Patents

Literature

40results about How to "Uniform microporous" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resisting lithium-ion battery membrane with plurality of types of coatings and preparation method of high-temperature-resisting lithium-ion battery membrane

The invention provides a high-temperature-resisting lithium-ion battery membrane with a plurality of types of coatings and belongs to the technical field of battery membranes. The high-temperature-resisting lithium-ion battery membrane is prepared from a coating membrane composed of a battery membrane with one surface or double surfaces coated with coating slurry; one surface or double surfaces of the coating membrane are coated with slurry additional layers; each slurry additional layer comprises at least one layer of coating composed of the coating slurry. The invention further provides a preparation method of the high-temperature-resisting lithium-ion battery membrane with the plurality of types of coatings; the battery membrane has the advantages that a coating membrane has relatively high safety on a battery; meanwhile, the battery membrane can also be used for resisting high temperature, reducing the shrinkage rate of the membrane under a high-temperature condition and prolonging the service life of the battery; the high-temperature-resisting lithium-ion battery membrane can be used for improving the affinity of the membrane and electrolyte and can guarantee that the membrane is sufficiently swollen through the electrolyte and the service life of the battery is prolonged.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

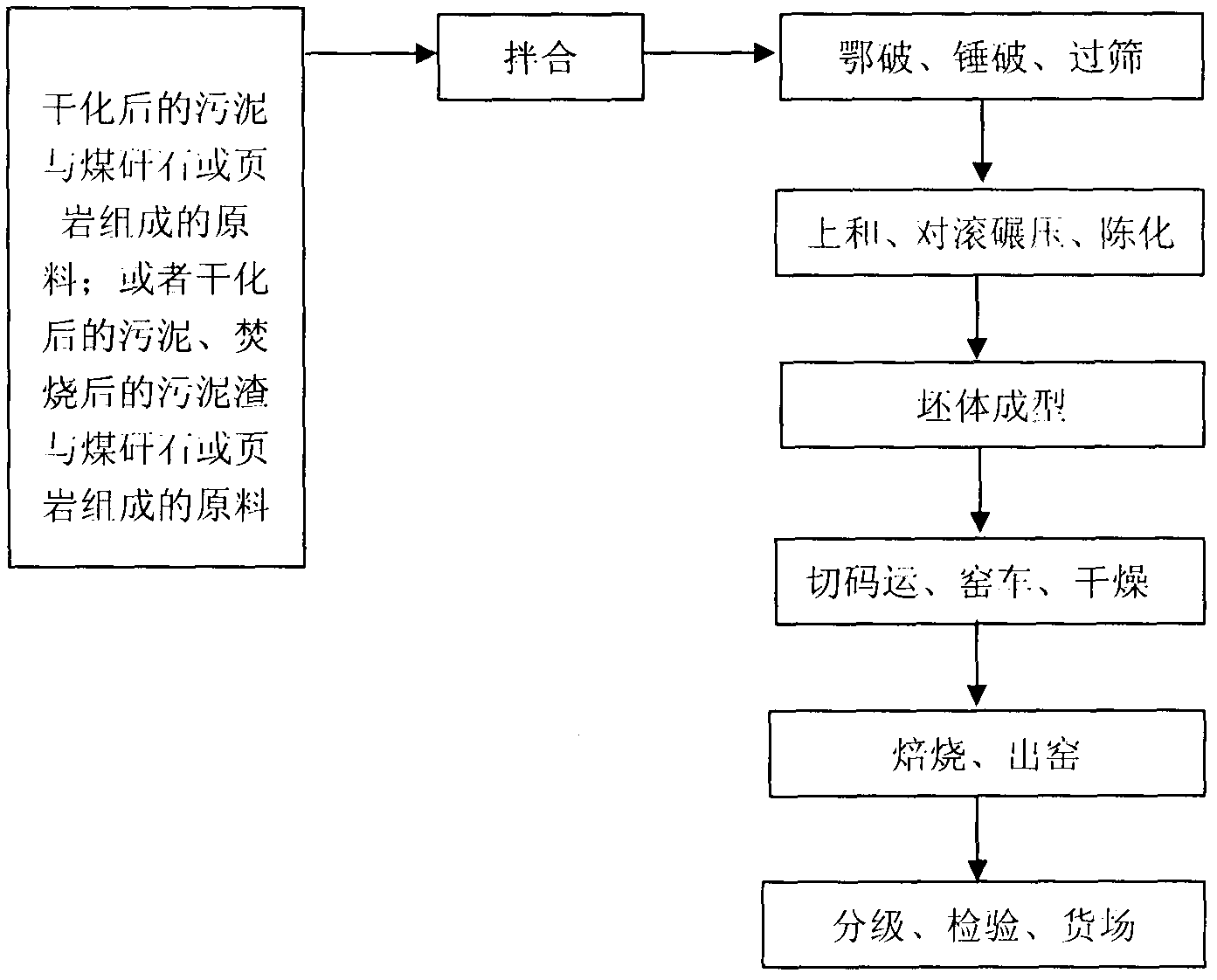

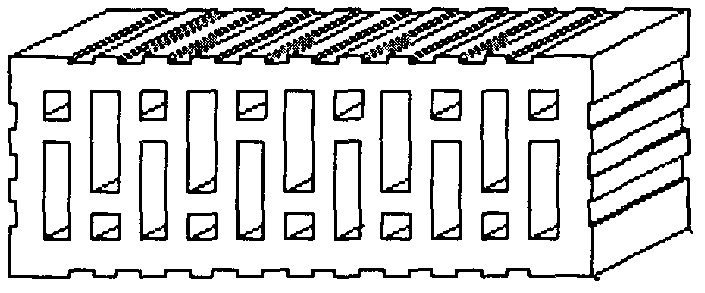

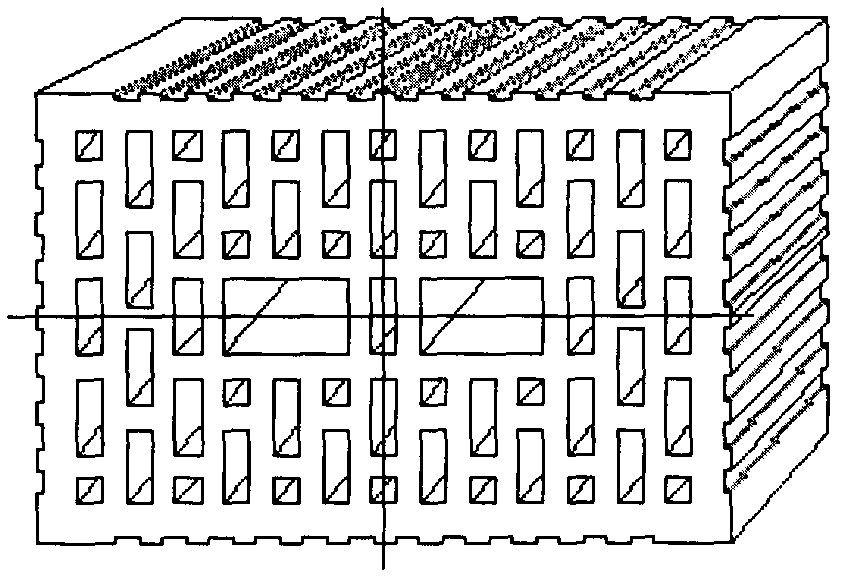

Technology for manufacturing brick by using dried sludge

The invention discloses a technology for manufacturing brick by using dried sludge. The process comprises the following steps: stirring mixed materials; pulverizing raw materials by jaw breaking and hammer breaking; evenly stirring; screening the pulverized mixed material by a vibrating screen; carrying out upward mixing and rolling lamination on the mixed material screened by the vibrating screen; putting into a brut cellar; conveying the aged raw material into a shaper by a conveyer belt to shape the blank; conveying into a drying kiln for drying by a cutting, stacking and transporting car;then, sintering in a calcining kiln; and obtaining common sintered bricks, porous bricks or hollow bricks after the sintering is finished. According to the technology, sludge instead of clay is addedinto various raw materials. On the aspect of producing sintered bricks with high doping volume by utilizing municipal sludge, the maximum municipal sludge doping amount can reach 50%. The technology has obvious breakthrough on the aspects of sludge decrement and reclamation, and sludge is consumed to realize the purpose of changing waste material into things of value.

Owner:南京鑫翔环保产业有限公司

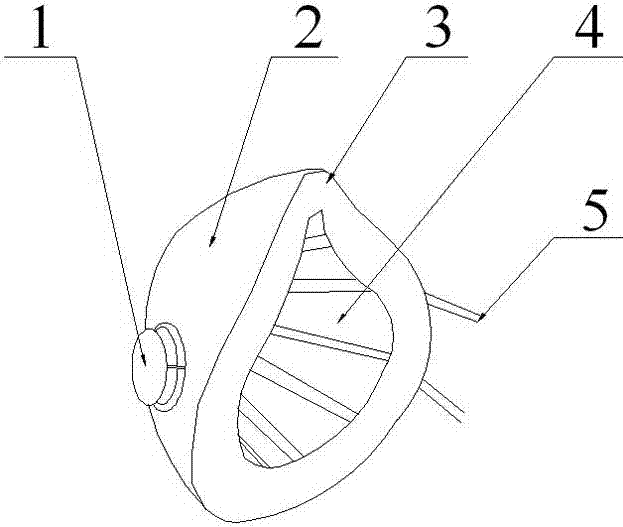

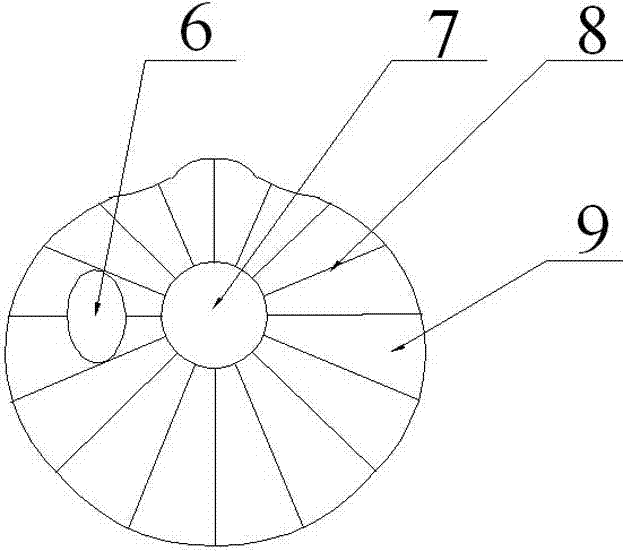

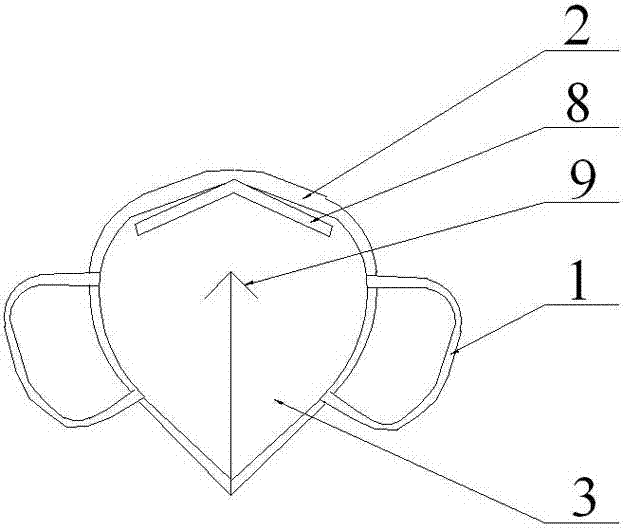

Gauze mask

PendingCN107343677AComfort functionRelieve nervous fatigueProtective garmentSpecial outerwear garmentsPolyesterEngineering

The invention discloses a gauze mask applied to the field of daily life. The gauze mask comprises a gauze mask body, an annular face connecting part and ear hangers, wherein the annular face connecting part is combined with the periphery of the gauze mask body, and the ear hangers are connected to two sides of the gauze mask body; a mask body bracket is further arranged on the inner surface of the gauze mask body and is of an annular structure; the face connecting part is synthesized from nylon fibers or polyester fibers; a radial protruded flow guide component is arranged on the mask body bracket and forms a channel between the gauze mask body on the outer side and the mask body bracket on the inner side; and an air suction hole and an air exhaust hole are further formed in the mask body bracket, and the channel is connected with the air suction hole. The gauze mask is simple in structure, novel in design and high in practical value, simultaneously has the effects of oxygen supplementation, antibiosis and deodorization as well as dust removal, purification and haze prevention and is convenient to mount, dismount and clean, and harmful substances of bacteria are unlikely to propagate.

Owner:张争

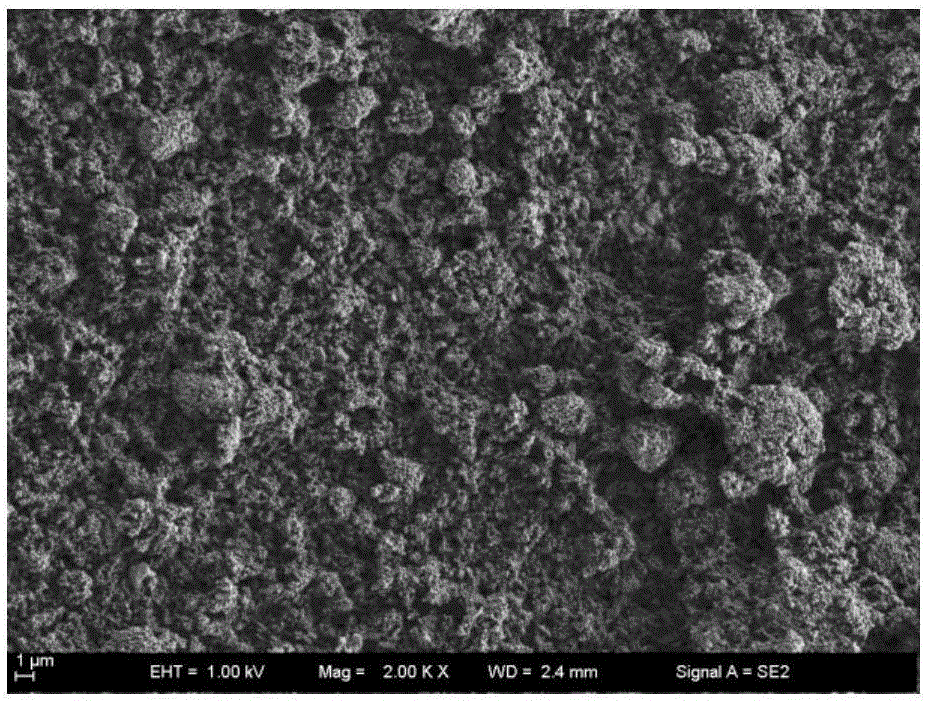

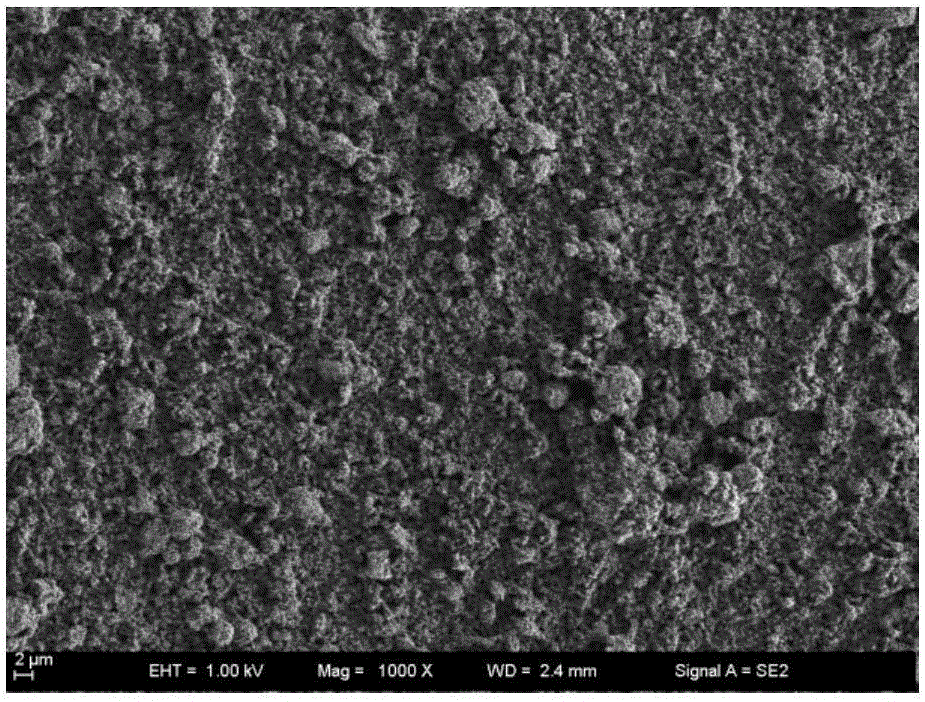

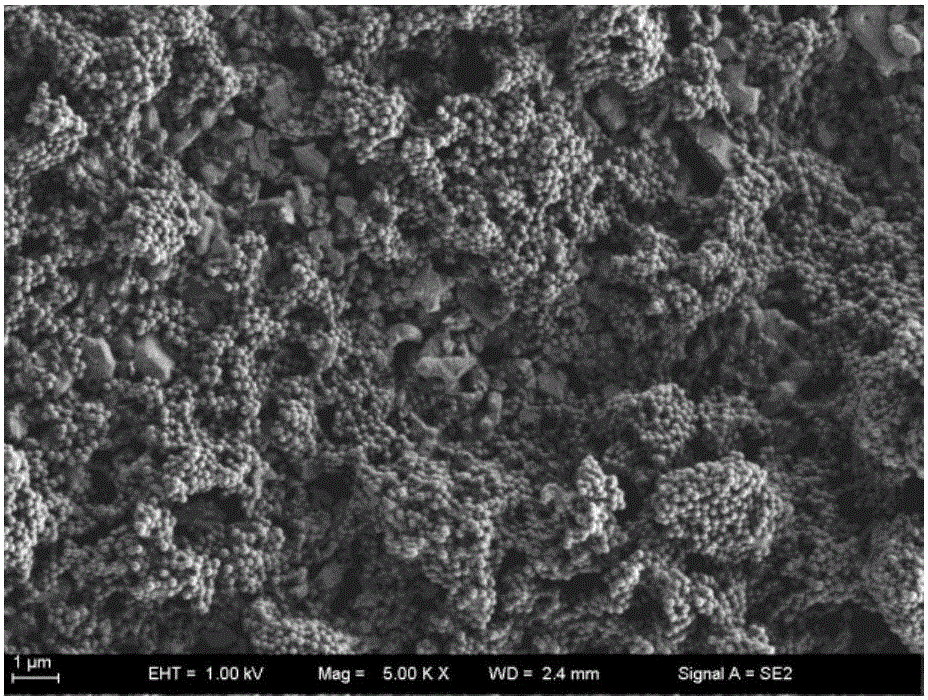

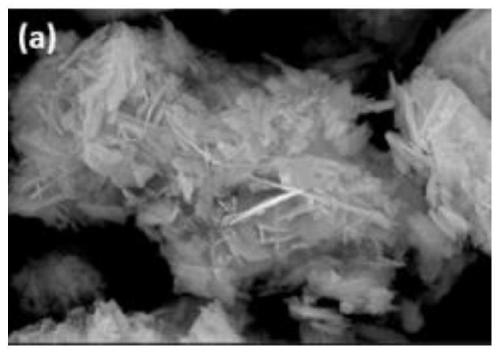

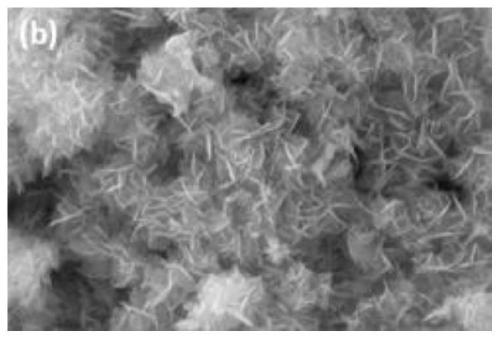

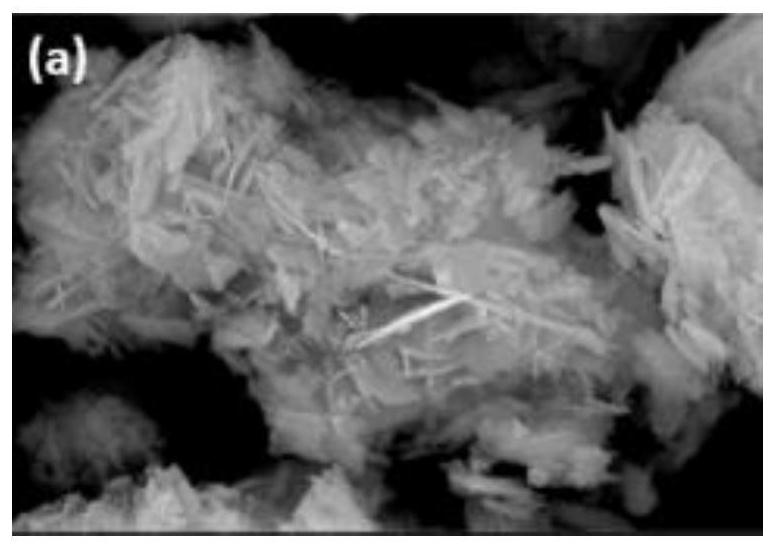

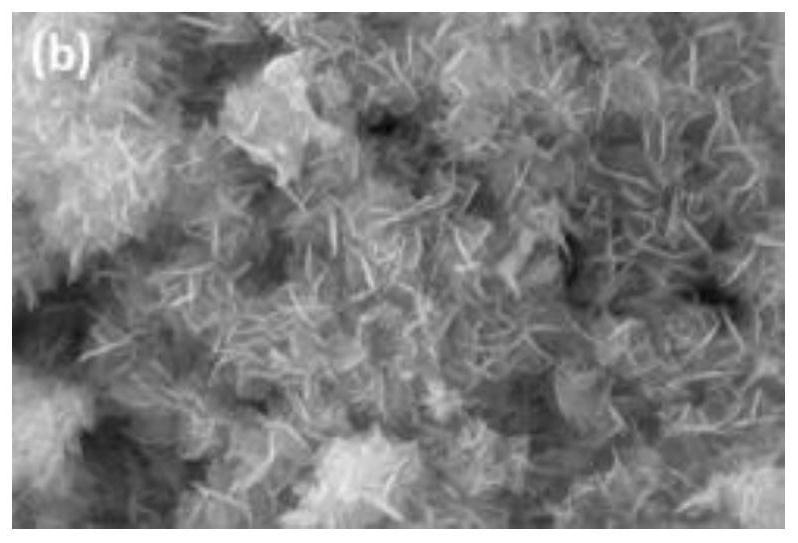

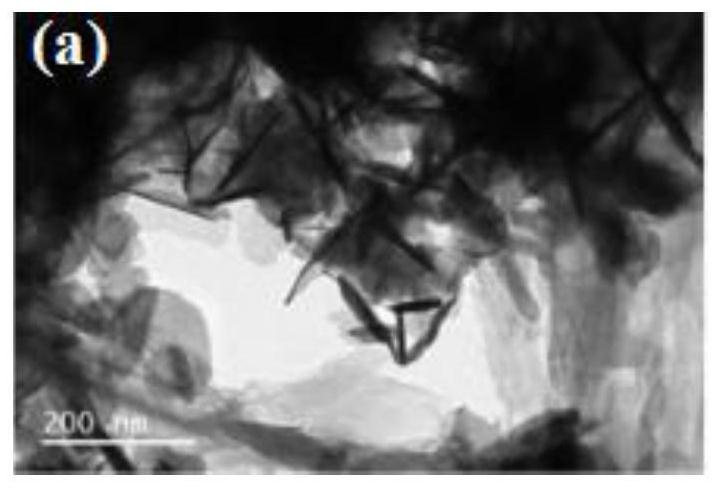

Preparation method and application of BiOCl/carbonized egg membrane composite visible light catalyst

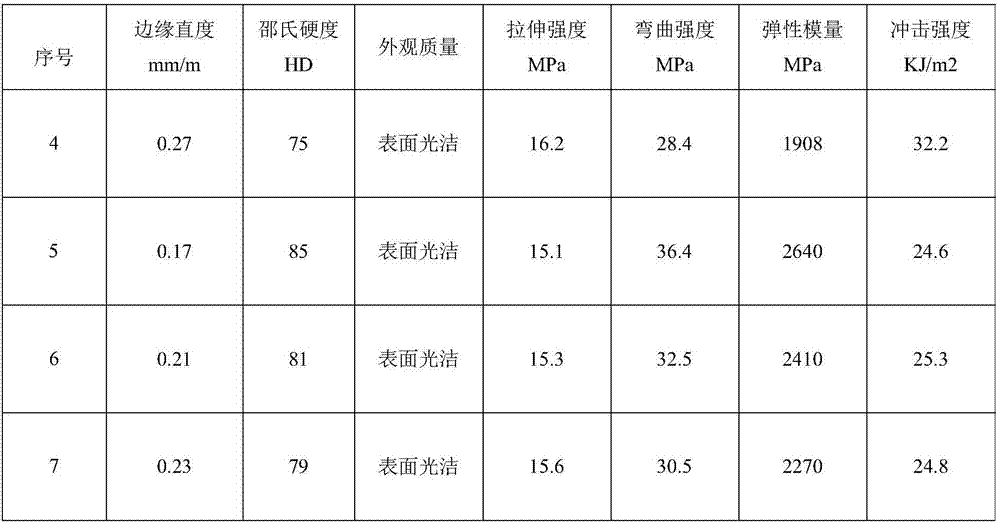

ActiveCN110302810AUniform microporousUniform structurePhysical/chemical process catalystsWater/sewage treatment by irradiationIndustrial waste waterPtru catalyst

The invention relates to a preparation method of a BiOCl / carbonized egg membrane composite visible light catalyst. The preparation method comprises the following steps that S1, egg membranes are driedand cut into pieces; S2, egg membrane fragments are calcined, and are grinded to particles after being calcined, and carbonized egg membranes are obtained; and S3, hydrochloric acid, deionized waterand ethanol are added to a Bi(NO3)3 solid body, then the carbonized egg membranes are added, ultrasonic treatment is carried out for 30-120 min, stirring is carried out for 30 min, a NaOH solution isadded in the stirring process, finally aging is carried out for 8-12 hours, liquid is filtered out, drying is carried out at 100 DEG C for 12-15 hours, finally the modified BiOCl / carbonized egg membrane catalyst is obtained, and the catalyst is applied to degradation of dye wastewater containing rhodamine B, antibiotic wastewater containing tetracycline hydrochloride and industrial wastewater containing organic pollutants. According to the preparation method of the BiOCl / carbonized egg membrane composite visible light catalyst, the pressure of waste treatment and environmental pollution can bereduced, waste is turned into treasure, and efficient catalytic degradation of the industrial waste water is realized.

Owner:JIANGXI UNIV OF SCI & TECH

Method for preparing alumina ceramic tube used for sodium-nickel battery

The invention relates to a method for preparing a beta-Al2O3 aluminum oxide solid electrolyte material used for a sodium-nickel battery, and in particular relates to the method for preparing an alumina ceramic tube used for the sodium-nickel battery. The method comprises the following steps of: firstly mixing MgO and MnO2 additives with alumina powder with purity reaching 99%, then blending, grinding and calcining the three raw materials, regrinding and thermally grouting for preparing molding, and finally preparing a die by the molding. The size of the die is 35*35*280mm, geometric-shaped grooves are arranged on sides in the extending direction, the molding is sintered, and the sintering temperature is 1700-1900 DEG C. The method is unique, the electric current density, A current collection effect and the strength of the ceramic tube can be increased.

Owner:宁夏绿聚能源股份有限公司

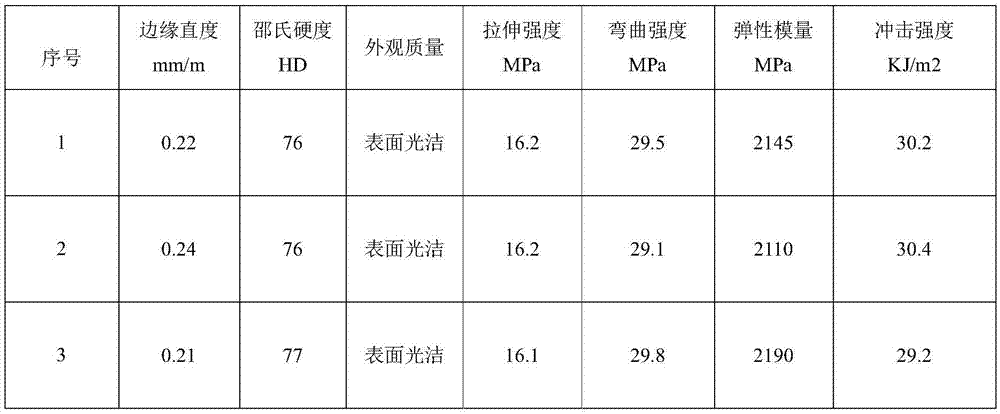

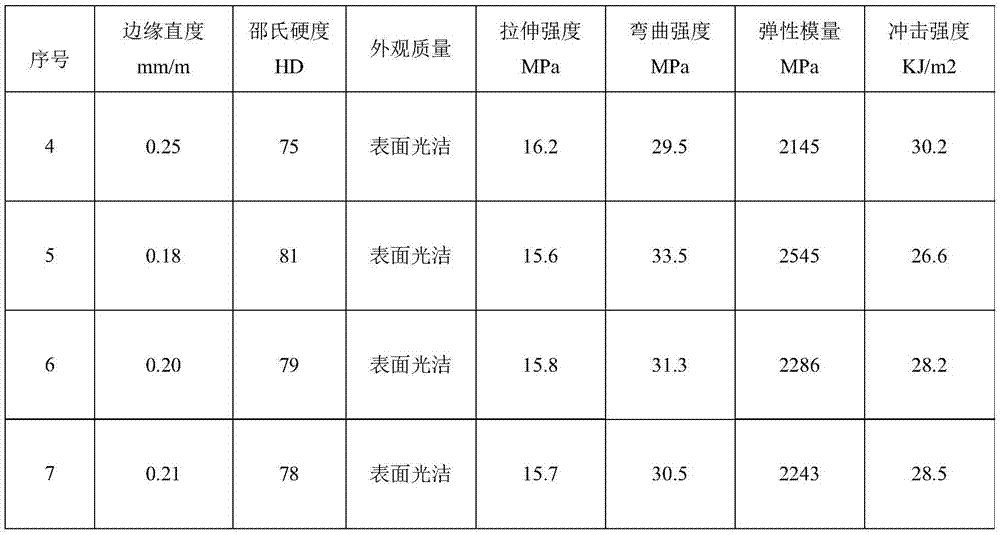

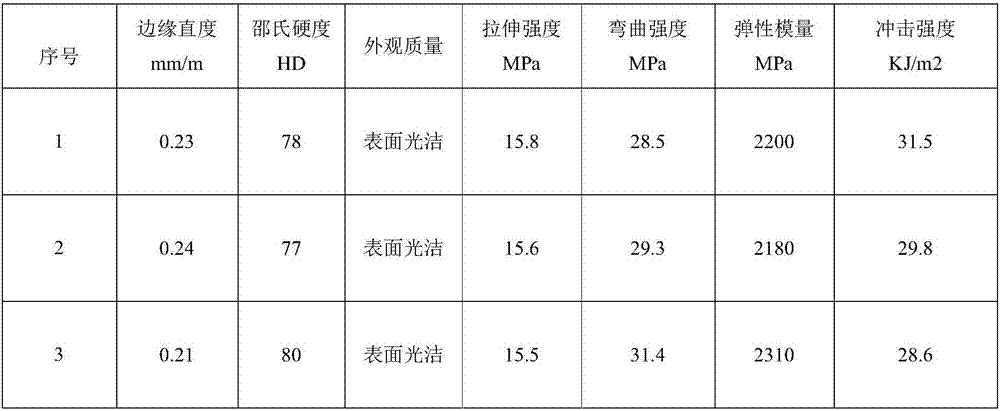

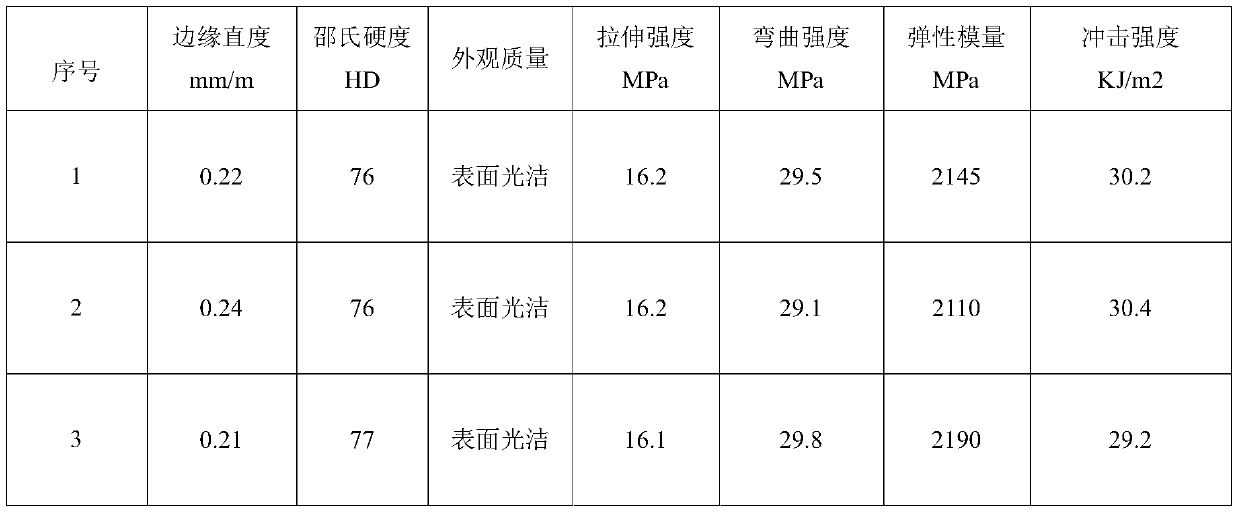

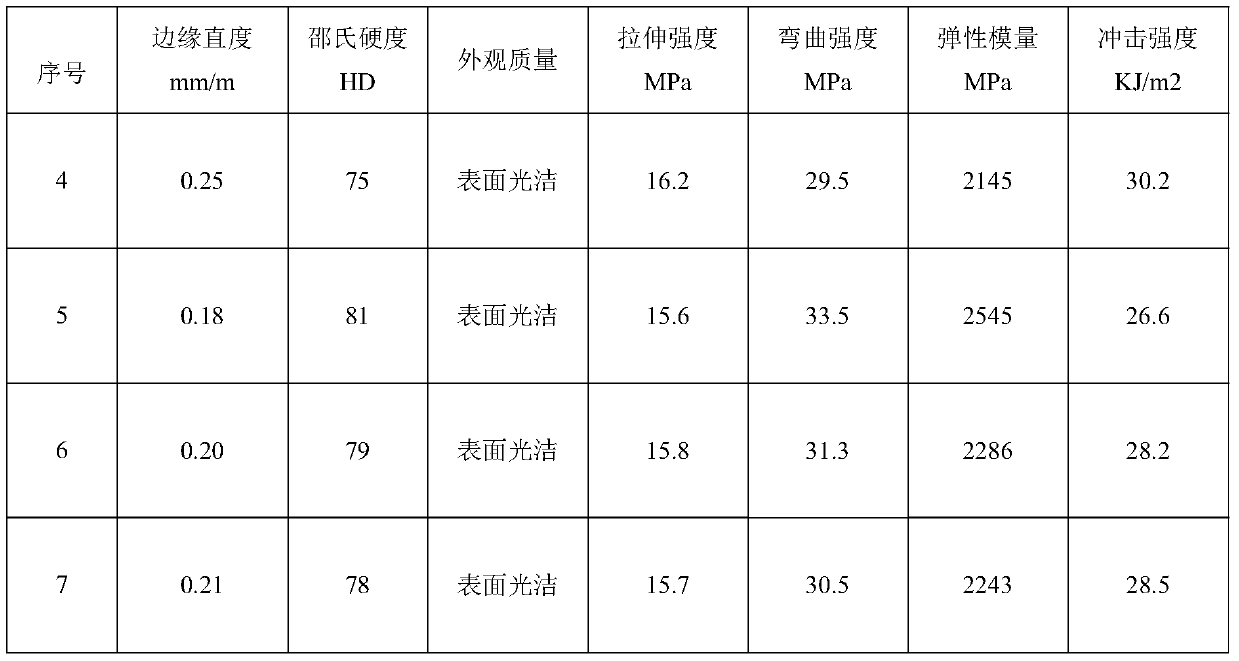

Novel PVC foamed profile and preparation method thereof

The invention relates to a composite material, in particular to a novel PVC foamed profile and a preparation method thereof. The novel PVC foamed profile is prepared from components in parts by weight as follows: 100 parts of PVC, 3-25 parts of a toughening agent, 10-50 parts of calcium sulfate, 3-8 parts of a stabilizer, 0.6-3.5 parts of a foaming agent, 2-15 parts of a foaming control agent, 0.3-2.0 parts of an internal lubricant, 0.3-2.0 parts of an external lubricant, 1.0-1.5 parts of a PVC processing agent and 0.3-1.2 parts of a coupling agent. The content of filler in the PVC foaming system can be increased by 10%-30% in the formula while the weight of the product per meter is kept basically unchanged, the material has higher cost performance, the novel PVC foamed profile is developed according to the technical principle of a new material, is innovative in new material application, has the characteristics of facilitating resource utilization and being energy-saving, environment-friendly, green and economical and is suitable for industrial production.

Owner:湖南天仁科技实业发展有限公司

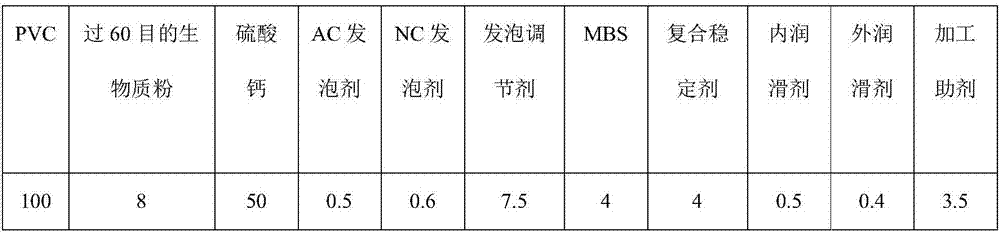

PVC (polyvinyl chloride) foaming profile and preparation method thereof

The invention relates to a composite, in particular to a PVC (polyvinyl chloride) biomass foaming composite and a preparation method thereof. The PVC biomass foaming composite is prepared from components of preparation raw materials in parts by weight as follows: 100 parts of PVC, 5-50 parts of PVC renewable materials, 5-30 parts of biomass powder, 50-130 parts of calcium sulfate, 5-12 parts of a stabilizer, 1-5 parts of a foaming agent, 2-18 parts of a foaming regulator, 0.6-3.5 parts of an internal lubricant, 0.6-3.5 parts of an external lubricant, 1.8-2.5 parts of a PVC processing aid and 0.6-2.5 parts of a coupling agent. By means of the formula, the filler content of a PVC foaming system can be increased by 20%-50%, the weight of the product per meter is basically unchanged, and the material has higher cost performance. With the adoption of technique principles of new materials, the PVC biomass foaming composite has creativity of new material application, has characteristics of resource utilization, energy conservation, environmental protection and green economy and is suitable for industrial production.

Owner:湖南天仁科技实业发展有限公司

Method for preparing medical collagen sponge from East sea dark gensing

ActiveCN103409488AImprove securityMicroporousPeptide preparation methodsAbsorbent padsChemistryChemical residue

The invention discloses a method for preparing medical collagen sponge from East sea dark gensing, which comprises the following steps: adding pepsase into East sea dark gensing defibrination going through dirt removing process; adding solid edible salt after the enzymolysis; salting, separating and collecting pulpy sediment, precipitating liquid, salting again, and separating; dissolving pulpy sediment by L- lactic acid, carrying out desalination process to the dissolved sea cucumber collagen liquid, adding food grade glutamine transaminase, spraying nepheloid sea cucumber collagen liquid into a mould, quick-freezing and forming the collagen liquid into collagen sponge instantly; freezing, alternating temperature and drying, and drying the material until the content of water is 1 to 3 %; withdrawing the collagen sponge, packing, irradiating, and entering the medical collagen sponge library. The method has the beneficial effects that East sea dark gensing is used as raw material to prepare the medical collagen sponge, the rich marine resource is enabled to be highly utilized, the sponge can also be used for crowd rejecting the mammal collagen, the problem of chemical residue in the product is solved, and the safety of the product is higher.

Owner:宁波超星海洋生物制品有限公司

Polyurethane slurry for producing PU (Polyurethane) stripped fur shell fabric

InactiveCN104045998AUniform microporousNot easy to expandTextiles and paperEnvironmental resistanceSlurry

The invention discloses polyurethane slurry for producing a PU (Polyurethane) stripped fur shell fabric. The polyurethane slurry is prepared from the following components in parts by weight: 100 parts of hydrolysis-resistant polyurethane, 5-7 parts of dimethyl acryl methylamine, 20 parts of butanone, 18-20 parts of toluene, 20 parts of deionized water, 1 part of N-methyl ethanol amine, 3 parts of di-iso-octyl maleate sodium sulfonate and 5-7 parts of dye paste. The coating shell fabric formed by the polyurethane slurry is uniform in micropore, and the polyurethane slurry is not easy to swell with water, thereby improving the water vapor permeability of the fabric. In addition, the polyurethane slurry can be freely colored, and the physical indexes such as color fastness, degree of sunlight, peel strength and tear strength can be randomly improved according to the demands of customers. The polyurethane slurry is free from extraneous odor, light in weight, less in possibility of hardening with water, perspiring, antibacterial and mildew-proof, and meets the environmental requirements.

Owner:罗静

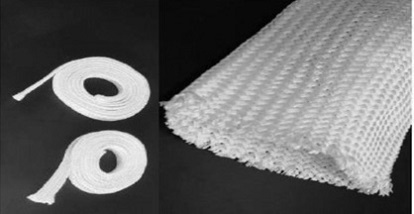

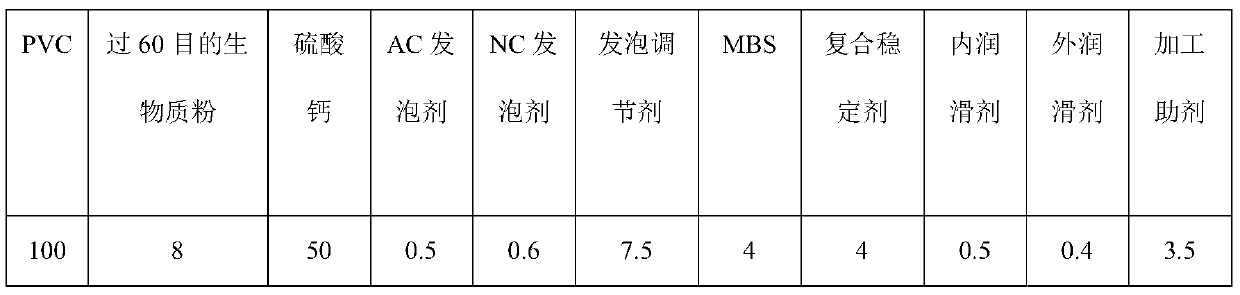

Preparation method of alumina fiber reinforced high-temperature-resistant anti-scouring thermal insulation material

The invention belongs to the technical field of ceramic matrix composite materials, and particularly relates to a preparation method of an alumina fiber reinforced high-temperature-resistant anti-scouring thermal insulation material. The preparation method comprises the following steps: S1, preparation of an aluminum oxide preform; S2, preparation of slurry of a high-temperature-resistant coating;S3, preparation of a high-temperature-resistant coating of the aluminum oxide preform; S4, preparation of a composite material blank. According to the method, the aluminum oxide preform is soaked inthe modifier, and after soaking is completed, the slurry obtained in the step S2 is soaked and / or coated and / or deposited on the modified green body, so that the high-quality high-temperature-resistant coating can be quickly, efficiently and uniformly obtained through the design; and the material which can meet the requirements of high-temperature resistance, anti-scouring, heat preservation, heatinsulation and high-temperature resistance, anti-scouring, heat preservation and insulation at the same time is prepared by matching with a subsequent process. The method is reasonable in step design, simple and controllable in process and convenient for large-scale industrial application.

Owner:湖南合为新材料科技有限公司

Self-breathable bionic skin care cosmetic and preparation method

InactiveCN108743452AEvenly dispersedGood microporousCosmetic preparationsToilet preparationsSpermacetiSilicon dioxide

The invention relates to a self-breathable bionic skin care cosmetic and a preparation method, belongs to the technical field of cosmetics and aims at solving the technical problem of providing the self-breathable bionic skin care cosmetic and the preparation method. The preparation method of the self-breathable bionic skin care cosmetic comprises the steps: evenly dispersing an acid-soluble chitosan solution with hyperbranched polylysine, polymer lipid ball and silicon dioxide aerogel which are crosslinked and spraying drying to obtain micropore micro powder; then mixing the micropore micro powder with high molecular weight protein, spermaceti wax, allantoin and the like to prepare cream. As the micropore micro powder has good even micropores and self humidifying breathability, the self-breathable bionic skin care cosmetic has good permeable, moisture permeable and regulatory functions to the skin, has better biological compatibility, has a bionic skin function, can effectively prevent micropores of a film formation layer from being plugged and can improve elasticity and a moisture preservation effect of the skin. In addition, the preparation method of the self-breathable bionic skin care cosmetic disclosed by the invention has the advantages of less steps, simple technological process, safety in operation and low cost.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

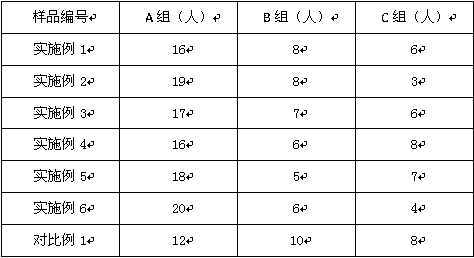

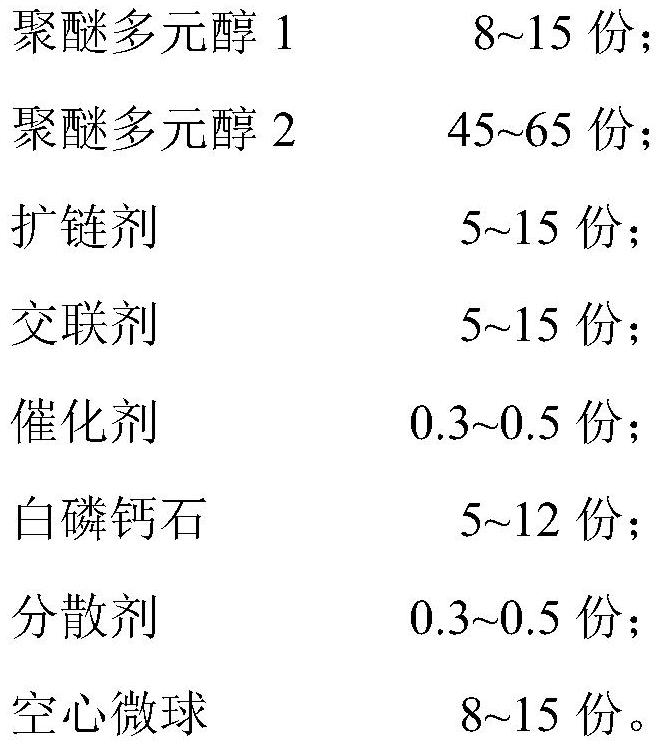

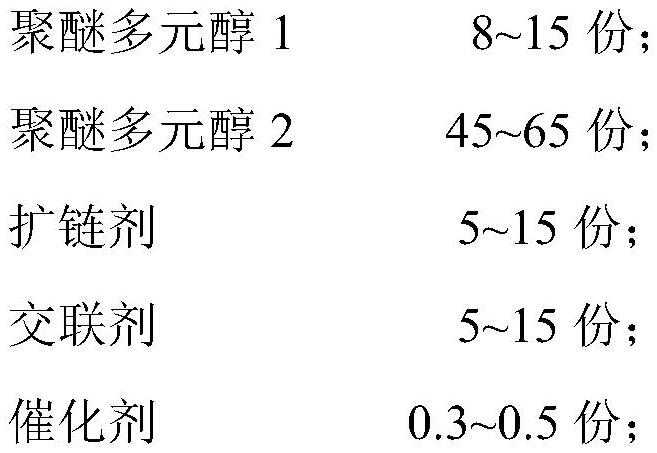

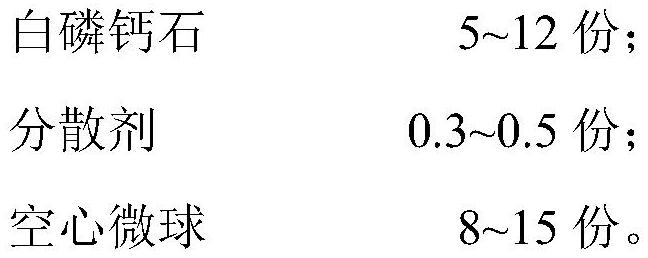

Lightweight polyurethane elastomer as well as manufacturing method and application thereof

The invention provides a light-weight polyurethane elastomer as well as a manufacturing process and application thereof. The polyurethane elastomer is obtained by reacting an isocyanate component and an isocyanate reactive component, the isocyanate reactive component comprises polyether polyol 1, polyether polyol 2, a chain extender, a cross-linking agent, a catalyst, white phosphorus calcium stone, a dispersing agent and hollow microspheres. On the basis of low density and light weight, the polyurethane elastomer disclosed by the invention also has excellent mechanical property and flame retardant property, and can be used for various line cables such as automobile application cables, optical fiber cables and the like.

Owner:广东安拓普聚合物科技股份有限公司

Imitation leather fabric production method

The invention discloses an imitation leather fabric production method. The imitation leather fabric production method includes the following steps that first, base fabric is selected and reeled up; second, the base fabric is evenly coated with resin material; third, the resin material is solidified; fourth, extrusion and water washing are performed; fifth, coating release paper is evenly coated with prepared polyurethane slurry, wherein the polyurethane slurry contains butanone and N-methyl ethanolamine; sixth, the coating release paper is attached to the base fabric and totally dried again; seventh, the release paper is separated. The imitation leather fabric production method is compact, reasonable and capable of effectively improving production efficiency; the coating fabric formed through the polyurethane slurry is even in micropore and not prone to expansion with water; besides, free coloring can be performed, physical indexes such as color fastness, illuminance, peel strength and tear strength can be freely adjusted, and thus the produced imitation leather fabric can be more excellent in performance.

Owner:罗静

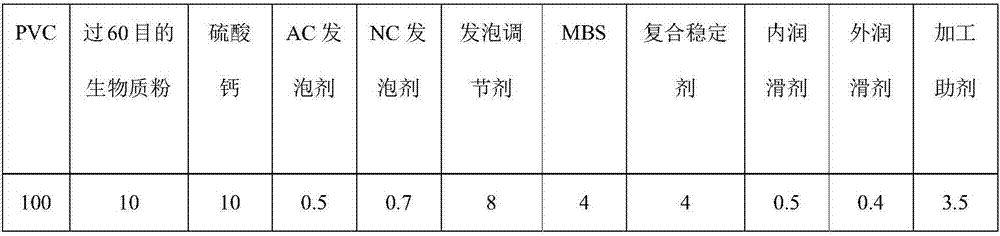

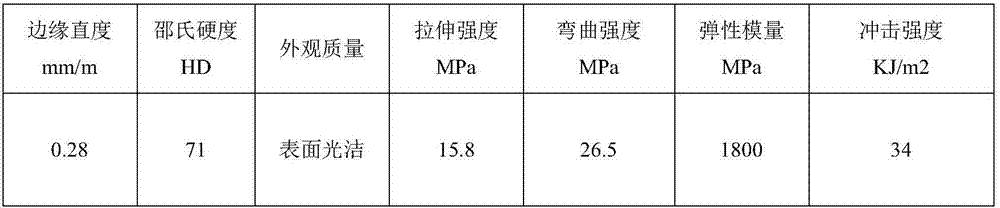

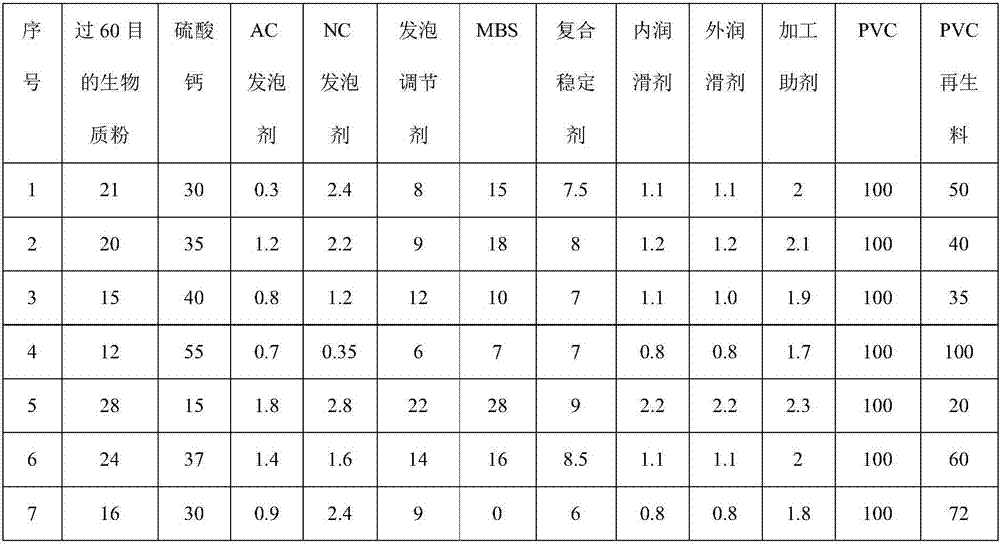

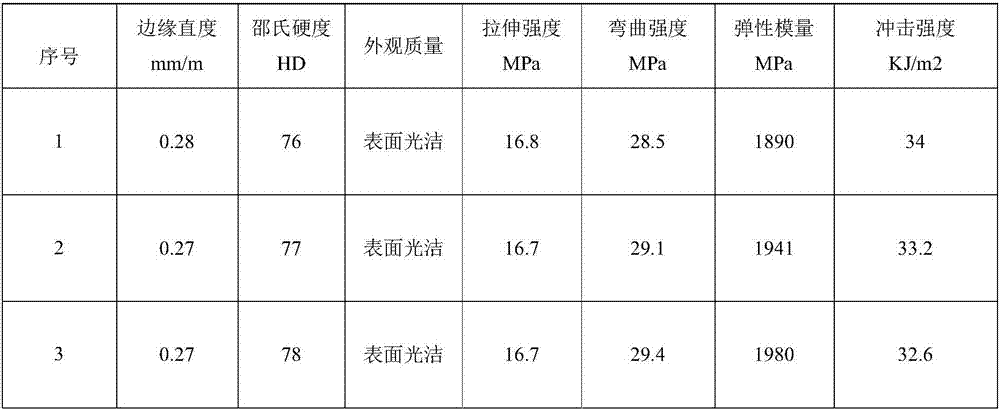

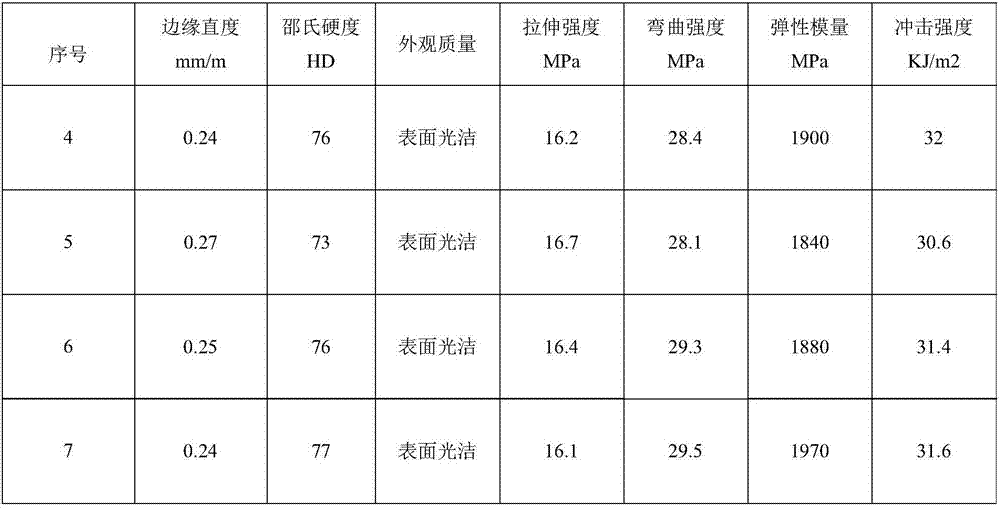

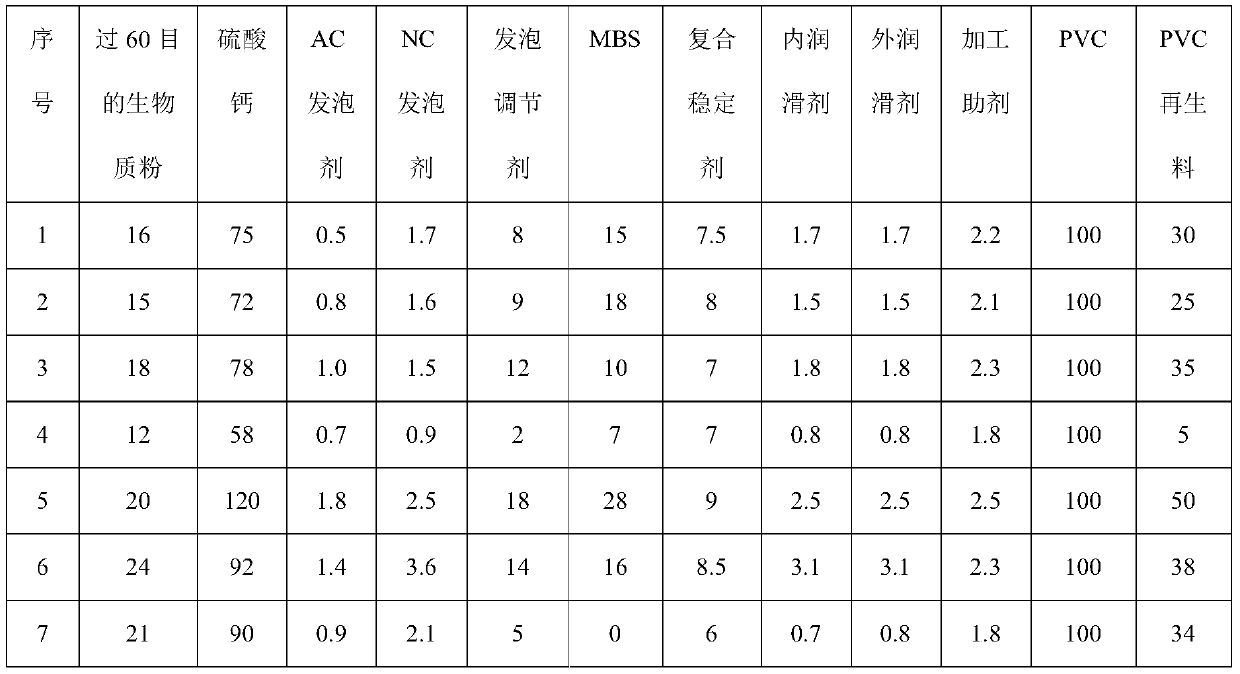

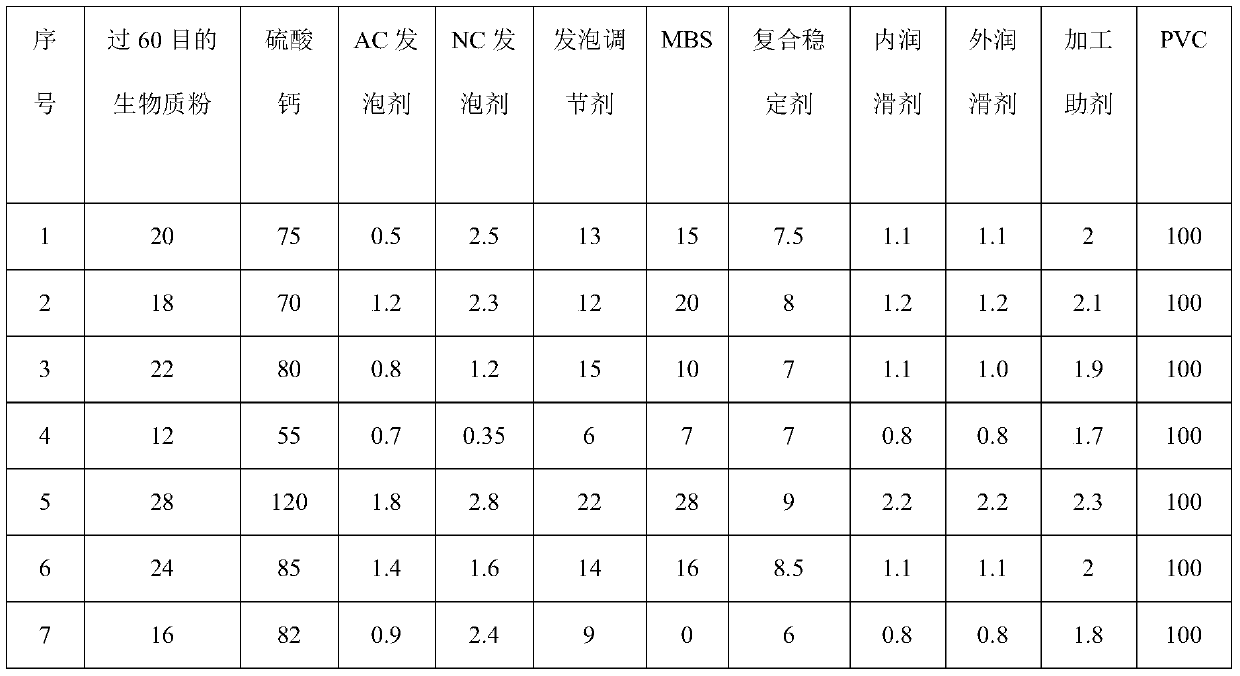

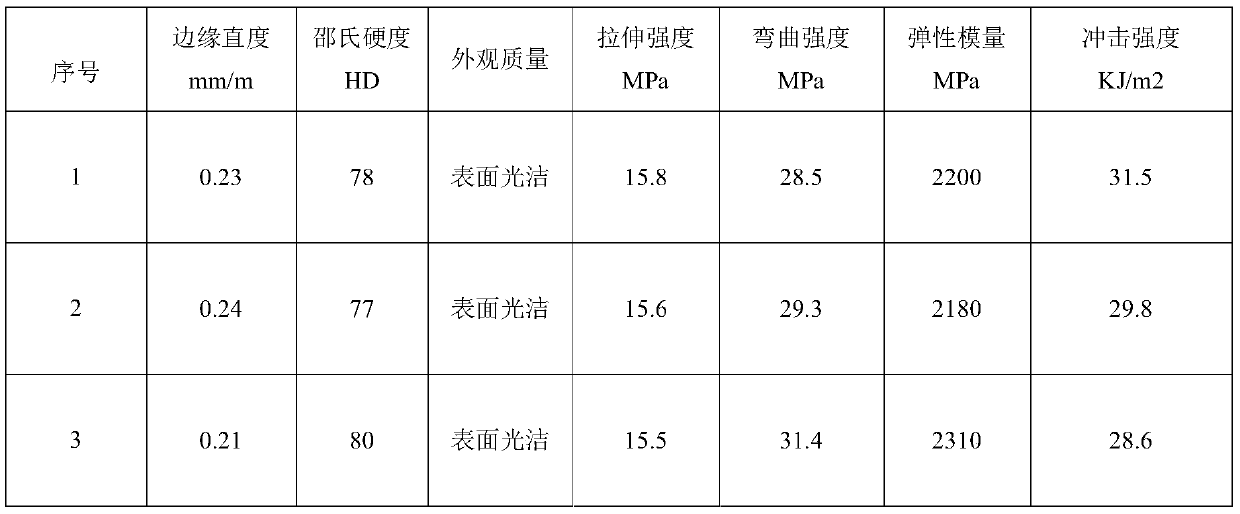

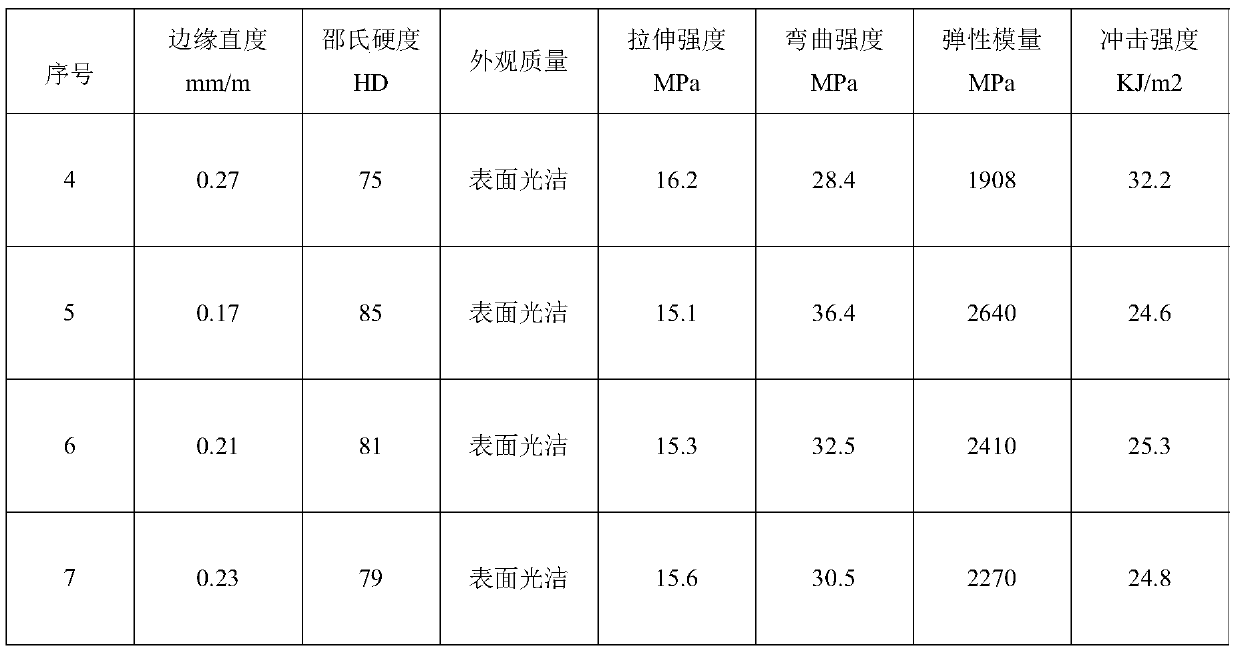

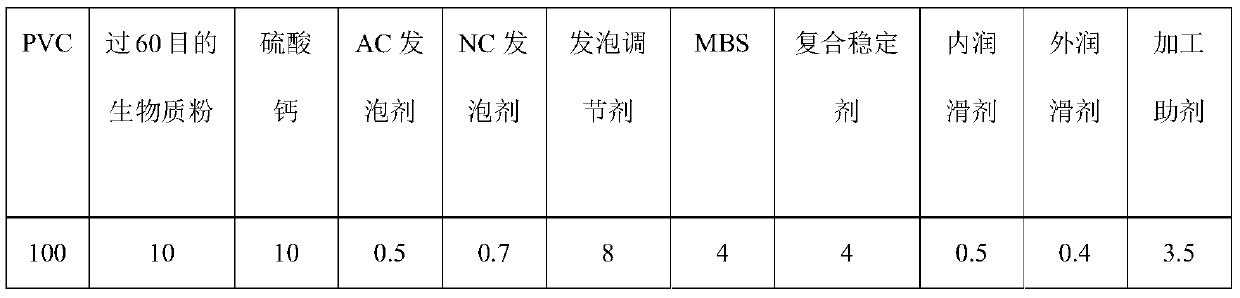

PVC (polyvinyl chloride) biomass foaming composite and preparation method thereof

ActiveCN107033480AUniform microporousImprove corrosion resistanceResource utilizationPolyvinyl chloride

The invention relates to a composite, in particular to a PVC (polyvinyl chloride) biomass foaming composite and a preparation method thereof. The novel PVC biomass foaming composite is prepared from components of preparation raw materials in parts by weight as follows: 100 parts of PVC, 10-100 parts of PVC renewable materials, 5-30 parts of biomass powder, 10-50 parts of calcium sulfate, 3-8 parts of a stabilizer, 0.6-3.5 parts of a foaming agent, 2-15 parts of a foaming regulator, 0.3-2.0 parts of an internal lubricant, 0.3-2.0 parts of an external lubricant, 1.0-1.5 parts of a PVC processing aid and 0.3-1.2 parts of a coupling agent. By means of the formula, the filler content of a PVC foaming system can be increased by 20%-50%, the weight of the product per meter is basically unchanged, and the material has higher cost performance. With the adoption of technique principles of new materials, the PVC biomass foaming composite has creativity of new material application, has characteristics of resource utilization, energy conservation, environmental protection and green economy and is suitable for industrial production.

Owner:江西板森新材料科技有限公司

Pressure sensitive adhesive and preparation method thereof

InactiveCN105001817AHigh transparent strengthHigh viscosityNon-macromolecular adhesive additivesEster polymer adhesivesReaction temperatureMethacrylate methyl

The invention discloses a pressure sensitive adhesive and a preparation method thereof. The pressure sensitive adhesive is composed of the following raw material components including, by weight, 5-8 parts of butyl acrylate, 1-2 parts of styrene, 1-2 parts of methyl methacrylate, 0.1-1 part of alpha-methacrylic acid, 0.3-0.5 part of potassium peroxodisulfate, 4-15 parts of 2-butanone, 1-5 parts of chlorosulphonated polyethylene and 0.1-0.8 part of dioctyl phthalate. The preparation method of the pressure sensitive adhesive comprises the steps that firstly, the butyl acrylate, the styrene, the methyl methacrylate, the alpha-methacrylic acid and the 2-butanone are added in a stirring barrel; secondly, the potassium peroxodisulfate is added, the temperature is increased to the reaction temperature, and reaction is performed for 2 h; thirdly, when liquid in the barrel is colorless, transparent and sticky, the liquid is cooled to the room temperature, then the chlorosulphonated polyethylene and the dioctyl phthalate are added, and after mixing is performed for several time, filtering and discharging are performed. The pressure sensitive adhesive is high in transparency and viscosity, easy to process and convenient to coat, and has the heat resistance and weather resistance; the light transmittance of light rays is improved, and the reliability of the product performance is guaranteed.

Owner:NANTONG KANGERLE MEDICAL MATERIALS CO LTD

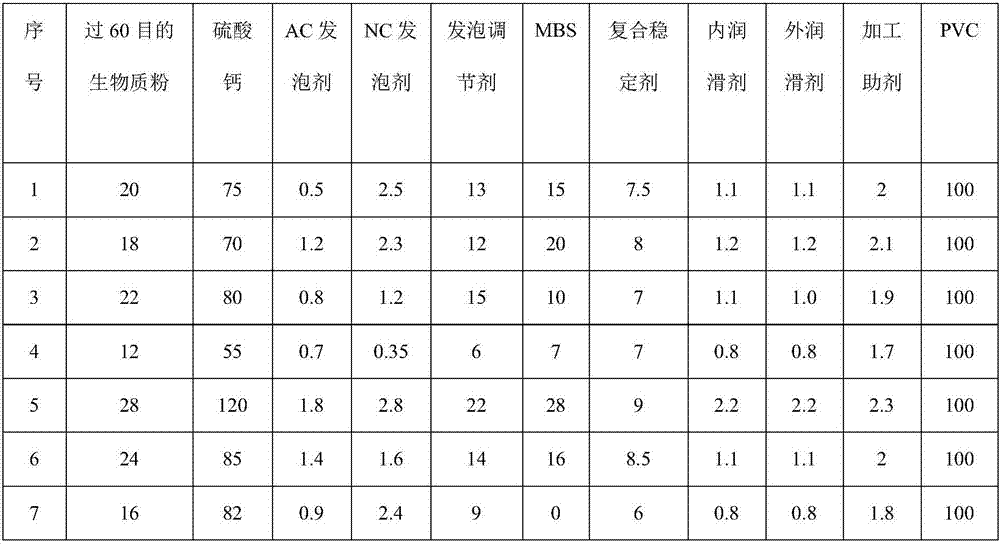

Novel PVC biomass foamed profile and preparation method thereof

The invention relates to a composite material, in particular to a novel PVC biomass foamed profile and a preparation method thereof. The novel PVC biomass foamed profile is prepared from components in parts by weight as follows: 100 parts of PVC, 10-30 parts of biomass powder, 50-130 parts of calcium sulfate, 5-10 parts of a stabilizer, 1-5 parts of a foaming agent, 5-25 parts of a foaming control agent, 0.5-2.5 parts of an internal lubricant, 0.5-2.5 parts of an external lubricant, 1.5-2.5 parts of a PVC processing agent and 0.5-1.8 parts of a coupling agent. The content of filler in the PVC foaming system can be increased by 20%-50% in the formula while the weight of the product per meter is kept basically unchanged, the material has higher cost performance, the novel PVC biomass foamed profile is developed according to the technical principle of a new material, is innovative in new material application, has the characteristics of facilitating resource utilization and being energy-saving, environment-friendly, green and economical and is suitable for industrial production.

Owner:江西板森新材料科技有限公司

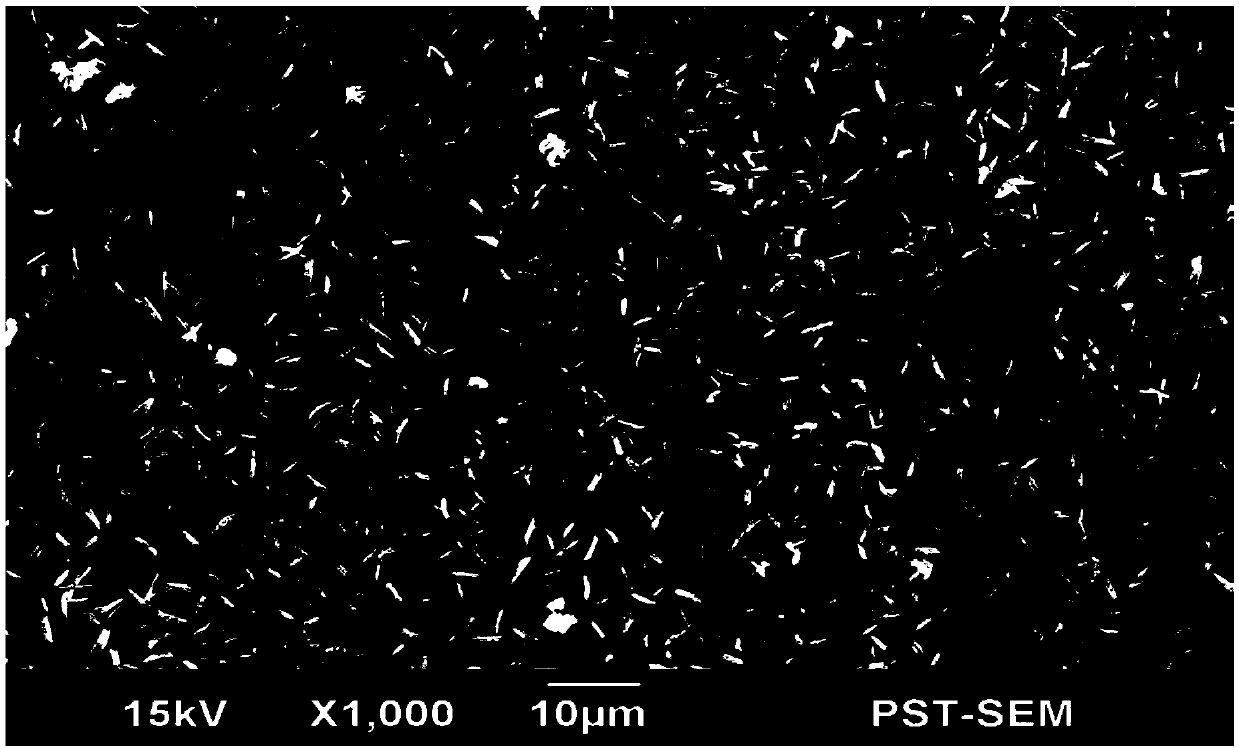

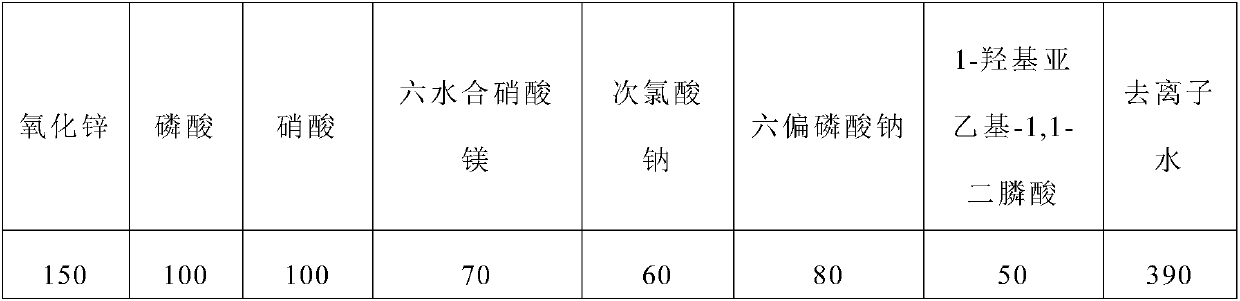

Coating liquid phosphatizing agent and preparation method thereof

ActiveCN107761086AImprove adhesionUniform microporousElectrophoretic coatingsMetallic material coating processesPhosphoric acidZinc

The invention discloses a coating liquid phosphatizing agent and a preparation method thereof, and belongs to the technical field of metal surface treatment. The coating liquid phosphatizing agent comprises the following components in percentage by mass: 5-15% of phosphoric acid, 5-15% of nitric acid, 8-15% of zinc oxide, 5-15% of an oxidation accelerant, 6-18% of composite additives and 39-71% ofdeionized water. The coating liquid phosphatizing agent disclosed by the invention is excellent in property, and the corrosion resistance after coating and the coating density of a coating can be effectively improved.

Owner:武汉钢铁有限公司

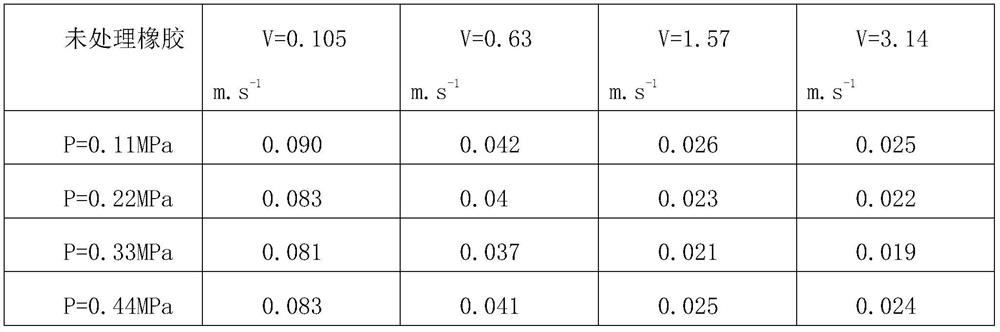

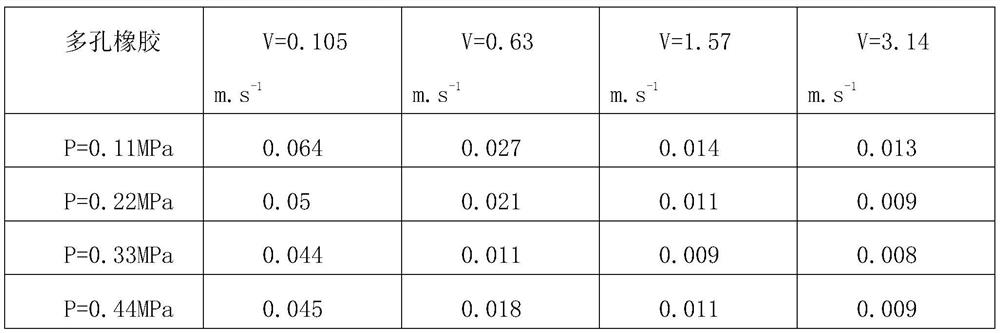

Preparation method of ultralow-friction rubber material

The invention discloses a preparation method of an ultralow-friction rubber material. The ultralow-friction rubber material comprises 6 parts by weight of rubber and 0.5-2 parts by weight of a pore-forming agent, the pore-forming agent is non-toxic water-soluble particles, and the particle size of the pore-forming agent is 140-200 [mu] m; rubber and the pore-forming agent are fully blended and then subjected to vulcanization treatment, and then the surface pore-forming agent is dissolved and removed. According to the preparation method of the ultralow-friction rubber material, uniform micropores are formed in the surface of the prepared rubber material, the friction coefficient and the wear rate are remarkably reduced, and compared with an existing rubber friction material surface treatment method, operation is simpler, and the cost is remarkably reduced.

Owner:CHONGQING UNIV

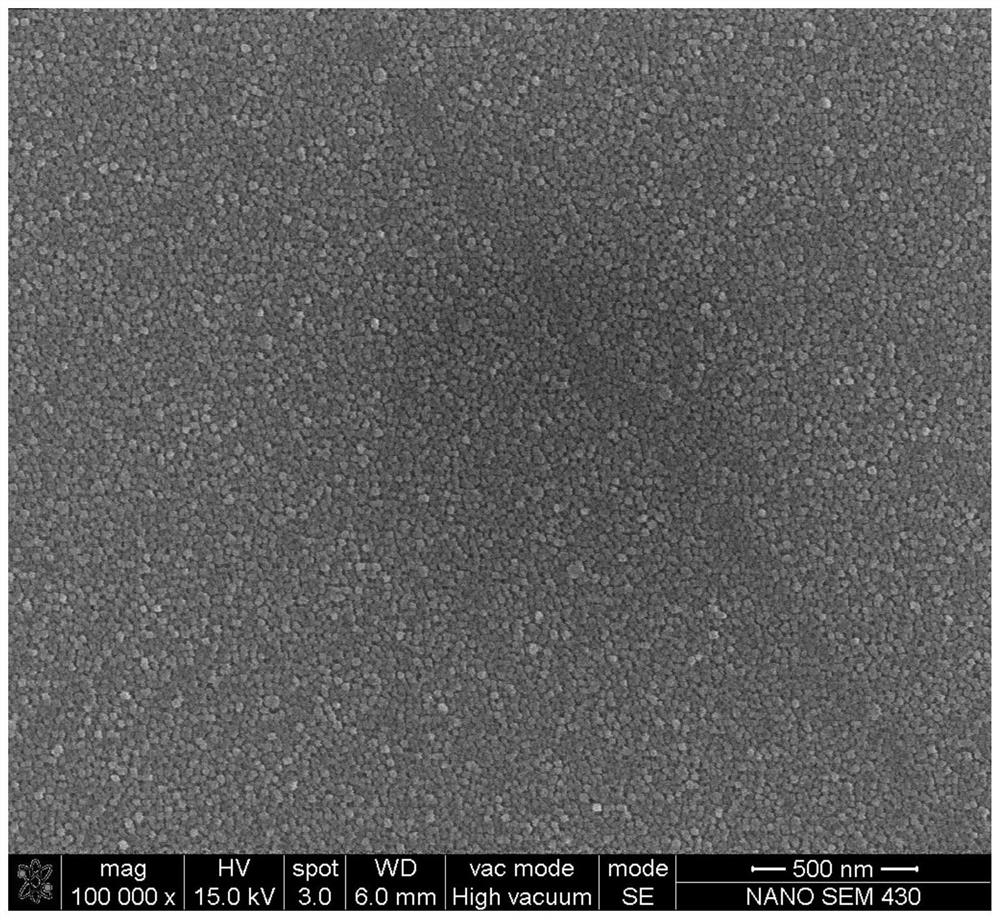

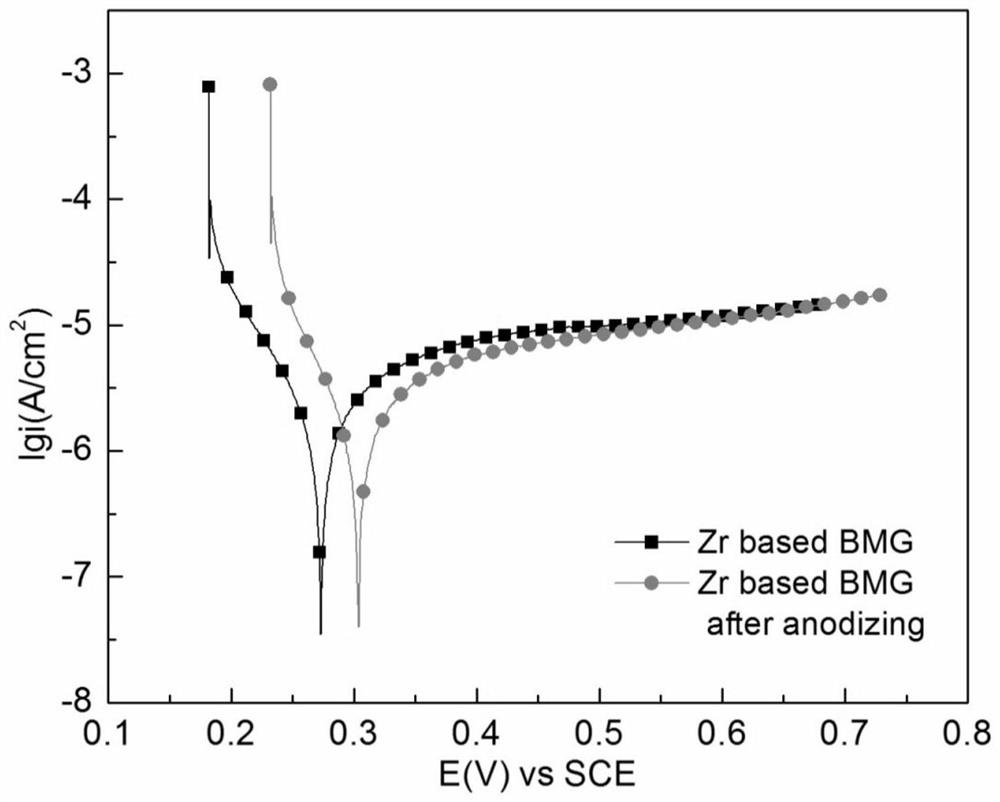

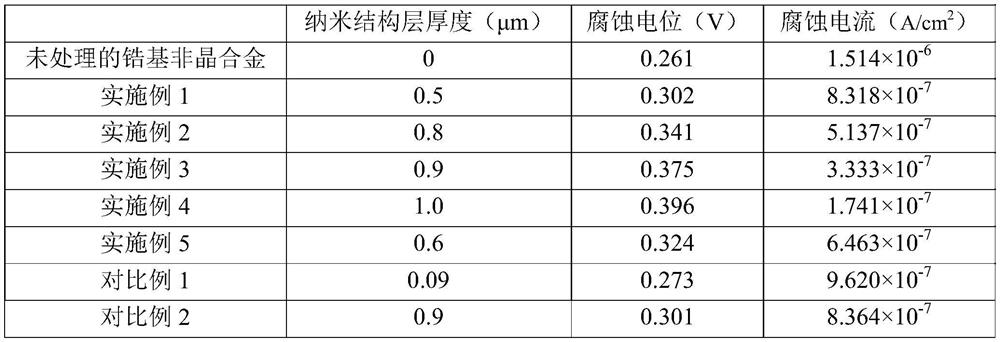

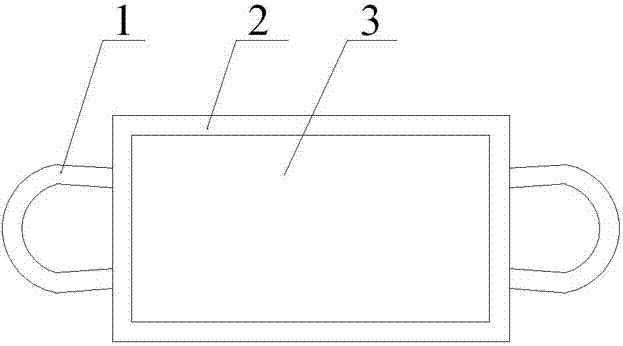

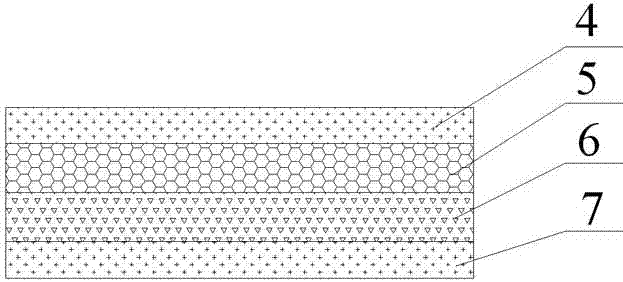

A kind of preparation method of zirconium-based amorphous alloy surface nanostructure layer

The invention belongs to the technical field of metal surface treatment, and specifically relates to a preparation method of a nanostructure layer of a zirconium-base amorphous alloy surface. According to the preparation method, a disc made of zirconium-base amorphous alloy is used as a working electrode, and a rotating disc electrode system is used for preparing the nanostructure layer on the zirconium-base amorphous alloy surface. According to the preparation method, the nanostructure layer can be formed on the zirconium-base amorphous alloy surface, the nanostructure layer is composed of aplurality of nanorods with the diameter between 10 and 30 nm, and uniform micropores are formed between the nanorods; when the zirconium-base amorphous alloy with the nanostructure layer is implantedin vivo, bone ingrowth is facilitated, and synostosis is formed together with target tissues; the rotating disc electrode system is used for preparing the nanostructure layer, and by-products and impurities can be thrown away from the surface of the disc during high-speed rotation of the rotating disc in the forming process of the nanostructure layer, so that adverse effects of the by-products andthe impurities on the nanostructure layer are avoided, and the uniform fine nanostructure layer is obtained.

Owner:CHANGZHOU STREAM LIQUID METAL CO LTD

Mask

PendingCN107373819AUniform microporousWith high pressure adsorption oxygen functionProtective garmentSpecial outerwear garmentsFiberRespirator

The invention discloses a mask which is applied to the field of daily life and comprises a transparent cover and a mask body clamped in the transparent cover. The transparent cover comprises ear hooks and an edge patch, a groove for clamping the mask body is formed in the inner surface of the edge patch, the mask body comprises an outer antibacterial layer and an inner antibacterial layer, an oxygen supplementation layer is arranged between the inner antibacterial layer and the outer antibacterial layer, a movable clamping edge corresponding to the groove in the edge patch is arranged at the edge of the mask body and functions in clamping the inner antibacterial layer, the oxygen supplementation layer and the outer antibacterial layer together, negative ion powder is added into the transparent cover, and both the outer antibacterial layer and the inner antibacterial layer are prepared from antibacterial fibers. The mask is simple in structure, novel in design, high in practical value, convenient to mount, dismount and clean, has the functions of oxygen supplementation and antibacteria and deodorization and can also achieve the functions of dust removal, purification and haze prevention, and harmful substances such as bacteria do not easily breed.

Owner:李润萱

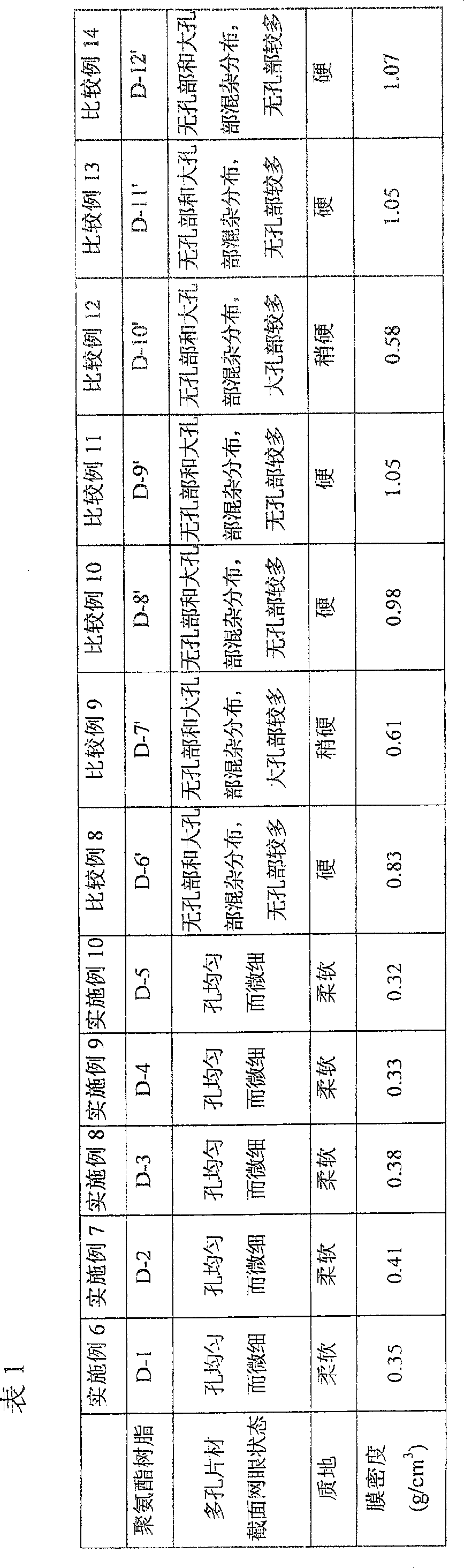

Polyurethane resin for synthetic leather and porous sheet material

A porous sheet material obtained through the wet coagulation of a polyurethane resin. The porous sheet is evenly microporous and has a highly flexible texture. The polyurethane resin for artificial leathers is characterized by being obtained by reacting high-molecular diols (A) comprising a polycarbonate diol (a1) obtained from a C4-6 alkanediol and a polycarbonate diol (a2) obtained from a C7-12 alkanediol, an organic diisocyanate (B), and a chain extender (C). It preferably is further characterized by having a coagulation value of 2 to 5.

Owner:SANYO CHEM IND LTD

A new em bacteria agent for manure composting

InactiveCN103787698BIncrease enzyme activityPromote degradationBio-organic fraction processingClimate change adaptationFecesMicrobial agent

Owner:深圳庆能城市环保科技有限公司

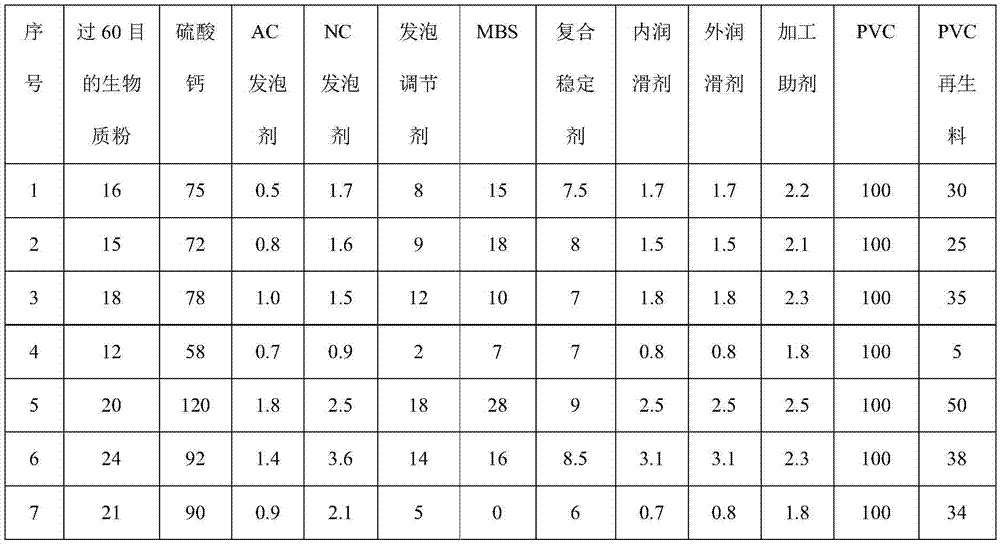

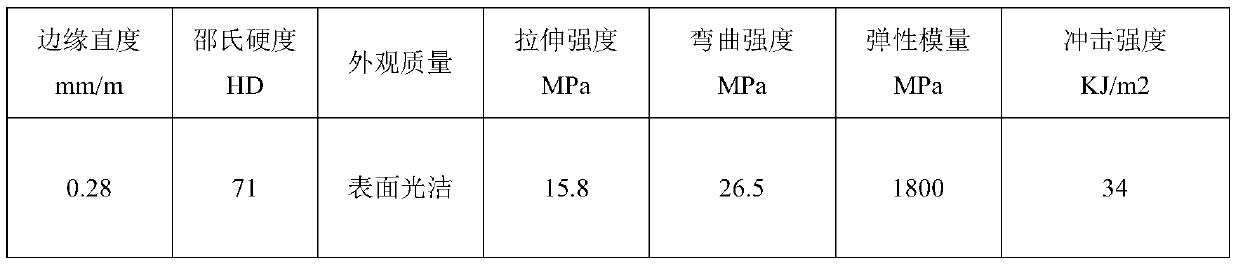

A kind of pvc foam profile and preparation method thereof

The invention relates to a composite, in particular to a PVC (polyvinyl chloride) biomass foaming composite and a preparation method thereof. The PVC biomass foaming composite is prepared from components of preparation raw materials in parts by weight as follows: 100 parts of PVC, 5-50 parts of PVC renewable materials, 5-30 parts of biomass powder, 50-130 parts of calcium sulfate, 5-12 parts of a stabilizer, 1-5 parts of a foaming agent, 2-18 parts of a foaming regulator, 0.6-3.5 parts of an internal lubricant, 0.6-3.5 parts of an external lubricant, 1.8-2.5 parts of a PVC processing aid and 0.6-2.5 parts of a coupling agent. By means of the formula, the filler content of a PVC foaming system can be increased by 20%-50%, the weight of the product per meter is basically unchanged, and the material has higher cost performance. With the adoption of technique principles of new materials, the PVC biomass foaming composite has creativity of new material application, has characteristics of resource utilization, energy conservation, environmental protection and green economy and is suitable for industrial production.

Owner:江西板森新材料科技有限公司

A kind of high temperature resistant multi-layer diaphragm composite lithium-ion battery diaphragm and preparation method thereof

A high temperature resistant multi-layer separator composite lithium ion battery separator belongs to the technical field of battery separators and includes a battery separator. The composite lithium ion battery separator is a laminated structure composed of at least two layers of battery separators. Between adjacent battery separator layers They are bonded and fixed with the help of coating slurry. The coating slurry includes, in terms of mass percentage, coating slurry 20-40%, adhesive 3-6%, dispersant 0.2-0.5%, and gelling agent 0.2 -0.5%, plasticizer 0.05-0.2%, anti-aging agent 0.05-0.2%, cross-linking agent 0.05-0.2%, thickener 0.1-0.5%, photoinitiator 0.3-1%, the balance is deionized water . The invention provides a method for preparing the high temperature resistant multi-layer separator composite lithium ion battery separator. The battery separator of the present invention not only has the high safety that the coated separator brings to the battery, but also can withstand high temperatures, reduce the shrinkage rate of the separator under high temperature conditions, increase the overall life of the battery, and can improve the resistance between the separator and the electrolyte. Affinity ensures that the separator is fully swollen by the electrolyte, which helps extend the cycle life of the battery.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

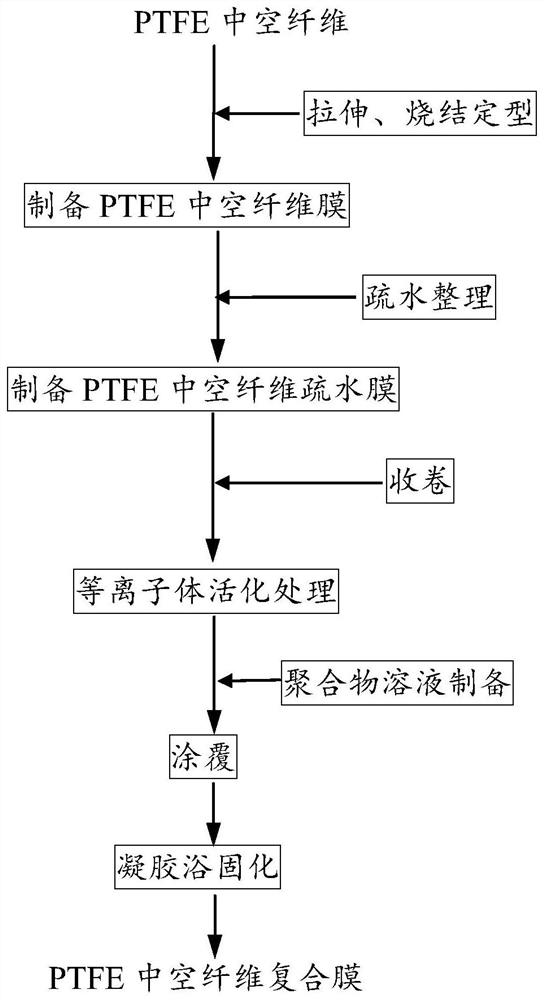

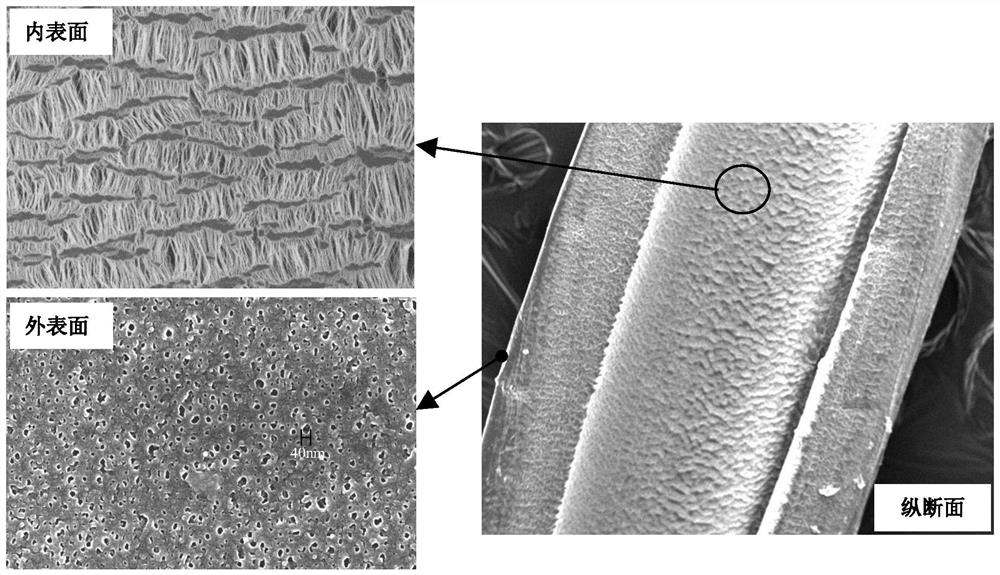

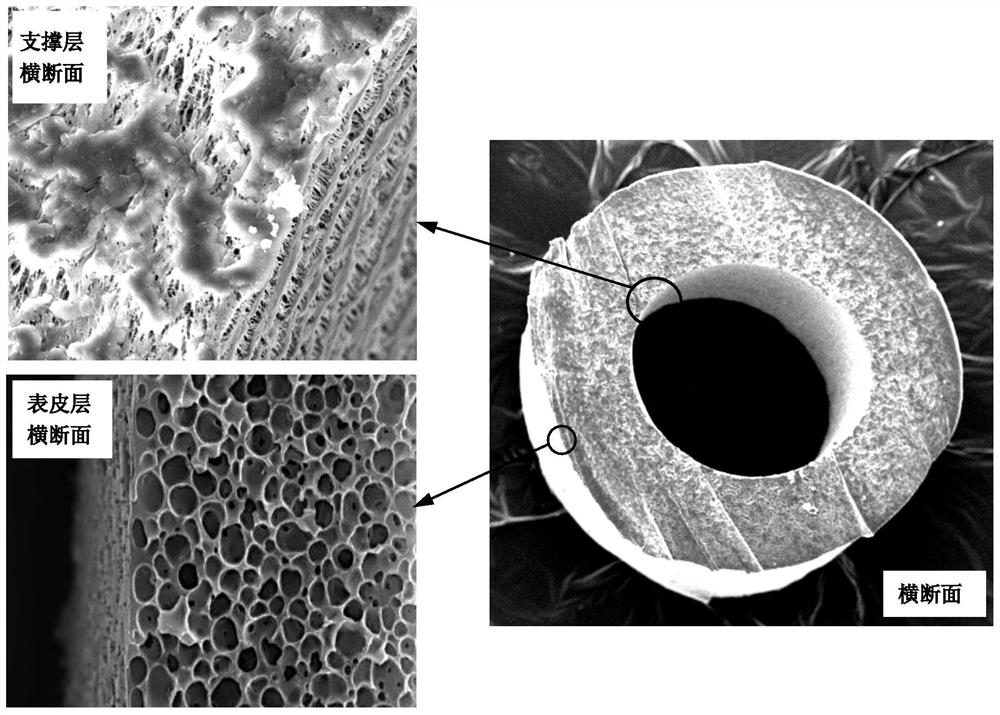

Polytetrafluoroethylene hollow fiber composite membrane and preparation method thereof

The invention belongs to the technical field of separation membranes, and in particular relates to a polytetrafluoroethylene hollow fiber composite membrane and a preparation method thereof. The composite membrane has a double-layer structure, and the composite membrane includes an outer hydrophilic ultrafiltration skin layer and an inner hydrophobic PTFE support layer, the initial contact angle of the hydrophilic ultrafiltration skin layer is 20°-85°, the thickness of the hydrophilic ultrafiltration skin layer is 2 μm-50 μm, and the microporous structure on the surface is circular and evenly distributed. The average pore diameter of the pores is 5nm-100nm, the cross-section of the hydrophilic ultrafiltration skin layer is a sponge-like hole, the initial contact angle of the hydrophobic PTFE support layer is 108°-158°, and its microporous structure is composed of gaps between fine fibers The formed point-line separation pores have an average pore diameter of 750nm-4000nm and a porosity of 65%-85%. The beneficial effects of the invention are: the polytetrafluoroethylene hollow fiber membrane with composite structure has durable hydrophobicity and high-efficiency separation performance. At the same time, the preparation method of the invention is simple, efficient, economical and environmentally friendly, and the prepared composite membrane has good stability.

Owner:自然资源部天津海水淡化与综合利用研究所

A novel pvc biomass foam profile and preparation method thereof

The invention relates to a composite material, in particular to a novel PVC biomass foamed profile and a preparation method thereof. The novel PVC biomass foamed profile is prepared from components in parts by weight as follows: 100 parts of PVC, 10-30 parts of biomass powder, 50-130 parts of calcium sulfate, 5-10 parts of a stabilizer, 1-5 parts of a foaming agent, 5-25 parts of a foaming control agent, 0.5-2.5 parts of an internal lubricant, 0.5-2.5 parts of an external lubricant, 1.5-2.5 parts of a PVC processing agent and 0.5-1.8 parts of a coupling agent. The content of filler in the PVC foaming system can be increased by 20%-50% in the formula while the weight of the product per meter is kept basically unchanged, the material has higher cost performance, the novel PVC biomass foamed profile is developed according to the technical principle of a new material, is innovative in new material application, has the characteristics of facilitating resource utilization and being energy-saving, environment-friendly, green and economical and is suitable for industrial production.

Owner:江西板森新材料科技有限公司

Novel PVC foam profile and preparation method thereof

The invention relates to a composite material, in particular to a novel PVC foamed profile and a preparation method thereof. The novel PVC foamed profile is prepared from components in parts by weight as follows: 100 parts of PVC, 3-25 parts of a toughening agent, 10-50 parts of calcium sulfate, 3-8 parts of a stabilizer, 0.6-3.5 parts of a foaming agent, 2-15 parts of a foaming control agent, 0.3-2.0 parts of an internal lubricant, 0.3-2.0 parts of an external lubricant, 1.0-1.5 parts of a PVC processing agent and 0.3-1.2 parts of a coupling agent. The content of filler in the PVC foaming system can be increased by 10%-30% in the formula while the weight of the product per meter is kept basically unchanged, the material has higher cost performance, the novel PVC foamed profile is developed according to the technical principle of a new material, is innovative in new material application, has the characteristics of facilitating resource utilization and being energy-saving, environment-friendly, green and economical and is suitable for industrial production.

Owner:江西板森新材料科技有限公司

A kind of preparation method of alumina fiber-reinforced high-temperature-resistant and anti-scour thermal insulation material

ActiveCN112500183BUniform and stable beltUniform and stable chargeThermal insulationAluminium matrix

The invention belongs to the technical field of ceramic-based composite materials, and in particular relates to a preparation method of an alumina fiber-reinforced high-temperature-resistant and erosion-resistant thermal insulation material. The preparation method comprises the following steps: S1. preparation of alumina preform, S2. preparation of slurry for high temperature resistant coating, S3. preparation of high temperature resistant coating of alumina preform, S4 preparation of composite material green body, S5 low temperature sintering Preparation of alumina matrix composites. In the present invention, the alumina preform is soaked in the modifier, and after the soaking is completed, the slurry obtained in S2 is impregnated and / or coated and / or deposited on the modified green body. This design can be fast, efficient, and Uniformly obtain high-quality high-temperature resistant coatings, and cooperate with subsequent processes to prepare materials that can meet the requirements of high temperature resistance, erosion resistance, thermal insulation and high temperature resistance, erosion resistance, thermal insulation and insulation. The invention has reasonable step design, simple and controllable process, and is convenient for large-scale industrial application.

Owner:湖南合为新材料科技有限公司

Preparation method and application of biocl/carbonized egg membrane composite visible light catalyst

ActiveCN110302810BUniform microporousUniform structurePhysical/chemical process catalystsWater/sewage treatment by irradiationIndustrial waste waterPtru catalyst

The invention relates to a preparation method of a BiOCl / carbonized egg film composite visible light catalyst, comprising the following steps: S1, drying and shredding the egg film; S2, calcining the egg film fragments, and grinding them into particles after calcining to obtain carbonized egg film; S3 , to Bi(NO 3 ) 3 Add hydrochloric acid, deionized water and ethanol to the solid, then add carbonized egg membrane, sonicate for 30-120 minutes, stir for 30 minutes, add NaOH solution during the stirring process, and finally age for 8-12 hours, filter out the liquid, and dry at 100°C for 12 hours. After ~15h, the modified BiOCl / carbonized egg membrane catalyst was finally obtained, and the catalyst was applied to the degradation of dye wastewater containing rhodamine B, antibiotic wastewater containing tetracycline hydrochloride and industrial wastewater containing organic pollutants. The invention can reduce the pressure of waste treatment and environmental pollution, turn waste into wealth, and realize efficient catalytic degradation of industrial waste water.

Owner:JIANGXI UNIV OF SCI & TECH

Process for preparing alumina ceramic foil materials with penetrative nanohole

InactiveCN100532317CUniform microporousGood market prospectCeramicwareElectrically conductiveAlumina ceramic

The invention provides a preparation method of aluminum oxide ceramic foil material with penetrating nano-holes, which includes firstly attaching aluminum foil to the surface of a conductive material, making the surfaces of the materials contact, and maintaining conduction between the materials; The conductive material attached to the aluminum foil is placed as an anode in an electrochemical anodizing solution to make the aluminum foil undergo an oxidation reaction, so as to convert the aluminum foil into aluminum oxide, and form penetrating micropores in the thickness direction. After the ceramic foil is separated from the surface of the conductive material, a pure Al2O3 ceramic foil material with uniformly penetrating micropores is obtained. The aluminum oxide ceramic foil material can be directly applied to fine filtration of gas and liquid. The invention can effectively, quickly, conveniently and completely prepare Al2O3 ceramic foil material with nano-scale pore size independently, and has the advantages of simple process, convenient operation, low economic cost and high production efficiency, and is suitable for industrial mass production application and market The prospects are very broad.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com