Patents

Literature

38results about How to "No insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

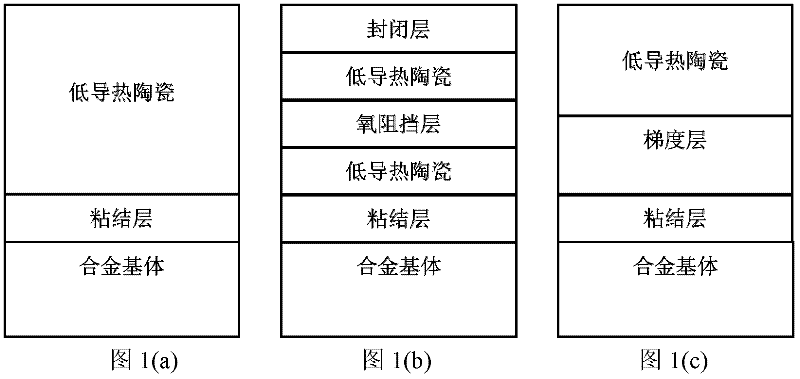

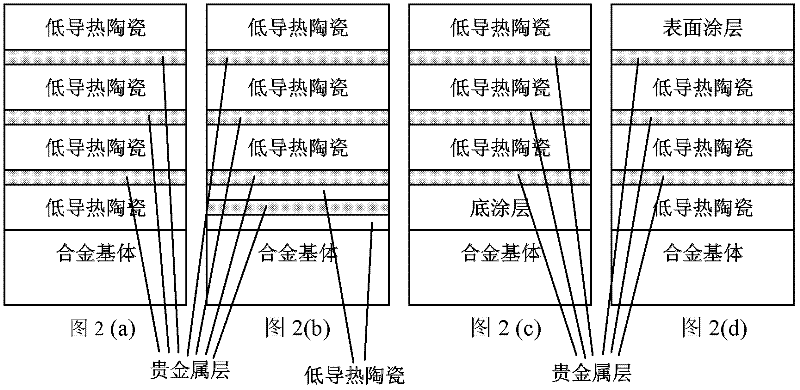

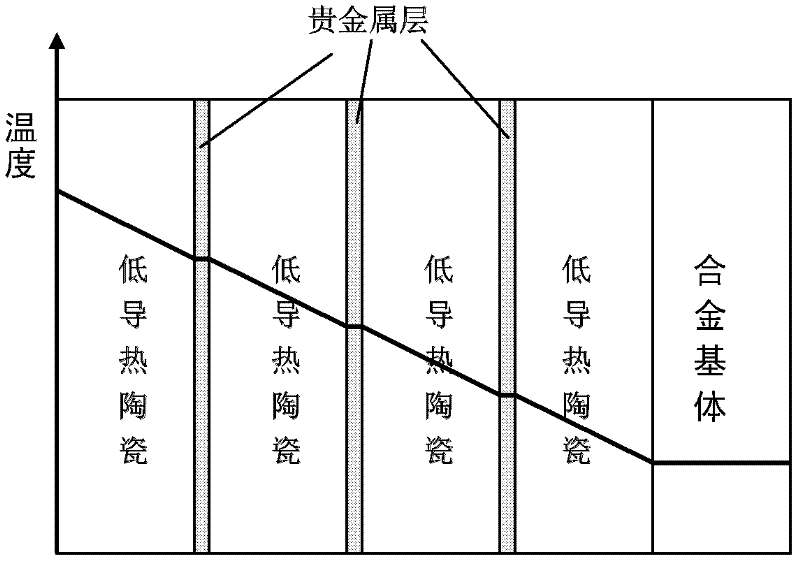

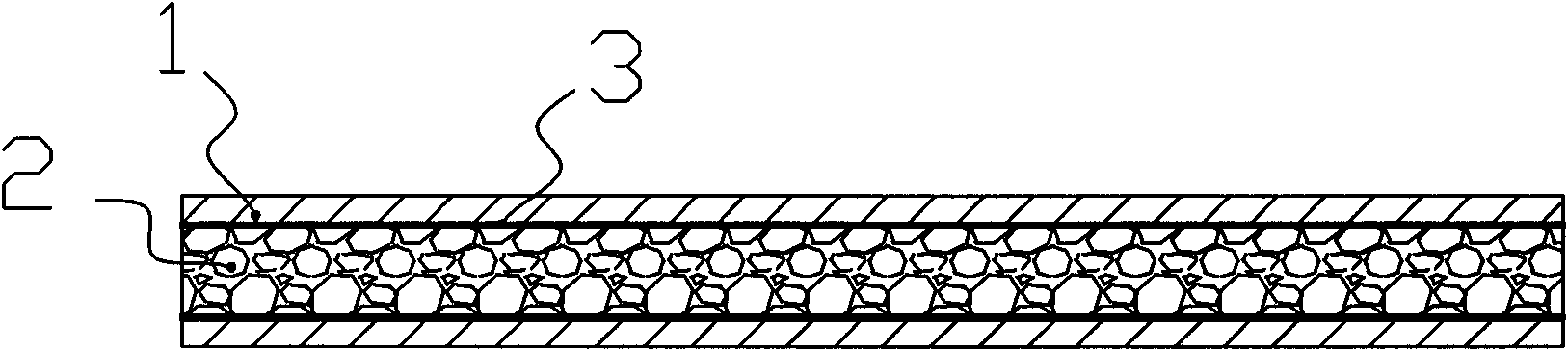

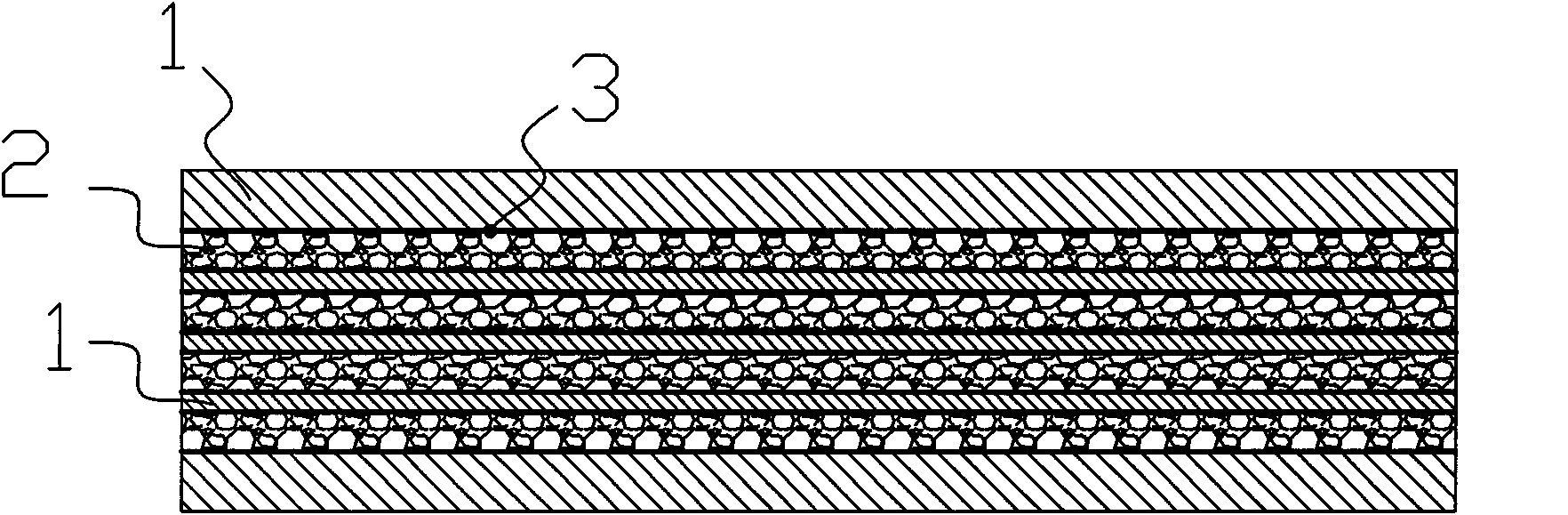

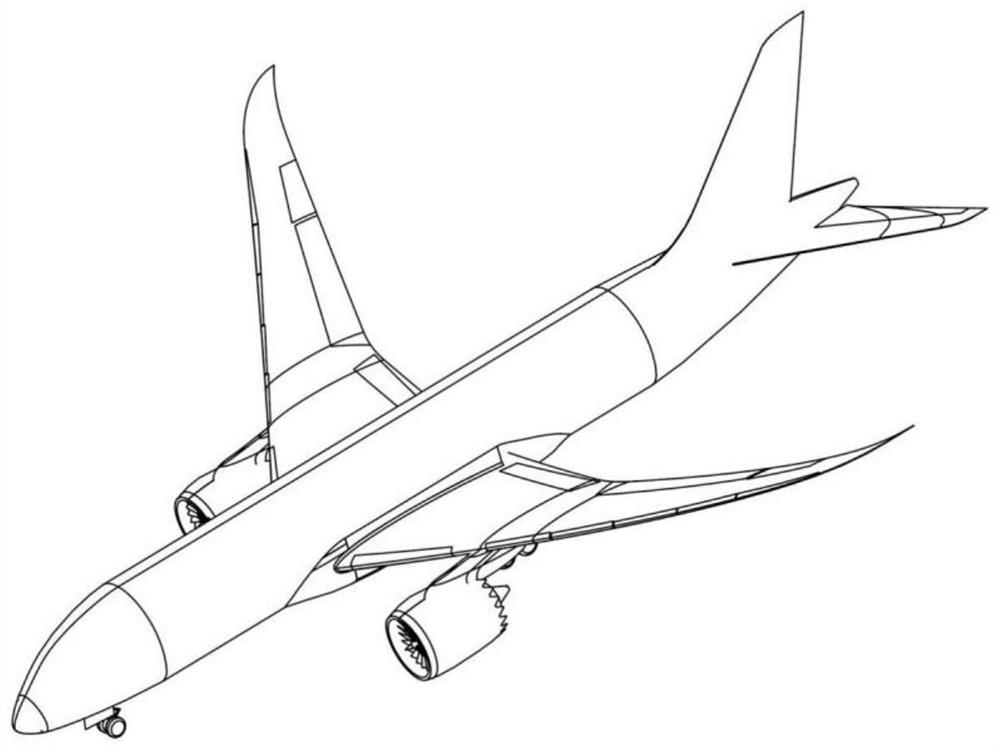

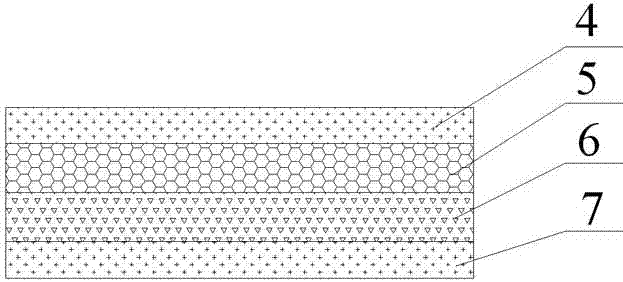

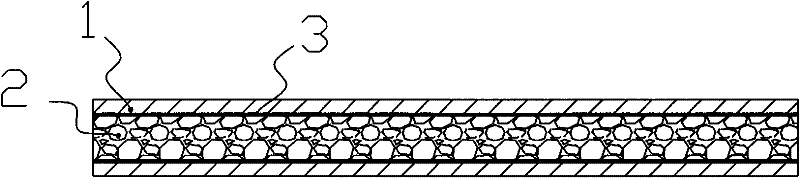

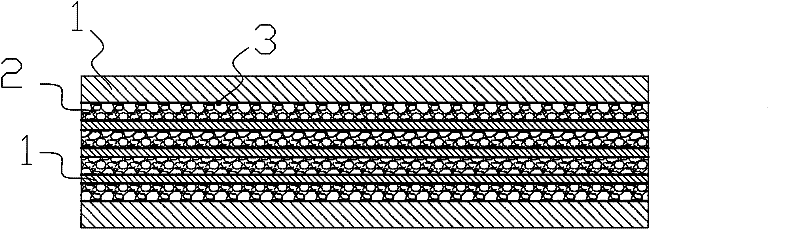

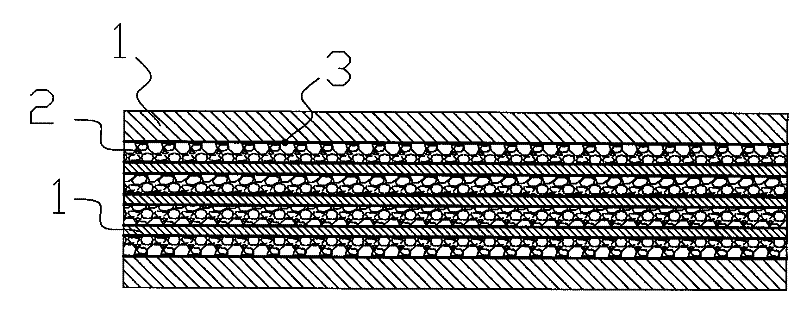

Multipurpose low-conductivity ceramic/noble metal lamellar composite thermal barrier coating

InactiveCN102345122AGood heat insulationNo insulationBlade accessoriesEfficient propulsion technologiesAviationThermal insulation

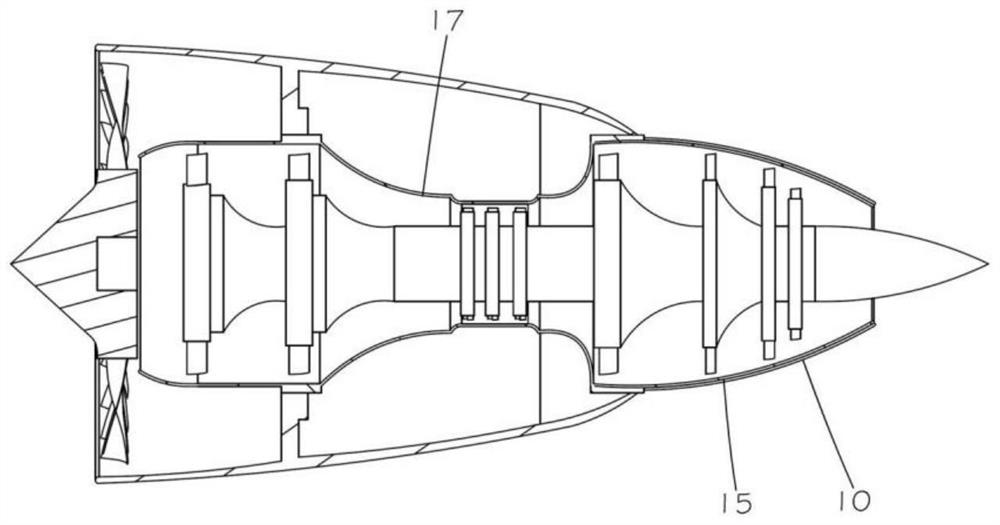

The invention discloses a multipurpose low-conductivity ceramic / noble metal lamellar composite thermal barrier coating, relating a composite material and coating technology. The coating is divided into four types: (1) regularly and alternatively depositing low-conductivity ceramic layers and noble metal layers; (2) irregularly and alternatively depositing low-conductivity ceramic layers and noblemetal layers; (3) exerting low-conductivity ceramic and noble metal lamellar composite thermal barrier coatings on antioxidant protection layers deposited on the surface of a basic alloy; and (4) depositing other functional coatings on the outer surface of the low-conductivity ceramic / noble metal lamellar composite thermal barrier coating. According to the invention, the lamellar composite thermal barrier coating formed by alternatively depositing the low-conductivity ceramic layers and the noble metal layers has the advantages of excellent thermal insulation performance and thermal shock resistance, stable coating structure and long service life and can be applied to the high temperature protection of hot end components of refractory alloys or high temperature alloys such as an aircraft engine, a marine engine, a ground gas turbine, a rocket engine, and the like.

Owner:UNIV OF SCI & TECH BEIJING

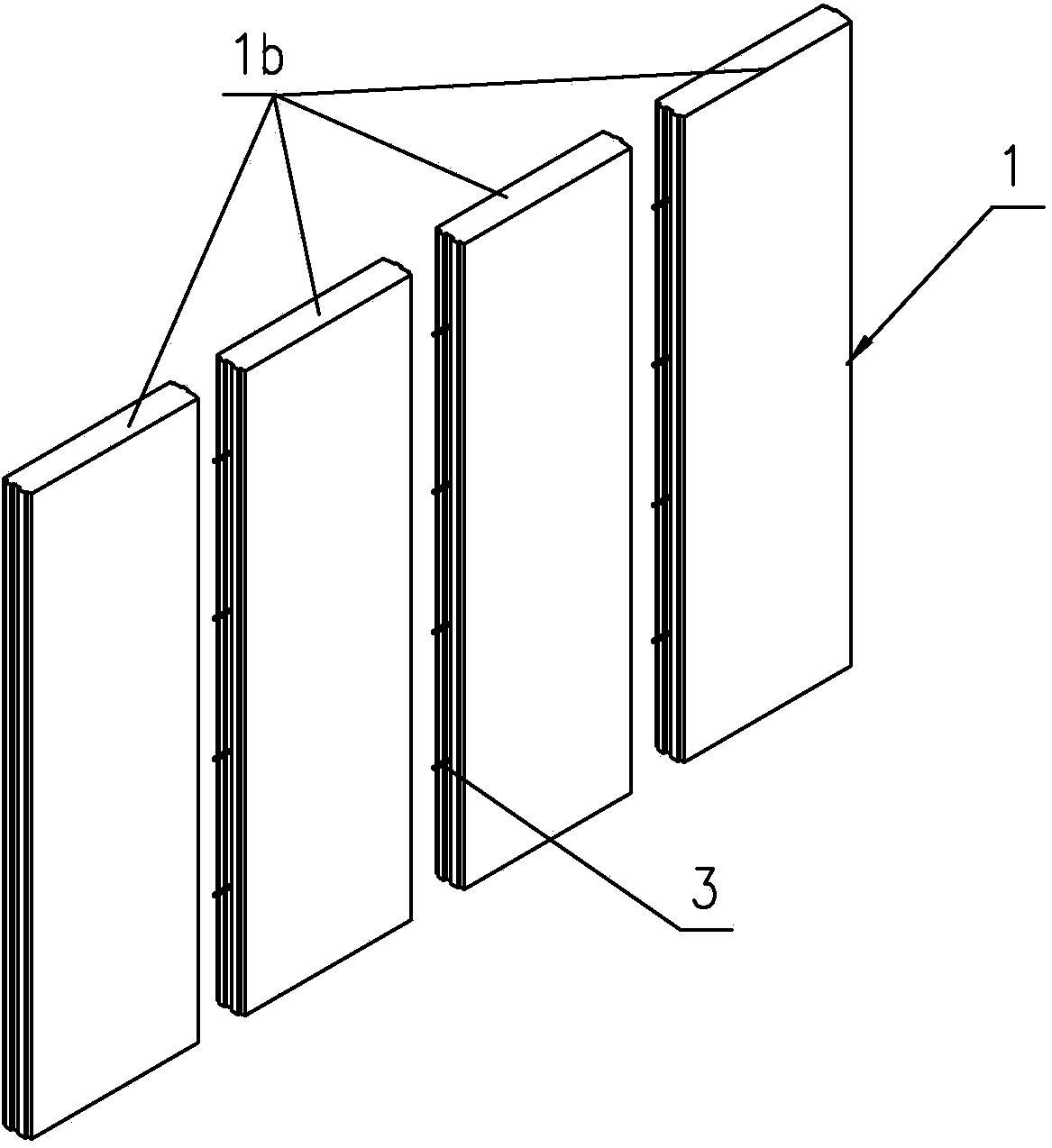

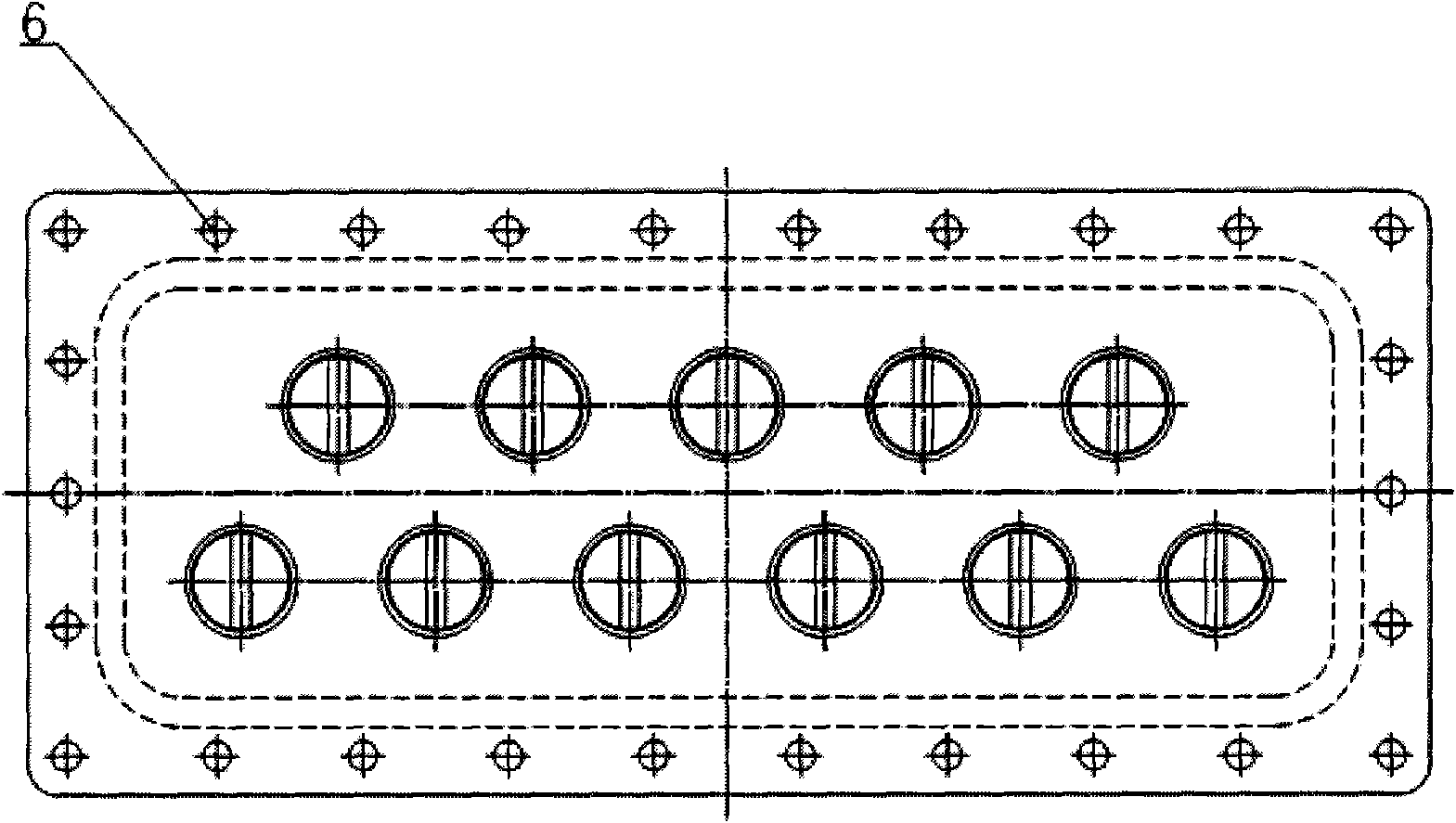

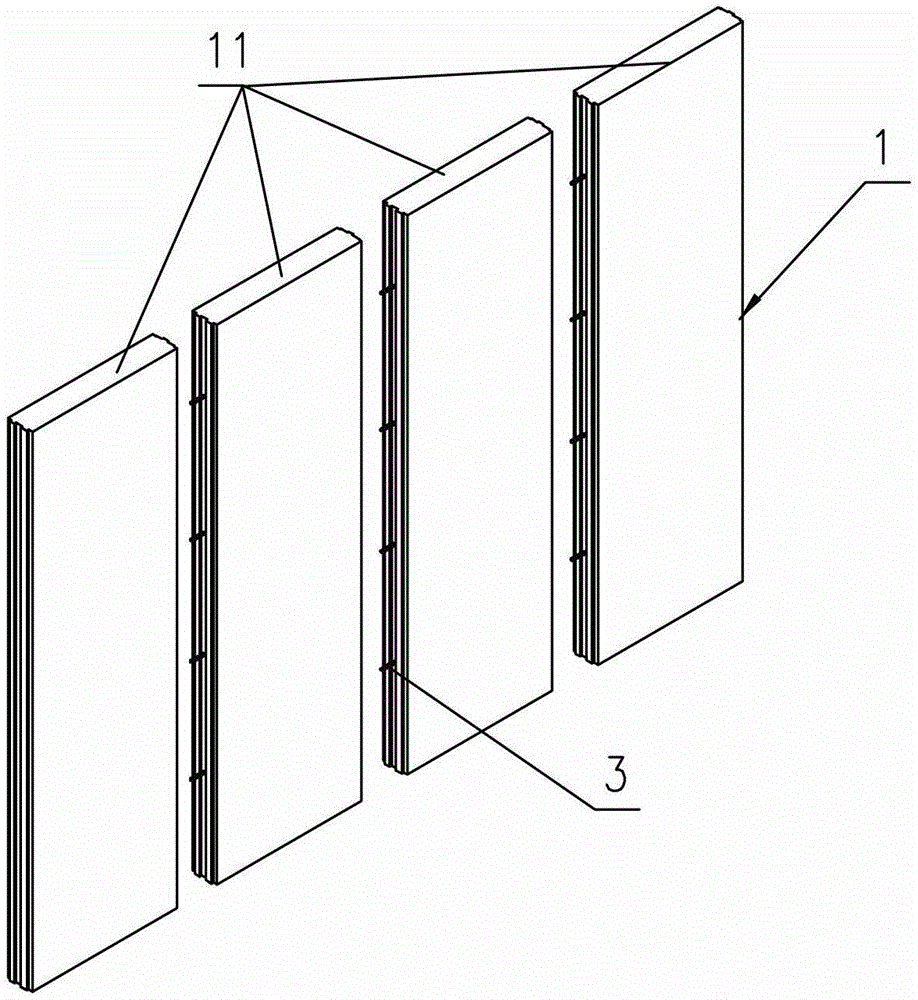

Self-heat-insulation decoration integral multifunctional light-weight concrete composite plate and curtain wall

The invention discloses a self-heat-insulation decoration integral multifunctional light-weight concrete composite plate, which mainly consists of an inner light-weight concrete plate, an outer light-weight concrete plate and heat insulation materials, wherein the outer surface of the outer light-weight concrete plate is used for installing a decoration surface; the inner light-weight concrete plate and the outer light-weight concrete plate are opposite, and in addition, a gap is formed between the inner light-weight concrete plate and the outer light-weight concrete plate; the heat insulation materials are filled in the gap; the inner light-weight concrete plate and the outer light-weight concrete plate are connected and fixed through a connecting structure; and pendants used for being connected with a building main body structure are arranged on the inner light-weight concrete plate. The self-heat-insulation decoration integral multifunctional light-weight concrete composite plate is based on the self structural strength of the light-weight concrete plate; in addition, the double-layer structure formed by the inner and outer light-weight concrete plates and the heat insulation materials arranged in the gap formed between the inner and outer light-weight concrete plates are suitable to be used for building exterior wall enclosure systems in northern area with cold weather; high strength, heat insulation performance, fireproof performance, waterproof performance, low dry shrinkage rate and good sound isolation performance are realized; the factory prefabrication and the in-site installation are realized; construction waste is little; and the installation is safe and fast.

Owner:GUANGDONG HEYUAN LIANTIAN BUILDING INDZATION MFG

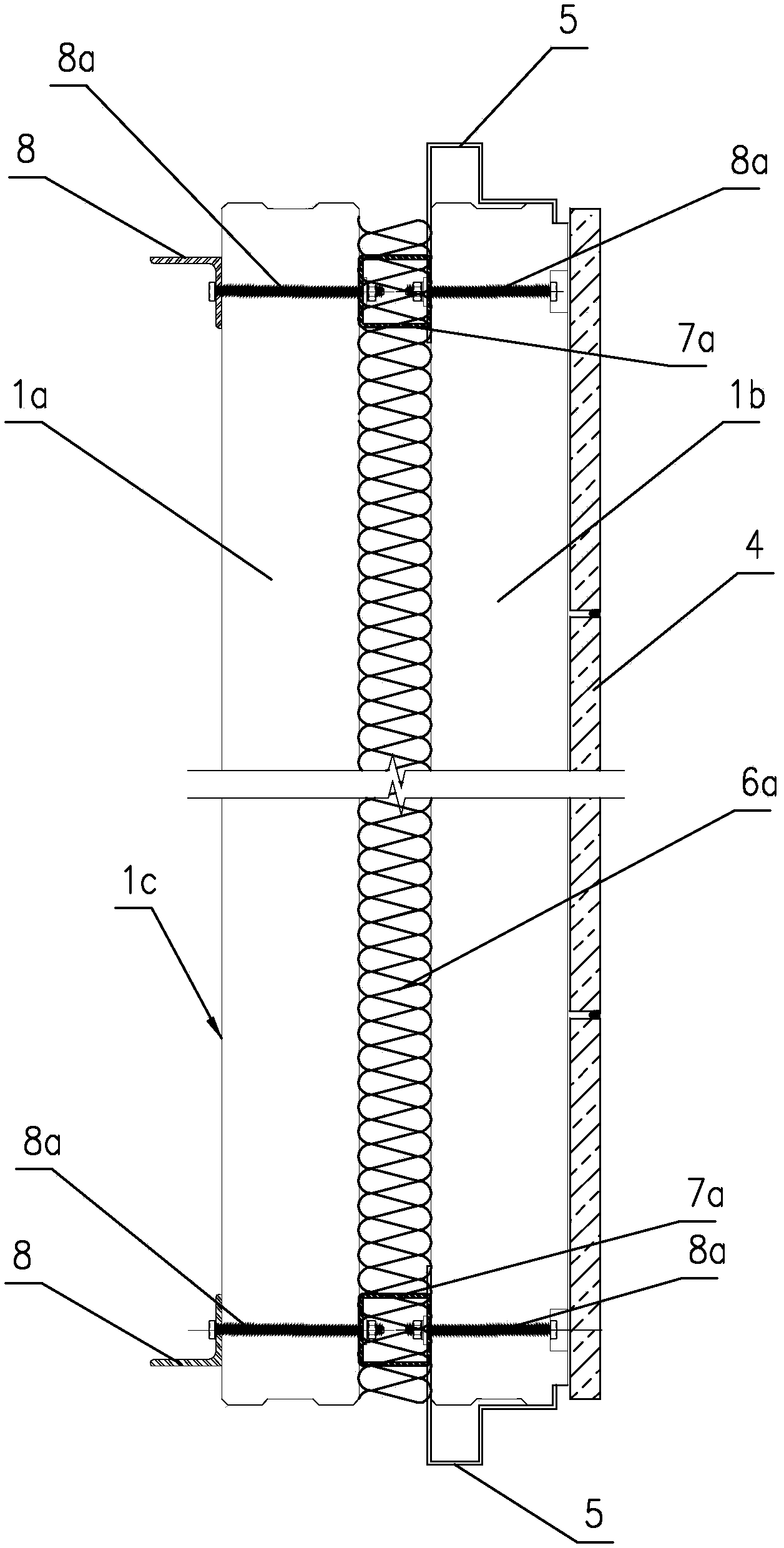

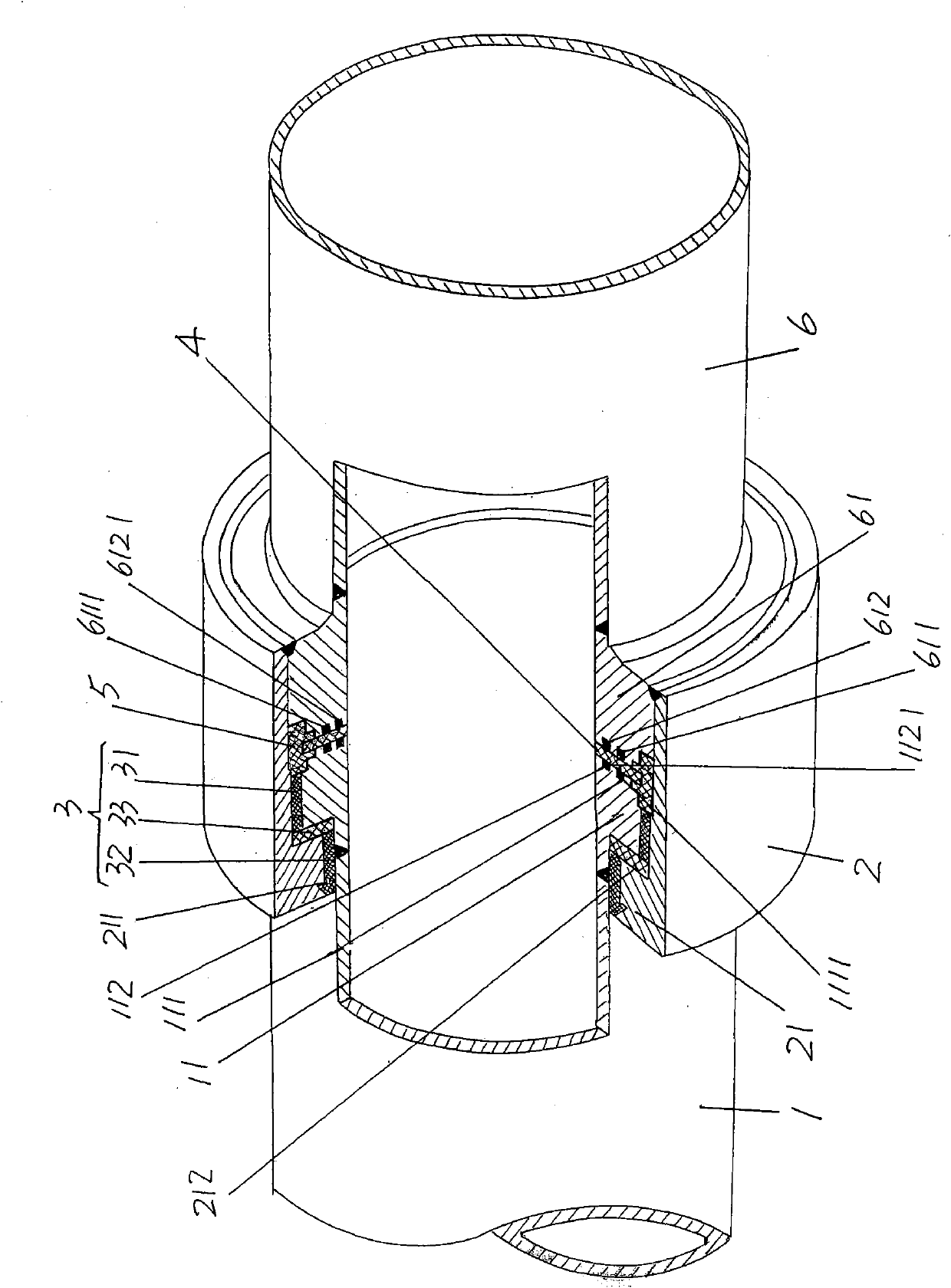

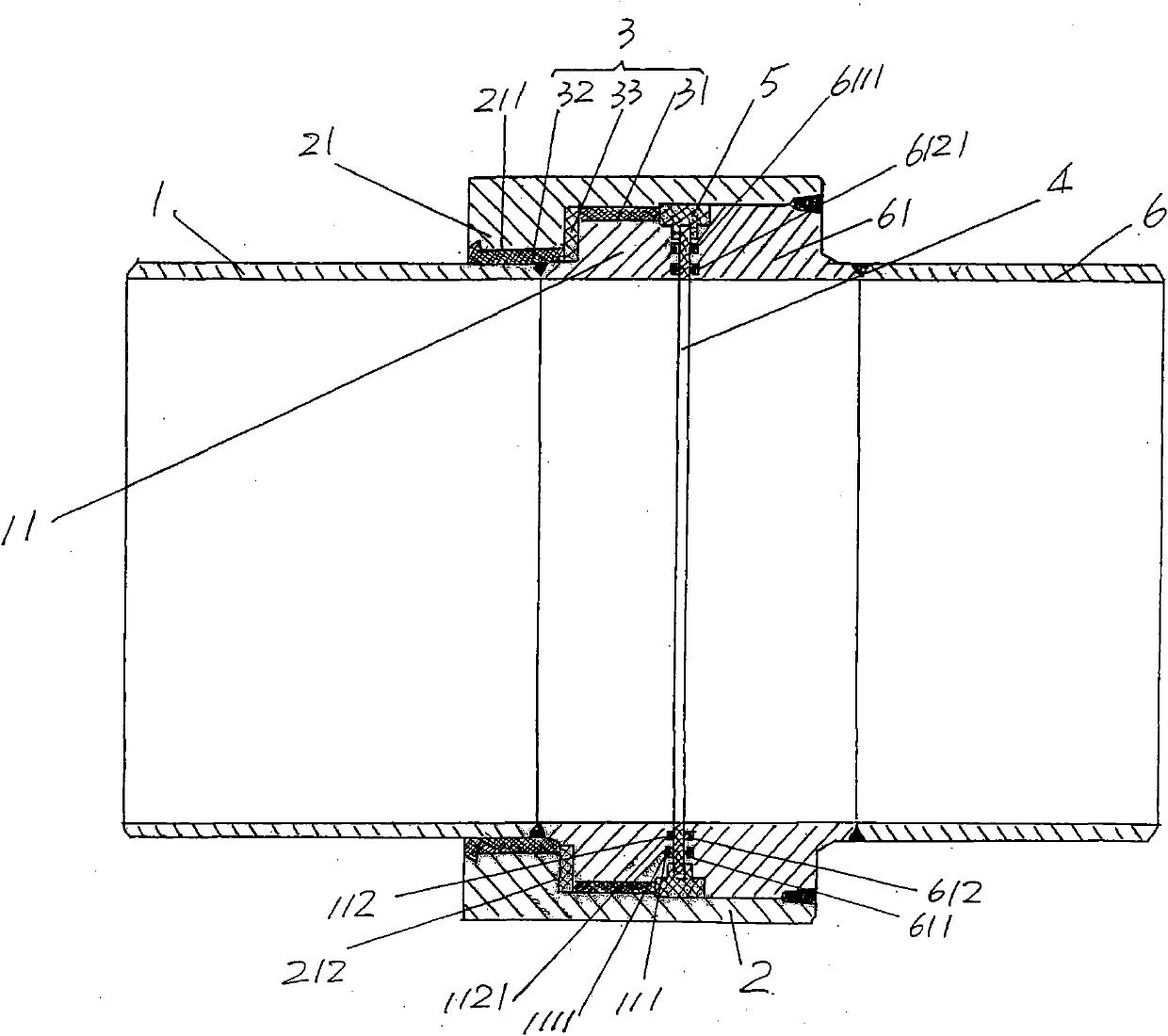

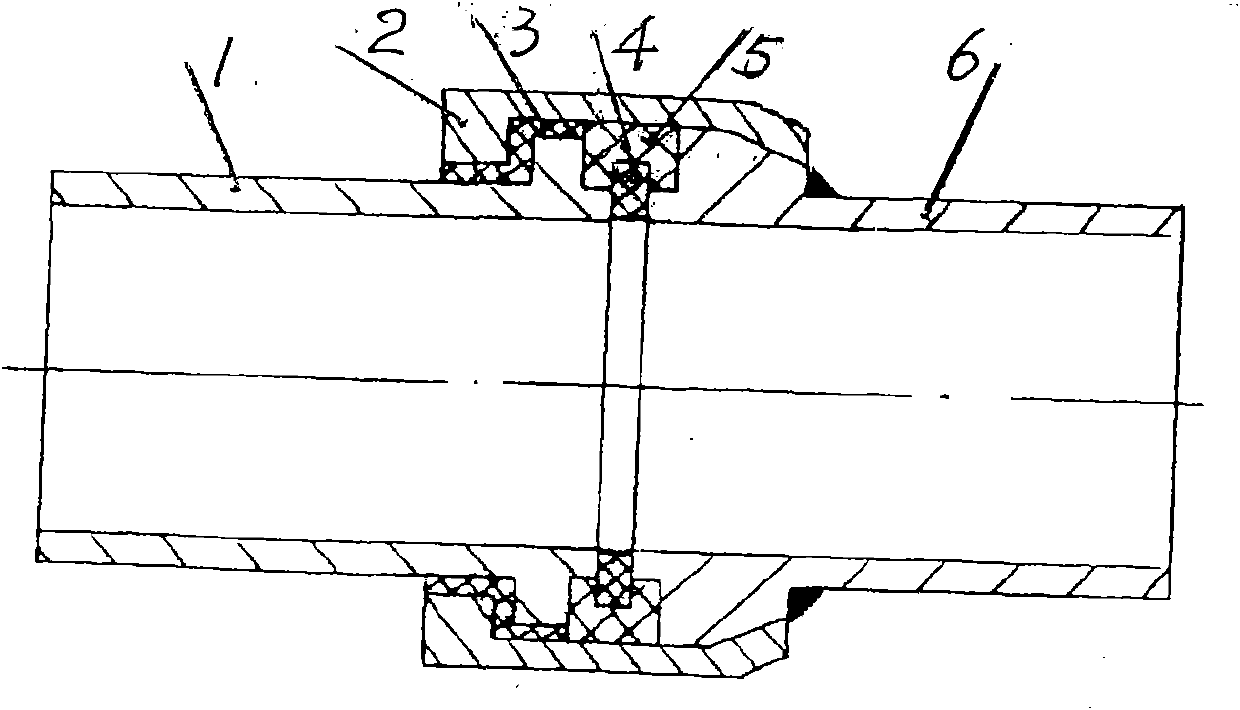

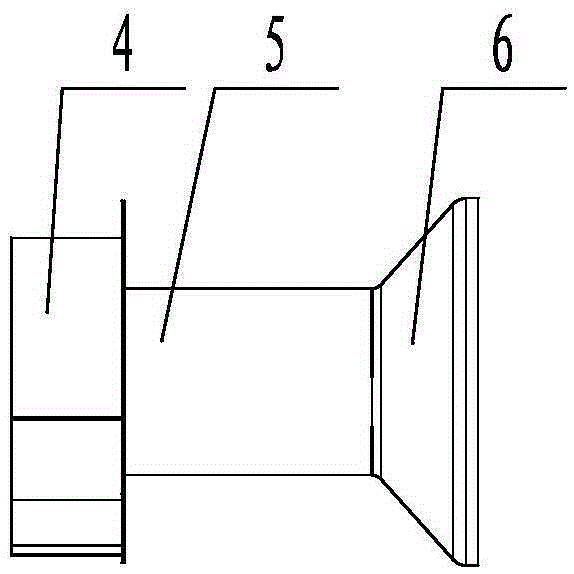

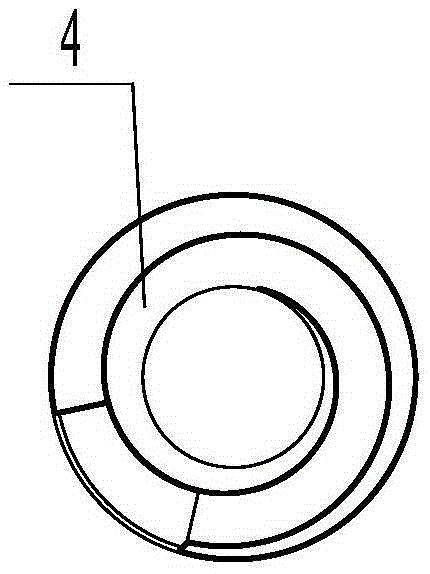

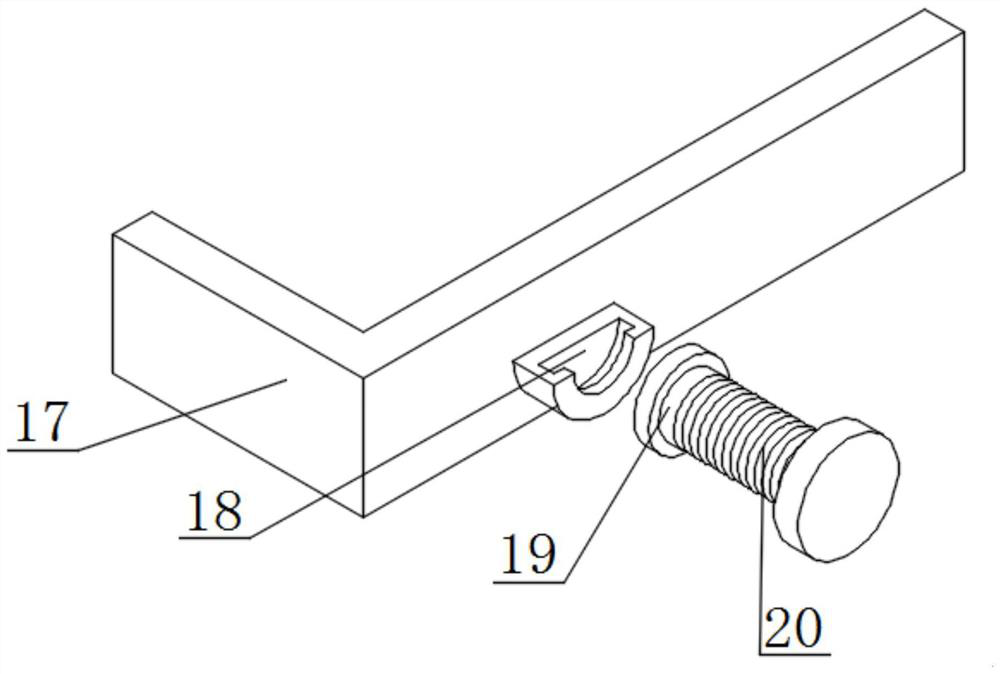

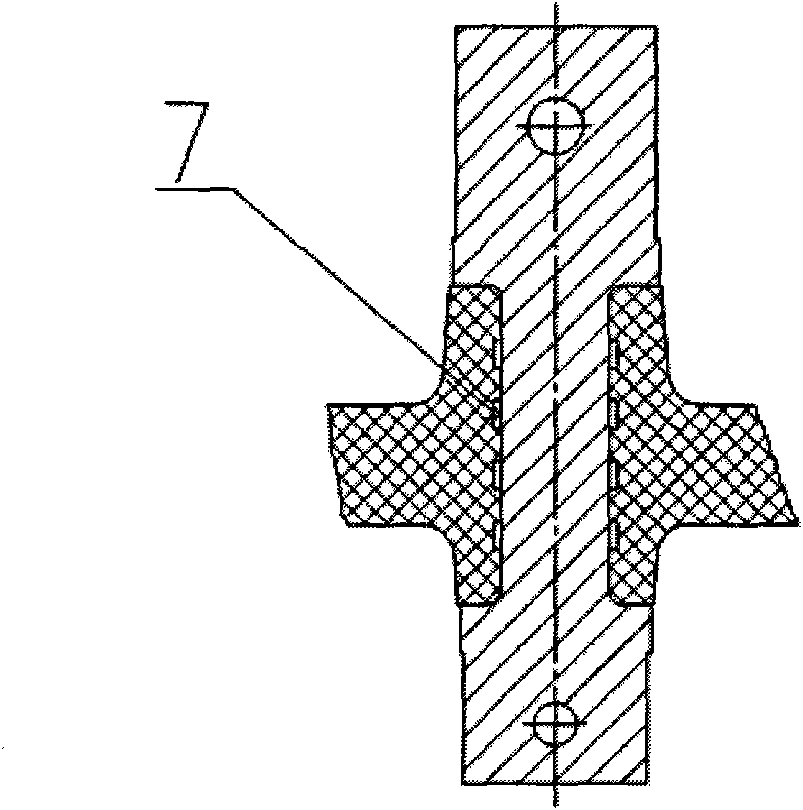

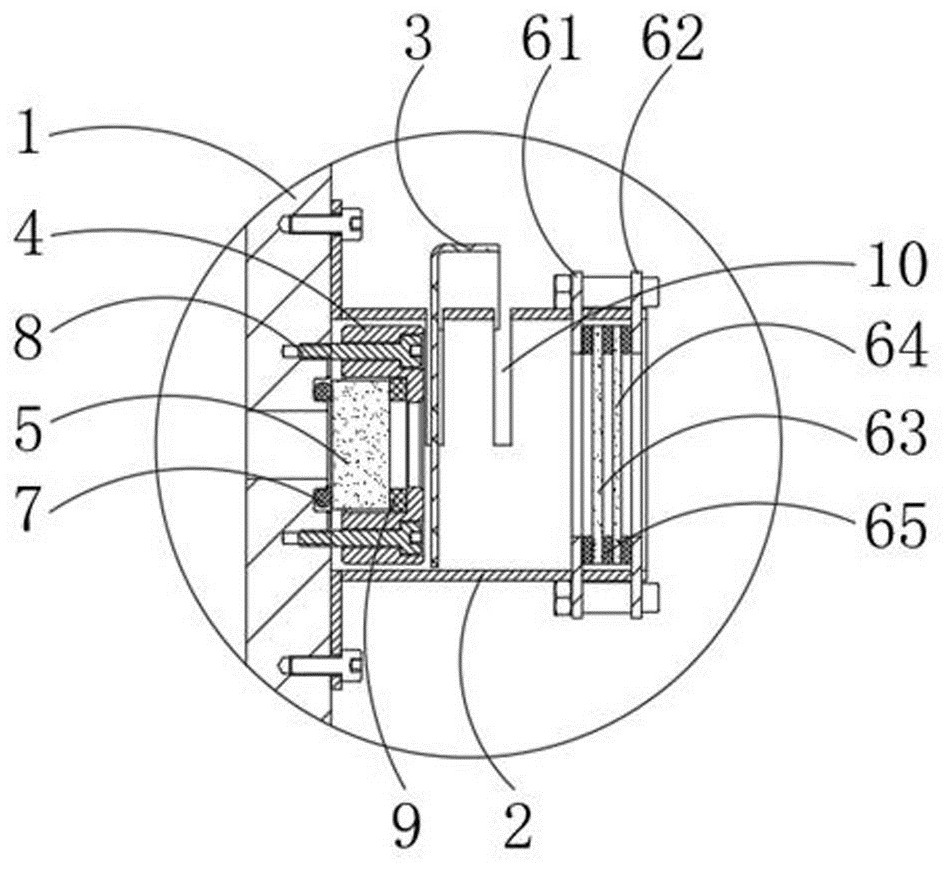

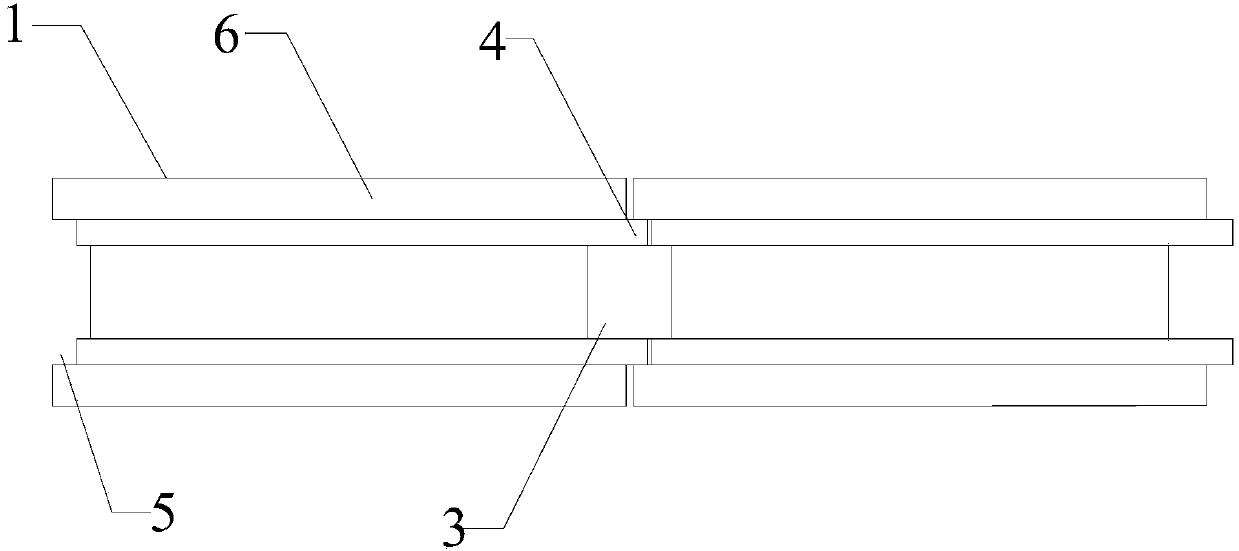

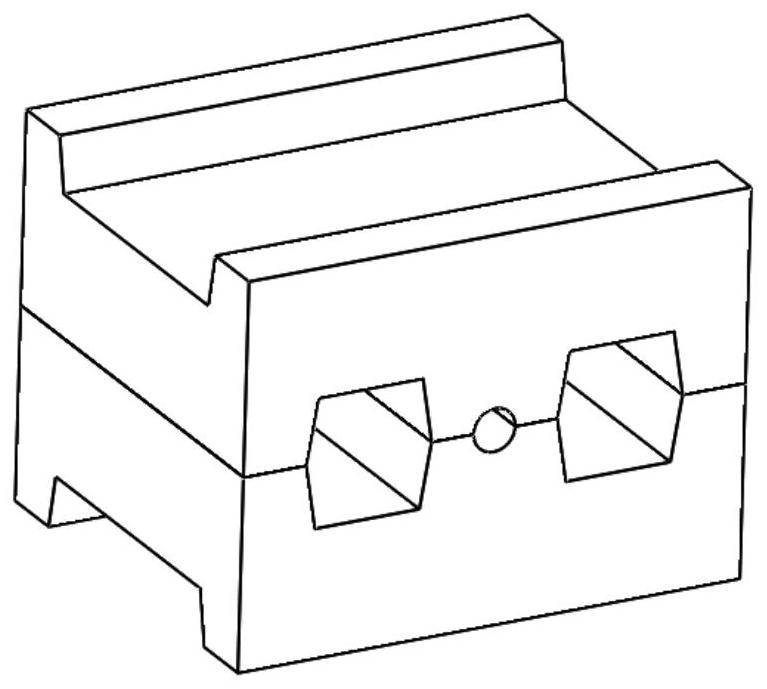

Integral insulating joint

InactiveCN101994886AImprove insulation performanceImprove sealingPipe-jointsEngineeringCircular surface

The invention discloses an integral insulating joint belonging to pipeline fittings and comprising an upper conduit, a lower conduit, a casing, an insulating device, an insulating gasket and a sealing pad, wherein a lower conduit flange is arranged on the lower conduit; and an upper conduit flange is arranged on the upper conduit. The integral insulating joint is characterized in that a first sealing ring groove and a second sealing ring groove are arranged on the surface on one side of the lower conduit flange; a first sealing ring and a second sealing ring are embedded into the first sealing ring groove and the second sealing ring groove; a third sealing ring groove and a fourth sealing ring groove are arranged on the surface at the other side of the upper conduit flange; a third sealing ring and a fourth sealing ring are embedded into the third sealing ring groove and the fourth sealing ring groove; the insulating device comprises a first insulated filling layer, a second insulated filling layer and a sealing washer; the first insulated filling layer is positioned between the external circular surface of the lower conduit flange and the inner wall of the casing; the second insulated filling layer is positioned between the outer wall of the lower conduit and the first surface of a step of the casing; and the sealing washer is arranged between the second inner surface of the step and the lower conduit flange. The invention has the advantages of excellent insulating performance and no phenomena of damaging to the insulating and the sealing.

Owner:CHANGSHU NO 2 CHEM ENG EQUIP PLANT

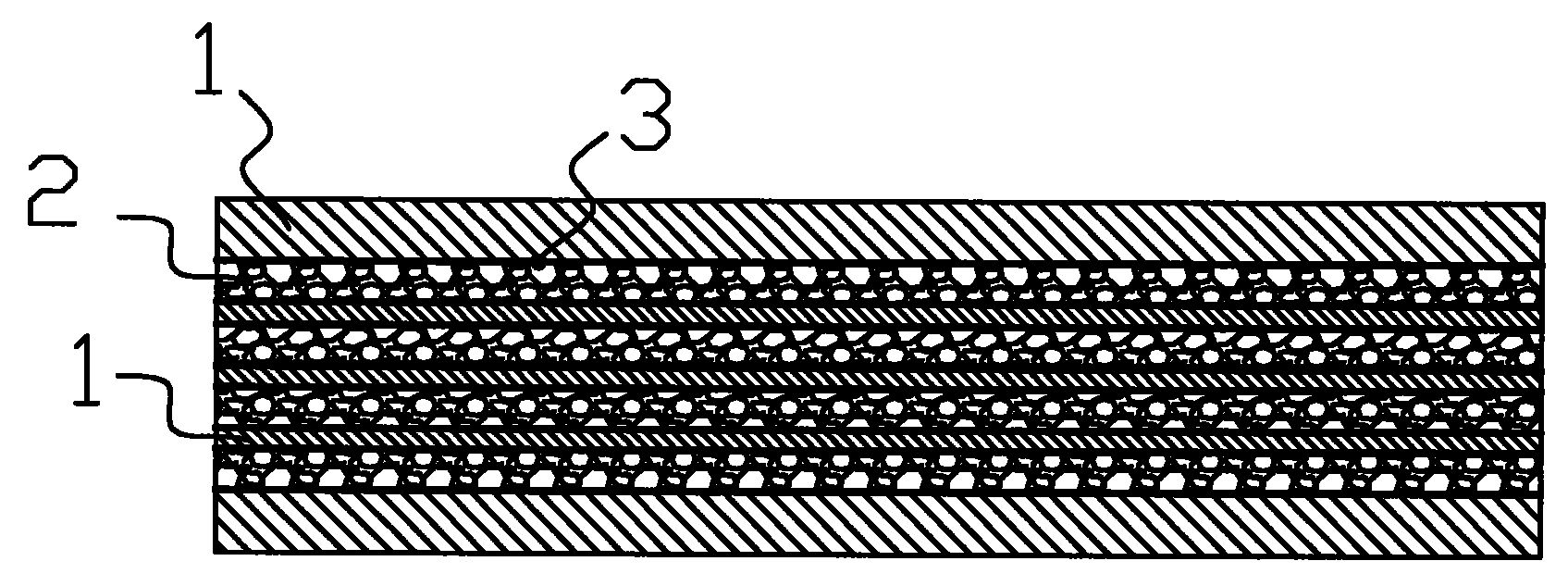

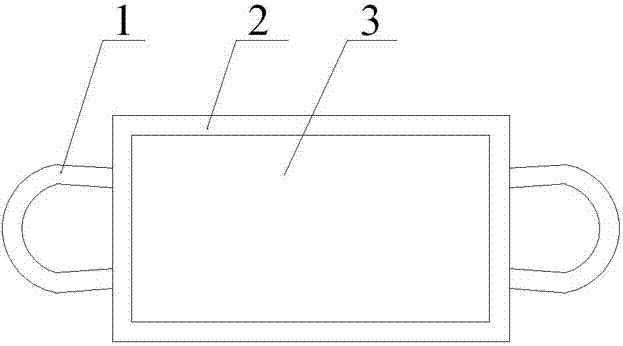

Multilayer perlite composite flame-retardant sheet and preparation method thereof

InactiveCN101793063ASave woodSave moistureWater-setting substance layered productFire proofingFiberSodium phosphates

The invention relates to a multilayer perlite composite flame-retardant sheet. The flame-retardant sheet has a laminated structure containing at least three layers, wherein the surface layer is a wooden layer, a middle wooden layer is separated from a flame-retardant layer, adhesive is used between the layers; the wooden layers are processed through conventional flame-retardant treatment, the thickness is 1-5mm; the thickness of the flame-retardant layer is 1-120cm and comprises the following components by weight: 10-25kg of expanded perlite with 1.5-3mm of particle diameter, 25-40kg of magnesium chloride, 10-25kg of magnesium oxide, 100-300kg of sodium phosphate, 150-350kg of lithopone, 0.1-2.0kg of emulsifier and 50-200kg of adhesive, wherein magnesium chloride, magnesium oxide, sodium phosphate, lithopone, emulsifier and adhesive are used as auxiliary material and filler. As flame-retardant treatment is preformed to the wooden layers and the flame-retardant layer is prepared by mixing expanded perlite and adhesive, the flame-retardant sheet is fire-retardant, wood is saved, no pollution is caused, and the flame-retardant sheet is free from any insect and is the best replacement of the existing shaving board, fiber-board, core-board, solid wood board and other materials.

Owner:杨光伟

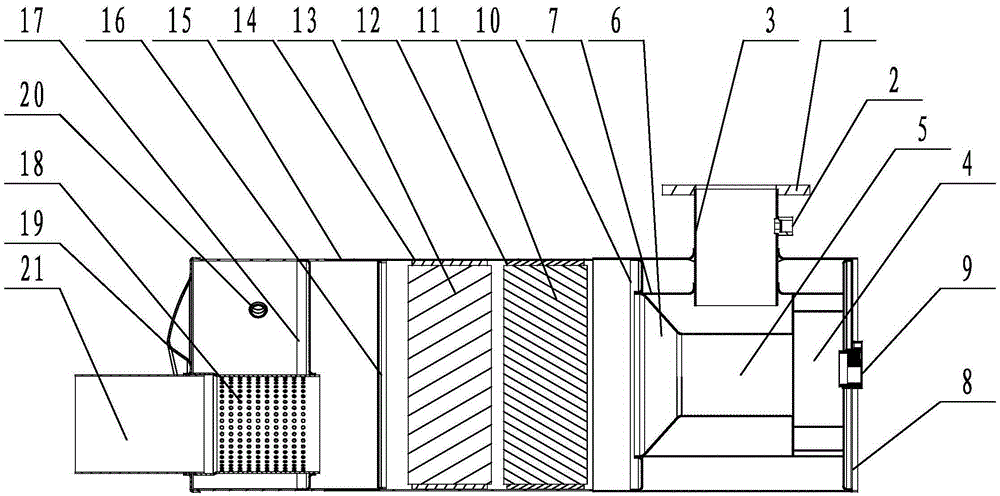

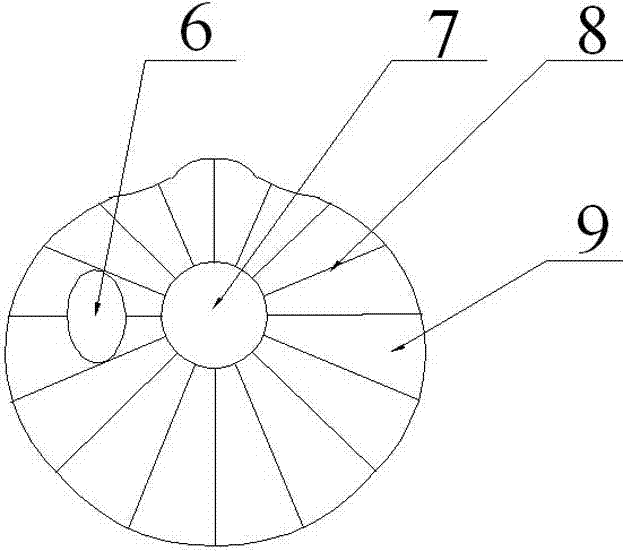

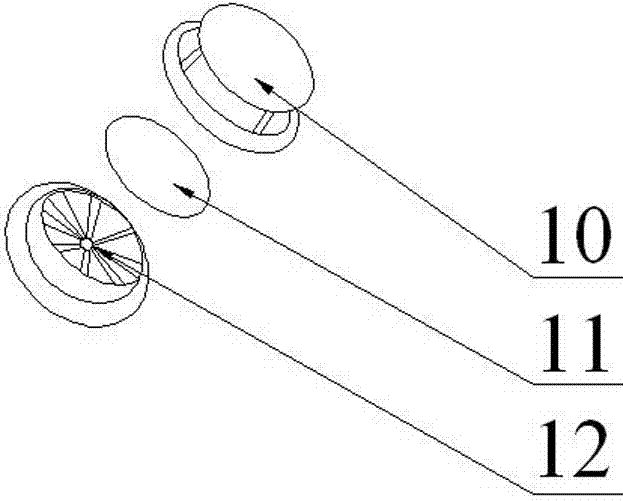

Spiral mixer for integrated injection of SCR catalyst

InactiveCN105402009AReduced insulation performanceNo insulationInternal combustion piston enginesExhaust apparatusEngineeringAmmonia

The invention belongs to the technical field of diesel engine tail gas aftertreatment, and relates to a spiral mixer for integrated injection of an SCR catalyst. The spiral mixer comprises a barrel. A front end cover and a rear end cover are arranged at the two ends of the barrel respectively. A first SCR carrier and a second SCR carrier are arranged in an inner cavity of the barrel. A gas inlet pipe is arranged at the position, between a first separation plate and the front end cover, of the barrel. A mixer device is arranged below the gas inlet pipe and comprises a taper pipe, a mixing pipe and a mixer body which are sequentially connected. The gas outlet end of the taper pipe is fixed to the first separation plate, and the gas inlet end of the mixer body is fixed to the front end cover. By means of the mixer, the aims of urea crushing, urea crystallization and even ammonia distribution can be effectively achieved.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

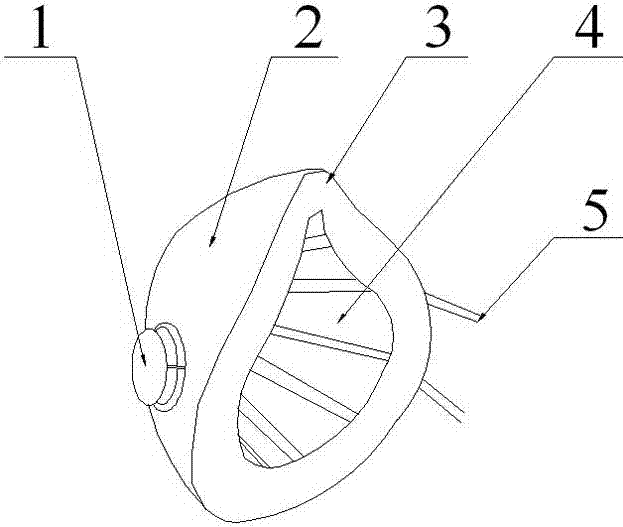

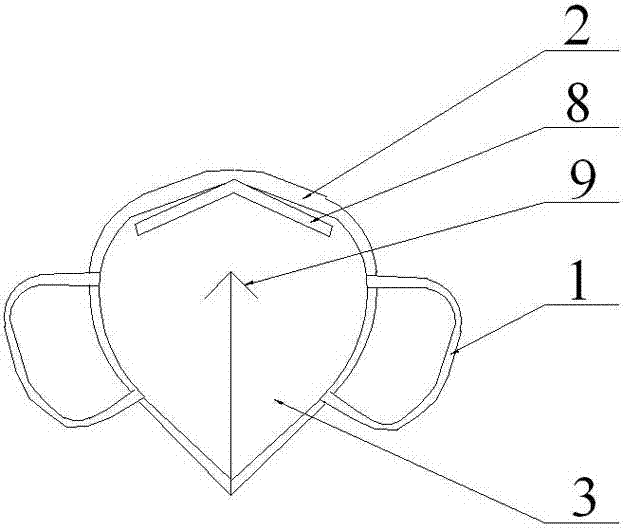

Gauze mask

PendingCN107343677AComfort functionRelieve nervous fatigueProtective garmentSpecial outerwear garmentsPolyesterEngineering

The invention discloses a gauze mask applied to the field of daily life. The gauze mask comprises a gauze mask body, an annular face connecting part and ear hangers, wherein the annular face connecting part is combined with the periphery of the gauze mask body, and the ear hangers are connected to two sides of the gauze mask body; a mask body bracket is further arranged on the inner surface of the gauze mask body and is of an annular structure; the face connecting part is synthesized from nylon fibers or polyester fibers; a radial protruded flow guide component is arranged on the mask body bracket and forms a channel between the gauze mask body on the outer side and the mask body bracket on the inner side; and an air suction hole and an air exhaust hole are further formed in the mask body bracket, and the channel is connected with the air suction hole. The gauze mask is simple in structure, novel in design and high in practical value, simultaneously has the effects of oxygen supplementation, antibiosis and deodorization as well as dust removal, purification and haze prevention and is convenient to mount, dismount and clean, and harmful substances of bacteria are unlikely to propagate.

Owner:张争

Microwave plasma method for sintering calcium, phosphor bioceramic

A microwave plasma sinter method for preparing Ca-P bioceramics includes such steps as die pressing or foam shaping of Ca-P bioceramics powder, removing adhesive at 400 deg.C, sintering at 600-1100 deg.C for 5-45 min in the working gas (O2, N2 and / or CO2) in microwave plasma sintering cavity, and slowly cooling. Its advantages are high speed, high bioactivity and mechanical performance of product.

Owner:SICHUAN UNIV

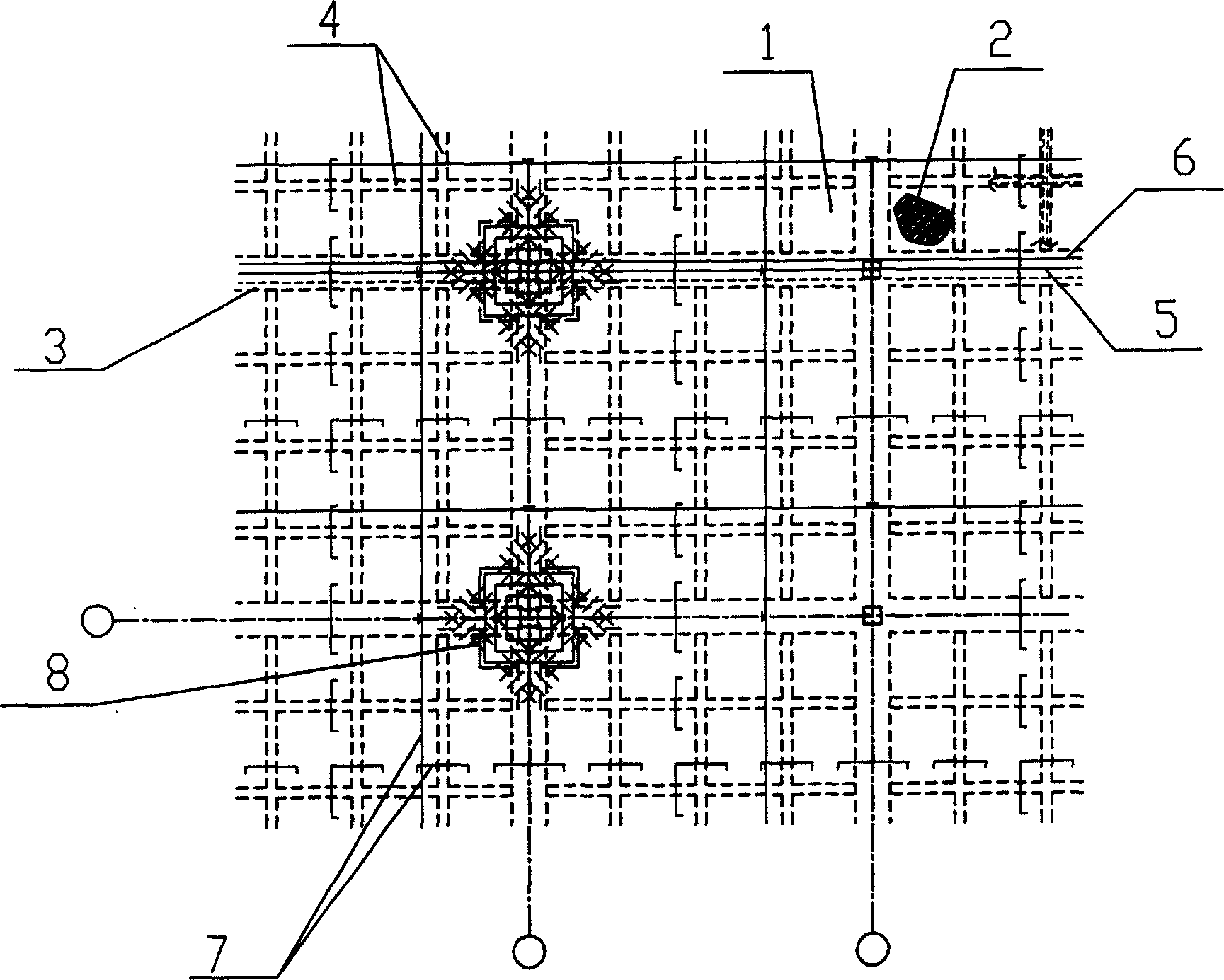

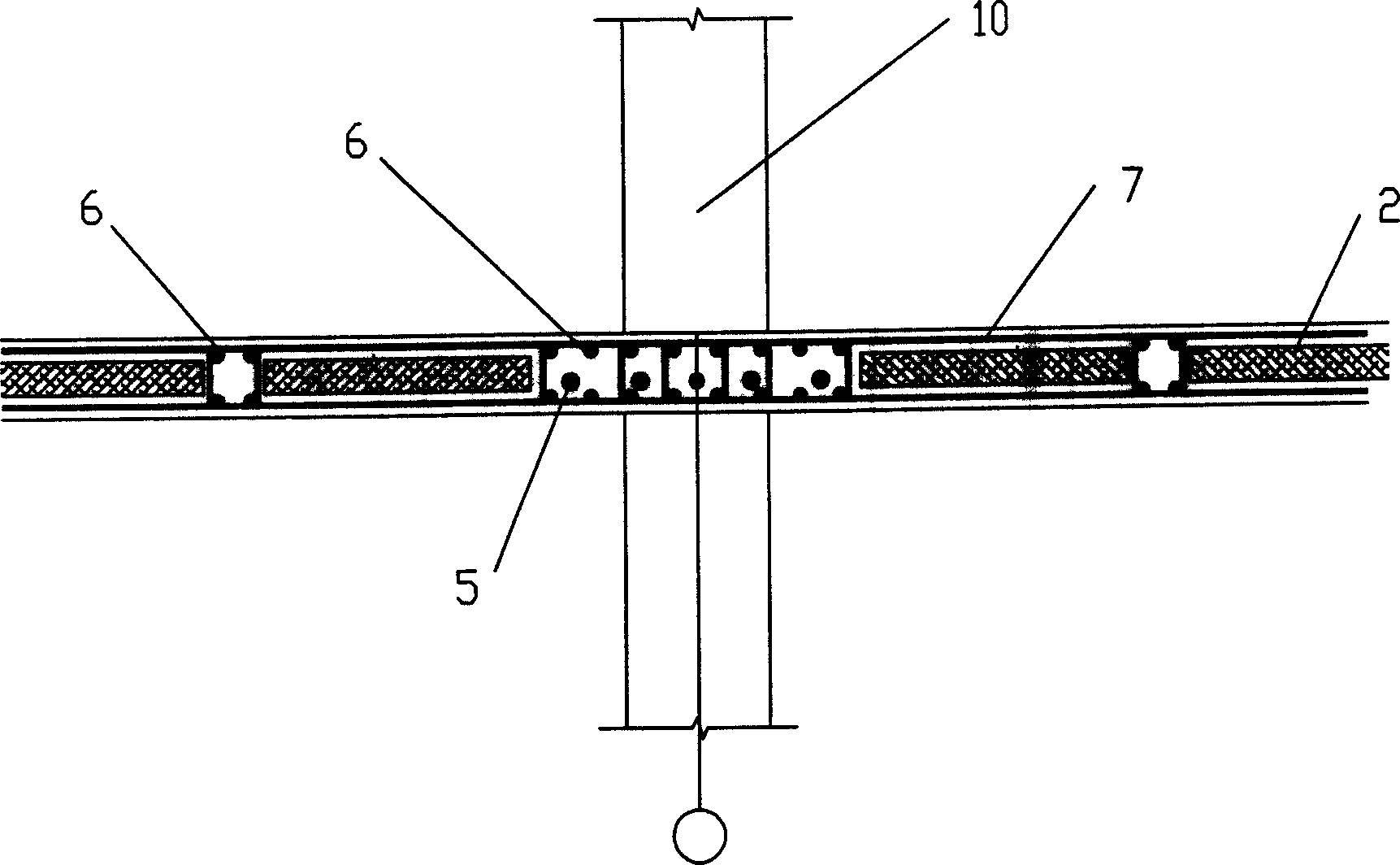

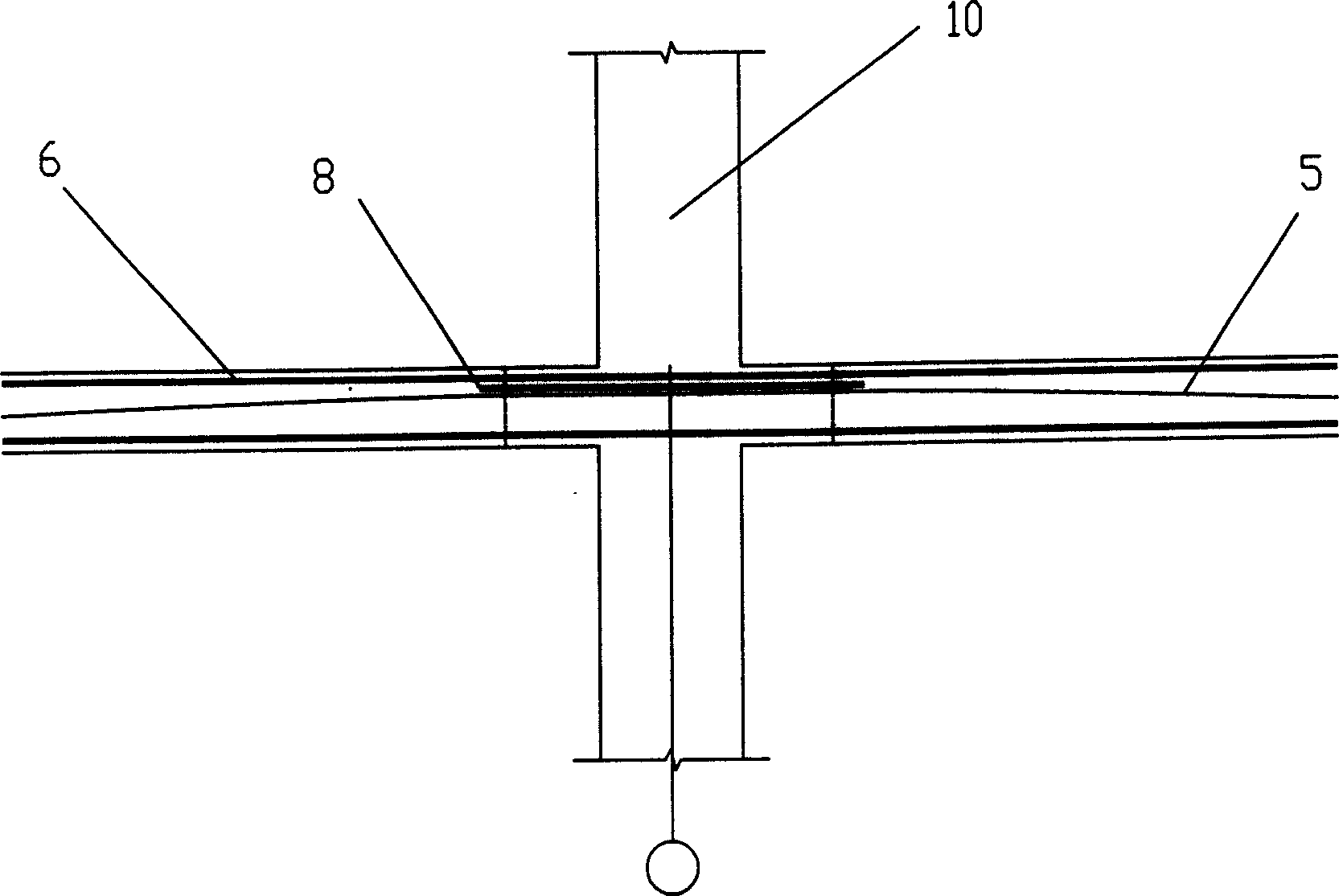

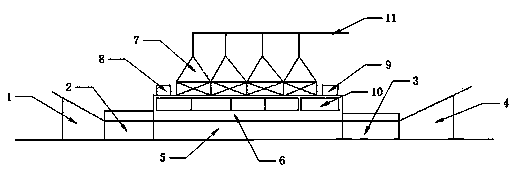

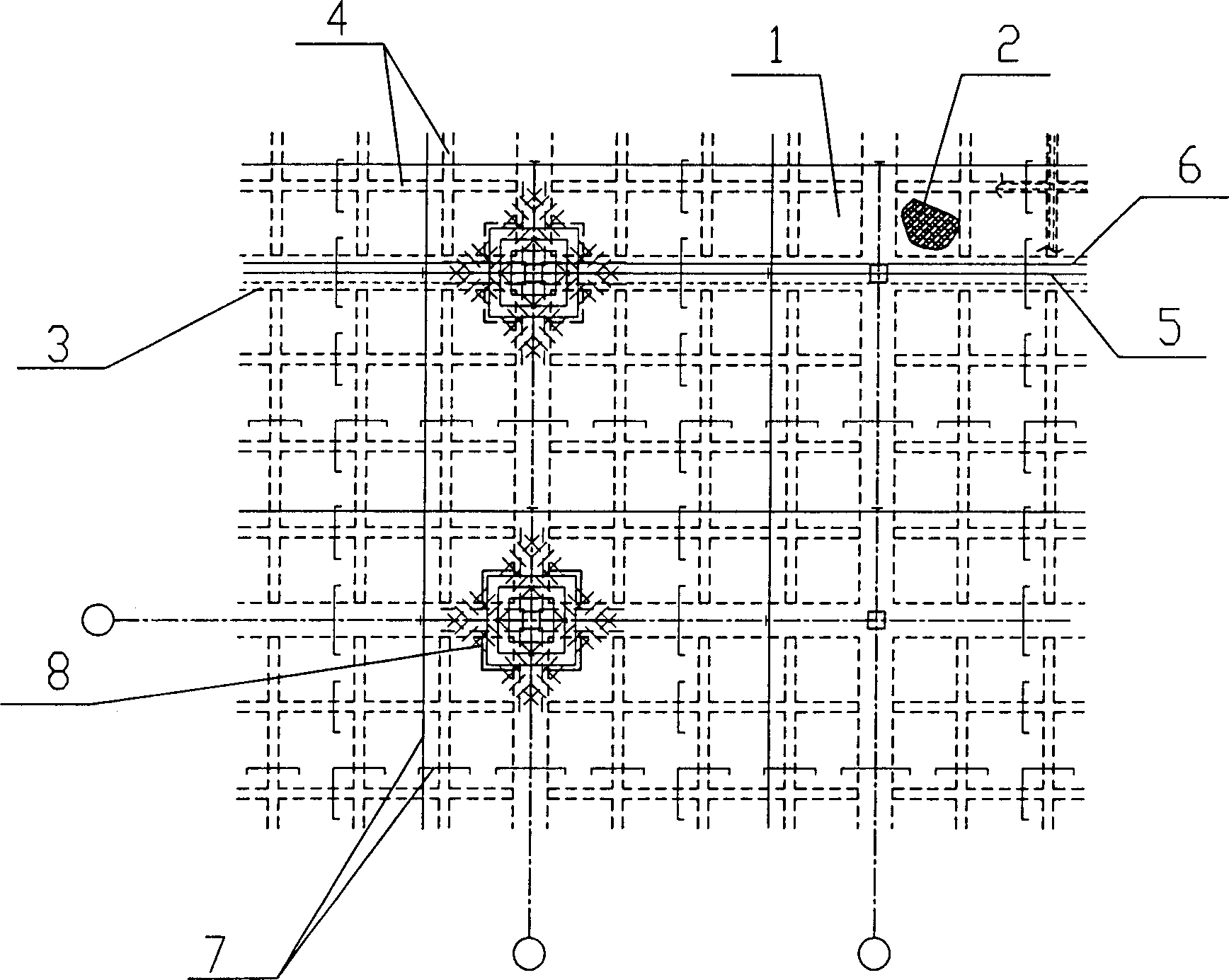

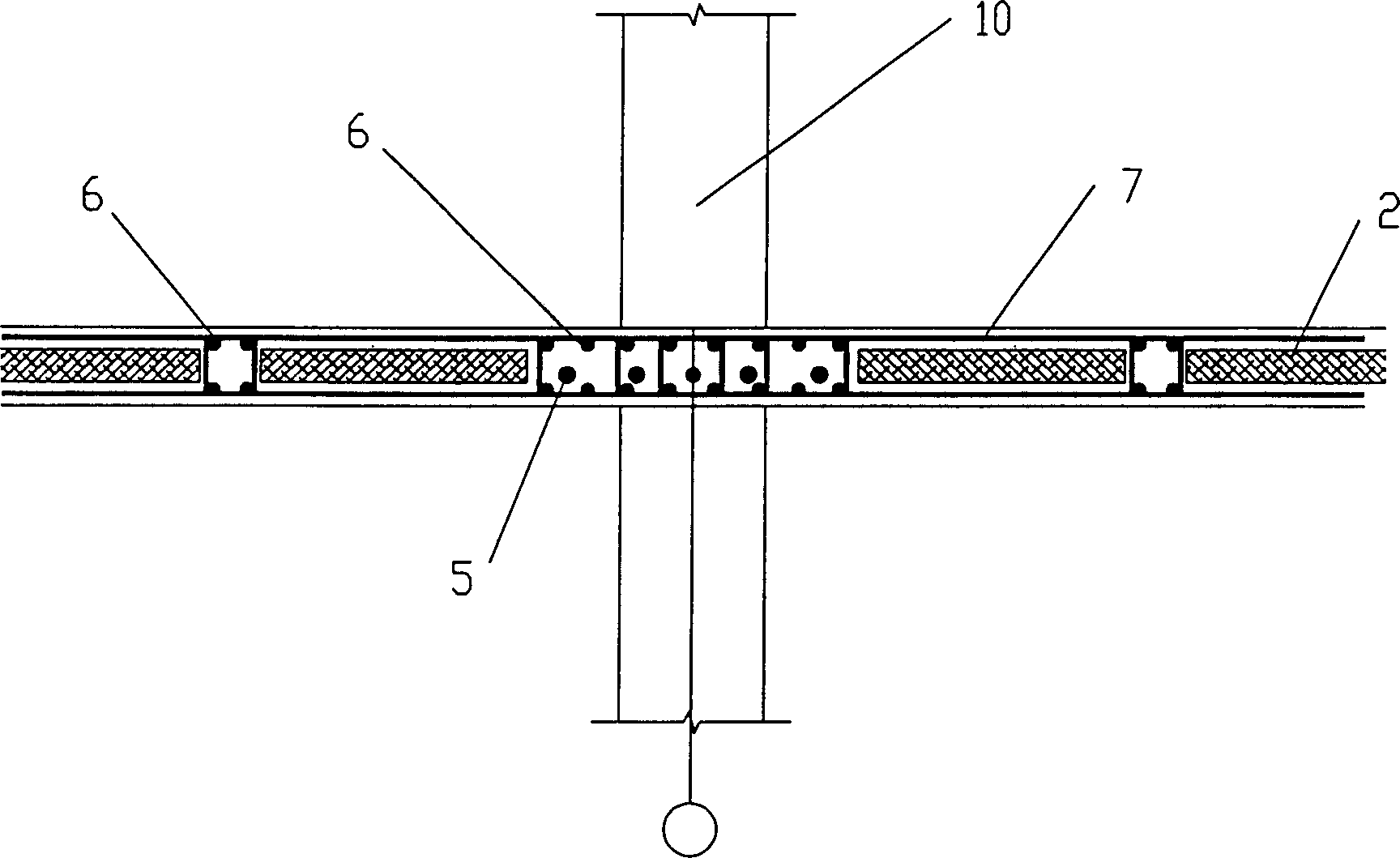

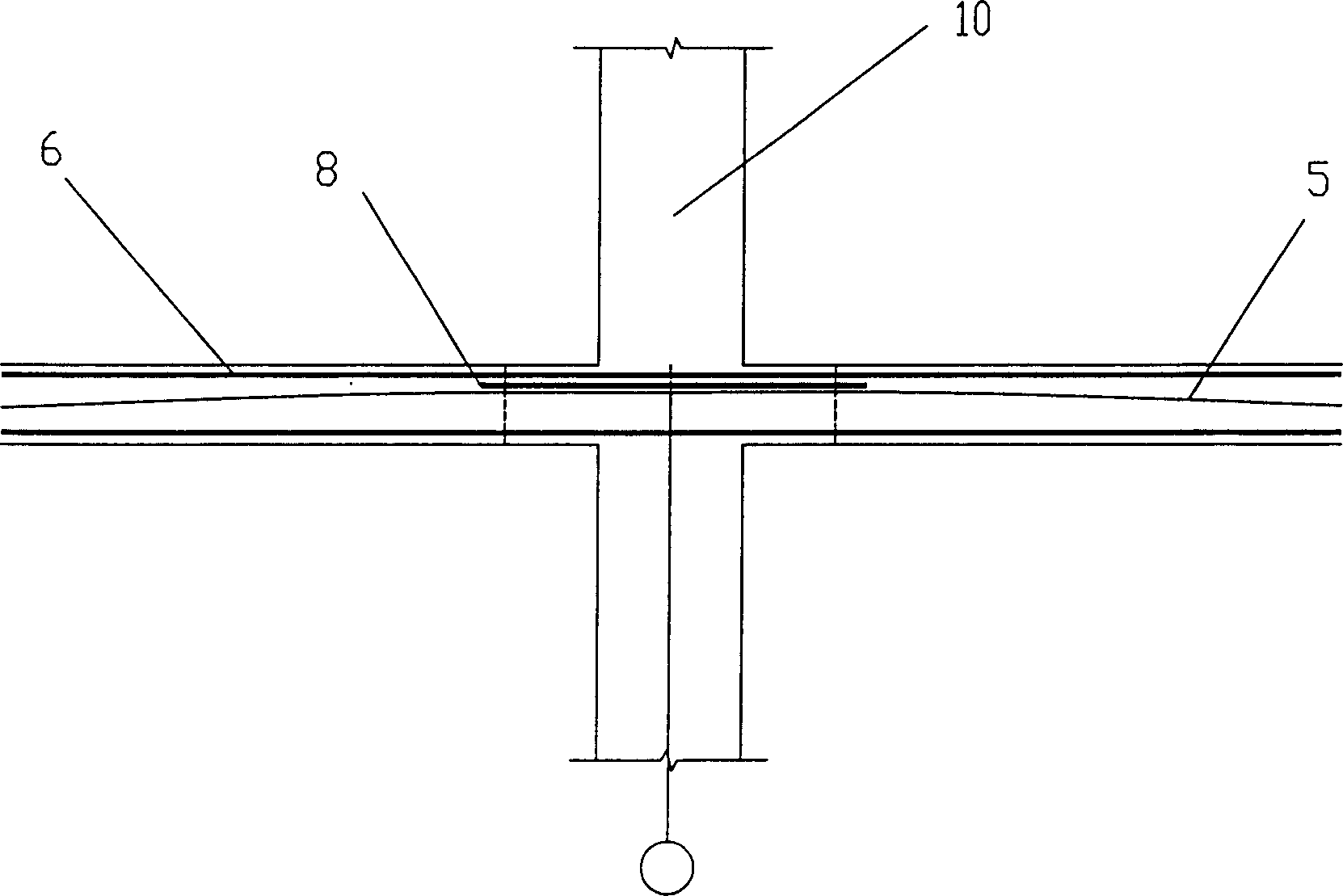

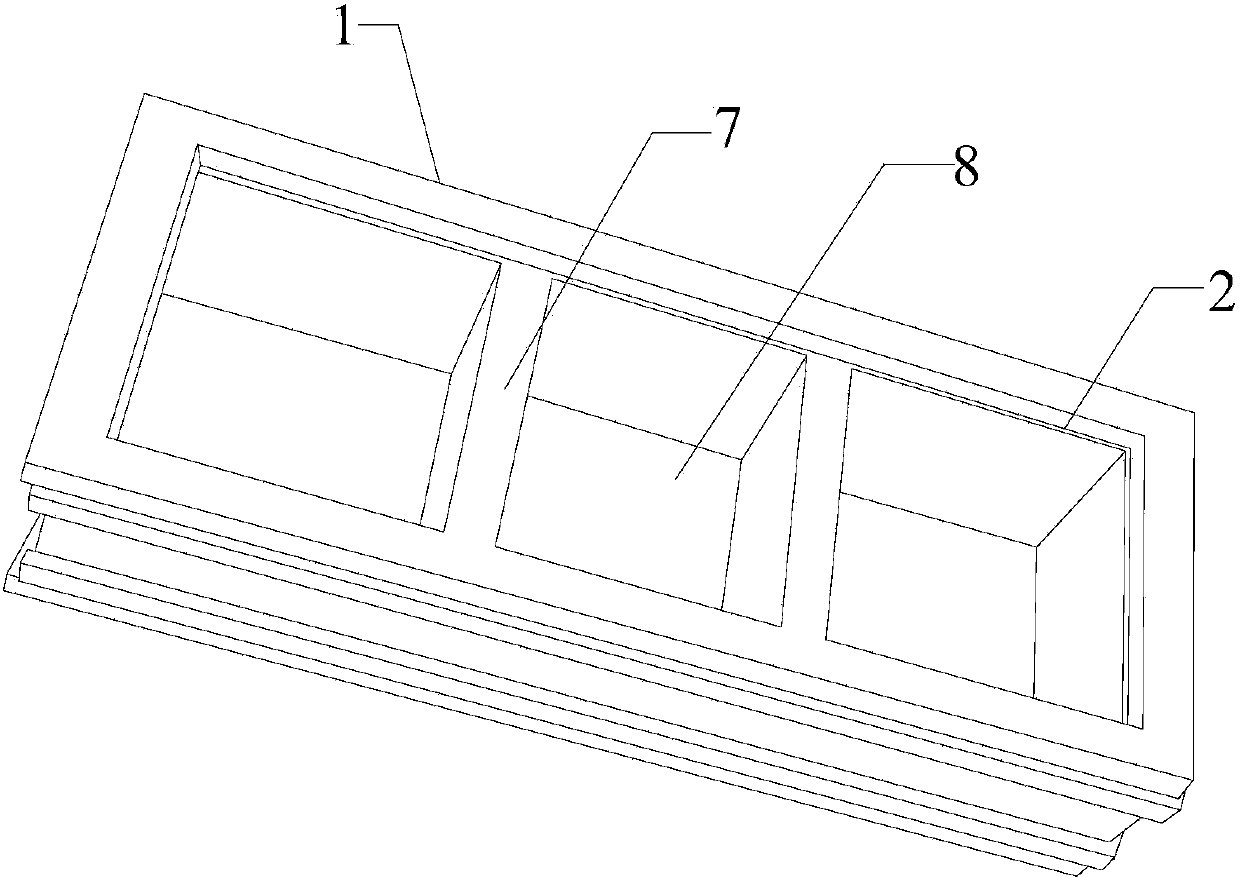

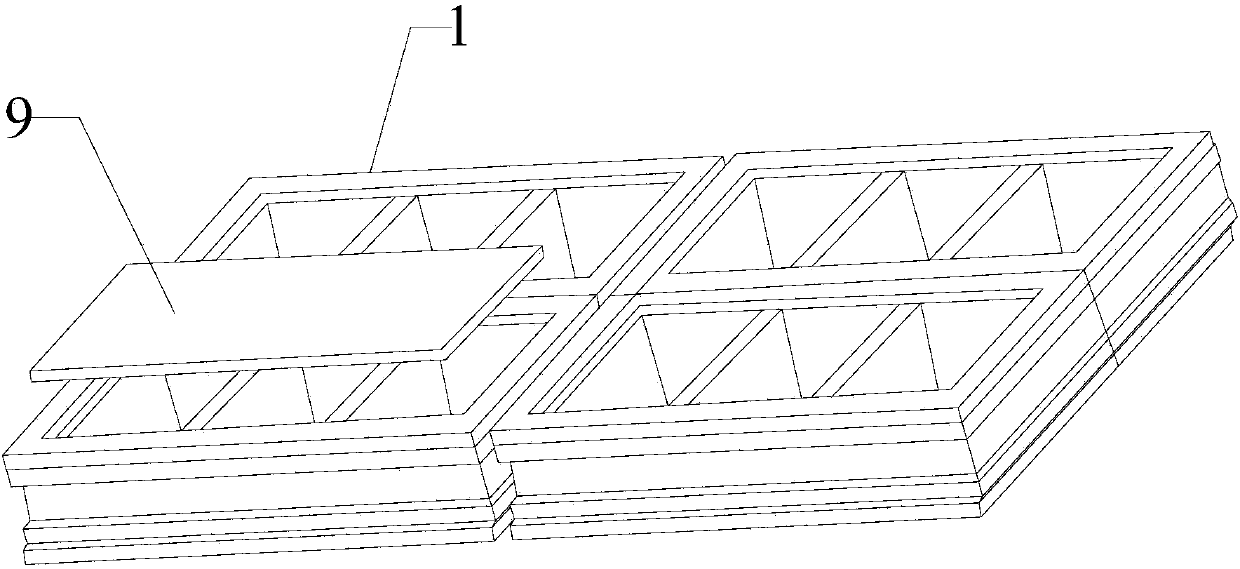

In-site prestressed concrete sandwiched composite beamless floor structure system and construction method

This invention discloses a kind of sandwich and compound beamless slab construction of watering prestress concrete and its constructing method. This construction includes beamless slab body, ribs of inner main and dark slabs and ribs of inner secondary dark slabs with cross arranged. The prestess and stress concrete reinforced bars are arranged in the ribs of main and dark slabs, and the stress concrete reinforced bars are laid out in the upper and lower crust of beamless slab body and in the inner secondary dark slabs with cross arranged. The inner space of the body is stuffed with polystyrene foam sandwich boards. In the job site, first, the form board is propped up and the prestress bars are arranged and stretched and drawn; second, the polystyrene foam sandwich boards should be laid out and fastened and the stress bars are arranged; then the concrete is poured and shaped into the construction, which can satisfy the constructing load-bearing requirements like fireproofing, sound insulation, heat insulation, high-intensity and light quality. Such beamless slab can be used in civilian and various industries construction.

Owner:胡战波

Insulating flame-retardant pressure-sensitive adhesive applied to power battery, adhesive tape and preparation method of insulating flame-retardant pressure-sensitive adhesive

InactiveCN112126384AMeet safety requirementsStable and excellent insulationNon-macromolecular adhesive additivesEster polymer adhesivesIsooctyl acrylateElectrolytic agent

The invention relates to the technical field of special adhesive tapes for new energy batteries, in particular to an insulating flame-retardant pressure-sensitive adhesive applied to a power battery,an adhesive tape and a preparation method of the adhesive tape. The pressure-sensitive adhesive comprises the following components in parts by weight: 15-20 parts of 2-ethylhexyl acrylate, 10-15 partsof butyl acrylate, 7-10 parts of methyl acrylate, 5-7 parts of isobornyl acrylate, 5-7 parts of acrylic acid, 0.3-0.6 part of an initiator, 20-40 parts of ceramic powder, 0.3-0.6 part of aziridine and 40-71 parts of a solvent.Compared with an existing adhesive tape for a power battery, the pressure-sensitive adhesive tape has excellent insulation, flame retardancy and electrolyte resistance; andthe change of the bonding strength of the pressure-sensitive adhesive tape is extremely small in high-temperature and electrolyte environments, so that the safety requirement of the existing power battery can be well met.

Owner:广东安利华新材料科技有限公司

Preparation method of prestressed prefabricated component

InactiveCN111531702AFireproof constructionImprove appearance qualityCeramic shaping apparatusExcavationsChemical treatmentRough surface

The invention relates to the technical field of prestressed prefabricated components, and discloses a preparation method of a prestressed prefabricated component. The preparation method comprises thefollowing steps that when an original component is heated and cured, a curing system to control the time for standing, heating, constant temperature and cooling is formulated, standing is performed atnormal temperature for 2-6 hours, the difference value between the surface temperature of the prefabricated component discharged out of a pool and the environment temperature does not exceed 25 DEG C, the original component adopts a prefabricated component joint surface connected by post-poured concrete or mortar and grouting materials, and rough surface treatment is carried out according to design requirements during manufacturing. When the design has no specific requirements, the rough surface can be manufactured through chemical treatment, galling or chiseling and other methods, a sandwichexternal wallboard of the original component is suitable for being produced through a flat die technology, and during production, an external wallboard concrete layer needs to be poured firstly, thena heat preservation material and a pulling piece need to be installed, and finally an internal wallboard concrete layer needs to be poured; and when a vertical die technology is adopted for production, inner and outer wallboard concrete layers should be poured synchronously, and measures should be taken to ensure accurate positions of thermal insulation materials and tie pieces.

Owner:武汉市华江幸福装配式建筑有限公司

Manufacturing method for pure natural decorative coating of interior and exterior walls of buildings

The invention discloses a manufacturing method for a pure natural decorative coating of interior and exterior walls of buildings. The method comprises the following steps: weighting the following raw materials by weight percent: 5-10% of glutinous rice flour, 40-55% of red clay, 5-10% of husk, 15-20% of lime and 20-30% of water; crushing the glutinous rice flour and gelatinizing under high temperature, thereby acquiring glutinous rice slurry; grinding the lime to 325 meshes or above, thereby acquiring lime powder; grinding the red clay to red clay powder at 250-350 meshes or above; cooking and disinfecting the husk under high temperature, thereby acquiring disinfected husk; dispersing and stirring the glutinous rice slurry, lime powder, red clay powder, disinfected husk and water and packaging, thereby acquiring the coating. According to the invention, the coating is prepared from various natural raw materials, so that the coating is nontoxic and harmless, can be used for decorating the interior and exterior walls of buildings, has the characteristics of simplicity in operation, high adhesive property, quick drying, waterproof and damp-proof effect, non-scaling and non-falling effect, no toxicity, no harm, no pollution and natural color and can achieve the heat-insulating, heat-preserving and soundproof functions when the coating is used for decorating the interior and exterior walls of buildings.

Owner:毛小文

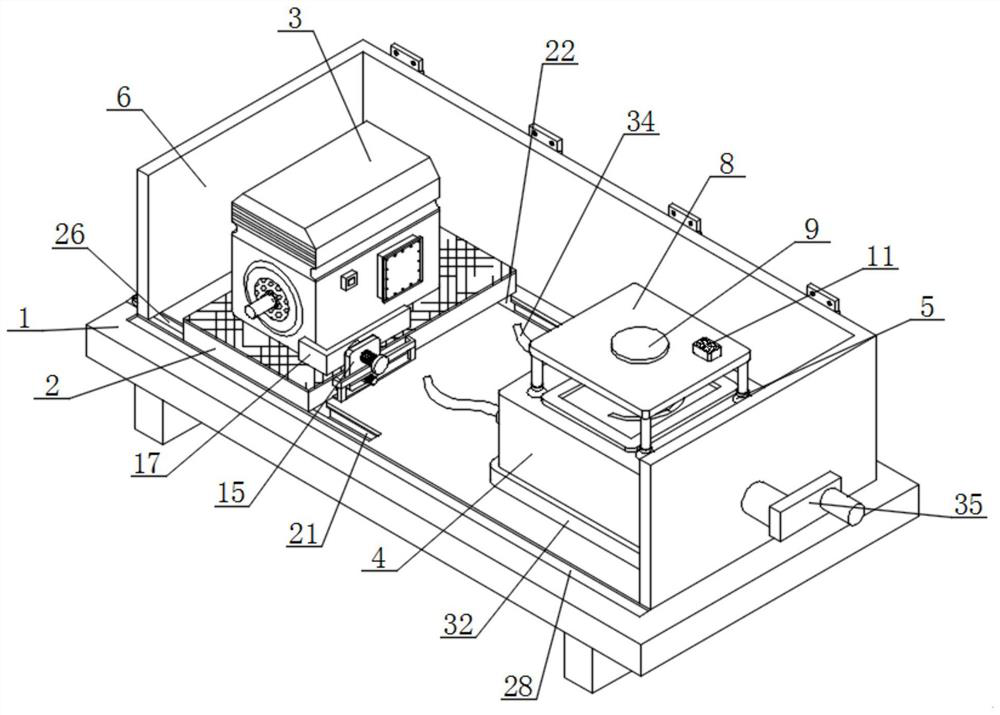

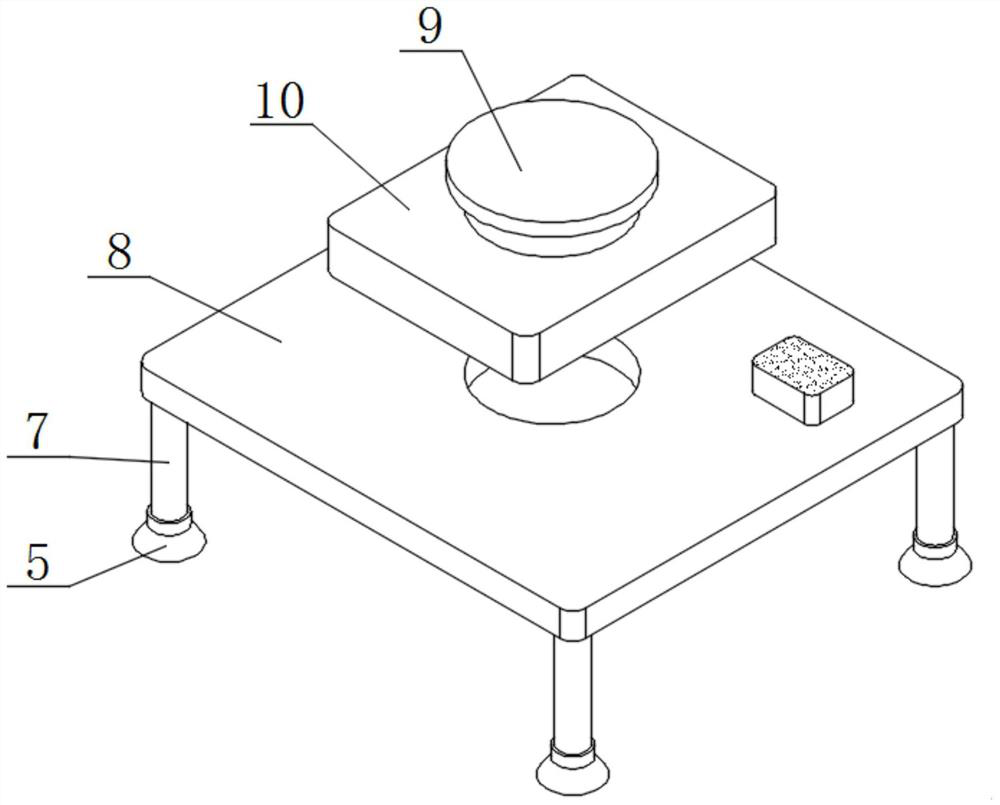

Insulation performance detection device for high-voltage motor

InactiveCN113884840ANo insulationAvoid moving phenomenonTesting dielectric strengthElectric machineStructural engineering

The invention discloses an insulation performance detection device for a high-voltage motor. The insulation performance detection device comprises a bottom plate, a movable plate, the high-voltage motor, a megger, rubber suction cups and a ferromagnetic enclosure frame, wherein the movable plate is mounted at the top part of the bottom plate, the high-voltage motor is mounted at the top part of the movable plate, and the megger is mounted at the top part of the bottom plate; the ferromagnetic enclosure frame is mounted at the top part of the bottom plate; and the top part of the megger is provided with four sets of the rubber suction cups arranged in a square shape, the top parts of the rubber suction cups are provided with supporting columns, and the top parts of the supporting columns are provided with square plates. Data of a dial plate of the megger can be captured through using a recorder and then backed up and stored, the to-be-measured motor on the moving plate has a fixed and anti-moving function when placed, and the distance between the motor and the megger can be changed, so that the distances between the motors of different sizes and the megger can be within the effective length range of a measuring flexible wire, when the insulation performance detection device detects, magnetic field isolation can be carried out, and the influence of a magnetic field of an external component on a detection result is avoided.

Owner:JIAXING NANYANG POLYTECHNIC INST

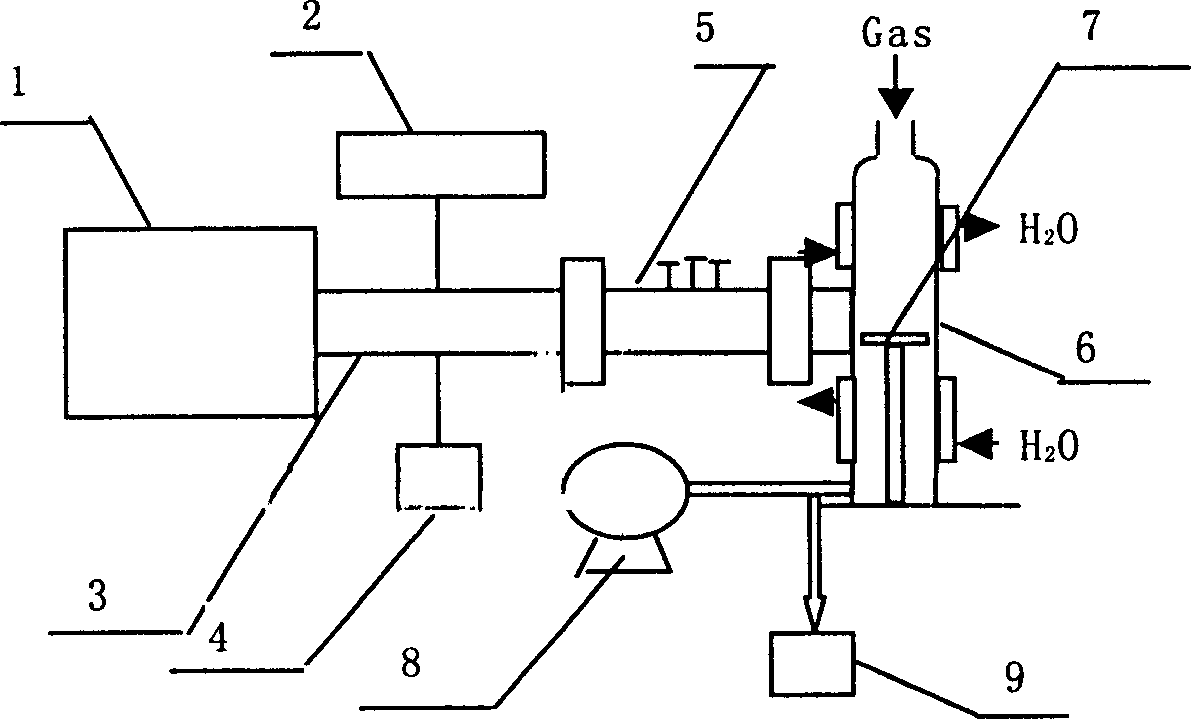

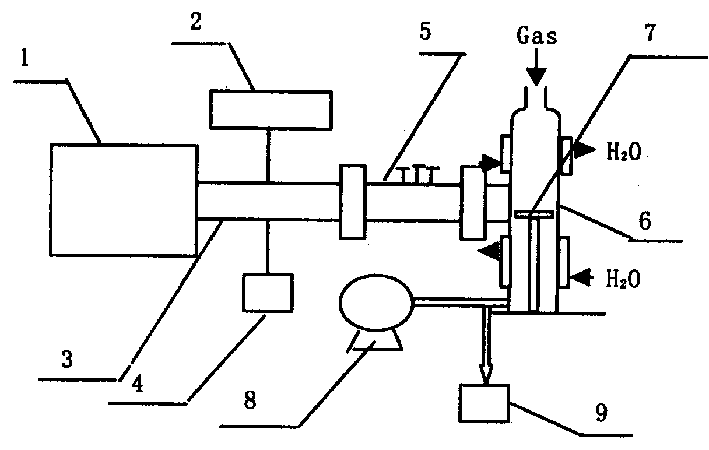

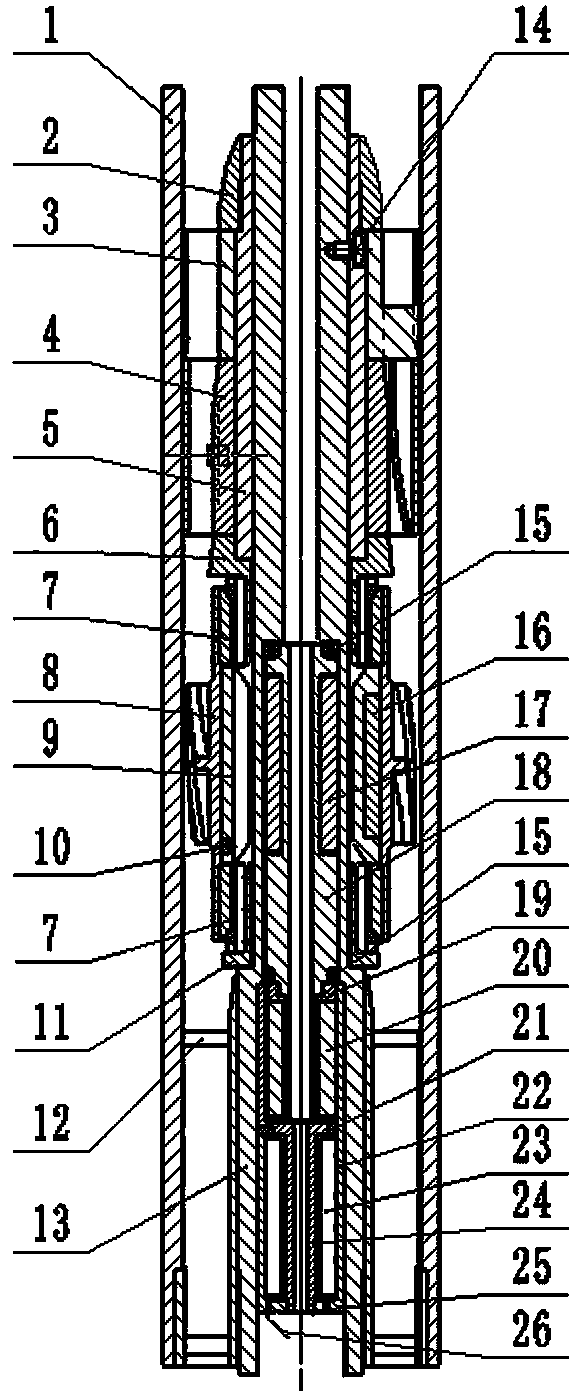

Underground magnetic coupling turbine power cantilever type alternating current generator

ActiveCN103701259ANo qualityNo performanceMagnetic circuit rotating partsDynamo-electric gearsCouplingStator coil

The invention discloses an underground magnetic coupling turbine power cantilever type alternating current generator, which comprises flow pipes, pressing caps, flow guide rings, fluid directors, supporting pipes, upper bearings, magnetomotive turbine assemblies, lower bearings, straight-wing fluid directors, a generator shell, a positioning screw, supporting bearings, a generator rotor and a generator stator, wherein the generator rotor is a cantilever type alternating current generator rotor and consists of coupling magnetic steel, a coupling magnetic steel bracket, a rotor magnetic steel bracket and rotor magnetic steel; the generator stator is a cantilever type alternating current generator stator and consists of a magnetic separation frame, a stator outer shell body, a stator coil, a stator inner shell body and a locating pin. The generator has the advantages of high power generation efficiency, low manufacture and use cost and long service life, and large-power generation can be realized.

Owner:东营市创元石油机械制造有限公司

Microwave heat-energy tentering setting machine

ActiveCN103643429AAvoid wastingFully endowed with drapeHeating/cooling textile fabricsMicrowaveFree cooling

The invention relates to a microwave heat-energy tentering setting machine which comprises a cloth feeding device, a tentering area, a heating and setting device, a natural cooling area and a cloth discharging device, wherein the heating and setting device comprises a heating and setting area and a microwave heating device; the microwave heating device comprises a main heater, a plurality of gas collecting hoods above the main heater, a waveguide tube and a water load device; leak energy inhibitors are arranged at openings behind the heating and setting area. The microwave heat-energy tentering setting machine can congruently heat by generating heat through interaction of microwaves and a heated medium by adopting microwaves penetration acted on the medium. In a heating process, only the medium (fabric) is acted without heating and preserving the heat of the whole heating and setting area, and other parts do not heat, so that the heat efficiency is greatly improved, the waste on the heat energy is fully avoided, and exhaust gas discharge is greatly reduced. Meanwhile, according to the heating method, molecular intense motion, friction, and motion inside and outside at the same time and motion from inside to outside and the like are realized, so that the heated fabric is fluffy.

Owner:ZHEJIANG ZHONGTE INTELLIGENT EQUIP CO LTD

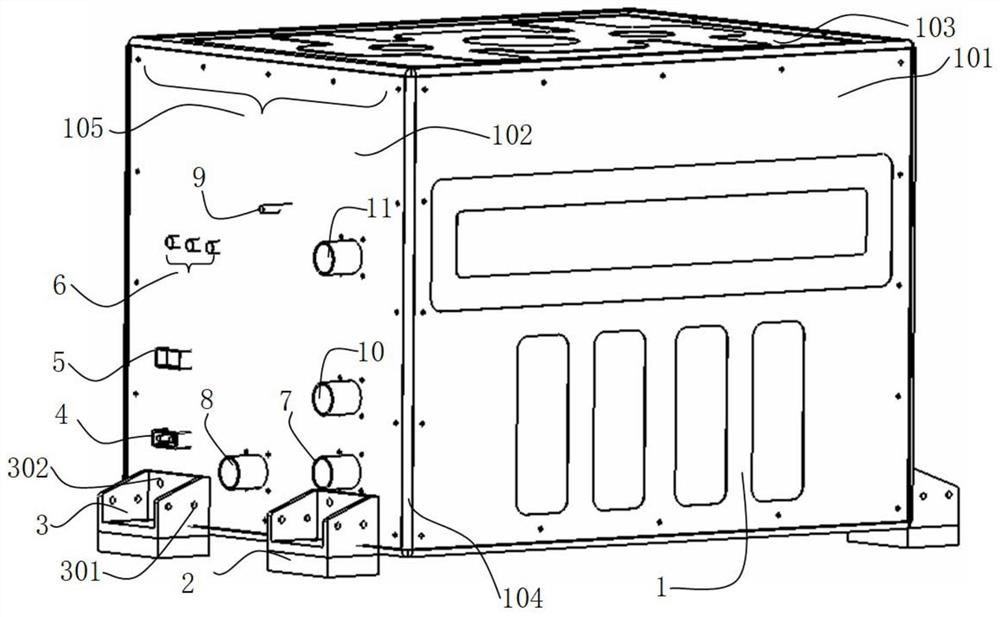

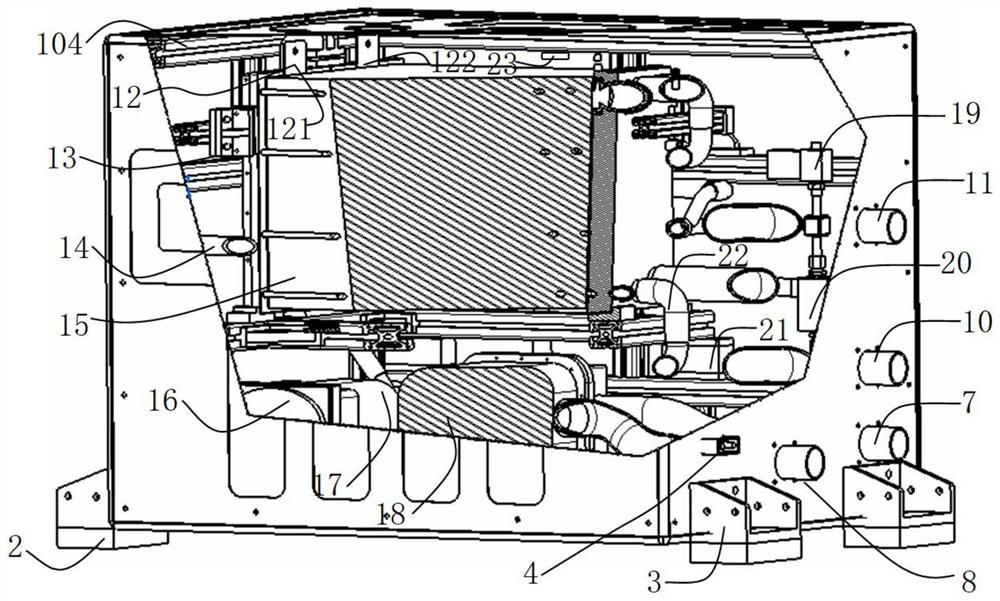

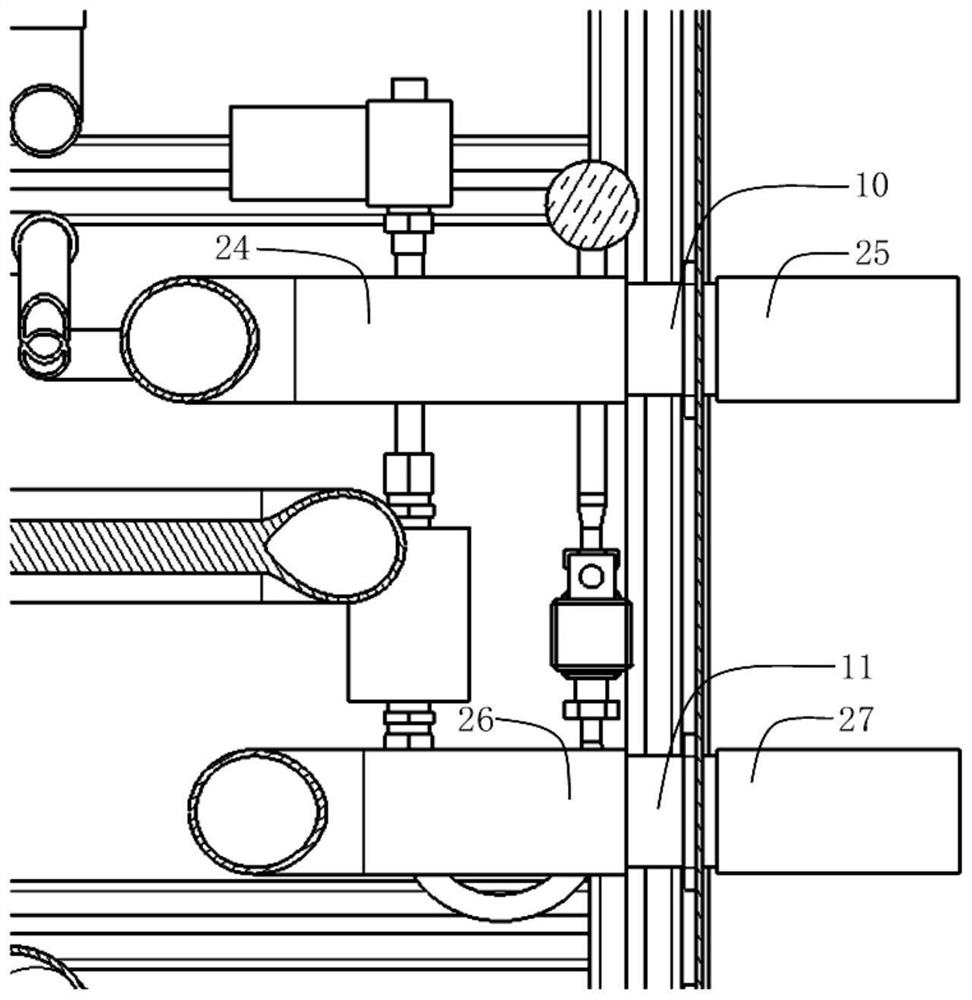

Vehicle-mounted fuel cell system and fuel cell vehicle

PendingCN111725540AImprove insulation performanceReduced insulation valueFuel cell heat exchangeMotive system fuel cellsFuel cellsIn vehicle

The invention discloses a vehicle-mounted fuel cell system. The vehicle-mounted fuel cell system comprises a fuel cell box body, a first liquid passing pipe for guiding cooling liquid, a first inner connecting pipe connected with the first liquid passing pipe and located in the fuel cell box body, and a first outer connecting pipe connected with the first liquid passing pipe and located outside the fuel cell box body, a first connecting flange is arranged on the first liquid passing pipe, the first connecting flange is connected with the fuel cell box body, and gaps are formed between the first inner connecting pipe and the first connecting flange and between the first outer connecting pipe and the first connecting flange. According to the vehicle-mounted fuel cell system, the fuel cell cooling liquid inlet, the fuel cell cooling liquid outlet and the cooling loop are subjected to insulation design, it is ensured that the whole fuel cell vehicle system still has the good insulation performance even in a humid and hot environment, and the running safety of the whole vehicle can be improved. The invention also discloses a fuel cell vehicle.

Owner:CHERY COMML VEHICLE ANHUI

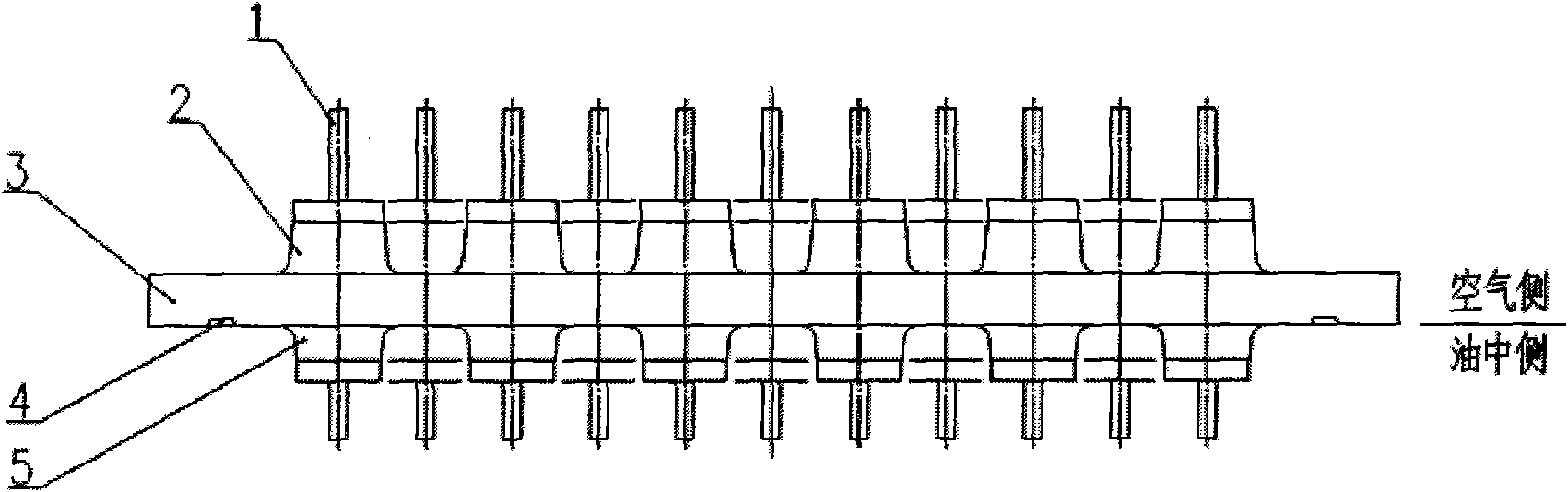

Terminal strip for electric locomotive hauling transformer

InactiveCN101667486AImprove insulation performanceHigh mechanical strengthTransformers/inductances coils/windings/connectionsEpoxyEngineering

The invention relates to a terminal strip for an electric locomotive hauling transformer, which consists of a connecting terminal, an air side insulated post, a mounting flange, a seal groove and an oil middle side insulated post; the air side insulated post, the mounting flange and the oil middle side insulated post have an integral structure formed by vacuum pouring of epoxy resin; the contacting surface of the connecting terminal and the epoxy resin is circularly provided with buffer circles; the air side insulated post and the oil middle side insulated post have a cone frustum shape, and joints of the roots of the two and the flange are provided with fillets; two ends of the connecting terminal are platy and the middle of the connecting terminal has a cylindrical structure; and the buffer circles are 4 to 6, made of elastic silicon rubber, and are circularly arranged on the contacting surface of the middle cylinder of the connecting terminal and the epoxy resin. The terminal striphas reliable insulation, strong mechanical strength, convenient operation, flexible installation, reliable seal, and long service life.

Owner:DALIAN NORTH INSTR TRANSFORMER GROUP

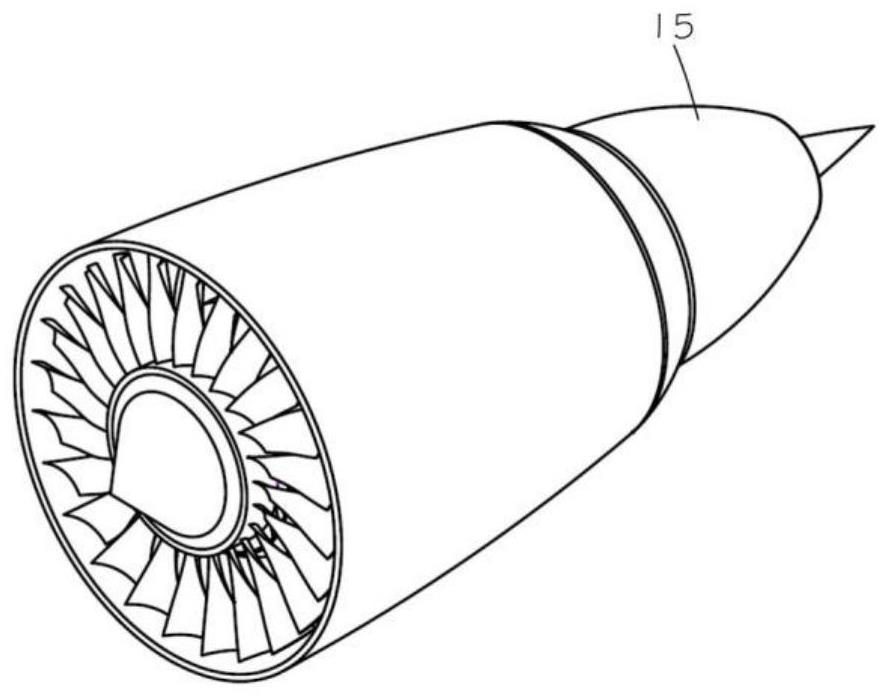

High-performance special heat insulation piece for aero-engine exhaust nozzle

PendingCN114014693APrevent collapseImprove physical stabilityJet propulsion plantsCeramicwareFiberInsulation layer

The invention discloses a high-performance special heat insulation piece for an aero-engine exhaust nozzle, which comprises a first stainless steel sheet metal layer, a heat insulation layer and a second stainless steel sheet metal layer. The heat insulation layer is positioned between the first stainless steel sheet metal layer and the second stainless steel sheet metal layer, and the heat insulation layer is made of a porous foaming composite material. The porous foaming composite material comprises the following components in percentage by mass: 20%-30% of fire-resistant fibers, 30%-55% of an inorganic silicon prepolymer, 15%-25% of expanded graphite, 10%-15% of a halogen-free flame retardant, 7%-11% of titanium oxide powder and 2-4% of an additive. The porous foaming material adopts an inorganic silicon material as a matrix and titanium oxide powder as a reinforcement, so that a composition of the heat insulation piece has higher physical and chemical stability, the heat insulation piece is effectively prevented from collapsing in the manufacturing or assembling process, and the loss of effectiveness is avoided. Besides, as the stainless steel metal plate layers are arranged on the two sides of the porous foaming material, the structural stability is further improved, and collapse in the assembling process is avoided.

Owner:江西九由航空装备有限公司

Bacteriostatic autoclaved aerated concrete block capable of adsorbing peculiar smell and preparation method therefor

The invention discloses a bacteriostatic autoclaved aerated concrete block capable of adsorbing peculiar smell. Bamboo fibers are subjected to an acetylation reaction, so that free hydroxyl groups in cellulose are sealed and the hydrophobic property and thermal stability of a material are improved; other effective components are added in combination with a physical modification method, so that the durability and dispersity of the fibers in autoclaved aerated concrete are improved; added jade powder improves the strength, apparent density and bacterial inhibition property of the block; added cassava dregs solve the problem of environmental pollution, replace the effect of gypsum, reduce production cost and realize the themes of saving energy, protecting the environment and turning waste into wealth; a process is simple, easy in operation and low in production cost; a product has the advantages of capabilities of inhibiting bacteria and adsorbing peculiar smell, high strength, low shrinkage rate and the like, and is low in self weight; and when the bacteriostatic autoclaved aerated concrete block is used as a building brick, the density of the bacteriostatic autoclaved aerated concrete block is only 1 / 3 of that of a clay brick, so that the self weight of a building can be greatly reduced, the service life of the bacteriostatic autoclaved aerated concrete block is synchronous with that of the building, and worries of secondary insulation and maintenance do not exist.

Owner:DANGTU COUNTY KEHUI TRADING

Intelligent laser edge bonding machine

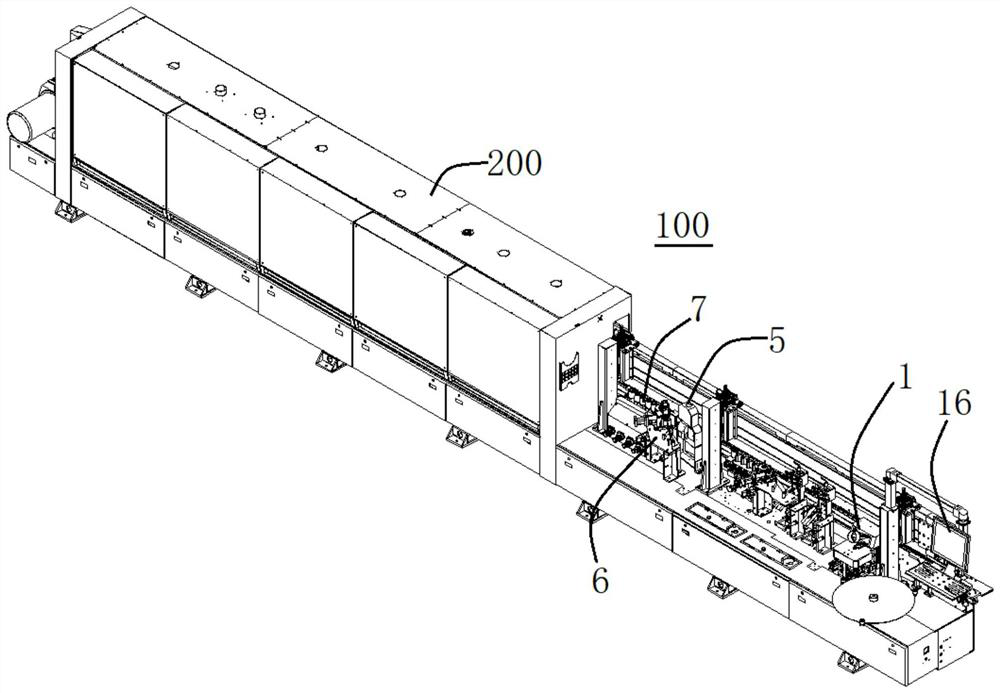

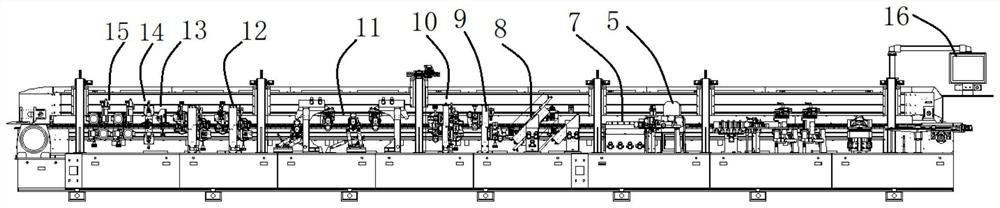

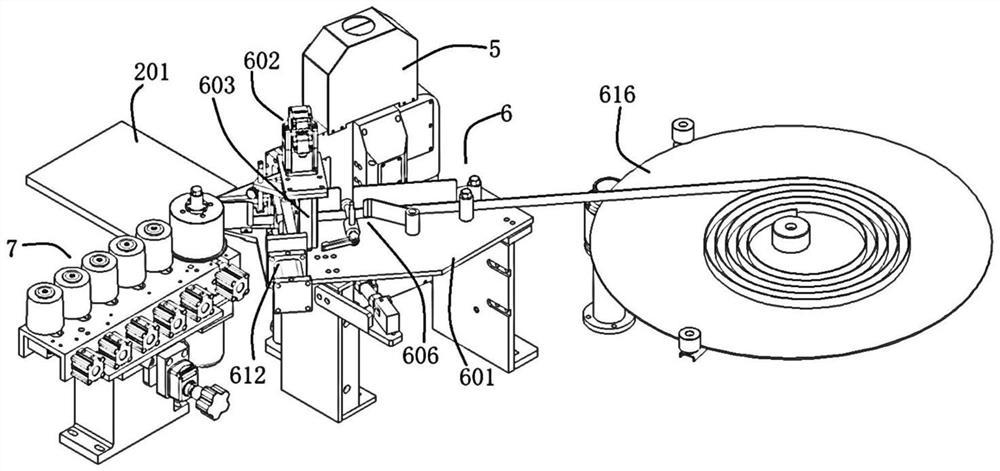

ActiveCN114670306AAvoid harmRealize the purpose of edge bandingMulti-purpose machinesDomestic articlesHigh energyElectrical connection

The invention discloses an intelligent laser edge banding machine which comprises an edge banding machine body, an intelligent industrial control screen, a pre-milling mechanism, a laser edge banding mechanism and a six-wheel fixed belt pressing and pasting mechanism are installed on the edge banding machine body from right to left, and the pre-milling mechanism, the laser edge banding mechanism and the six-wheel fixed belt pressing and pasting mechanism are electrically connected with the intelligent industrial control screen. According to the intelligent laser edge bonding machine, high-energy laser generated by the laser edge bonding mechanism is used for carrying out glue melting on the laser edge bonding belt with a functional sol layer, a glue coating mechanism is omitted, hot melt glue does not need to be used, and the functional sol layer on the laser edge bonding belt is rapidly melted before the laser edge bonding belt makes contact with a workpiece; the laser edge sealing belt is pressed on the workpiece through the six-wheel fixed belt pressing and pasting mechanism, so that the laser edge sealing belt can be used immediately after being started, waiting is not needed, and heat preservation is not needed. And meanwhile, glue melting is conducted through the laser edge sealing mechanism, cleanliness, neatness, environmental protection and no peculiar smell are achieved, one-time edge sealing is completed, other additional protection is not needed, the reject ratio of products is reduced, production precision is guaranteed, the thickness of workpieces is ignored, high-speed edge sealing can be dealt with, production efficiency is improved, and production cost is reduced.

Owner:广东豪德数控装备股份有限公司

Green circulation anniversary production method for interplanting of soybeans and ganoderma lucidum karstganoderma lucidum karst

InactiveCN111296169ASolve the problem of heating required for cultivationAlleviate shortagesFabaceae cultivationCultivating equipmentsMyceliumEconomic benefits

The invention provides a green circulation anniversary production method for interplanting of soybeans and ganoderma lucidum karst. The method comprises the following steps: in July to August in a same year, producing ganoderma lucidum karst bags by using soybean straw instead of wheat bran, and in September to October, collecting ganoderma lucidum karst from the bags for a first round, and simultaneously collecting ganoderma lucidum karst spore powder; burying the bags into dug furrows; in March to April in a next year, interplanting soybeans among the bags, culturing the ganoderma lucidum karst by virtue of land resources and beneficial conditions such as light, temperatures, humidity and atmospheres of a soybean land, harvesting the ganoderma lucidum karst in May to September, and harvesting soybeans in August; and crushing soybean straw to reproduce ganoderma lucidum karst bags, and returning ganoderma lucidum karst dregs as an organic fertilizer into a land. In the interplanting period, no small shed, topdressing or nutrient substance replenishing is needed, and diseases and insects can be also reduced. By adopting the method, the problems that in the prior art, heating is needed for mycelium culture and confliction of ventilation and heat preservation can be caused can be solved, the problem of shortage of energy, raw materials, lands, labor resources and the like can bealleviated, and good practicability and good economic benefits and ecological benefits can be achieved.

Owner:古田县鹤塘明艳茶叶专业合作社 +1

A kind of microporous foamed glass pumice and its preparation method

ActiveCN103073184BGreen planting soil improvementLight weightGlass shaping apparatusPumice dustOptoelectronics

The invention relates to a micro-pore foaming glass pumice stone, which is characterized by being prepared by carrying out high-temperature heating and foaming, and cooling on a foaming mixture of components according to weight percentage of 85-95 of waste glass grains, 1-10 of marble powder and 1-10 of quick lime. The diameter of a micro-pore of the micro-pore foaming glass pumice stone is 0.23-5mm. The invention further relates to a preparation method of the micro-pore foaming glass pumice stone. The micro-pore foaming glass pumice stone is obtained by regenerating and utilizing waste glass and is a novel material; and the micro-pore foaming glass pumice stone has the advantages of no pollution, light weight, water permeability, water-retaining property, ventilation, fire resistance (non-combustibility and fireproof property), heat insulation property and long-period effectiveness.

Owner:江苏晶瑞特环保新材料有限公司

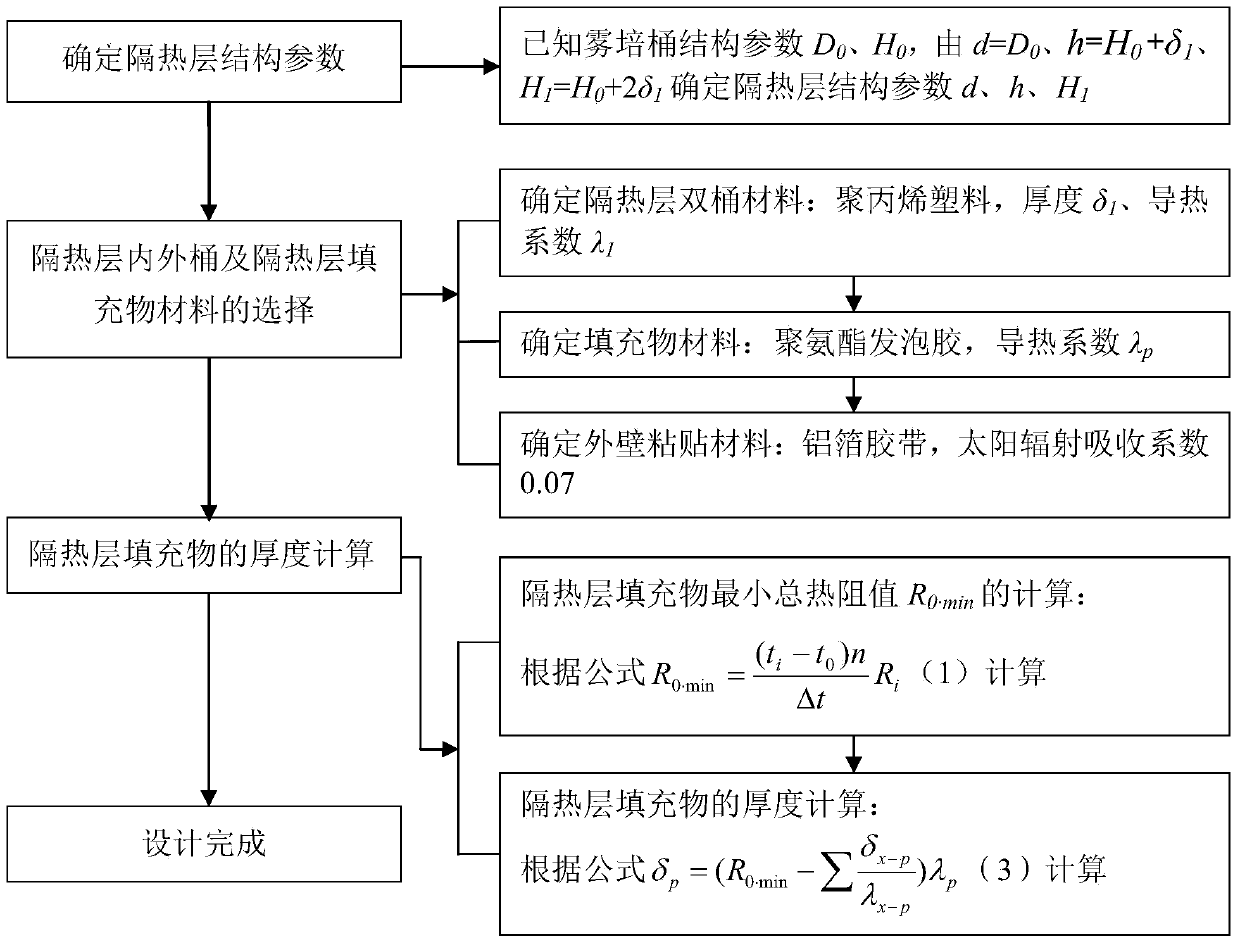

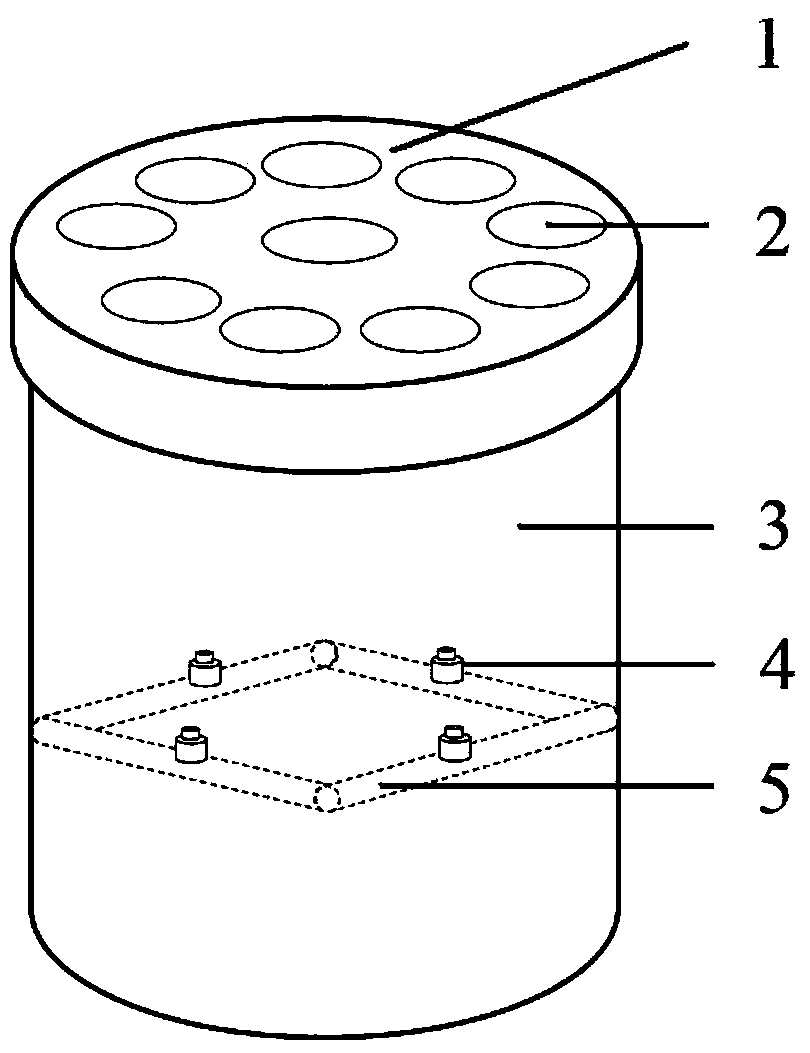

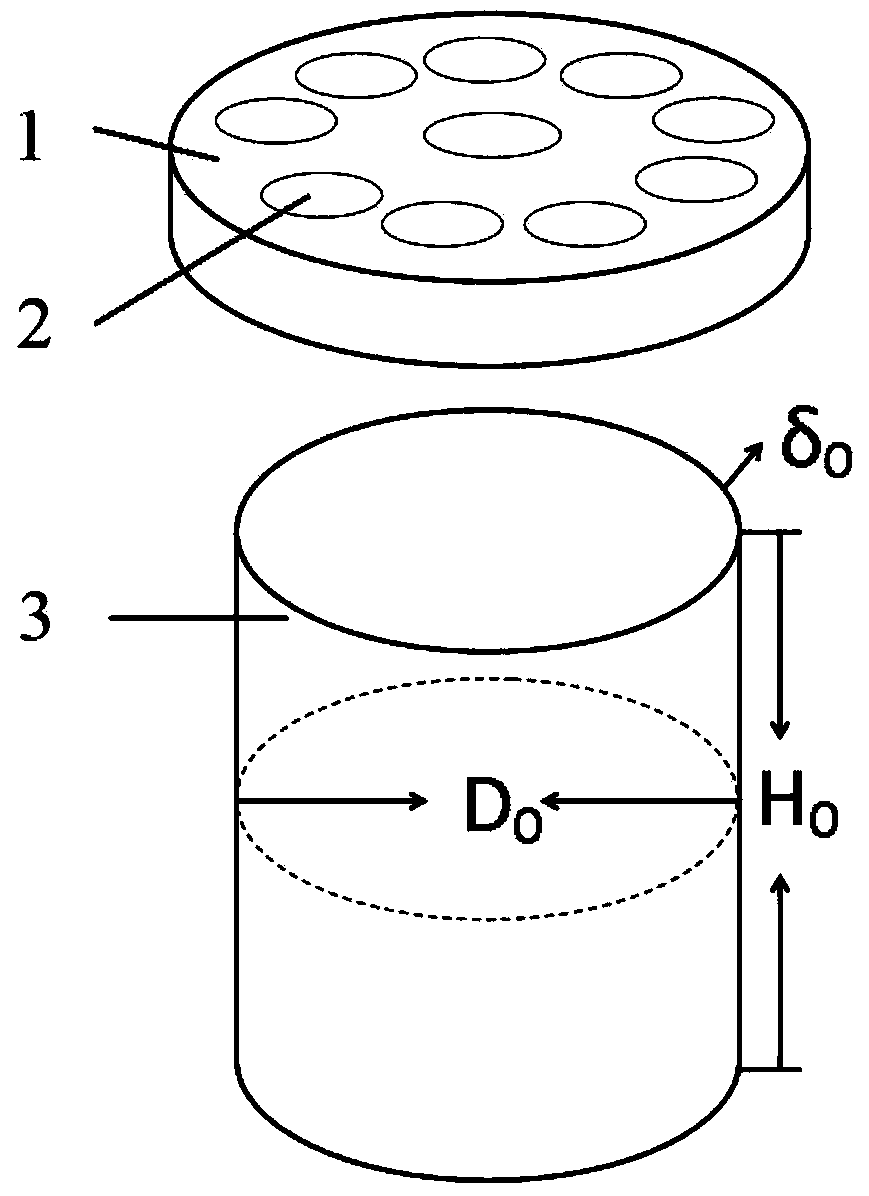

Mist culture barrel thermal insulation layer and design method thereof

InactiveCN104175651ANo insulationSimple calculationAgriculture gas emission reductionCultivating equipmentsThermal insulationEngineering

The invention discloses a mist culture barrel thermal insulation layer and a design method thereof and aims at solving the problem that the temperature environment of a plant root system is poor in buffering in an existing small mist culture barrel. The mist culture barrel thermal insulation layer is composed of a thermal insulation layer outer barrel, a thermal insulation layer filler and a thermal insulation layer inner barrel, wherein both the thermal insulation layer outer barrel and the thermal insulation layer inner barrel are respectively an opened cylindrical structural component with a bottom, and the thermal insulation layer filler is a ring-body structural component; the thermal insulation layer outer barrel, the thermal insulation layer filler and the thermal insulation layer inner barrel are sequentially sleeved together for fixed connection, particularly, the thermal insulation layer inner barrel is put in the thermal insulation layer outer barrel, the rotation axes of the thermal insulation layer inner barrel and the thermal insulation layer outer barrel are collinear, the inner side surface of the barrel bottom of the thermal insulation layer outer barrel is in contacted connection with the bottom surface of the barrel bottom of the thermal insulation layer inner barrel, namely the thermal insulation layer filler does not exist, the thermal insulation layer filler is positioned between the thermal insulation layer inner barrel and the thermal insulation layer outer barrel, and the top end surfaces of the thermal insulation layer outer barrel, the thermal insulation layer filler and the thermal insulation layer inner barrel are coplanar. The invention further provides the design method of the mist culture barrel thermal insulation layer.

Owner:JILIN UNIV

In-site prestressed concrete sandwiched composite beamless floor structure system and construction method

This invention discloses a kind of sandwich and compound beamless slab construction of watering prestress concrete and its constructing method. This construction includes beamless slab body, ribs of inner main and dark slabs and ribs of inner secondary dark slabs with cross arranged. The prestess and stress concrete reinforced bars are arranged in the ribs of main and dark slabs, and the stress concrete reinforced bars are laid out in the upper and lower crust of beamless slab body and in the inner secondary dark slabs with cross arranged. The inner space of the body is stuffed with polystyrene foam sandwich boards. In the job site, first, the form board is propped up and the prestress bars are arranged and stretched and drawn; second, the polystyrene foam sandwich boards should be laid out and fastened and the stress bars are arranged; then the concrete is poured and shaped into the construction, which can satisfy the constructing load-bearing requirements like fireproofing, sound insulation, heat insulation, high-intensity and light quality. Such beamless slab can be used in civilian and various industries construction.

Owner:胡战波

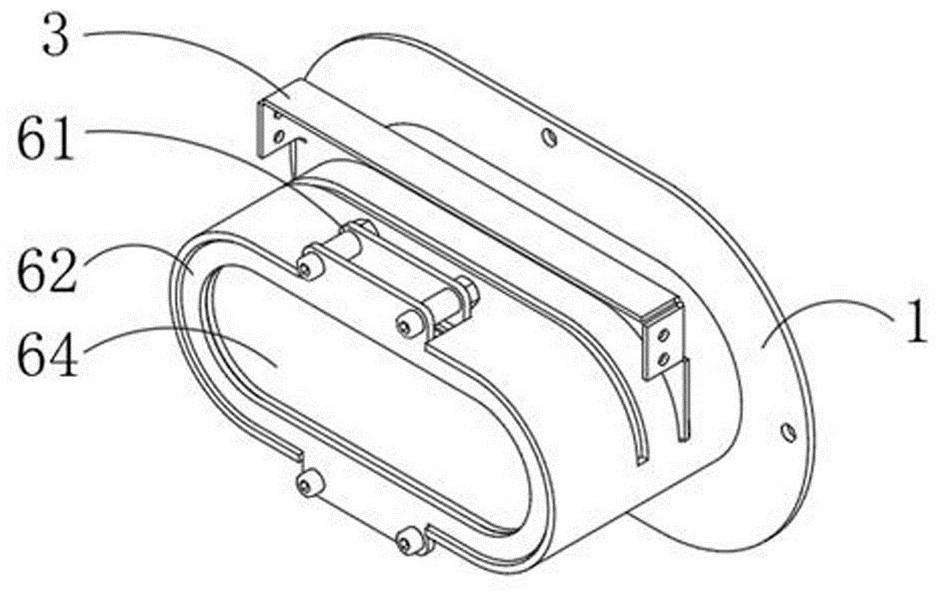

Device for observing high-temperature operation state in furnace chamber

PendingCN112833419AImprove firmnessImproves stability and firmnessChamber safety arrangementEngineeringNaked eye

The invention discloses a device for observing a high-temperature operation state in a furnace chamber. The device comprises a furnace body and a shell, one side of the shell is attached to one side of the furnace body, an observation hole is formed at the position, corresponding to the shell, of the surface of the furnace body, and a pressing plate is slidably connected to one side of an inner cavity of the shell. Through an O-shaped ring, first transparent glass, a nylon gasket, the pressing plate, a screw and a screw rod, the sealing function of a through hole in the surface of the furnace body is achieved, a shielding plate has the function of shielding high-temperature rays in the normal state and preventing a second transparent glass plate from being broken due to long-time irradiation, a half groove is formed in the shell, and the shielding plate can be taken out of and put into the half groove; and the second transparent glass plate and a dark lens are spaced by the nylon gasket, and a first clamping plate and a second clamping plate are clamped in the shell through bolts, so that the device simultaneously achieves the aims of sealing of the furnace chamber and shielding of the high-temperature rays, and the high-brightness rays are weakened to be visible to naked eyes.

Owner:厦门兴鸿基业机械制造有限公司

Environment-friendly porcelain plate set brick

The invention relates to the field of building materials, in particular to an environment-friendly porcelain plate set brick. The environment-friendly porcelain plate set brick comprises a brick body, grooves allowing a porcelain plate to be set are formed in the front face of the brick body, and an annular mounting groove is formed in the middle of the side wall of the brick body. Protruding inserting clamping heads and groove-shaped inserting clamping grooves are arranged on the side wall of the brick body, and the inserting clamping heads and the inserting clamping grooves of adjacent brick bodies are connected in a clamped mode. The environment-friendly porcelain plate set brick has the advantages of being high in strength, undeformed and light, preventing fire and water, insulating sounds, insulating heat, preserving heat, being insulated, non-oxidizable and resistant to corrosion, preventing earthquakes and the like, and has no radioactive side effects, all the whitewashing and decorating projects of a wall can be eliminated, the material, color and pattern of the porcelain plate set brick can be selected at will according to actual needs, and the service life of the porcelain plate set brick is equal to that of a cement brick wall. Time, labor and money are saved, the brick is easy to construct, house quality can be improved, the construction progress is accelerated, energy is saved, rubbish is not generated in the operating process, housing industrialization is met, and the application range is wide.

Owner:湖南速建模块砖科技有限公司

Mask

PendingCN107373819AUniform microporousWith high pressure adsorption oxygen functionProtective garmentSpecial outerwear garmentsFiberRespirator

The invention discloses a mask which is applied to the field of daily life and comprises a transparent cover and a mask body clamped in the transparent cover. The transparent cover comprises ear hooks and an edge patch, a groove for clamping the mask body is formed in the inner surface of the edge patch, the mask body comprises an outer antibacterial layer and an inner antibacterial layer, an oxygen supplementation layer is arranged between the inner antibacterial layer and the outer antibacterial layer, a movable clamping edge corresponding to the groove in the edge patch is arranged at the edge of the mask body and functions in clamping the inner antibacterial layer, the oxygen supplementation layer and the outer antibacterial layer together, negative ion powder is added into the transparent cover, and both the outer antibacterial layer and the inner antibacterial layer are prepared from antibacterial fibers. The mask is simple in structure, novel in design, high in practical value, convenient to mount, dismount and clean, has the functions of oxygen supplementation and antibacteria and deodorization and can also achieve the functions of dust removal, purification and haze prevention, and harmful substances such as bacteria do not easily breed.

Owner:李润萱

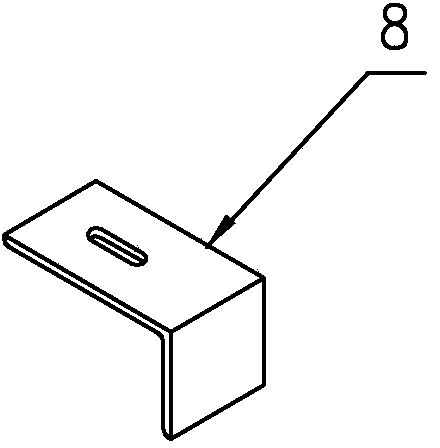

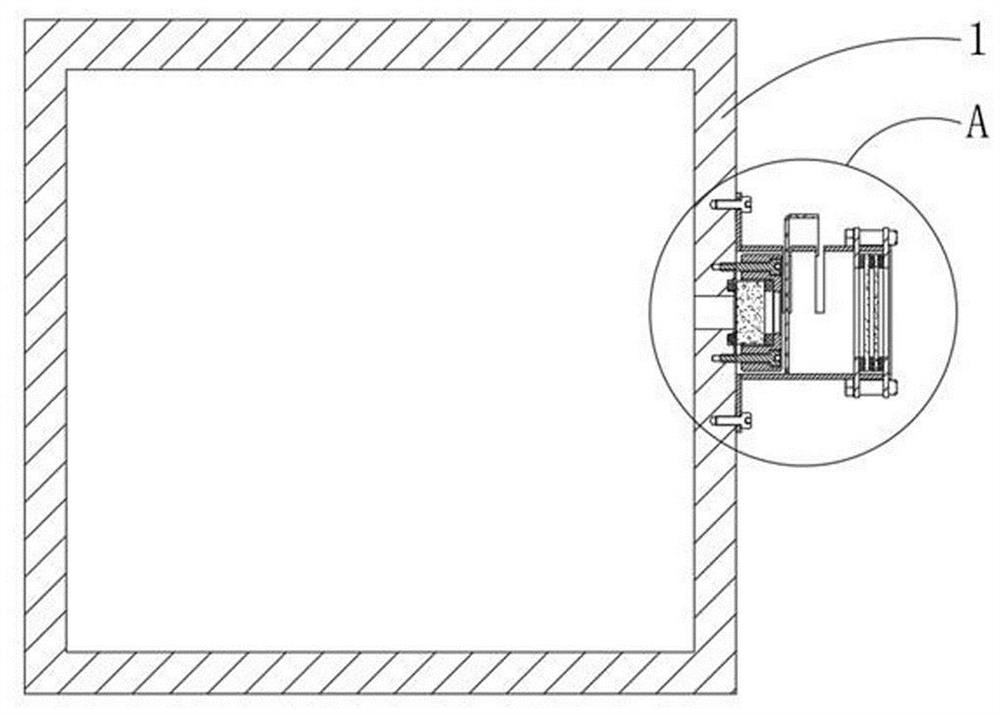

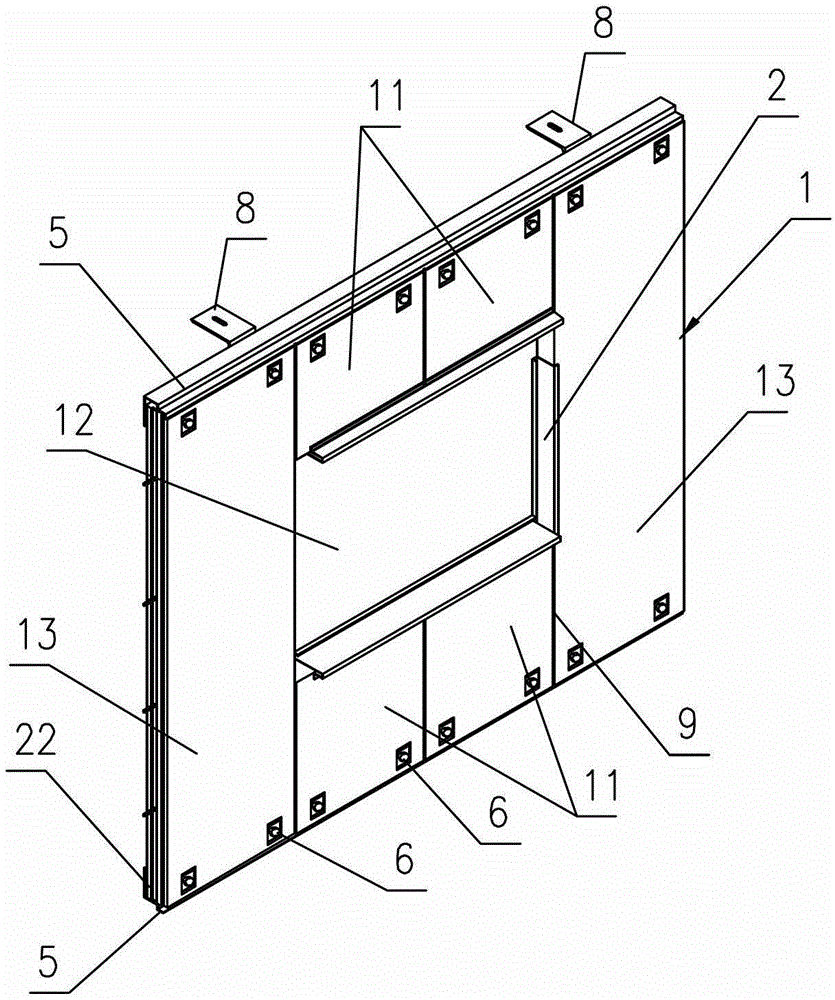

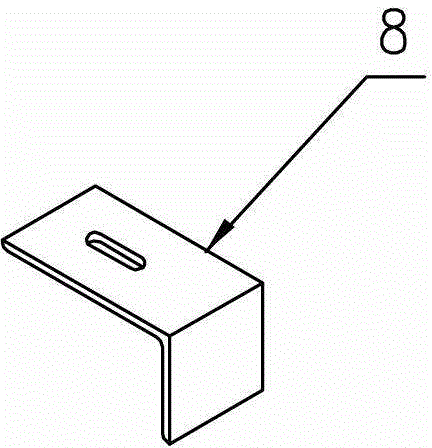

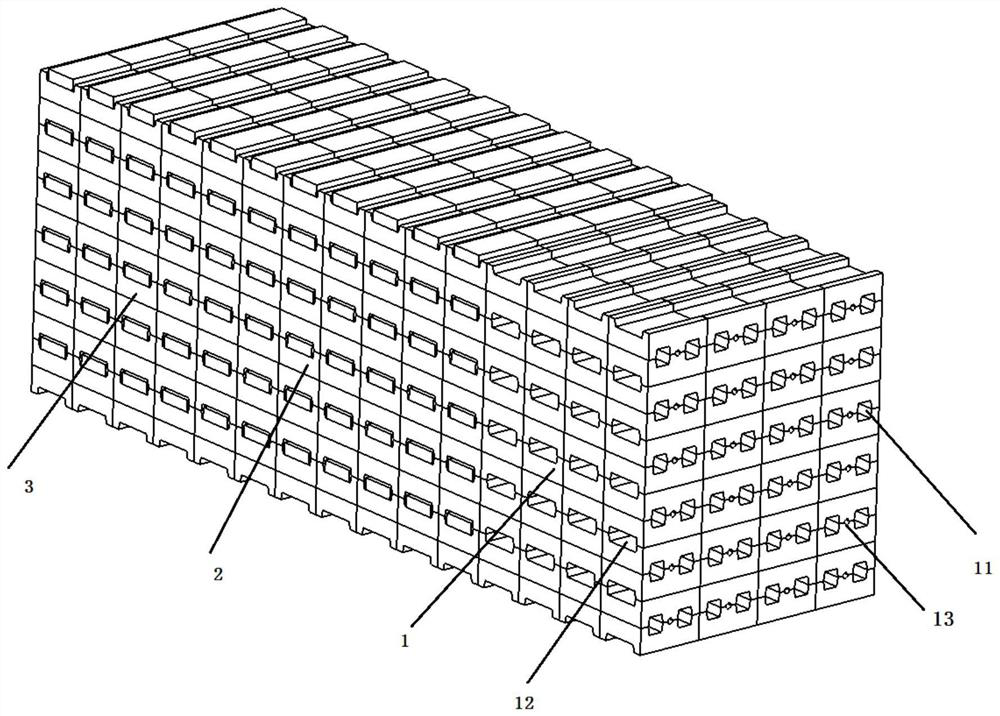

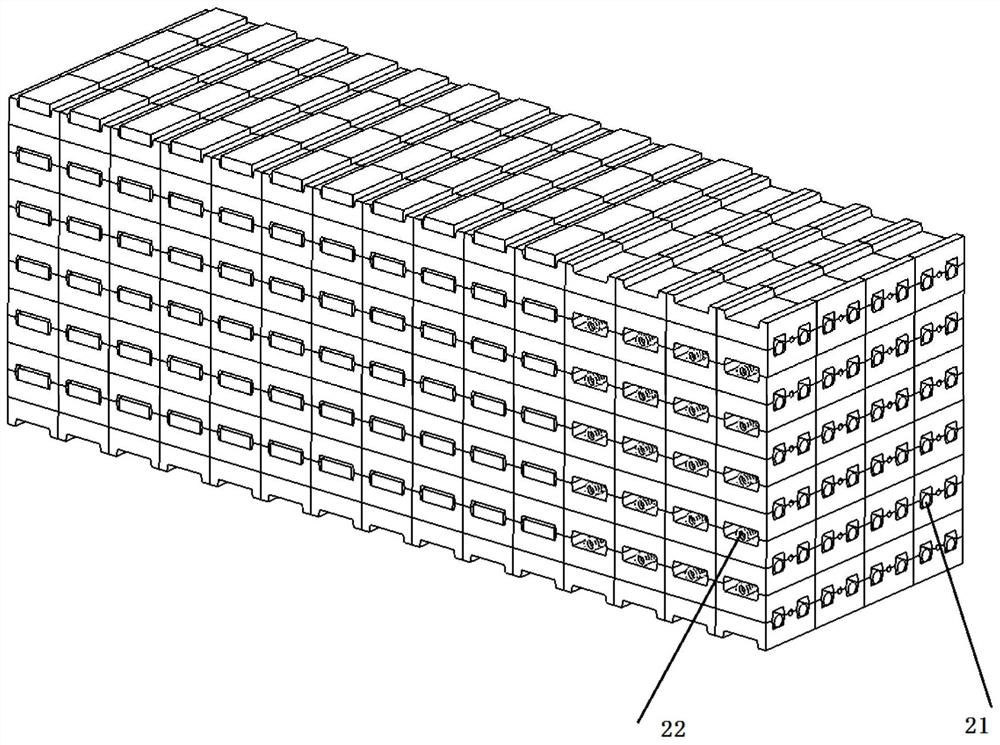

A kind of multifunctional combined lightweight concrete curtain wall and its making method

ActiveCN103374986BNo skeletonNo insulationWallsBuilding material handlingUltimate tensile strengthWeight light

The invention discloses a multifunctional combined lightweight concrete curtain wall and a constructing method thereof. The multifunctional combined lightweight concrete curtain wall is mainly composed of lightweight concrete board units along the outer surface of the main structure of a building. Each lightweight concrete board unit comprises at least two lightweight concrete boards which are horizontally arranged and spliced. A decorating surface is disposed on the outer surface of each lightweight concrete board. The upper end and lower end of each lightweight concrete board unit are respectively clamped into profile steel with a grooved cross section, and the profile steel located at the upper end of the lightweight concrete board unit is provided with hanging pieces for being connected with the main structure of the building. Gaps among the lightweight concrete boards and among the lightweight concrete board units are filled. The multifunctional combined lightweight concrete curtain wall based on self-structural-strength of the lightweight concrete boards and having the advantages of the lightweight concrete curtain walls has the advantages that structure and decoration are produced at one step in factories, construction garbage is few, noise pollution is reduced, safe and fast mounting is achieved, work efficiency is high, construction cost is lowered, and the multifunctional combined lightweight concrete curtain wall is widely applicable to building outer wall containment systems.

Owner:GUANGDONG HEYUAN LIANTIAN BUILDING INDZATION MFG

Hybrid heat storage device and heating method

PendingCN111947491AHigh energy storage densityImprove heat storage capacityHeat storage plantsHeat exchange apparatusHybrid typeBrick

The invention discloses a hybrid heat storage device and a heating method. The heat storage main body structure of the hybrid heat storage device is formed by coupling a first heat storage brick, a second heat storage brick and a third heat storage brick; the first heat storage brick and the second heat storage brick are made of solid sensible heat storage material; the third heat storage brick ismade of solid phase change heat storage material; and the shape of the third heat storage brick is matched with a placed channel. The hybrid heat storage device can increase the energy storage density of a heat accumulator and improves the heat storage capacity of a heat storage device; and the solid phase change heat storage material is not stressed and does not make direct contact with an electric heating element, so that the problems of corrosion, insulation and the like are avoided, and the safety and stability are high. According to the heating method, heating elements are placed in a first channel and a second channel close to an air inlet end, the heating states of the heating elements are independently controlled, so that the heat storage brick bodies absorb and release heat evenly, meanwhile, the temperature difference between the air inlet end and the air outlet end of the heat storage body after the heat storage device stably operates can be made up, and the material utilization rate is increased.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

Multilayer perlite composite flame-retardant sheet and preparation method thereof

InactiveCN101793063BSave woodSave moistureWater-setting substance layered productFire proofingFiberSodium phosphates

The invention relates to a multilayer perlite composite flame-retardant sheet. The flame-retardant sheet has a laminated structure containing at least three layers, wherein the surface layer is a wooden layer, a middle wooden layer is separated from a flame-retardant layer, adhesive is used between the layers; the wooden layers are processed through conventional flame-retardant treatment, the thickness is 1-5mm; the thickness of the flame-retardant layer is 1-120cm and comprises the following components by weight: 10-25kg of expanded perlite with 1.5-3mm of particle diameter, 25-40kg of magnesium chloride, 10-25kg of magnesium oxide, 100-300kg of sodium phosphate, 150-350kg of lithopone, 0.1-2.0kg of emulsifier and 50-200kg of adhesive, wherein magnesium chloride, magnesium oxide, sodium phosphate, lithopone, emulsifier and adhesive are used as auxiliary material and filler. As flame-retardant treatment is preformed to the wooden layers and the flame-retardant layer is prepared by mixing expanded perlite and adhesive, the flame-retardant sheet is fire-retardant, wood is saved, no pollution is caused, and the flame-retardant sheet is free from any insect and is the best replacementof the existing shaving board, fiber-board, core-board, solid wood board and other materials.

Owner:杨光伟

A kind of foamed lightweight partition board and preparation method thereof

The invention discloses a foam light partition board and a preparation method of the same. The foam light partition board is characterized by being prepared from the following raw materials in parts by weight: 100-120 parts of medium density polyethylene, 30-35 parts of metallocene linear low density polyethylene, 10-14 parts of cellulose acetate, 40-45 parts of iron ore slag powder, 10-12 parts of glass fiber, 3-5 parts of sodium dodecyl benzene sulfonate, 40-50 parts of quartz sand, 12-14 parts of ardealite, 20-24 parts of fly ash, 10-12 parts of straw powder, 1-2 parts of used oil, 8-10 parts of municipal sludge powder, 1-2 parts of dipropyl ethanol amine, 30-35 parts of modified loess powder and 3-4 parts of Freon. The foam light partition board provided by the invention has the advantages of being free from steam or autoclaved curing, rapidly reacting and curing at normal temperature, being high in strength, excellent in water resistance, free from moisture absorption and scumming, anti-freeze, soundproof, heat insulating, heat retaining and inflaming retarding, largely using industrial residue and agricultural wastes, saving resource and energy, avoiding discharge of waste gas, waste water and waste residues, and the like.

Owner:湖北博悦佳实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com