Coating liquid phosphatizing agent and preparation method thereof

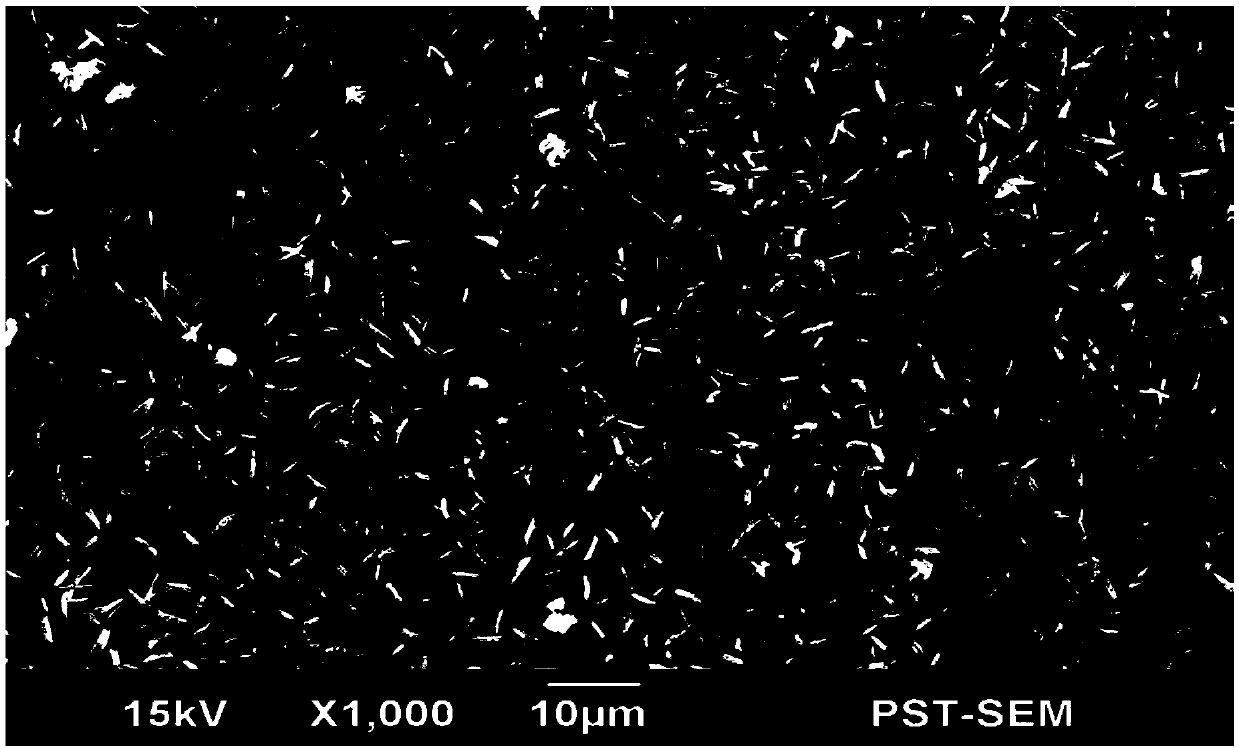

A phosphating agent and liquid technology, applied in the field of metal surface treatment, can solve the problems of weak film forming strength and corrosion resistance of phosphating liquid, and achieve the effect of dense and complete overall coverage, fine film layer and uniform micropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

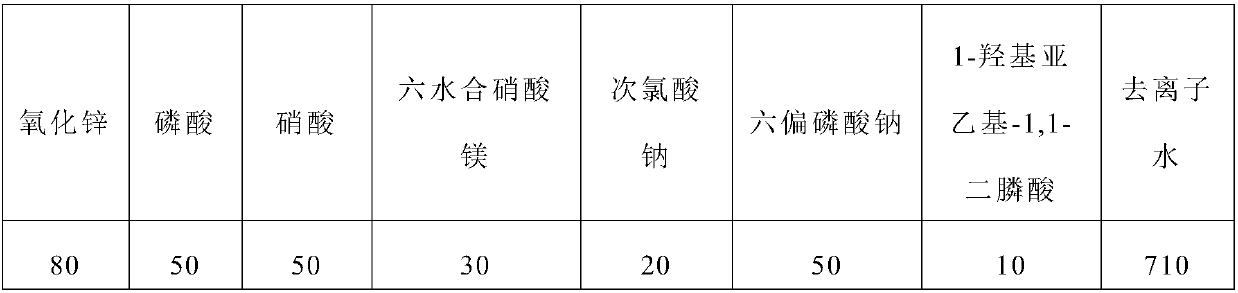

[0029] It is necessary to configure 1000kg liquid phosphating solution, and the required components are shown in Table 1:

[0030] The specific content list (kg) of each component of table 1

[0031]

[0032] The specific configuration process is:

[0033] Get 80kg zinc oxide and add in the container, then add deionized water in the container and stir into a paste, get 58.8L laboratory commonly used 85% phosphoric acid (mass volume ratio is 85%), add a small amount of deionized water to dilute, and then divide Slowly add twice to the above-mentioned container containing zinc oxide. Bubbles are released during the reaction between phosphoric acid and zinc oxide. The phosphoric acid solution is added dropwise until no bubbles are generated for the first time, and the remaining phosphoric acid solution is dripped for the second time. After the addition was completed, a clear solution was obtained. Under stirring, another solution with a density of 1.42 g cm was added. -3 35....

Embodiment 2

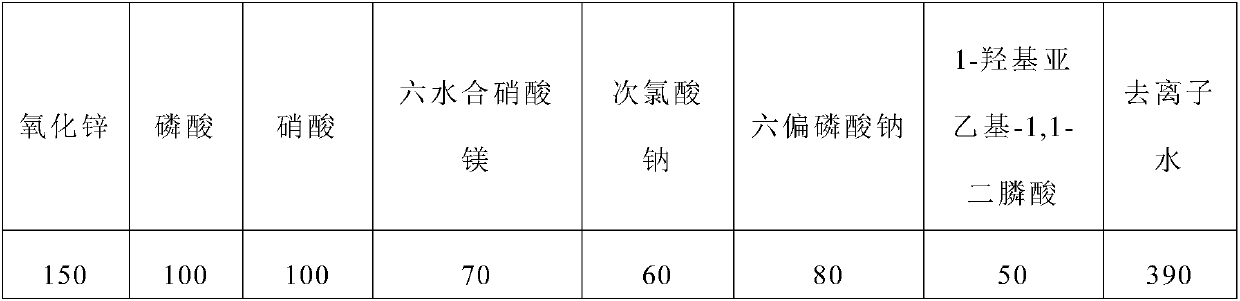

[0037] 1000kg liquid phosphating solution needs to be configured, and the required components are shown in Table 2:

[0038] The specific content list (kg) of each component of table 2

[0039]

[0040] The specific configuration process is:

[0041] Get 150kg zinc oxide and add in the container, then add deionized water in the container and stir into a paste, get 117.6L laboratory commonly used 85% phosphoric acid (mass volume ratio is 85%), add a small amount of deionized water to dilute, and then divide Slowly add twice to the above-mentioned container containing zinc oxide. Bubbles are released during the reaction between phosphoric acid and zinc oxide. The phosphoric acid solution is added dropwise until no bubbles are generated for the first time, and the remaining phosphoric acid solution is dripped for the second time. After the addition was completed, a clear solution was obtained. Under stirring, another solution with a density of 1.42 g cm was added. -3 70.4L o...

Embodiment 3

[0043] 800kg liquid phosphating solution needs to be configured, and the required components are shown in Table 3:

[0044] The specific content list (kg) of each component of table 3

[0045]

[0046]The specific configuration process is:

[0047] Get 80kg zinc oxide and add in the container, then add deionized water in the container and stir into a paste, get 65.9L laboratory commonly used 85% phosphoric acid (mass volume ratio is 85%), add a small amount of deionized water to dilute, and then divide Slowly add twice to the above-mentioned container containing zinc oxide. Bubbles are released during the reaction between phosphoric acid and zinc oxide. The phosphoric acid solution is added dropwise until no bubbles are generated for the first time, and the remaining phosphoric acid solution is dripped for the second time. After the addition was completed, a clear solution was obtained. Under stirring, another solution with a density of 1.42 g cm was added. -3 45.0L of ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com