Hybrid heat storage device and heating method

A technology of a heat storage device and a heating method, which is applied in the directions of heat storage equipment, lighting and heating equipment, heat exchange equipment, etc., can solve the problem of uneven heat absorption and release, and excessive temperature difference between the two ends of the heat storage body. The utilization rate of heat storage materials and other problems, to achieve the effect of absorbing and releasing heat uniformly, improving material utilization rate, and high safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

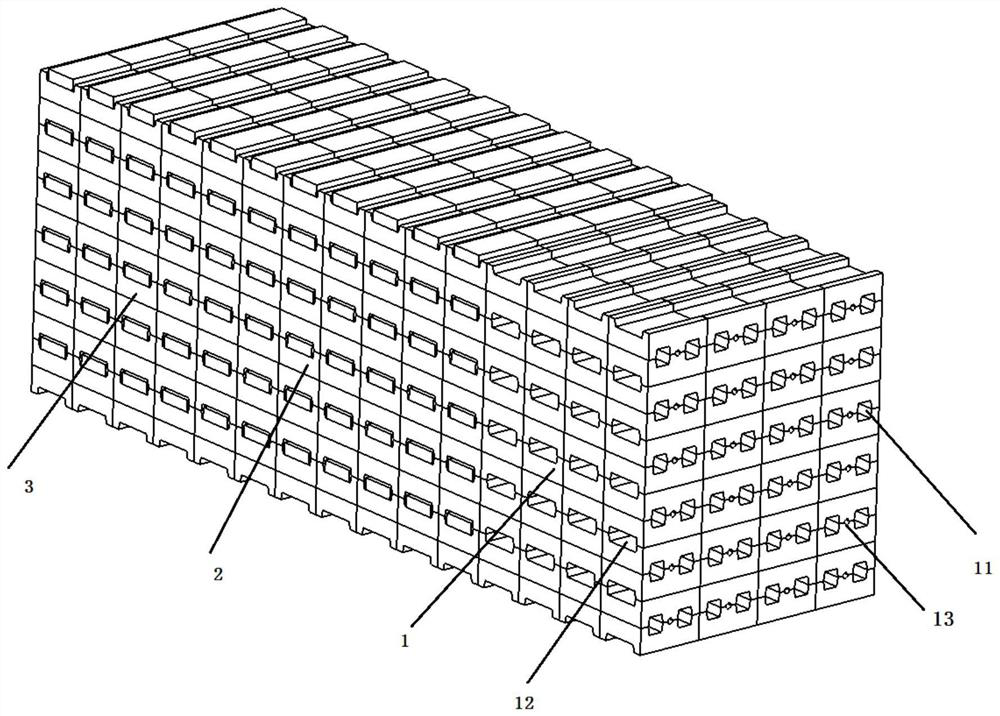

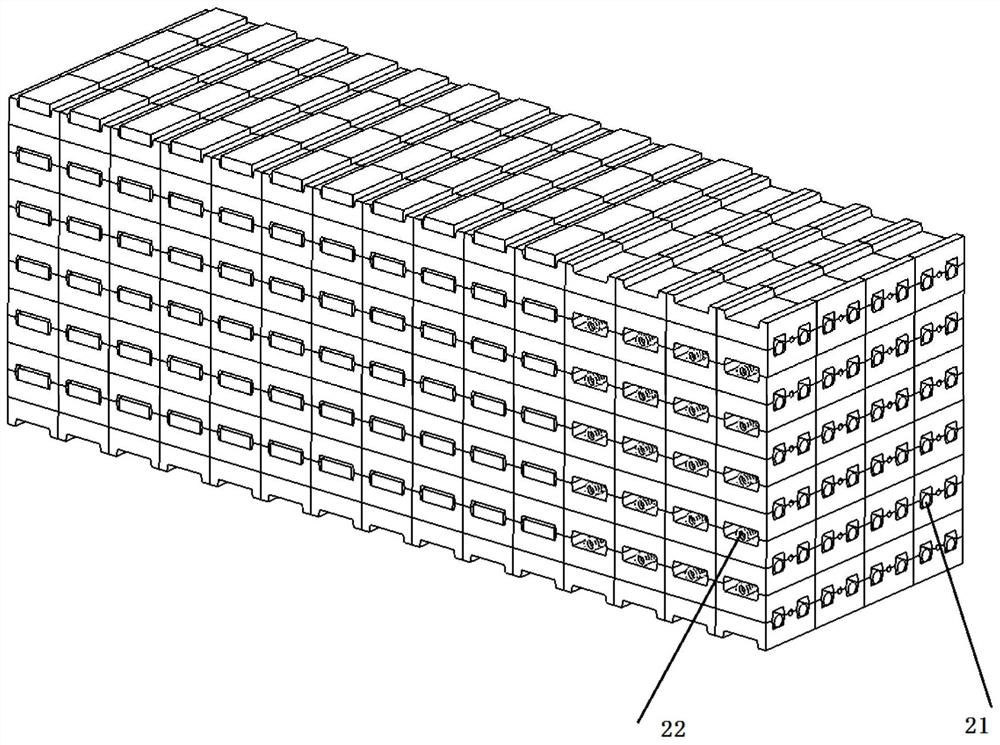

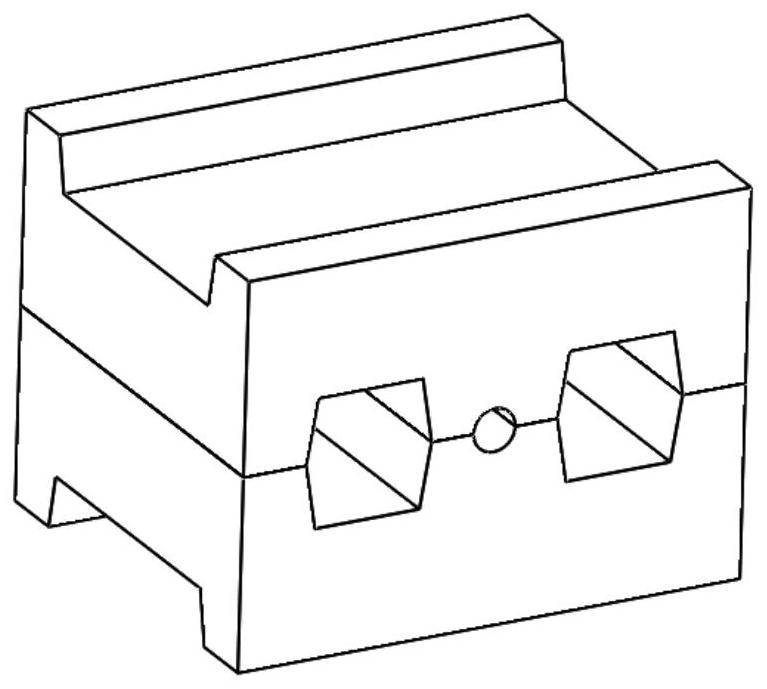

[0029] An embodiment of the present invention provides a hybrid thermal storage device, including: a heating element, a thermal storage main structure, such as figure 1 As shown, the heat storage main body structure is divided into three sections according to the preset length ratio. The first section 1 and the third section 3 located at both ends are composed of the first heat storage bricks, and the second section 2 in the middle is composed of the second heat storage bricks. Composed of heat bricks, the first heat storage brick and the second heat storage brick are both solid sensible heat storage materials, and each has at least one first channel 11 and at least one second channel 12 that run through the brick body, wherein The first passage 11 is along the direction of air circulation, and the second passage 12 is along the direction perpendicular to the air circulation. The first passages of the first heat storage brick and the second heat storage brick are both used to p...

Embodiment 2

[0037] An embodiment of the present invention provides a heating method for a hybrid heat storage device, based on the hybrid heat storage device in Example 1, such as Figure 5 shown, including:

[0038]Step S1: Place a heating element in the first channel of all the heat storage bricks in the heat storage main structure to heat the heat storage device;

[0039] Step S2: placing a heating element in the second channel of the first section of the heat storage main structure to assist in heating the heat storage device;

[0040] Step S3: placing a third heat storage brick in the second channel of the second section and the third section of the main heat storage structure for heat storage;

[0041] Step S4: Place a temperature measuring element in the installation hole of the first section of the heat storage main structure for monitoring the temperature at the air inlet end.

[0042] It should be noted that the order of the above steps is only a specific embodiment, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com