A kind of preparation method of alumina fiber-reinforced high-temperature-resistant and anti-scour thermal insulation material

A technology of alumina fiber and alumina, which is applied in the field of ceramic matrix composite materials, can solve the problems of poor high temperature resistance of products, many processes, and long preparation cycle, so as to improve strength and high temperature resistance, increase sintering temperature, and shorten production cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] S1. Preparation of alumina preform:

[0071] Prepare an alumina preform with pores according to requirements; the alumina preform is alumina wool, and the alumina wool density is 0.8g / cm 3 , the thickness is 25mm, and the thermal conductivity at 25-1600°C is 0.05-0.45W / (m·K).

[0072] S2. prepare the slurry of high temperature resistant coating:

[0073]Put the ceramic powder, solvent, dispersant, and adhesive in a ball mill in proportion to the ball mill and mix them evenly, then add ammonia water to adjust the pH value to 7-9, and stir evenly to prepare the alumina fiber high temperature resistant coating slurry ;

[0074] The ceramic powder is α-Al 2 o 3 Aluminum oxide ceramic powder, yttrium oxide. The particle size of the ceramic powder is 0.1-0.3 microns (the mass ratio of the two is 1:1).

[0075] The solvent is deionized water.

[0076] The dispersant is acrylic resin.

[0077] The adhesive is acrylic resin.

[0078] In S2, the mass ratio of ceramic pow...

Embodiment 2

[0098] S1. Preparation of alumina preform:

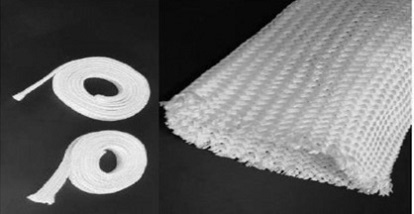

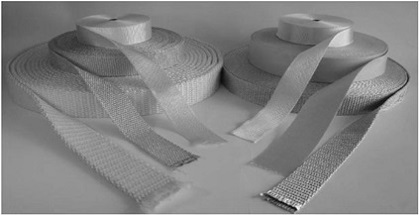

[0099] Prepare alumina preforms with pores according to requirements; the alumina preforms are alumina felts, and the alumina felts are composed of alumina fiber cloth, alumina cotton and alumina textile threads, with two layers of alumina on the top and bottom Thick fiber cloth with alumina cotton in the middle, each strand of alumina textile thread is composed of 1000 continuous alumina fibers, and the thermal conductivity of the felt at 25-1600°C is 0.05-0.5W / (m·K). The average density of the alumina felt is 1.2g / cm 3 , the thickness is 12mm.

[0100] S2. prepare the slurry of high temperature resistant coating:

[0101] Put the ceramic powder, solvent, dispersant, and adhesive in a ball mill in proportion to the ball mill and mix them evenly, then add ammonia water to adjust the pH value to 7-9, and stir evenly to prepare the alumina fiber high temperature resistant coating slurry ;

[0102] The ceramic powder is zirconia an...

Embodiment 3

[0112] Other conditions are consistent with embodiment 1; The difference is

[0113] The alumina preform is alumina fiber cloth, and the density of the alumina cloth is 1.8g / cm 3 , The thickness is 0.3mm, the weaving method is double twill, and the warp or weft yarn per 1cm of the fabric is 9 strands.

[0114] The finished density of the composite material obtained in S5 is 2.2 g / cm 3 When the porosity is 30% and the fiber volume content is 28%, the tensile strength of the obtained product is 202MPa, the bending strength is 380MPa, and the fracture toughness is 8MPa.m 1 / 2 , high temperature resistance is greater than or equal to 2200°C, and the thermal conductivity is 0.5W / (m·K); when the gas flushing speed is 6.8km / s, the time is 50s, and the temperature is 2200°C, its mass loss is less than 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com