PVC (polyvinyl chloride) foaming profile and preparation method thereof

A profile and foaming agent technology, applied in the field of PVC foam profiles and their preparation, can solve the problems of high energy consumption, weak corrosion resistance, irregular reinforcing ribs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

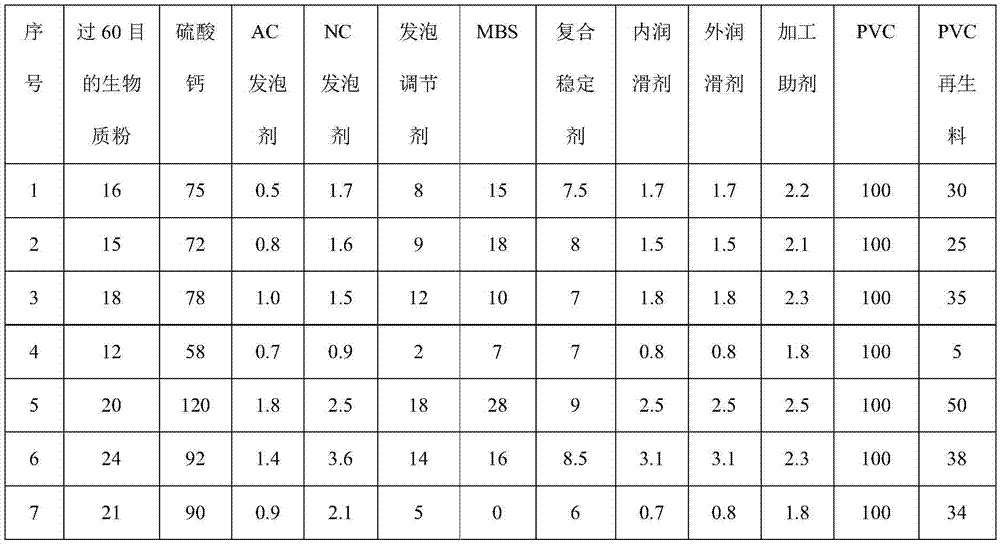

[0035] In terms of parts by weight, the formula composition of the new-type PVC biomass foamed profiles in Examples 1-7 of the present invention according to the serial number 1-7 is as follows:

[0036] Table 1

[0037]

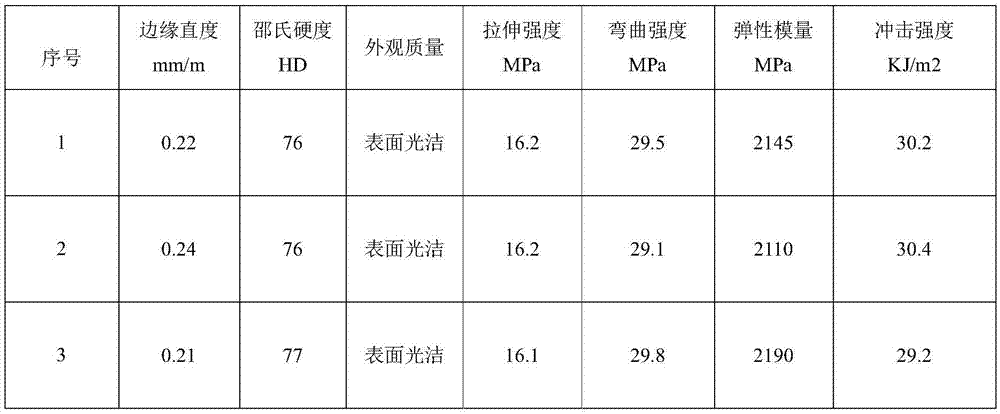

Embodiment 1-3

[0038] Example 1-3 The process of producing the new PVC biomass foamed profile is as follows:

[0039] Step 1. Put the components in the table into the high-speed mixer and mix thoroughly at high speed, and the temperature reaches 110~120℃, then transfer the mixture from the high mixer to the low-speed cold mixing pot, and lower the temperature to 40~60℃ to get the mixture material;

[0040] Step 2, mixing and extruding the mixture in a counter-rotating conical twin-screw extruder;

[0041] Step 3: Pass the extruded material through a heating die (heating die temperature 165~180℃) and then pump negative pressure to cool and shape;

[0042] Step 4, the material after shaping and cooling is drawn and cut into a certain size product by the auxiliary machine. The working parameters of the counter-rotating conical twin-screw extruder in this embodiment are as follows: The processing temperature is 156°C in the first zone, 165°C in the second zone, 175°C in the third zone, 180°C in the fou...

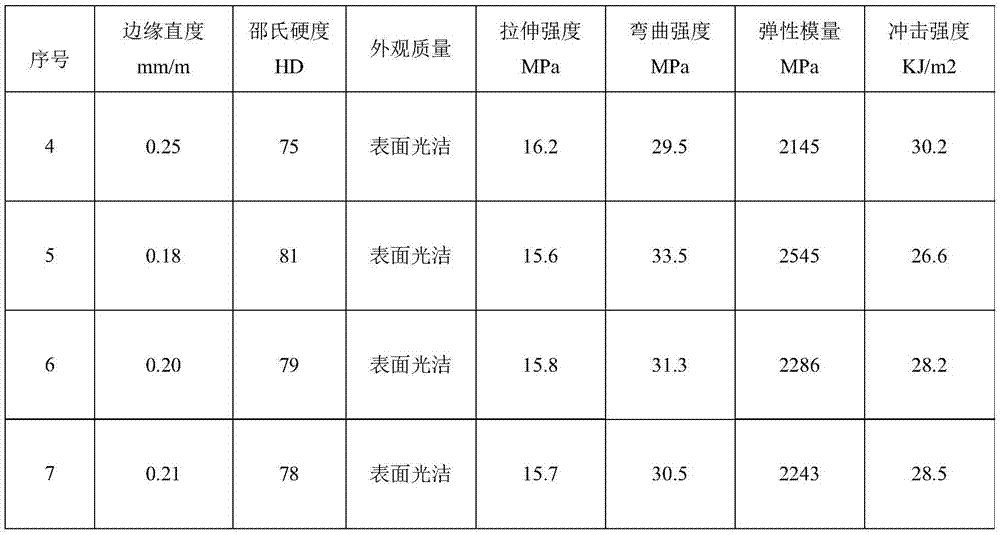

Embodiment 4-7

[0047] The process of producing the new-type PVC biomass foamed profile in Examples 4-7 is as follows:

[0048] Step 1. Put the ingredients in the table into the high-speed mixer and mix thoroughly at high speed, and the temperature reaches 110-120℃, then transfer the mixture from the high-mixer to the low-speed cold mixing pot, and lower the temperature to 40-60℃ to obtain a mixture material;

[0049] Step 2, mixing and extruding the mixture in a counter-rotating conical twin-screw extruder;

[0050] Step 3: Pass the extruded material through the heating mold and then pump negative pressure to cool and shape;

[0051] Step 4, the material after shaping and cooling is drawn and cut into a certain size product by the auxiliary machine. The process parameters of the counter-rotating conical twin-screw extruder in this embodiment are as follows: the processing temperature is 156°C in the first zone, 165°C in the second zone, 175°C in the third zone, 180°C in the fourth zone, 153°C in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com