Mist culture barrel thermal insulation layer and design method thereof

A heat insulation layer and aeroponics technology, which is applied in the field of aeroponic tank heat insulation layer and its design, can solve the problems of poor buffering of plant root temperature and environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

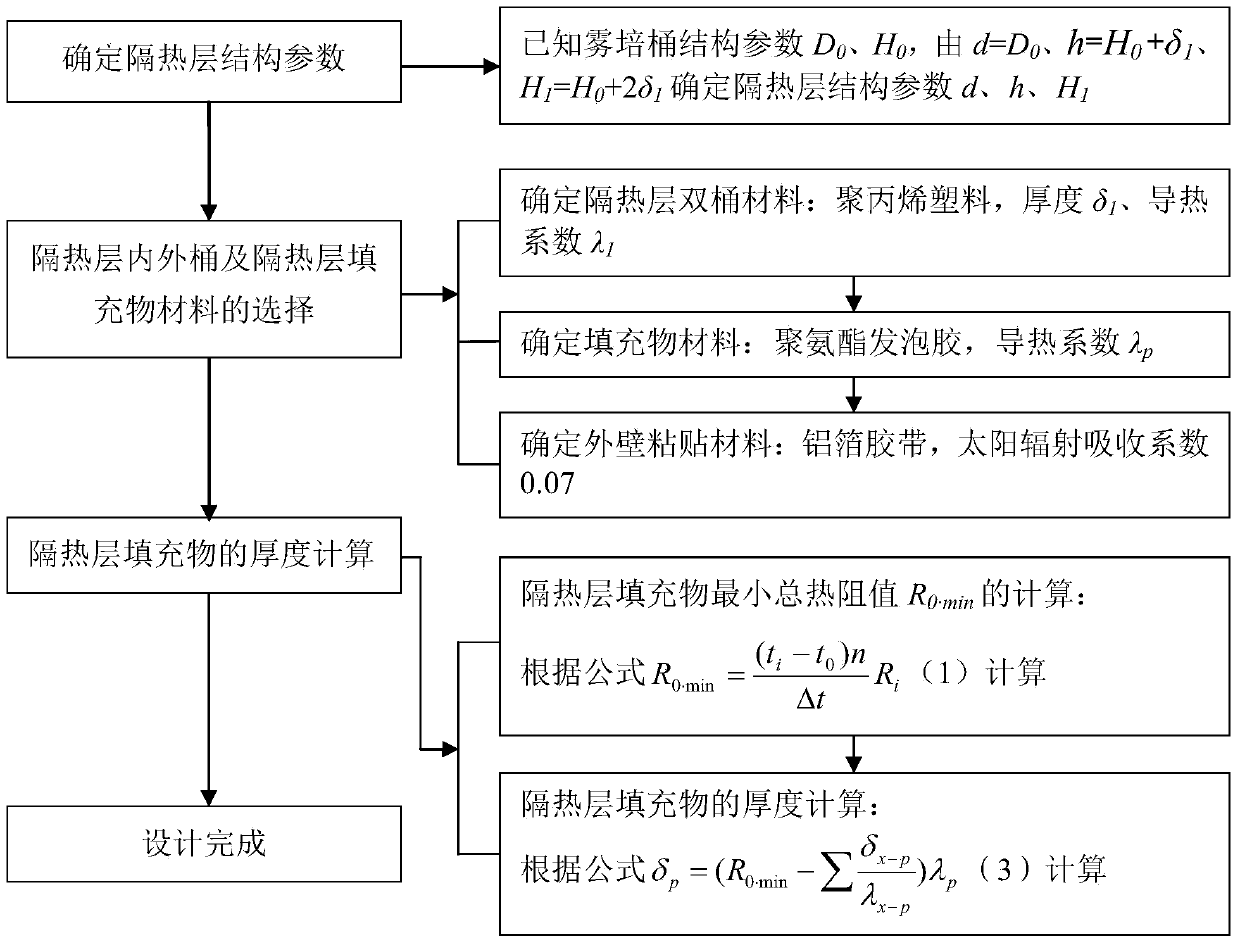

Method used

Image

Examples

Embodiment

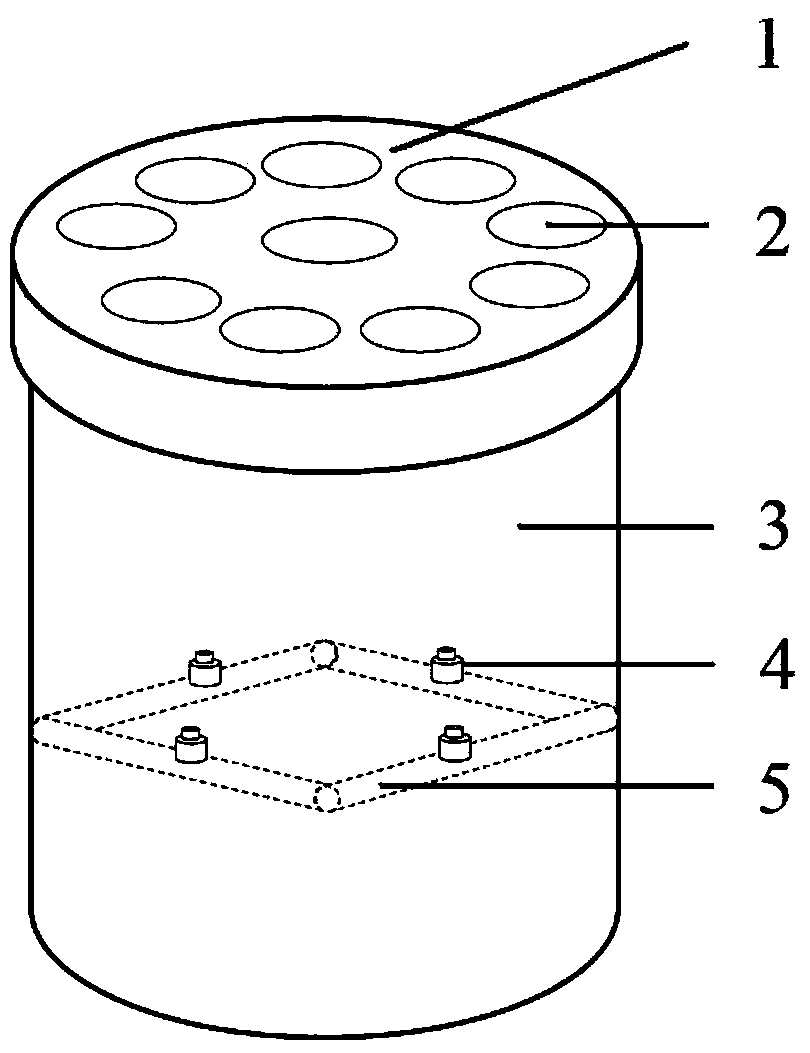

[0111] Using the method for designing the thermal insulation layer of the aeroponic bucket according to the present invention to design the thermal insulation layer of the traditional small aeroponic bucket, the steps are as follows:

[0112] 1. Known conditions:

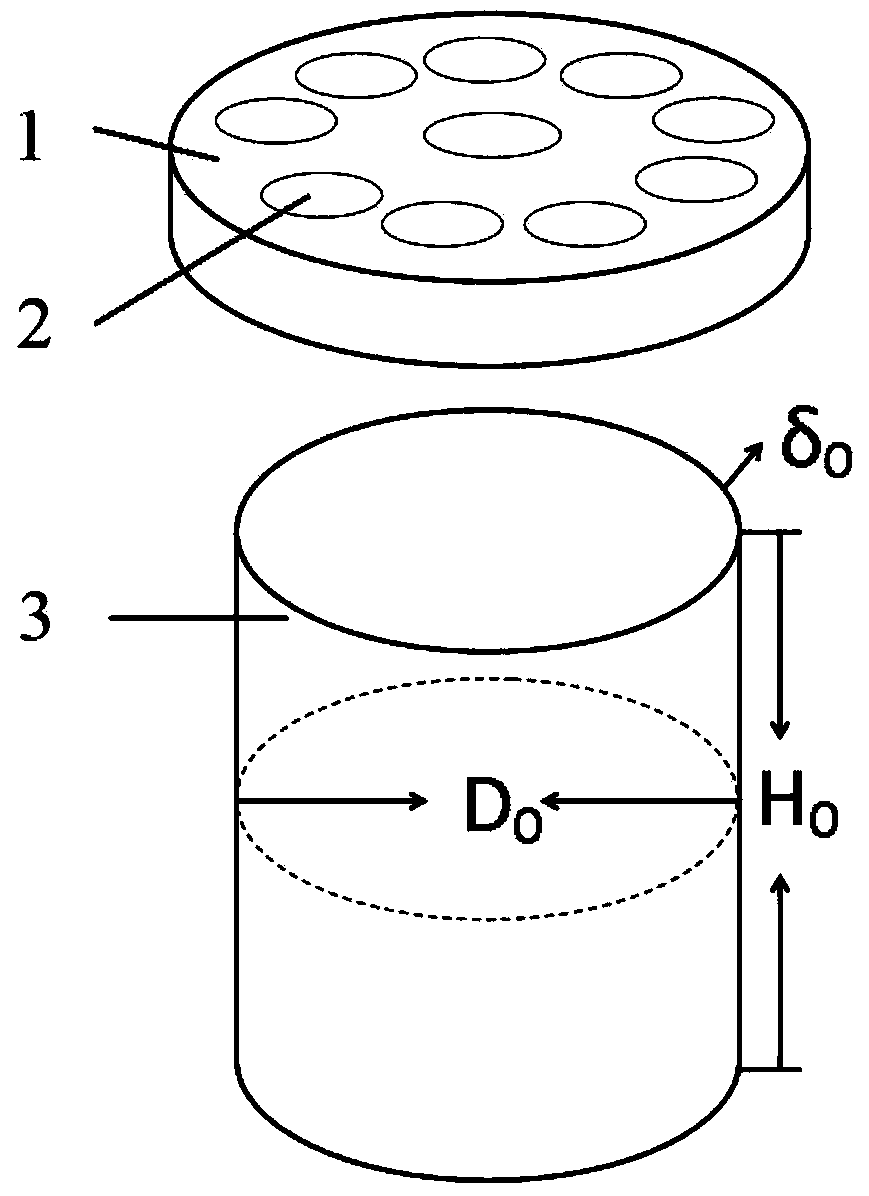

[0113] Height H of the existing aeroponic bucket 0 =40cm; outer diameter D 0 =20cm; Barrel wall thickness δ 0 =0.2cm; barrel wall thermal conductivity λ 0 =0.21W / m·°C.

[0114] 2. Structural design of double-barrel heat insulation layer:

[0115] In order to ensure the close fit between the heat insulation layer and the aeroponic bucket, the inner diameter of the double-barrel heat insulation layer is 20cm, that is, d=20cm; the outer barrel 6 of the heat insulation layer and the barrel wall of the inner barrel 8 of the heat insulation layer are selected to be made of PP material Thickness is δ 1 = δ 2 =0.3cm, thermal conductivity λ 1 =λ 2 =0.21W / m·℃; thermal conductivity λ of the filler (polyurethane foam) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com