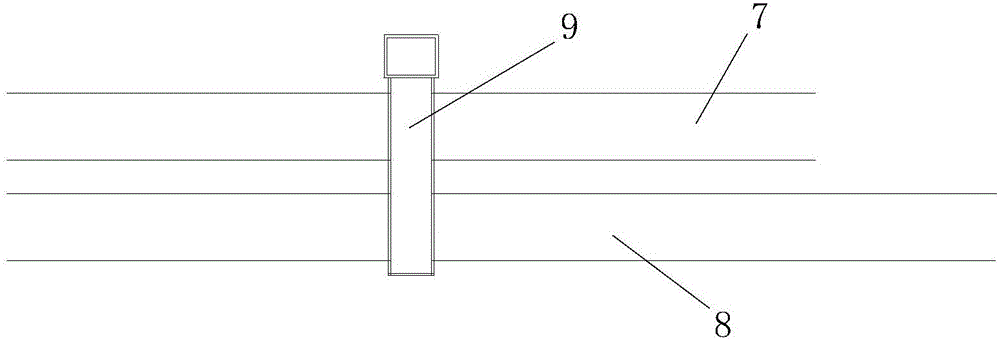

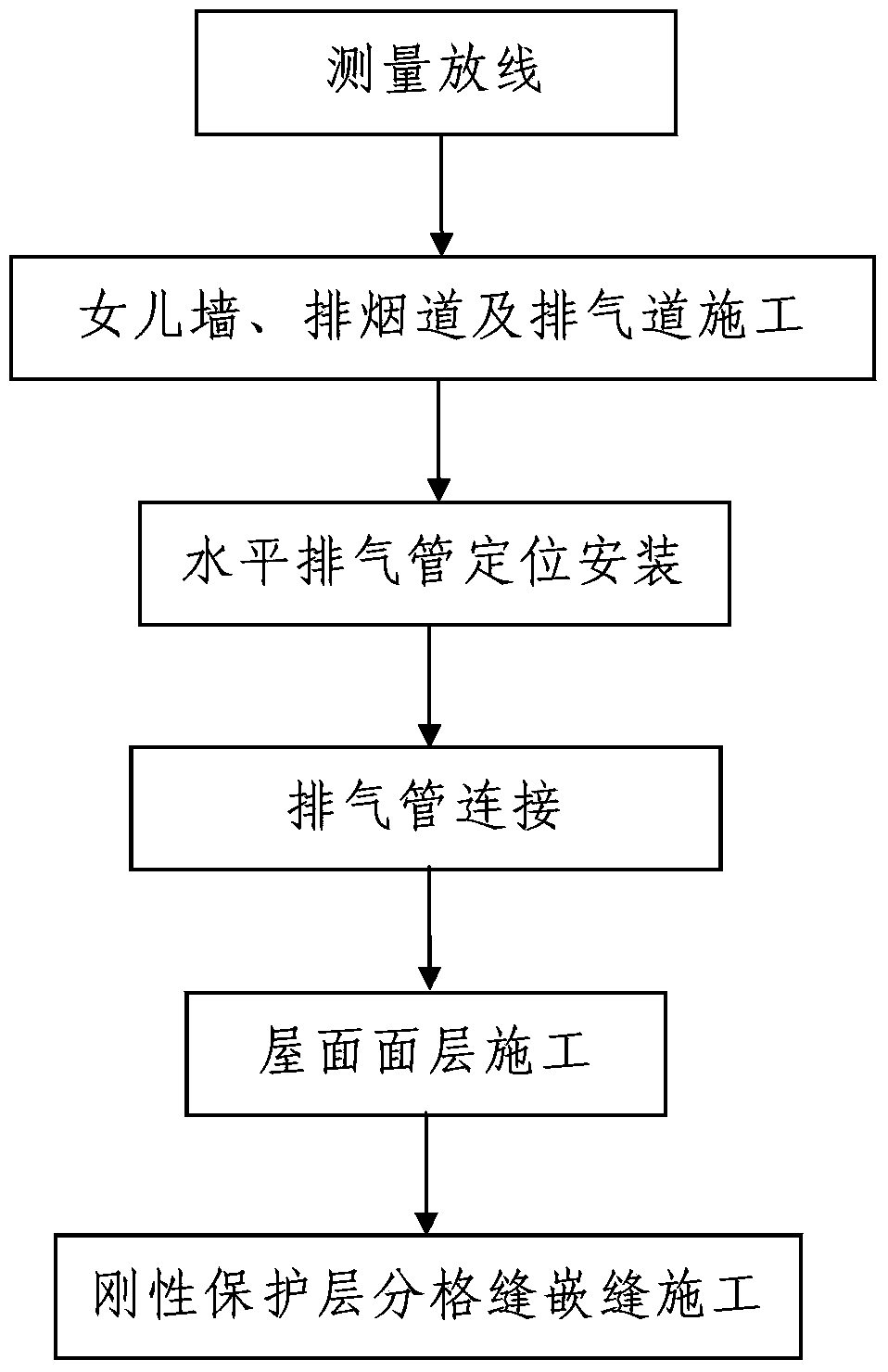

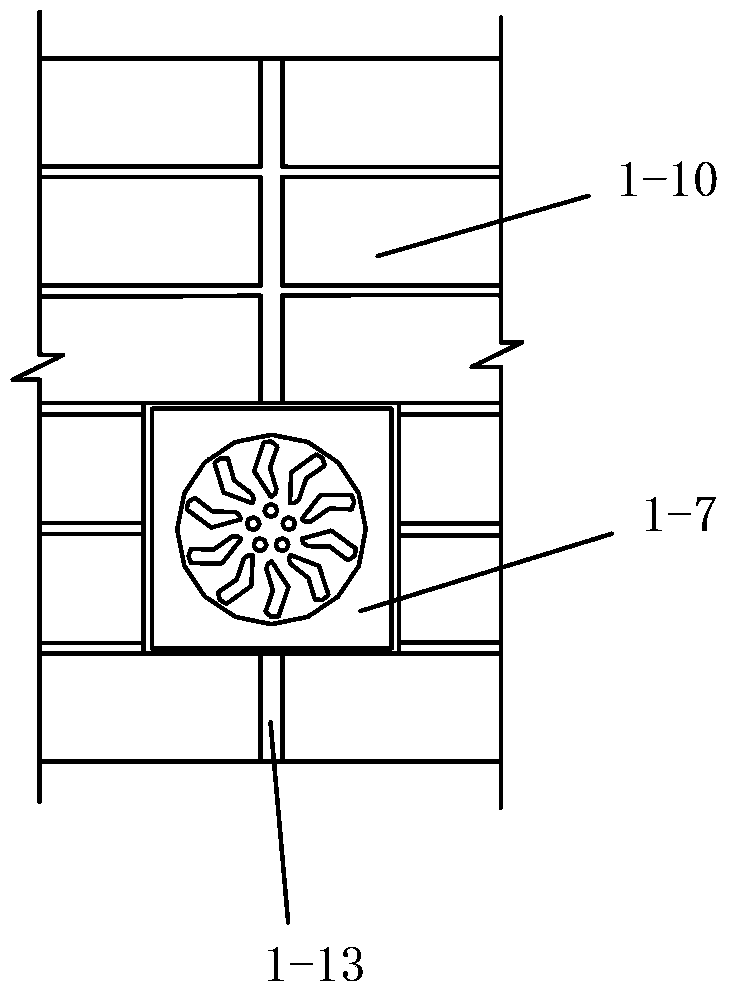

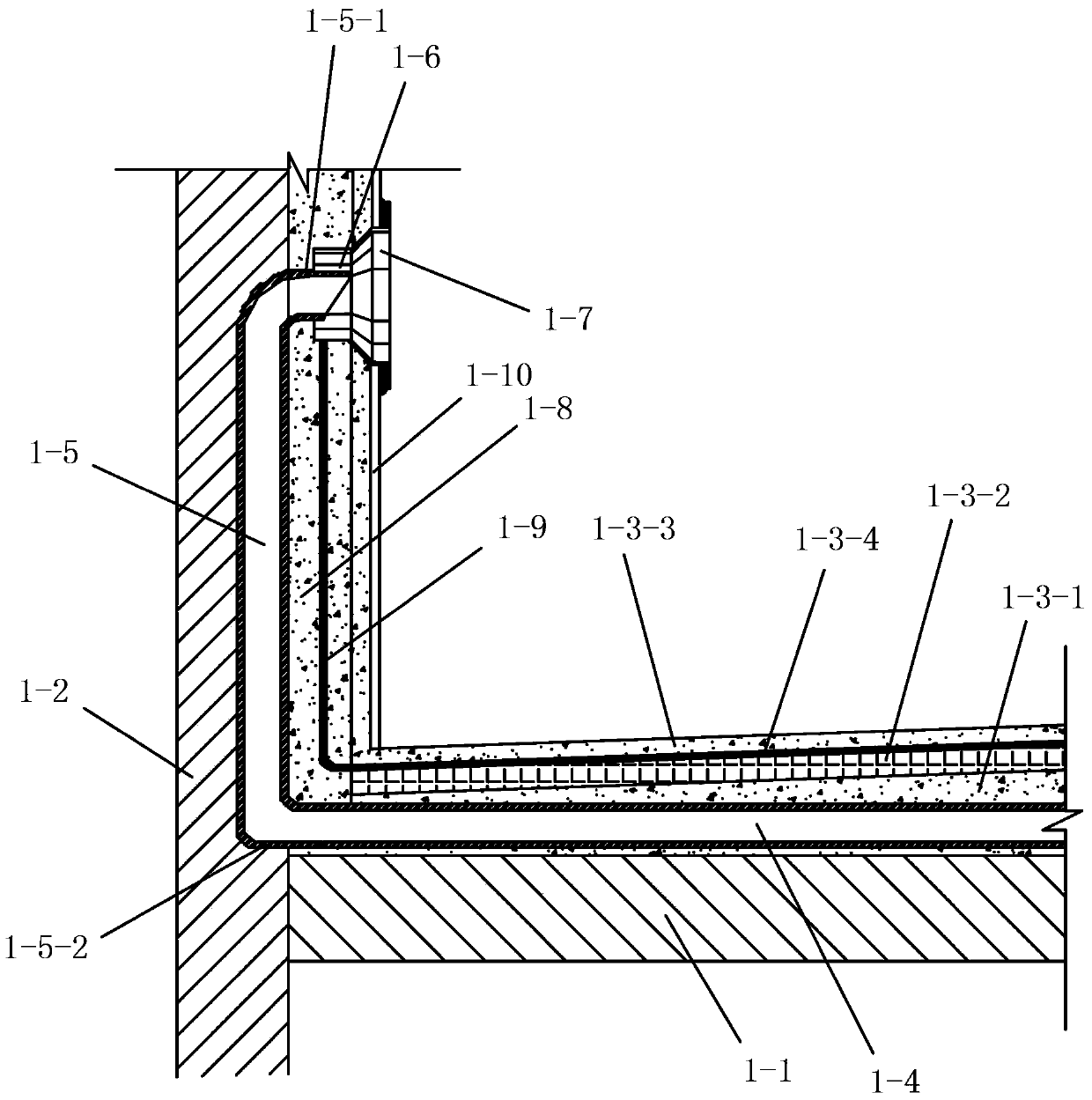

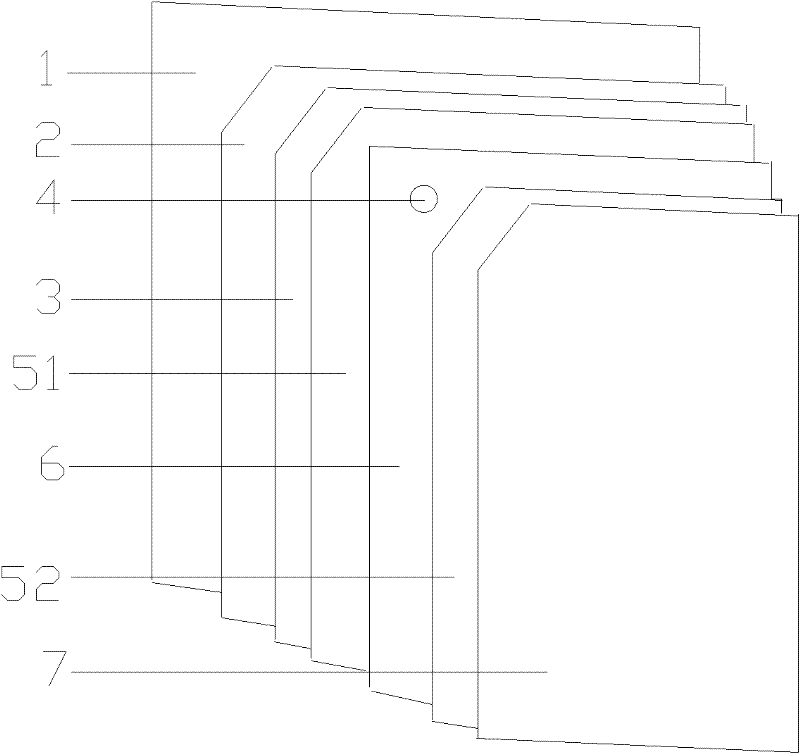

Building roof construction process

InactiveCN103362254ASimple stepsReasonable designLighting and heating apparatusBuild-up roofsInsulation layerSurface layer

The invention discloses a building roof construction process. A construction roof comprises a roof structure plate, a parapet wall and a roof surface layer, wherein the parapet wall is arranged above the roof structure plate, the roof surface layer is paved on the roof structure plate, a roof exhaust system is arranged on the construction roof and comprises a plurality of first horizontal exhaust pipes, the first horizontal exhaust pipes are respectively laid in a slope finding layer or a heat insulation layer in the roof surface layer, two ends of each first horizontal exhaust pipe are respectively connected with a vertical exhaust pipe, and the vertical exhaust pipes are embedded in the side walls of the parapet wall and a discharge flue or the side wall of an exhaust passage. The construction process of a construction roof comprises the steps of 1, surveying and setting out; 2, parapet wall, discharge flue and exhaust passage construction; 3, horizontal exhaust pipe positioning installation; 4, exhaust pipe connection; 5, roof surface layer construction; and 6, rigid protecting layer mesh division and caulking construction. The construction process has the advantages that the steps are simple, the operability is high, the realization is convenient, in addition, the work efficiency is high, the construction effect is good, and the construction quality of the construction forming building roof can be effectively ensured.

Owner:陕西建工集团有限公司 +1

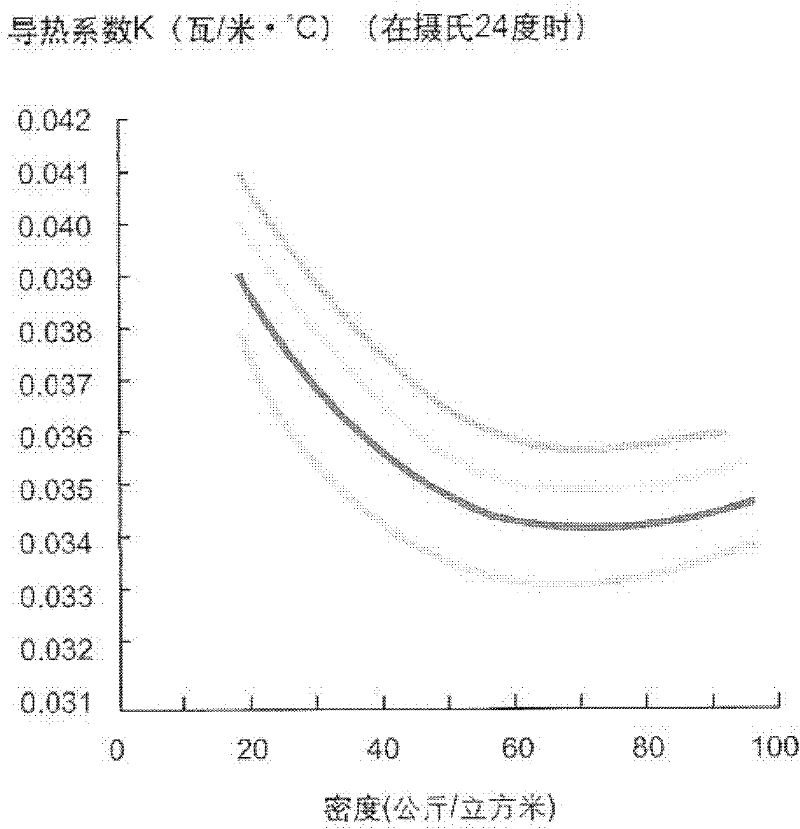

Outer wall heat-preserving system

InactiveCN102444213AGood safety and fire resistanceGuaranteed safety and reliabilityHeat proofingCorrosionFiberglass mesh

The invention relates to an outer wall heat-preserving system, which comprises a bonding mortar layer, a heat-preserving layer, a surfactant layer, a rendering coat mortar layer, glass fiber gridding cloth, an anchoring piece and a finishing coat, wherein the inner surface of the heat-preserving layer is bonded on a wall body by coating the bonding mortar layer; the surfactant layer is coated on the outer surface of the heat-preserving layer; the inner surface of the glass fiber gridding cloth is bonded on the surfactant layer through the rendering coat mortar layer; the finishing coat is bonded on the outer surface of the glass fiber gridding cloth through the rendering coat mortar layer; and the anchoring piece is arranged on the outer side of the glass fiber gridding cloth, and is fixed on the wall body by passing through the heat-preserving layer. Compared with the prior art, the outer wall heat-preserving system has the advantages of safety, moisture resistance, corrosion resistance, insect pest resistance, molding resistance, high heat-preserving performance, high sound insulating performance, high fire resistance, high durability, and the like.

Owner:SHANGHAI QIHONG TECH DEV

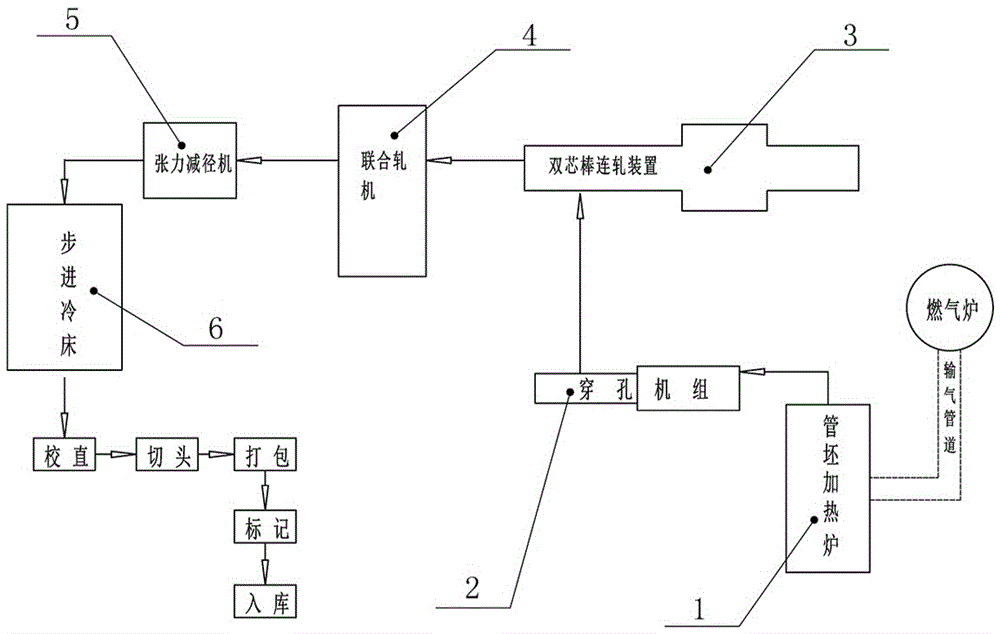

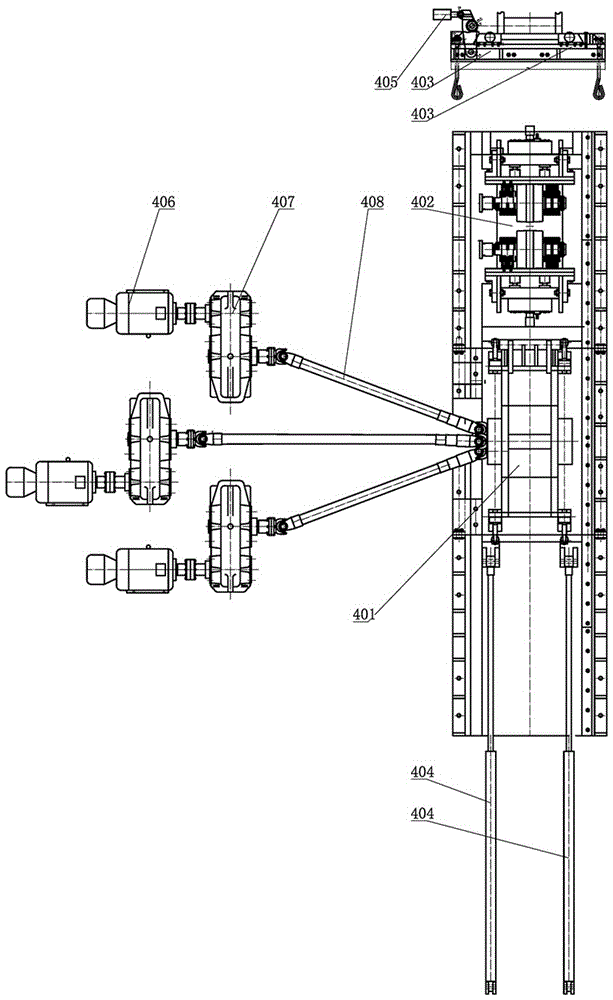

Hot-rolling seamless steel pipe producing method of double-mandrel combined rolling mill

ActiveCN106216399AIncrease productivityImprove product qualityMetal rolling arrangementsContinuous rollingSizing

The invention belongs to the technical field of production and machining of seamless steel pipes, and particularly relates to a hot-rolling seamless steel pipe producing method of a double-mandrel combined rolling mill. By adoption of the method, seamless steel pipes can be rolled at a high temperature, the radial structures of the steel pipes are not prone to rolling cracks, the production efficiency and the quality of the seamless steel pipes are high, and the production cost is low. The method comprises the specific steps of heating, perforating, penetrating of mandrels of a double-mandrel continuous rolling device, rolling, sizing reshaping, cooling and finished product collecting. The hot-rolling seamless steel pipe producing method of the double-mandrel combined rolling mill has the advantages that the seamless steel pipes can be rolled at the high temperature, the radial structures of the steel pipes are not prone to the rolling cracks, the production efficiency and the quality of the seamless steel pipes are high, and the production cost is low.

Owner:CHANGGE YIMING MACHINERY

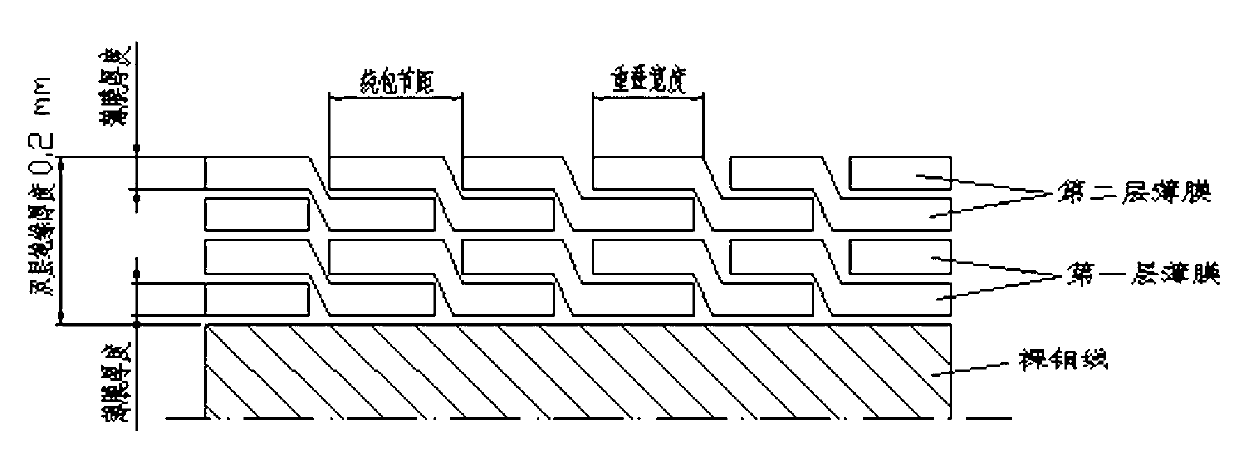

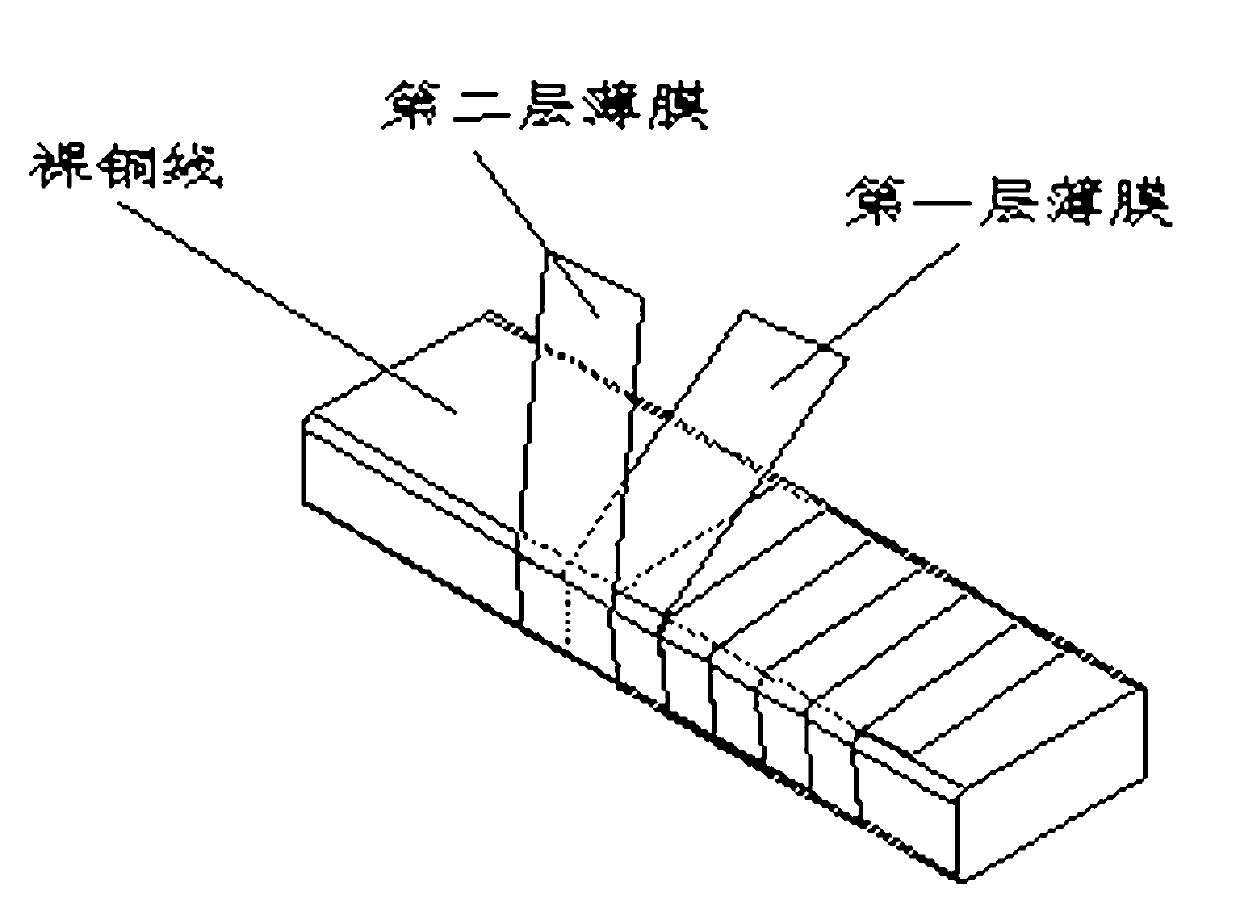

Double-imine copper lapped flat wire and production process thereof

ActiveCN103137252ASimple production processImprove insulation performanceFlat/ribbon cablesInsulated conductorsGlass fiberCold air

The invention discloses a production process of a double-imine copper lapped flat wire. The production process of the double-imine copper lapped flat wire comprises the following steps: (1) constant tension paying-off; (2) straightening and cleaning; (3) coating anti-oxidation material; (4) lapping double layers of polyimide films; (5) lapping glass fibers; (6) impregnating varnish; (7) baking in an oven; (8) coating an adhesive layer; and (9) cooling through cold air, online detection of voltage, metering and constant tension paying-off. The production process of the double-imine copper lapped flat wire is simple, an insulator outside the double-imine copper lapped flat wire comprises double layers of the polyimide films, an insulation layer mixed with the glass fibers and the impregnating varnish and an acetal adhesive layer from inside to outside, and is good in sealing performance. The double-imine copper lapped flat wire is good in insulation performance, high in puncture voltage value which reaches more than 9000 V, and good in heat resistance, the quality problems such as crack and fiber-falling are not easy to occur, the phenomenon of puncturing among turns does not occur in the winding process of a coil, and the mechanical damage is small.

Owner:GOLD CUP ELECTRIC APP CO LTD

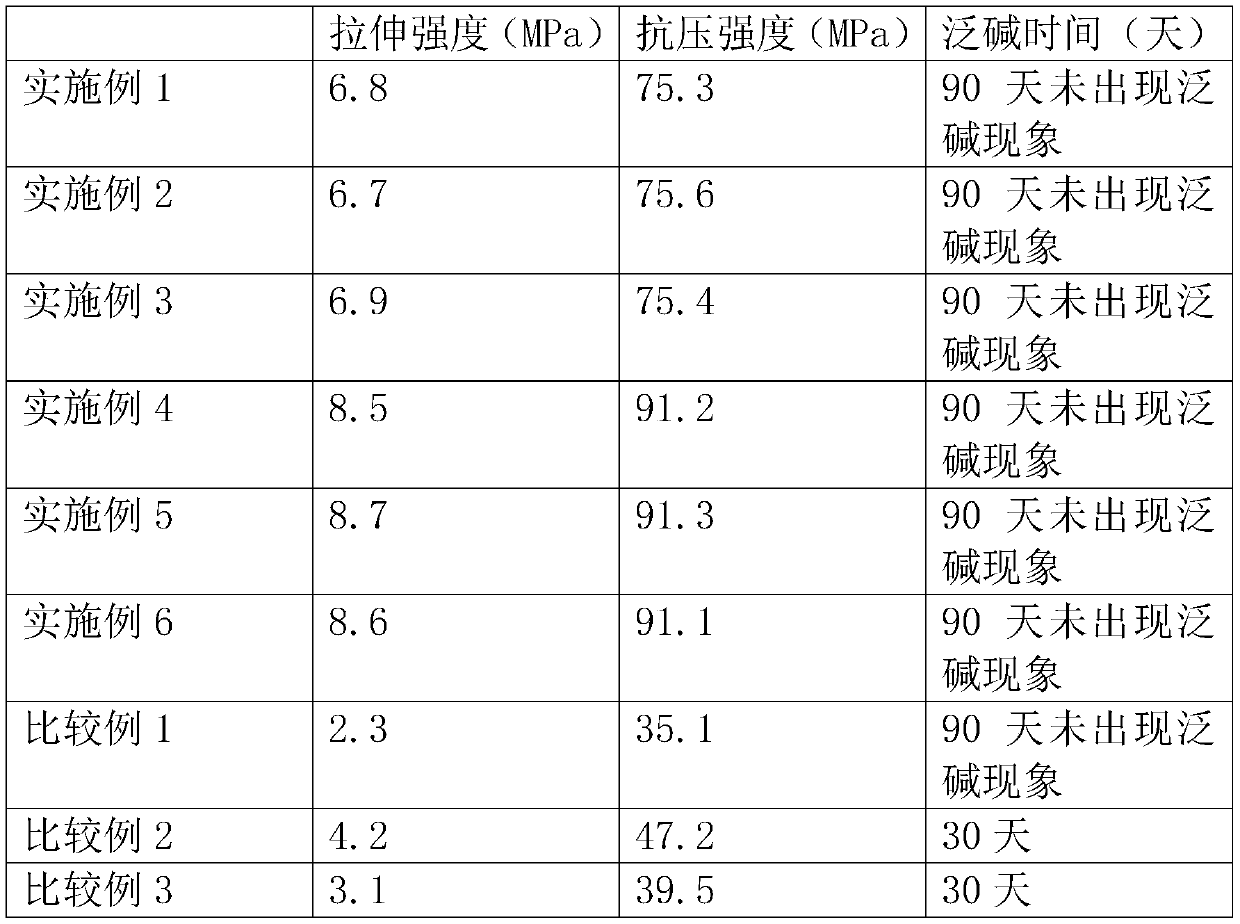

Road construction method

InactiveCN109853315AHigh compressive strengthHigh tensile strengthIn situ pavingsNatural factorCrushed stone

The invention relates to the field of municipal construction and provides a road construction method to solve a problem that a road is easy to crack under an effect of a natural factor. The road construction method comprises the following steps of S1, excavating a subgrade groove; S2, cleaning and flattening the subgrade groove; S3, back-filling a lime-soil cushion in the subgrade groove and compacting the lime-soil cushion to form a subgrade layer; S4, uniformly laying rubber asphalt on the subgrade layer; S5, laying crushed stones in the rubber asphalt and compacting the crushed stones to form a rubber asphalt and crushed stone mixed layer; and S6, pouring concrete to the rubber asphalt and crushed stone mixed layer and curing and molding the concrete to form a concrete pavement layer. By back-filling the subgrade layer in the subgrade groove first and then laying the rubber asphalt and crushed stone mixed layer and the concrete pavement layer, the road construction method is beneficial for enhancing compressive strength, tensile strength and toughness of a pavement; and therefore, the pavement is uneasy to crack when suffering stress; and the road construction method is beneficial for prolonging the service life of the pavement and is also beneficial for enhancing the safety of the pavement.

Owner:广州市诚利建设工程有限公司

Decorative panel

InactiveCN101929228AImprove thermal conductivityReduce distortionCovering/liningsLighting and heating apparatusHeat conductingEngineering

The invention relates to a decorative panel which is mainly laid on the ground or a wall, and belongs to the technical field of building decorative materials. The decorative panel comprises a bottom plate and a surface plate arranged on the bottom plate, wherein the bottom plate is rectangular; the left side and the right side of the bottom plate are provided with a plurality of connecting piece mounting grooves respectively; one end of each of male connecting pieces is fixedly arranged in the connecting piece mounting groove on the left side or the right side of the bottom plate through a fastener; one end of each of female connecting pieces is fixedly arranged in the connecting piece mounting groove on the right side or the left side, which is not provided with male connecting pieces, of the bottom plate through the fastener; the outer ends of the male connecting pieces can be coupled with the outer ends of the female connecting pieces of an adjacent bottom plate; the upper edges on the left side and the right side of the bottom plate are provided with clamping strips which are protruded upwards respectively; the lower edges on the two sides of the surface plate are provided with clamping strip grooves which are matched with the clamping strips on the bottom plate; the upper surface of the bottom plate is sequentially provided with an electric heating film and a heat insulating layer between the clamping strips of the left side and the right side from top to bottom correspondingly; the electric heating film is electrically connected with a power supply through the male connecting piece and the female connecting piece; the lower surface of the surface plate is provided with a plurality of open grooves in which reinforced heat conducting strips are embedded; and the reinforced heat conducting strips are made of a heat conducting material.

Owner:李增清

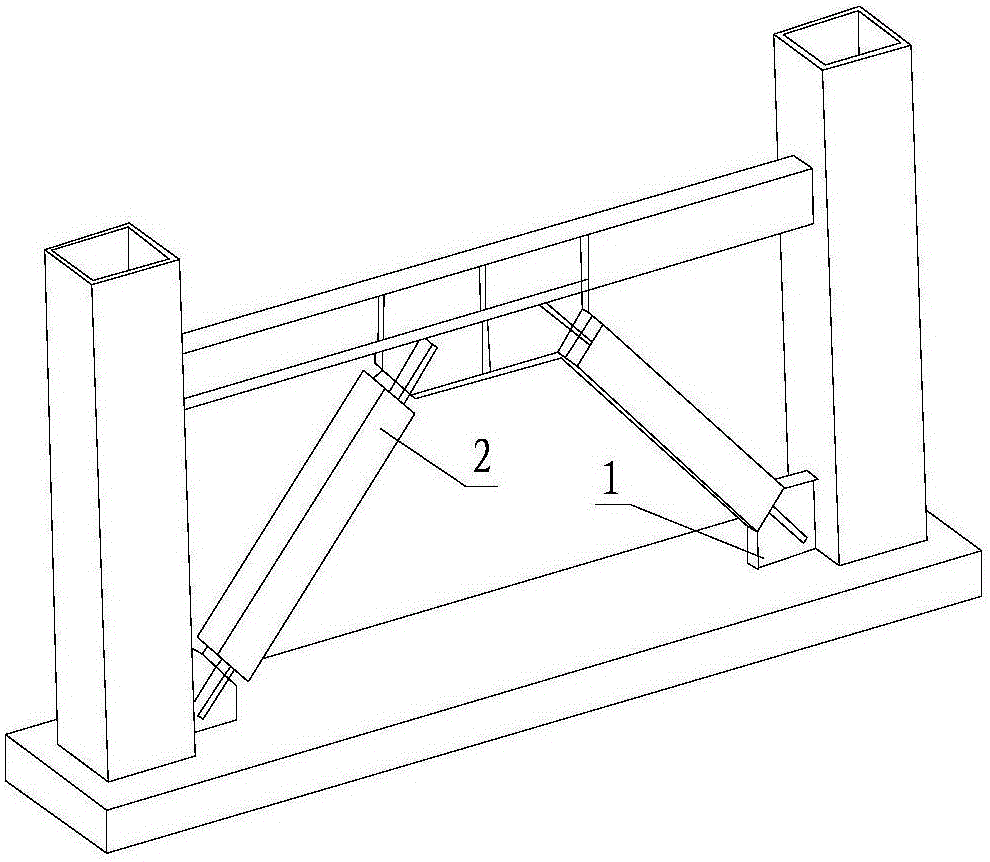

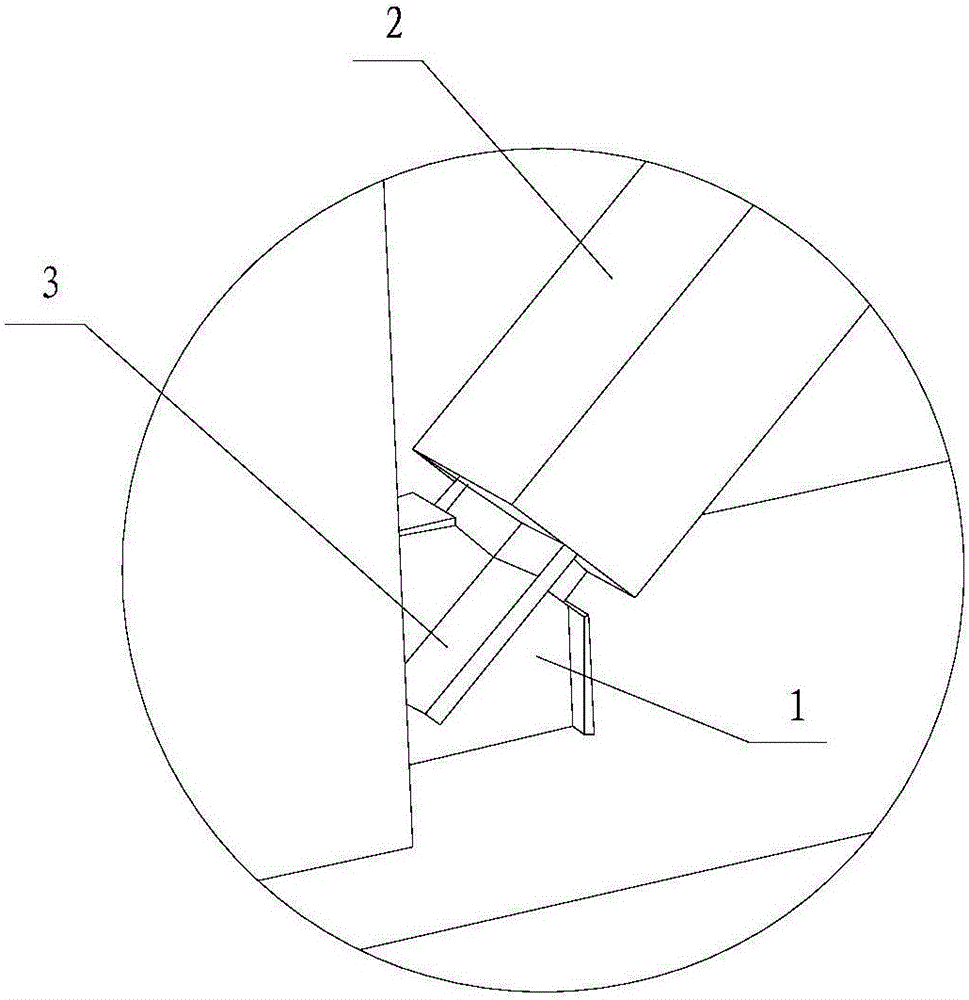

Installation and construction method for energy-dissipating type buckling-restrained brace

InactiveCN105952229AGuaranteed aestheticsImprove the earthquake resistance levelProtective buildings/sheltersShock proofingGusset plateBuckling-restrained brace

The invention discloses an installation and construction method for an energy-dissipating type buckling-restrained brace. The method comprises following steps: installing embedded parts, installing gusset plates, connecting supports and filling a wall body and the like. The embedded parts are made in the manner that webs are utilized for opening H-type steel plates. The gusset plates and the supports are installed in a high-precision welding mode. After a wall body is filled, a galvanized steel wire net is arranged in order to prevent cracks of the wall surface. The installation and construction method for the energy-dissipating type buckling-restrained brace has following beneficial effects: by adoption of a construction method, installation of the energy-dissipating type buckling-restrained brace is convenient and rapid so that anti-seismic performance of the supports can be given into full play and operation and construction can be conveniently carried out; an application scope of the energy-dissipating type buckling-restrained brace in the building construction is broadened so that anti-seismic performance of the structure is ensured, engineering quality is ensured and the anti-seismic performance of the overall construction is enhanced; when a slight earthquake occurs, the wall surface is not easily cracked so that aesthetic property of a building is ensured; meanwhile, little material is consumed so that the installation and construction method is of great popularization and application value.

Owner:CHENGDU NO 1 CONSTR

High-glossiness flame-retardant UV (Ultraviolet)-curable coating material and preparation method thereof

InactiveCN103788843AImprove toughnessHigh heat distortion temperatureFireproof paintsPolyester coatingsPolyesterDispersity

The invention relates to a high-glossiness flame-retardant UV (Ultraviolet)-curable coating material. The high-glossiness flame-retardant UV-curable coating material is prepared from the following raw materials in parts by weight: 35-40 parts of polyester acrylate, 8-11 parts of tetrahydrofuran acrylate, 5-9 parts of ethoxylated nonylphenol acrylate, 3-5 parts of triethyl citrate, 5-8 parts of carbic anhydride, 1-3 parts of nano calcium carbonate, 2-3 parts of benzil dimethyl ketal, 10-15 parts of glycol ethyl ether acetate, 6-9 parts of glycol, 5-9 parts of lauryl acrylate, 4-5 parts of auxiliaries and 5-7 parts of red phosphorus master batch. The UV coating material disclosed by the invention has the advantages of good toughness and difficulty in cracking; through adding nano calcium carbonate, the thermal deformation temperature and stability of the coating material are improved, and the glossiness is good; the coating material further has good flame retardance; due to the auxiliaries, the dispersity of the coating material is improved, the leveling property is good, and a coating layer is smooth and bright.

Owner:WUHU BAOYI AMUSEMENT EQUIP

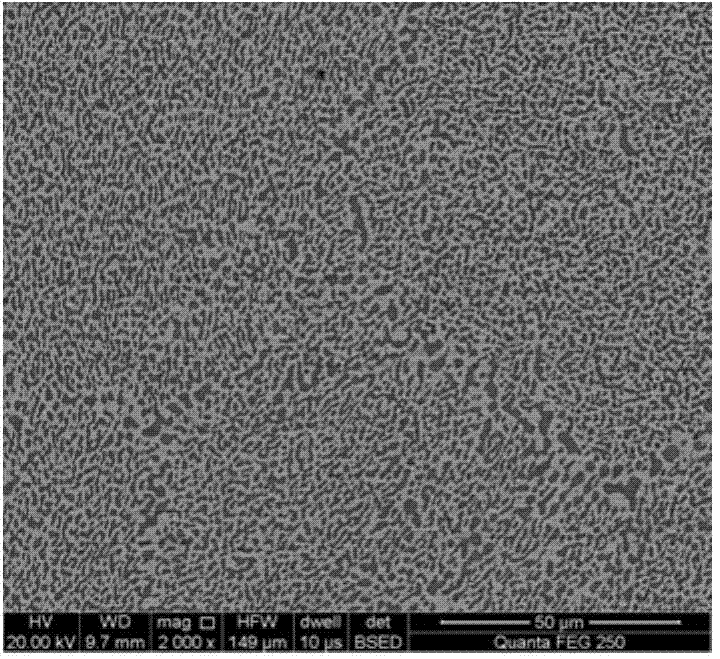

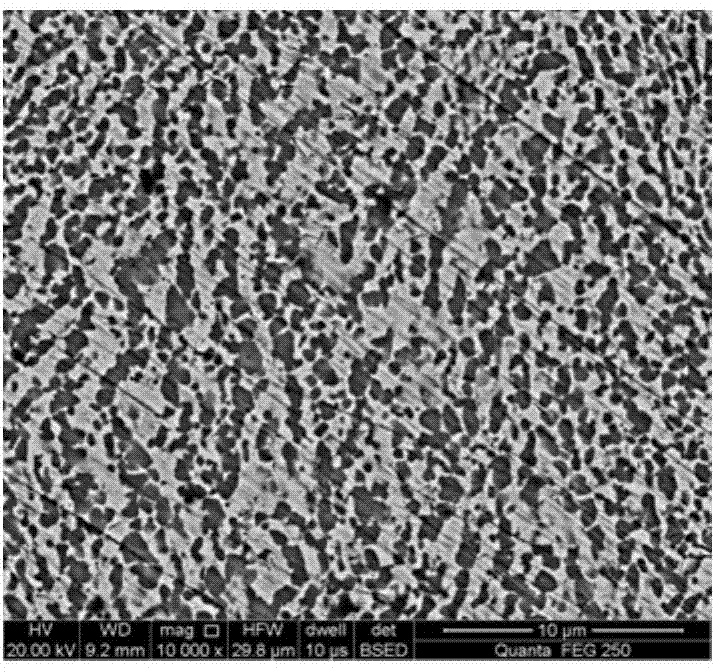

Super duplex stainless steel used on pump valve product and preparation method thereof

The invention discloses super duplex stainless steel used on a pump valve product and a preparation method thereof. The super duplex stainless steel comprises the following components in percentage by weight: 6.5-8.5% of nickel, 24-26% of chromium, 3-4% of molybdenum, 0.5-1% of copper, 0.2-0.3% of nitrogen, less than or equal to 0.02% of carbon, less than or equal to 1% of manganese, less than or equal to 1% of silicon, less than or equal to 0.03% of phosphorus, less than or equal to 0.025% of sulfur, 0.05-0.2% of cerium and the balance of iron. The preparation method comprises the following steps: smelting; deoxidizing and slagging; deoxidizing for the second time; and finally, adding ferromanganese and a refining agent, and after ferromanganese and the refining agent are fully smelted in smelting metal liquor, pouring to obtain the super duplex stainless steel. The super duplex stainless steel disclosed by the invention has the advantages that the super duplex stainless steel has good corrosion resistance and mechanical property, so that the service life of pump valve products is greatly prolonged.

Owner:ZHANGJIAGANG FEILANG PUMP & VALVE

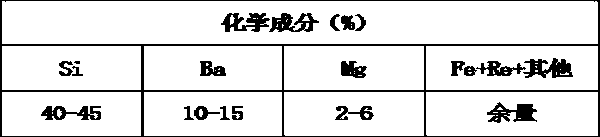

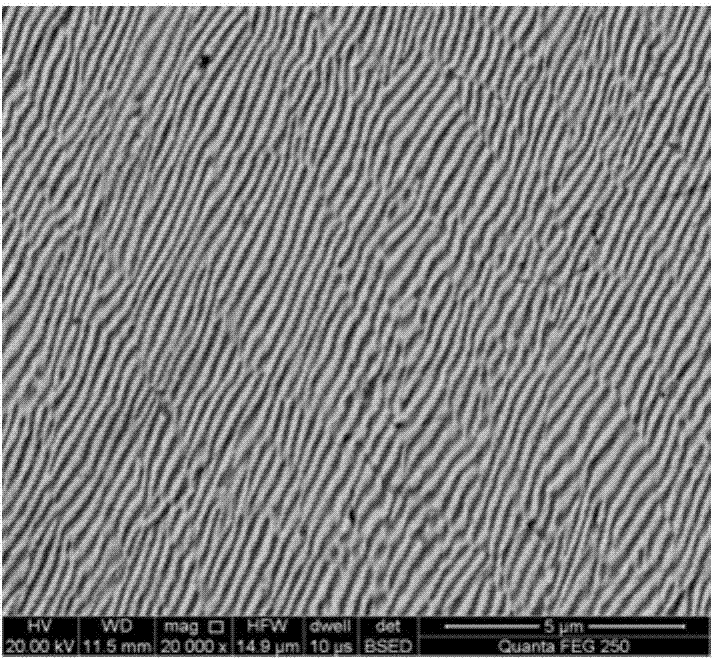

Preparation method for gold-tin eutectic alloy foil having uniform structure

The invention relates to a preparation method for a gold-tin eutectic alloy foil having a uniform structure. The preparation method comprises: accurately preparing a gold-tin alloy raw material with a tin mass percentage of 20% and a gold mass percentage of 80%; in a non-consumable electrical arc smelting furnace, under a vacuum degree of 10<-3> Pa, repeatedly carrying out smelting, electromagnetic stirring and cooling at least three times to obtain a gold-tin alloy casting ingot; and carrying out homogenization annealing on the casting ingot, and then carrying out multi-pass thermal compression to obtain the gold-tin eutectic foil. According to the present invention, the vacuum electrical arc smelting, the circular electromagnetic stirring and the cyclic thermal compression to prepare the whole lamellar eutectic structure, wherein the eutectic point component does not have the primary phase; and compared with the preparation method in the prior art, the preparation method of the prevent invention has the following characteristics that: the complete alloying is achieved, the strength is high, the weldability is good, other components are not added or the gold-to-tin ratio is not adjusted, the welding temperature and the welding performance are stable, the welding piece deformation and the force on the welding piece are uniform, the welding piece cracking condition is not easily generated, the yield is high, the production efficiency is much higher than the production efficiency of the electroplating method for preparing the gold-tin welding piece, the production cost is reduced, and the preparation method is suitable for mass production.

Owner:CENT SOUTH UNIV

Manufacturing method of adhesive type iron core of motor

ActiveCN101673986ASimplified demoulding stepsReduce stressManufacturing stator/rotor bodiesEngineeringMechanical engineering

The invention relates to a manufacturing method of an adhesive type iron core of a motor, comprising the following steps: 1. blanking stamping pieces of the iron core into stamping blank piece and matching the dimension of the stamping piece and the overall dimension of the iron core; 2. carrying out cleaning to the blank piece of the stamping piece and deburring; 3. gluing to the blank piece of the stamping piece, laminating and curing into a rough blank of the iron core; 4. cleaning the residue glue of the rough blank of the iron core; and 5. adopting a line cutting manner to process the shape and the edge of a tooth slot to the rough blank of the iron core. The manufacturing method does not carry out stamping to the stamping piece of the iron core, can simplify the structure of adhesiveand laminated mold, reduce the workload of demolding, cleaning and deburring, and can realize low labor intensity, high working efficiency and good product quality.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

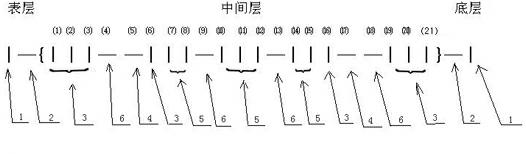

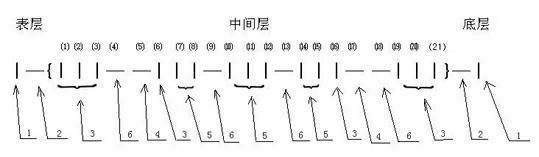

Bamboo-wood composited container floor and production method thereof

InactiveCN102581887AHigh strengthImprove flatnessWood veneer joiningWood layered productsWood veneerSurface layer

The invention relates to a bamboo-wood composited container floor and a production method thereof. The bamboo-wood composited container floor can meet service requirements, satisfies environment-friendly bamboo-and-wood composite boards, and comprises a surface layer, a bottom layer and a middle layer, wherein each of the surface layer and the bottom layer is a facing layer composed of longitudinal bond paper 1 and a transverse reconstructed veneer 2 or transverse nonwoven 2, and the middle layer is in a symmetrical structure composited with 21 layers of bamboo screens and wood veneers. Each facing layer of the container floor is composed of the bond paper and the transverse reconstructed veneer, or the bond paper and the transverse nonwoven, so that the problem cracking of surface coated films on three continuous longitudinal veneer layers is solved, and the strength of the bamboo-wood composited container floor is improved.

Owner:MAOYOU WOOD

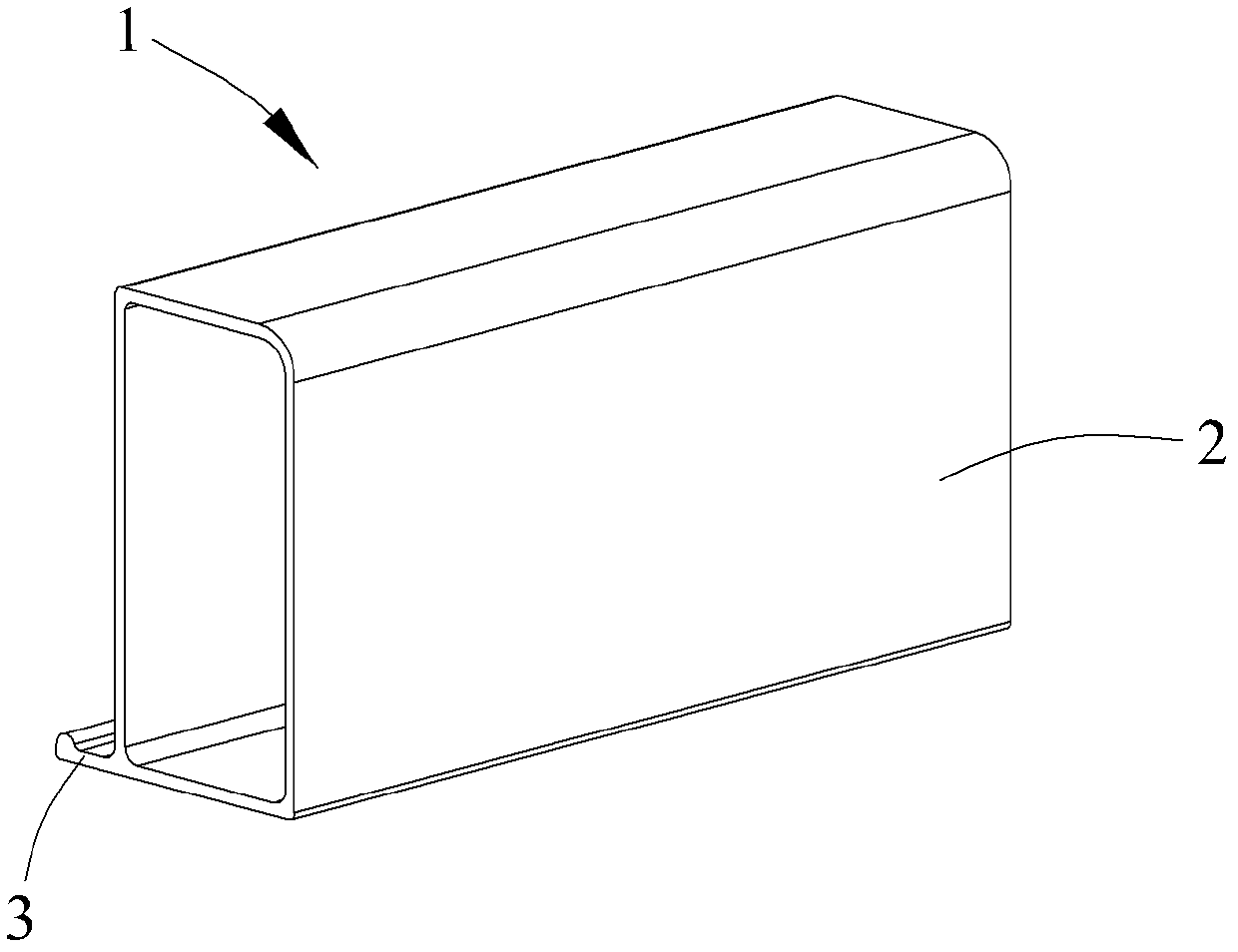

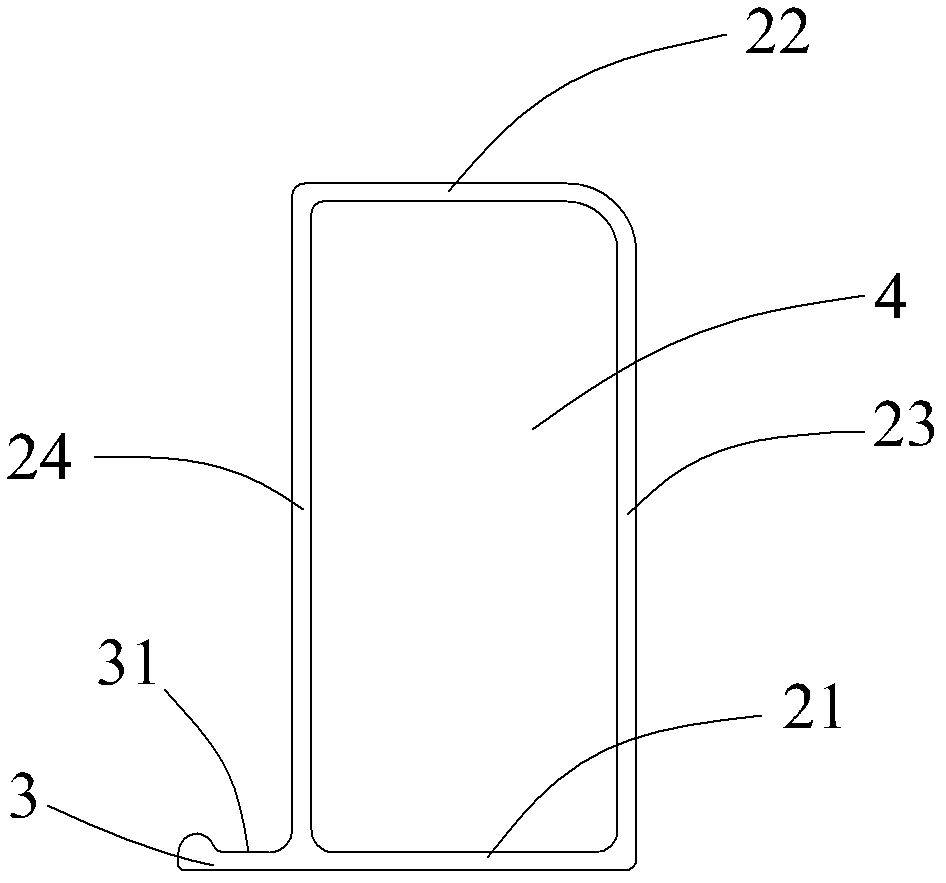

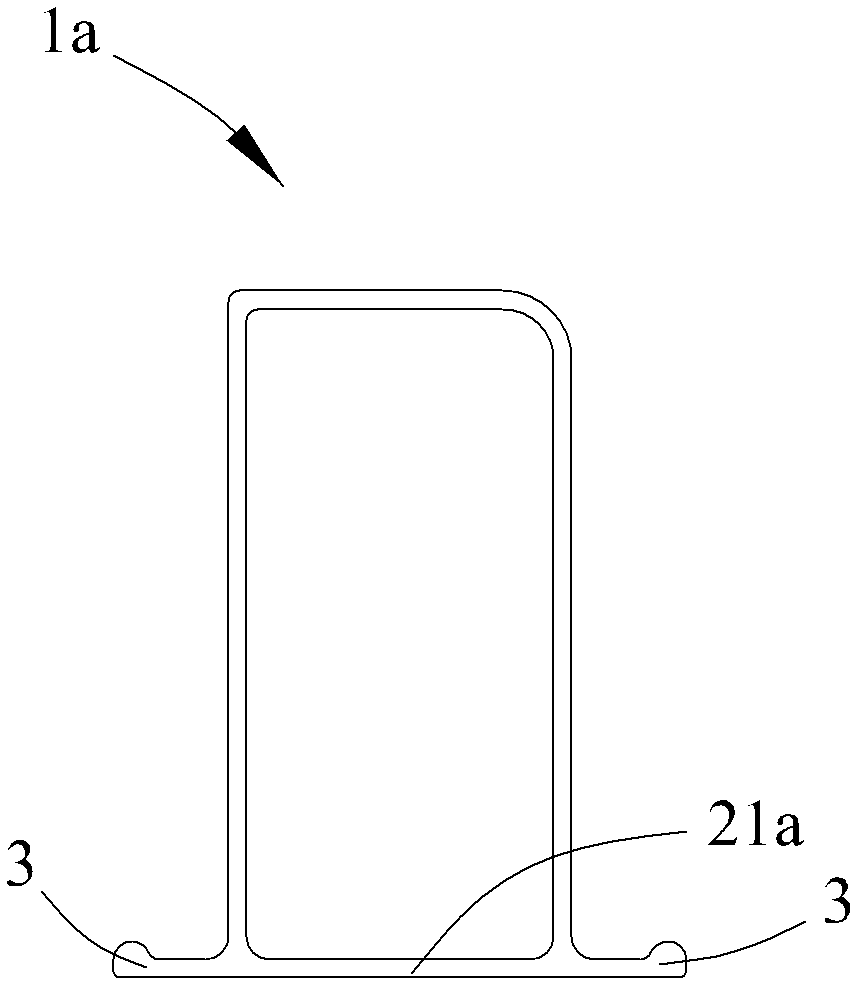

Plastic curb and plastic curbstone forming same

InactiveCN102605700AReduce weightEasy to processSingle unit pavingsPaving gutters/kerbsRear quarterPlastic materials

The invention relates to a plastic curbstone, which is made of plastic materials and comprises a horizontal hollow body and projecting edges extending out from bottom edges of the hollow body. The hollow body comprises a bottom plate, a top plate, a front plate and a rear plate. The top plate is connected between the top end of the front plate and the top end of the rear plate. The bottom plate is connected between the bottom end of the front plate and the bottom end of the rear plate. The bottom plate, the top plate, the front plate and the rear plate enclose a cavity transversely penetrating two ends of the hollow body. The plastic curbstone is light in weight, convenient in processing, transport and installation, low in cost and recyclable. The invention further relates to a plastic curb comprising the plastic curbstones. Each two adjacent plastic curbstones are tightly fitted and connected together through connectors. The plastic curb is convenient in installation and firm and is capable of effectively alleviating harm to vehicles and persons inside when the vehicles crash against the plastic curb.

Owner:广东盈创力新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com