Novel PVC foam profile and preparation method thereof

A profile and foaming agent technology, applied in the field of new PVC foam profiles and their preparation, can solve the problem of difficulty in meeting higher requirements for strength, narrow processing temperature range, and foaming effects of natural anhydrite, light calcium carbonate, and acrylic resin Bad question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

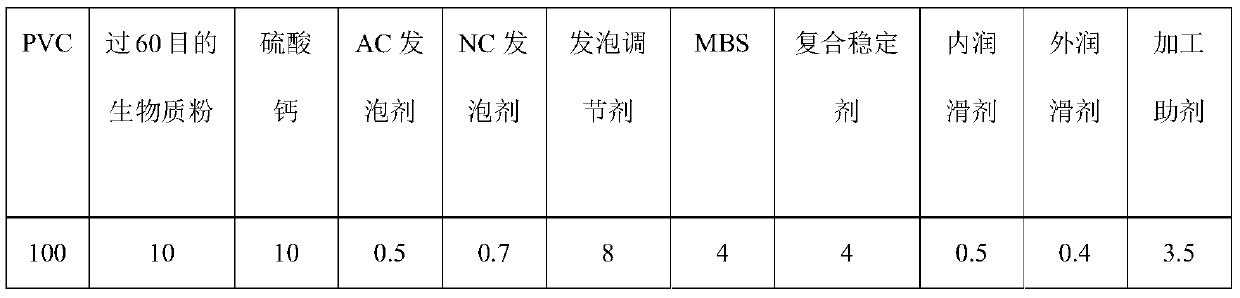

[0035] In parts by weight, the formula of the novel PVC foamed profile of the present embodiment consists of the following table:

[0036] Table 1

[0037]

[0038] Embodiment 1 produces the technique of novel PVC biomass foamed profile as follows:

[0039] Step 1. Put the ingredients in the table into a high-speed mixer and mix them thoroughly at high speed until the temperature reaches 110-120°C. Then transfer the mixture from the high-speed mixer to a low-speed cold mixing pot, and lower the temperature to 40-60°C to obtain a mixed material;

[0040] Step 2, kneading and extruding the mixture in a counter-rotating conical twin-screw extruder;

[0041] Step 3, pass the extruded material through the heating mold (the temperature of the heating mold is 165-180°C), and then pump negative pressure to cool and shape it;

[0042] Step 4, the shaped and cooled material is drawn and cut into products of a certain size by the auxiliary machine. The working parameters of the coun...

Embodiment 2

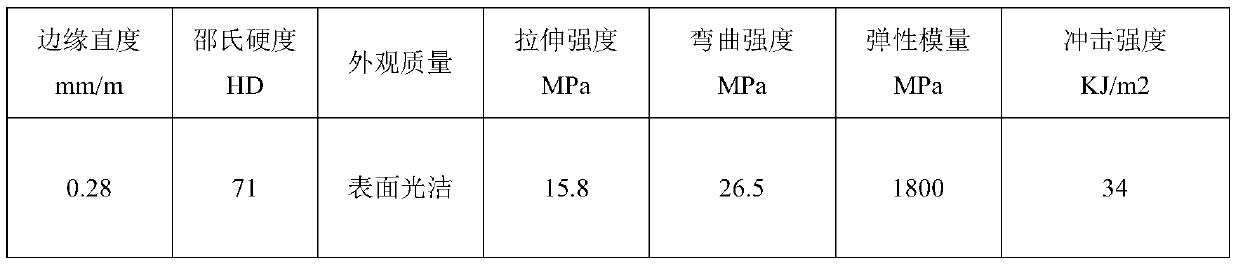

[0047] In parts by weight, the formula of the novel PVC biomass foamed profile of the present embodiment is as follows:

[0048] table 3

[0049]

[0050] Embodiment 2 produces the technique of novel PVC foam profile as follows:

[0051] Step 1: Put the ingredients listed in the table into the high-speed mixer and mix them thoroughly at high speed until the temperature reaches 110-120°C, then transfer the mixture from the high-speed mixer to a low-speed cold mixing pot, and lower the temperature to 40-60°C to obtain a mixture material;

[0052] Step 2, kneading and extruding the mixture in a counter-rotating conical twin-screw extruder;

[0053] Step 3, pass the extruded material through the heated mold and then pump negative pressure to cool and shape it;

[0054] Step 4, the shaped and cooled material is drawn and cut into products of a certain size by the auxiliary machine. The process parameters of the counter-rotating conical twin-screw extruder in this example are...

Embodiment 3

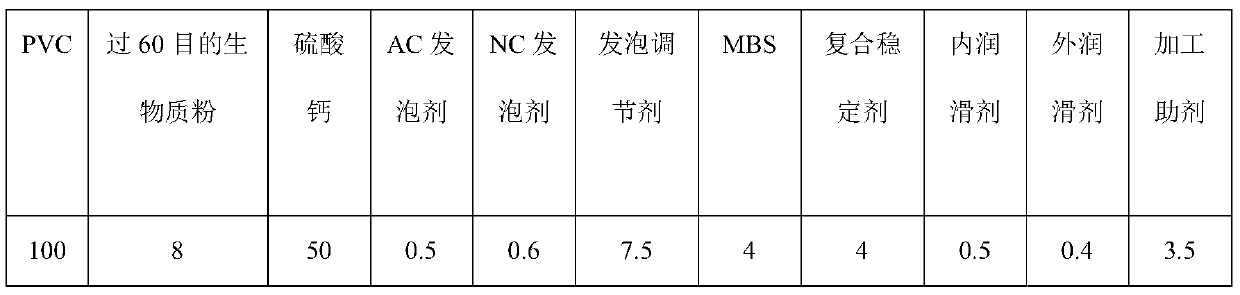

[0059] In parts by weight, the formula of the novel PVC biomass foamed profile of the present embodiment is as follows:

[0060] table 5

[0061]

[0062] Embodiment 3 produces the technique of novel PVC foam profile as follows:

[0063] Step 1: Put the ingredients listed in the table into the high-speed mixer and mix them thoroughly at high speed until the temperature reaches 110-120°C, then transfer the mixture from the high-speed mixer to a low-speed cold mixing pot, and lower the temperature to 40-60°C to obtain a mixture material;

[0064] Step 2, kneading and extruding the mixture in a counter-rotating conical twin-screw extruder;

[0065] Step 3, pass the extruded material through the heated mold and then pump negative pressure to cool and shape it;

[0066] Step 4, the shaped and cooled material is drawn and cut into products of a certain size by the auxiliary machine. The process parameters of the counter-rotating conical twin-screw extruder in this example are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com