Polytetrafluoroethylene hollow fiber composite membrane and preparation method thereof

A polytetrafluoroethylene and fiber composite technology, which is applied in the field of separation membranes, can solve the problems of complex preparation process, dense skin layer or uncontrollable pore size, poor bonding strength between skin layer and support layer, etc., and achieves a simple preparation method and is conducive to high efficiency. The effect of penetration, protection against contamination and penetration of wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

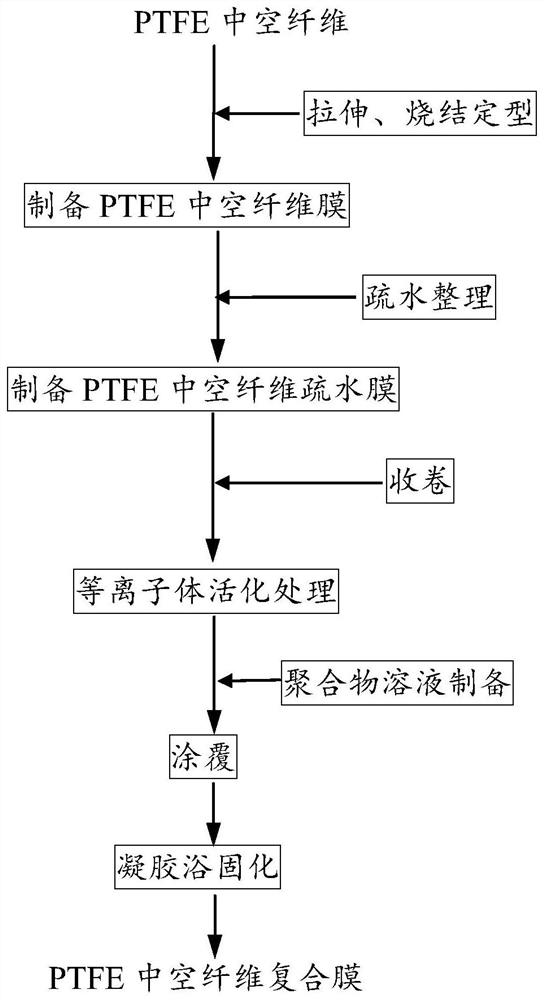

[0057] The technical process of the preparation of the PTFE hollow fiber composite membrane in this embodiment is according to figure 1 carry out, but this implementation does not involve the hydrophobic finishing step, the specific operation is as follows:

[0058] Step 1. Stretch the PTFE hollow fiber obtained after push molding and heat treatment to remove additives. The stretching ratio is 300%, and the stretching temperature is 30°C. A PTFE hollow fiber membrane is prepared.

[0059] Step 2: Perform dynamic plasma activation treatment on the PTFE hollow fiber membrane prepared by stretching, using a pipeline electrode with a treatment speed of 6m / min, a treatment power of 10kW, and a treatment distance of 3mm, and the electrodes are located in an air atmosphere.

[0060] Step 3, at first, prepare polymer solution: dissolve thermoplastic polyurethane in dimethylformamide solvent, prepare the solution of polymer concentration 15wt%, add the chloroform of polymer solution g...

Embodiment 2

[0063] The preparation process of the PTFE hollow fiber composite membrane of the present embodiment is as follows figure 1 As shown, the specific operation is as follows:

[0064] Step 1, using the same PTFE hollow fiber as in Example 1 step 1 to stretch, the stretching ratio is 600%, and the stretching temperature is 30°C; after stretching, the PTFE hollow fiber membrane is obtained by sintering at 400°C and 1min; further The PTFE hollow fiber membrane is diluted with n-hexane to a perfluorodecyltrichlorosilane hydrophobizing agent with a concentration of 3wt%, soaked at 40°C for 10s, dried and then cooled and wound to prepare a PTFE hollow fiber membrane with stronger hydrophobicity.

[0065] Step 2: Perform dynamic plasma activation treatment on the PTFE hollow fiber membrane, using a pipeline electrode, the treatment speed is 3m / min, the treatment power is 5kW, the treatment distance is 5mm, and the electrode is located in the air atmosphere.

[0066] Step 3, first, prep...

Embodiment 3

[0069] The preparation process of the PTFE hollow fiber composite membrane of the present embodiment is as follows figure 1 As shown, the specific operation is as follows:

[0070] Step 1, using the same PTFE hollow fiber as in Example 1 step 1 to stretch, the stretching ratio is 500%, and the stretching temperature is 30°C; after stretching, sintering and shaping at 380°C for 1min to obtain a PTFE hollow fiber membrane; further The PTFE hollow fiber membrane is dipped in perfluorodecyltriethoxysilane diluted to 0.5wt% with n-hexane, soaked at 40°C for 10s, dried and then cooled to make PTFE hollow fiber with stronger hydrophobicity membrane.

[0071] Step 2, the PTFE hollow fiber membrane is subjected to dynamic plasma activation treatment, the electrode used is a pipeline electrode, the treatment speed is 30m / min, the treatment power is 8kW, the treatment distance is 10mm, and a continuous oxygen concentration of 10v / v% is introduced into the electrode. A mixture of oxygen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com