Novel PVC foamed profile and preparation method thereof

A new type of profile technology, applied in the field of composite materials, can solve problems such as weak corrosion resistance, poor toughness, and narrow processing temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

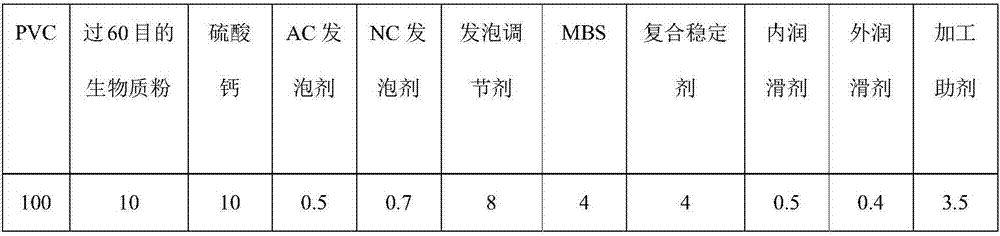

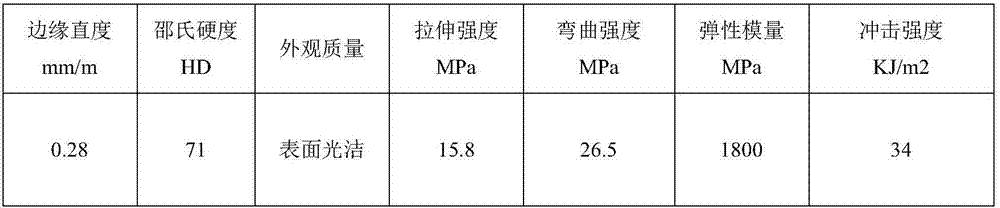

[0035] In parts by weight, the present embodiment new type The composition of PVC foam profile is as follows: The following table :

[0036] surface 1

[0037]

[0038] Example 1 Health new product The process of PVC biomass foamed profiles is as follows:

[0039] Step 1, will in the tableThe component materials are put into the high-speed mixer and mixed at a high speed, and the temperature reaches 110-120°C, and then the mixture is transferred from the high-speed mixer to a low-speed cold mixing pot, and the temperature is lowered to 40-60°C to obtain a mixture;

[0040] Step 2, kneading and extruding the mixture in a counter-rotating conical twin-screw extruder;

[0041] Step 3, pass the extruded material through the heating mold (the temperature of the heating mold is 165-180°C), and then pump negative pressure to cool and shape it;

[0042] Step 4, the shaped and cooled material is drawn and cut into products of a certain size by the auxiliary machine. The...

Embodiment 2

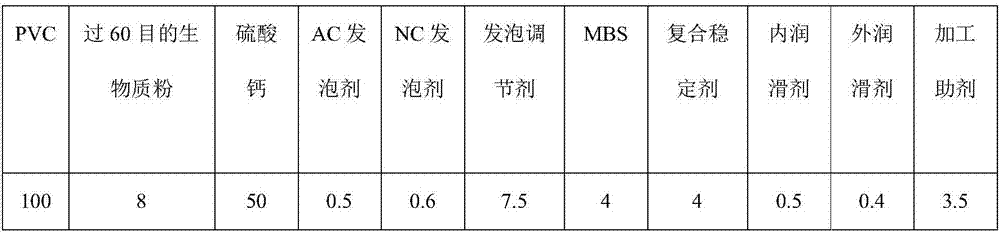

[0047] In parts by weight, the present embodiment new type The formula composition of PVC biomass foam profile is as follows: The following table :

[0048] surface 3

[0049]

[0050] Example 2 new product The process of PVC foam profiles is as follows:

[0051] Step 1, will in the table The component materials are put into the high-speed mixer and mixed at a high speed until the temperature reaches 110-120°C, and then the mixture is transferred from the high-speed mixer to a low-speed cold mixing pot, and the temperature is lowered to 40-60°C to obtain a mixture;

[0052] Step 2, kneading and extruding the mixture in a counter-rotating conical twin-screw extruder;

[0053] Step 3, pass the extruded material through the heated mold and then pump negative pressure to cool and shape it;

[0054] Step 4, the shaped and cooled material is drawn and cut into products of a certain size by the auxiliary machine. The process parameters of the counter-rotating conical ...

Embodiment 3

[0059] In parts by weight, the present embodiment new type The formula composition of PVC biomass foam profile is as follows: The following table :

[0060] surface 5

[0061]

[0062] Example 3 Health new product The process of PVC foam profiles is as follows:

[0063] Step 1, will in the table The component materials are put into the high-speed mixer and mixed at a high speed until the temperature reaches 110-120°C, and then the mixture is transferred from the high-speed mixer to a low-speed cold mixing pot, and the temperature is lowered to 40-60°C to obtain a mixture;

[0064] Step 2, kneading and extruding the mixture in a counter-rotating conical twin-screw extruder;

[0065] Step 3, pass the extruded material through the heated mold and then pump negative pressure to cool and shape it;

[0066] Step 4, the shaped and cooled material is drawn and cut into products of a certain size by the auxiliary machine. The process parameters of the counter-rotating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com