Patents

Literature

53 results about "Synostosis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synostosis (plural: synostoses) is fusion of two bones. It can be normal in puberty, fusion of the epiphyseal plate to become the epiphyseal line , or abnormal. When synostosis is abnormal it is a type of dysostosis.

Treatment of conditions that present with low bone mass by continuous combination therapy with selective prostaglandin ep4 receptor agonists and an estrogen

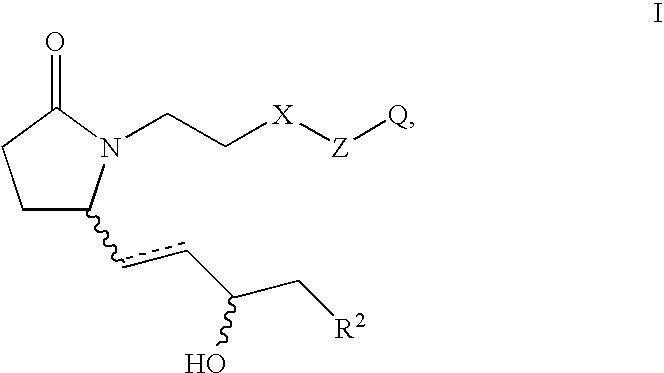

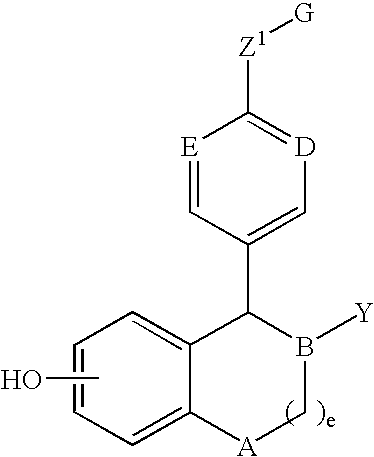

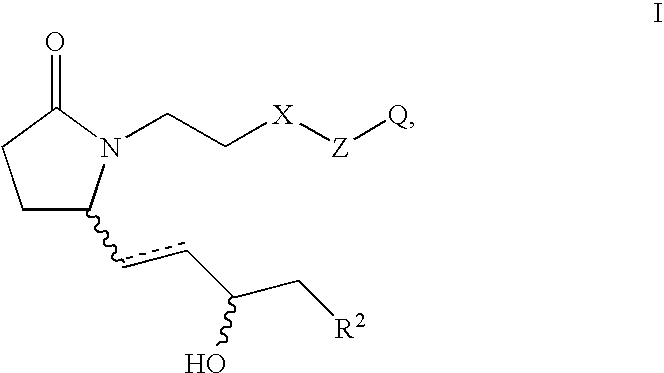

InactiveUS20070191319A1High cure rateLong bone extension is enhancedBiocideSkeletal disorderPresent methodCarboxylic acid

This invention is directed to methods for treating conditions which present with low bone mass in a patient in need thereof using continuous combination therapy with a synergistically effective combination of an EP4 receptor selective agonist or a pharmaceutically acceptable salt thereof, such as 5-(3-{2S-[3R-hydroxy-4-(3-trifluoromethyl-phenyl)-butyl]-5-oxo-pyrrolidin-1-yl}-propyl)-thiophene-2-carboxylic acid or a pharmaceutically acceptable salt thereof; and an estrogen or a pharmaceutically effective salt thereof, The present methods are useful for treating conditions that present with low bone mass including osteoporosis, osteotomy, osteoporotic fracture, childhood idiopathic bone loss, periodontitis and low bone mass and for enhancing bone healing following facial reconstruction, maxillary reconstruction or mandibular reconstruction, inducing vertebral synostosis, enhancing long bone extension, enhancing the healing rate of a bone graft or a long bone fracture or enhancing prosthetic ingrowth in a patient in need thereof.

Owner:PFIZER INC

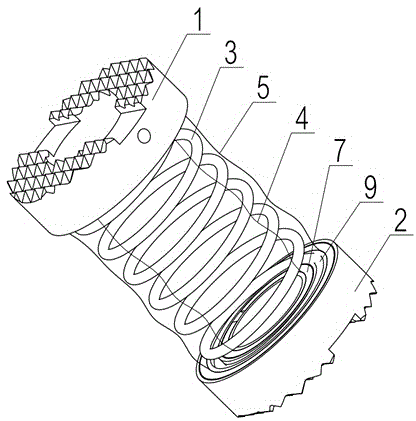

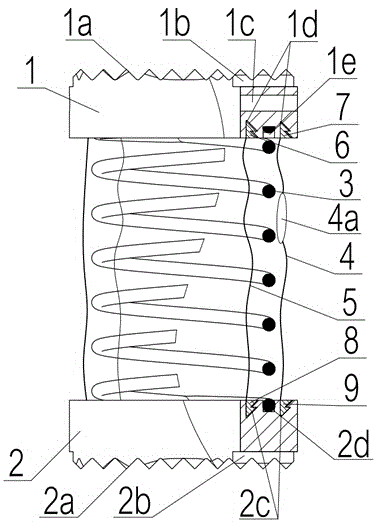

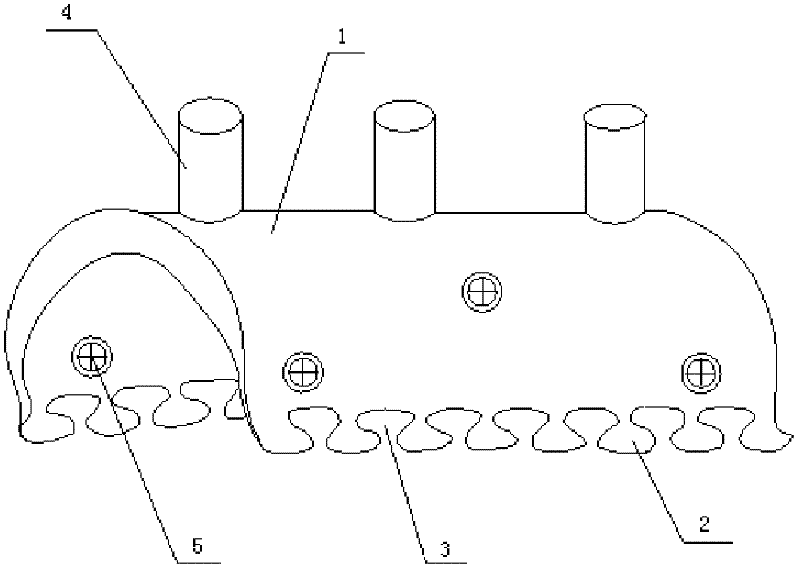

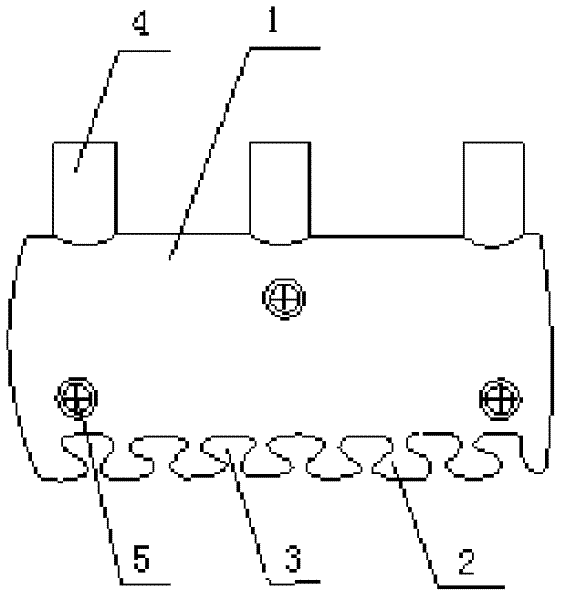

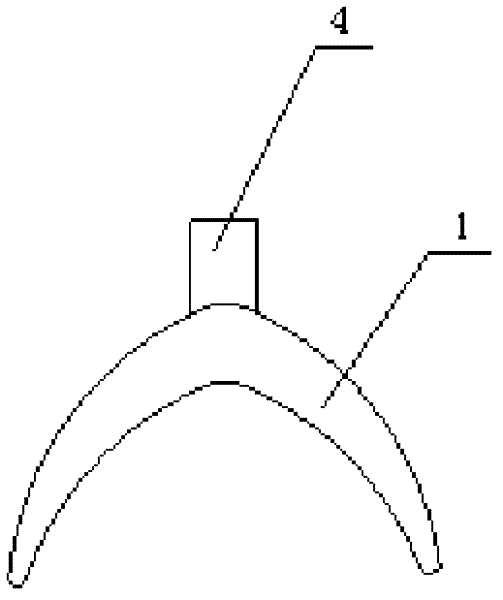

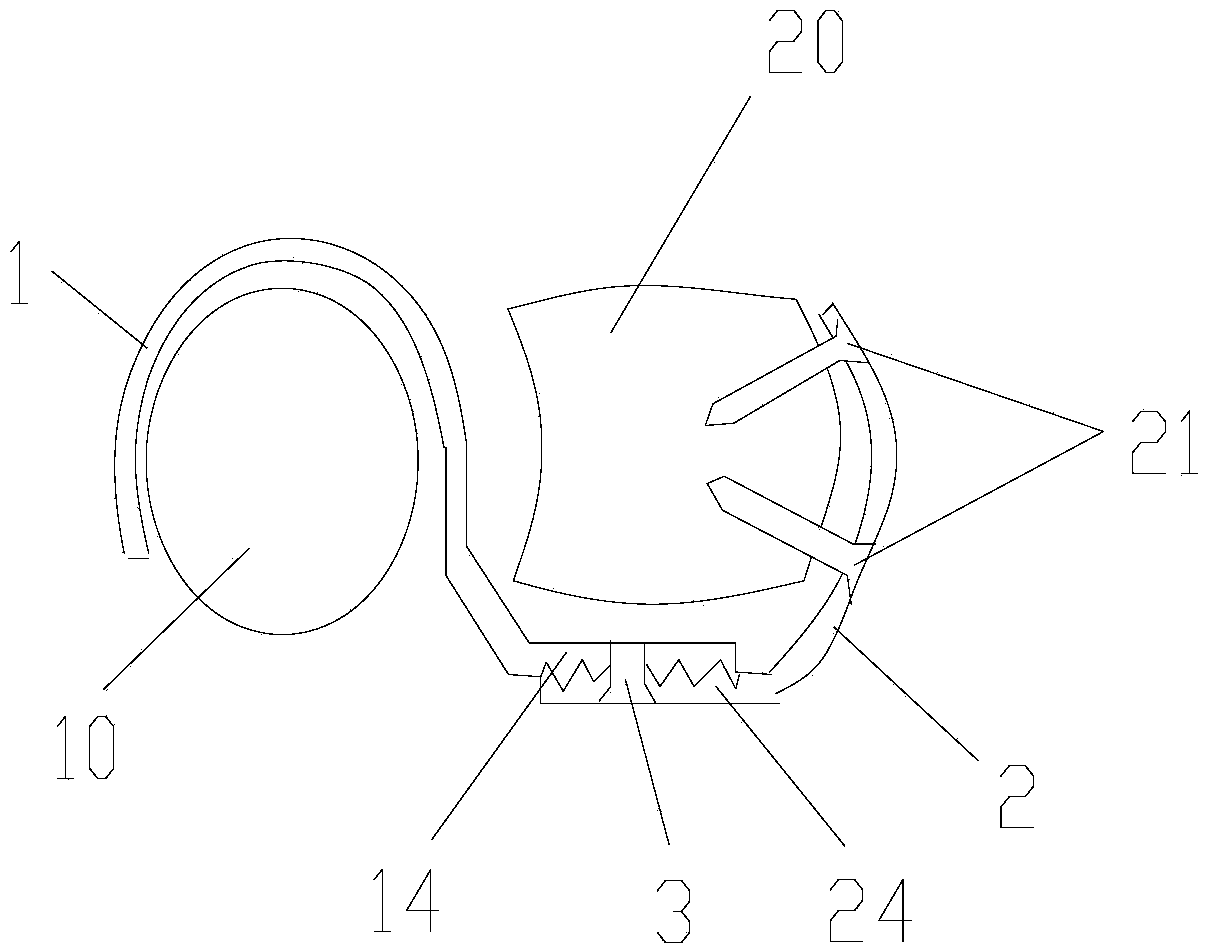

Moldable individual spine fusion device

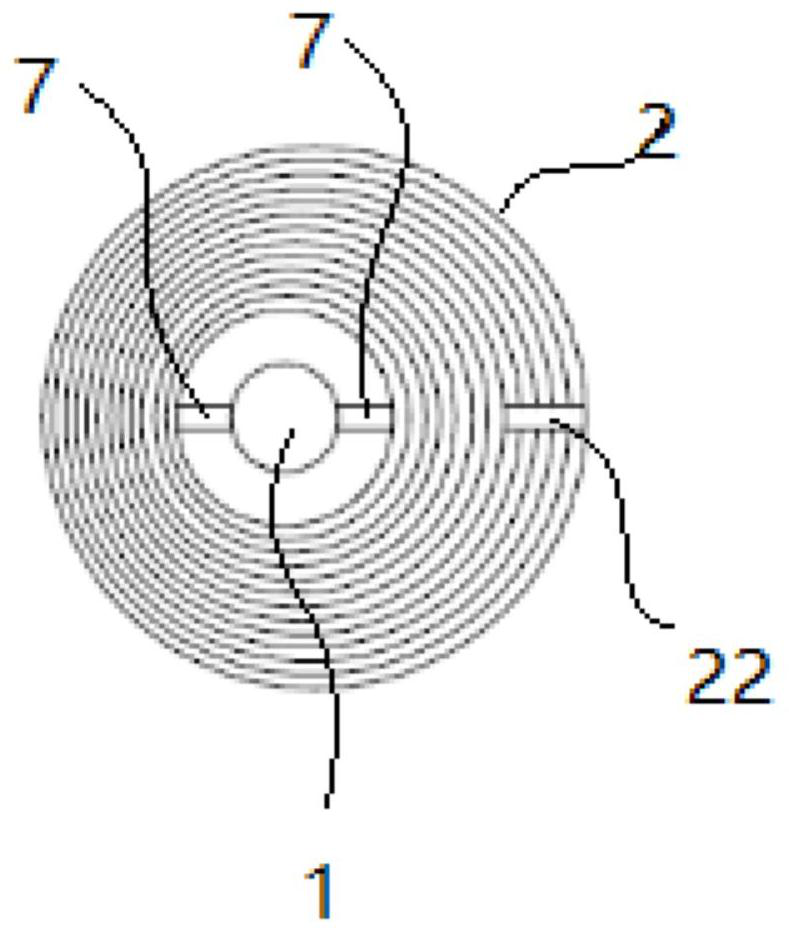

The invention relates to a moldable individual spine fusion device which comprises an upper top plate, a lower top plate, a molding spring, an inner biological silica gel ring, an outer biological silica gel ring, buckles A and buckles B. The upper top plate and the lower top plate are connected together through the molding spring, the inner biological silica gel ring and the outer biological silica gel ring are distributed on the inner side and the outer side of the molding spring and connected to the upper top plate and the lower top plate through the buckles A and the buckles B, and a bone cement injection hole is formed in the outer biological silica gel ring. The moldable individual spine fusion device can be self-adaptively adjusted according to practical physiological characteristics, such as the height (the distance), the angle and the gradient, between fusion centrums of a patient, and the moldable individual spine fusion device can be perfectly attached to the upper centrums and the lower centrums; bone cement is injected into the position between inner biological silica gel and outer biological silica gel, and due to the characteristics of the bone cement, the moldable individual spine fusion device can be rapidly solidified and molded to achieve the good supporting function; sclerotin is injected into an inner cavity of the moldable individual spine fusion device through a hole in the upper top plate, synostosis of the centrums is prompted, and the moldable individual spine fusion device is convenient to implant and has the good market prospects.

Owner:浙江德康医疗器械有限公司

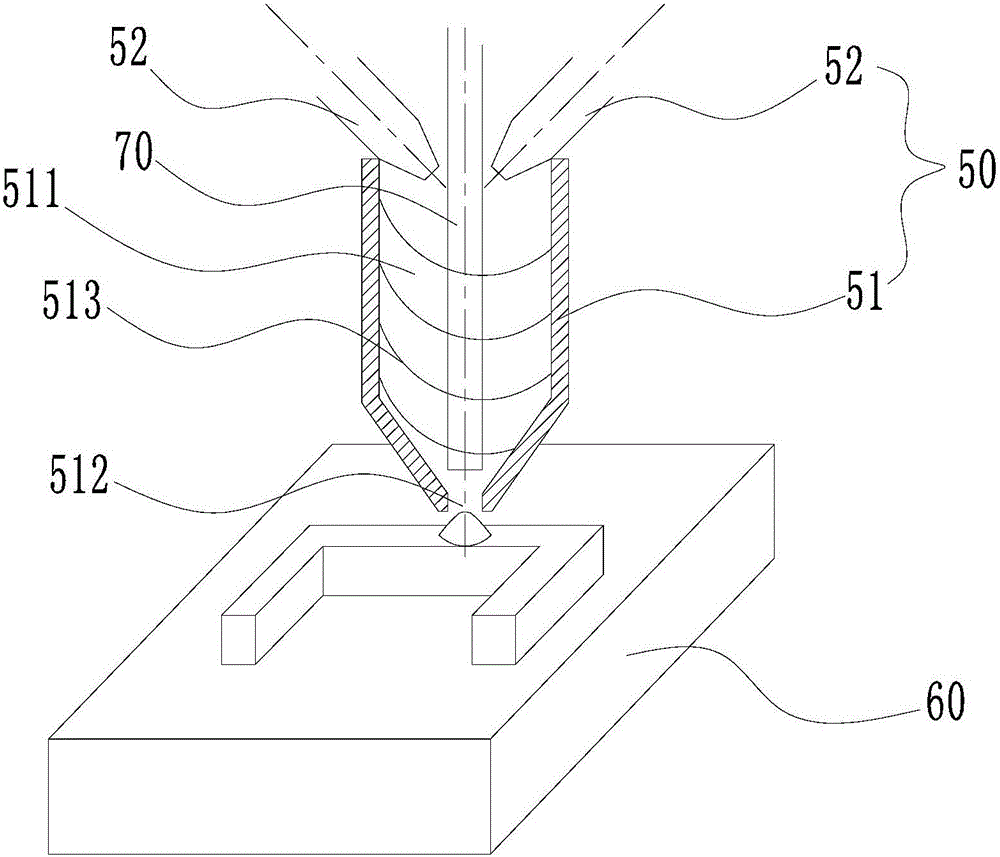

Preparation method of bionic human bone biologic material

InactiveCN101507839AGood biocompatibilityAchieve osseointegrationProsthesisHuman bodyBiocompatibility Testing

The invention provides a method for preparing a bionic human bone biomaterial. The method comprises the steps of utilizing a direct laser selective sintering technique to prepare a human bone bionic micropore bracket, injecting a material with the function of inducing bone growth into the bionic micropore bracket, drying and curing the obtained product and obtaining the bionic human bone biomaterial. The method combines the advantages of metal biomaterials and non-metal biological ceramic materials (hydroxyapatite), and utilizes the direct laser selective sintering technique, a vacuum impregnation technique and the like to prepare a novel bionic human bone biological composite material. The material has the advantages of biomechanical properties similar to natural bones, good biocompatibility, capability of realizing the synostosis of implanted bones and human tissue after the material is implanted into human bodies, safety and reliability. The bionic human bone biomaterial prepared by the preparation method has ultimate tensile strength more than 300 MPa, elongation between 10 and 12 percent, tension-compression elastic modulus less than 50 GPa and good biocompatibility.

Owner:SHAANXI UNIV OF SCI & TECH

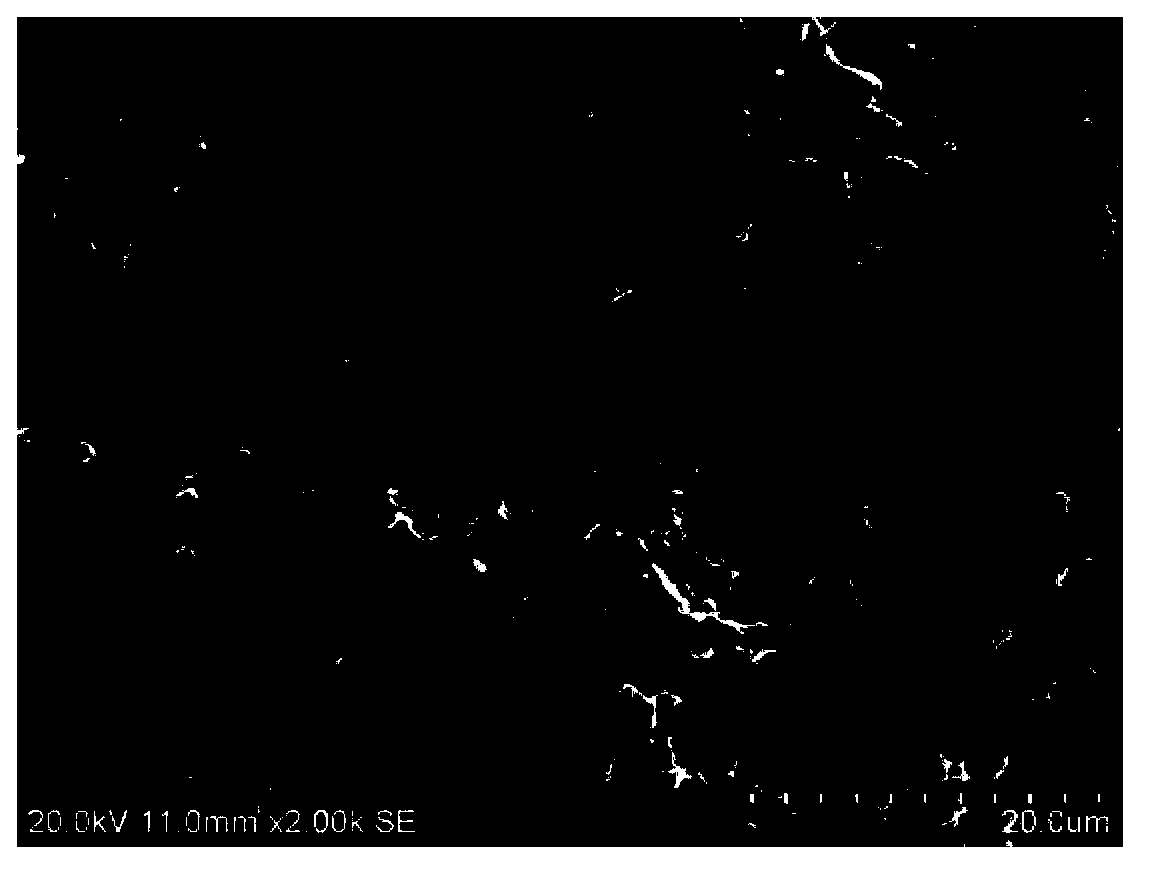

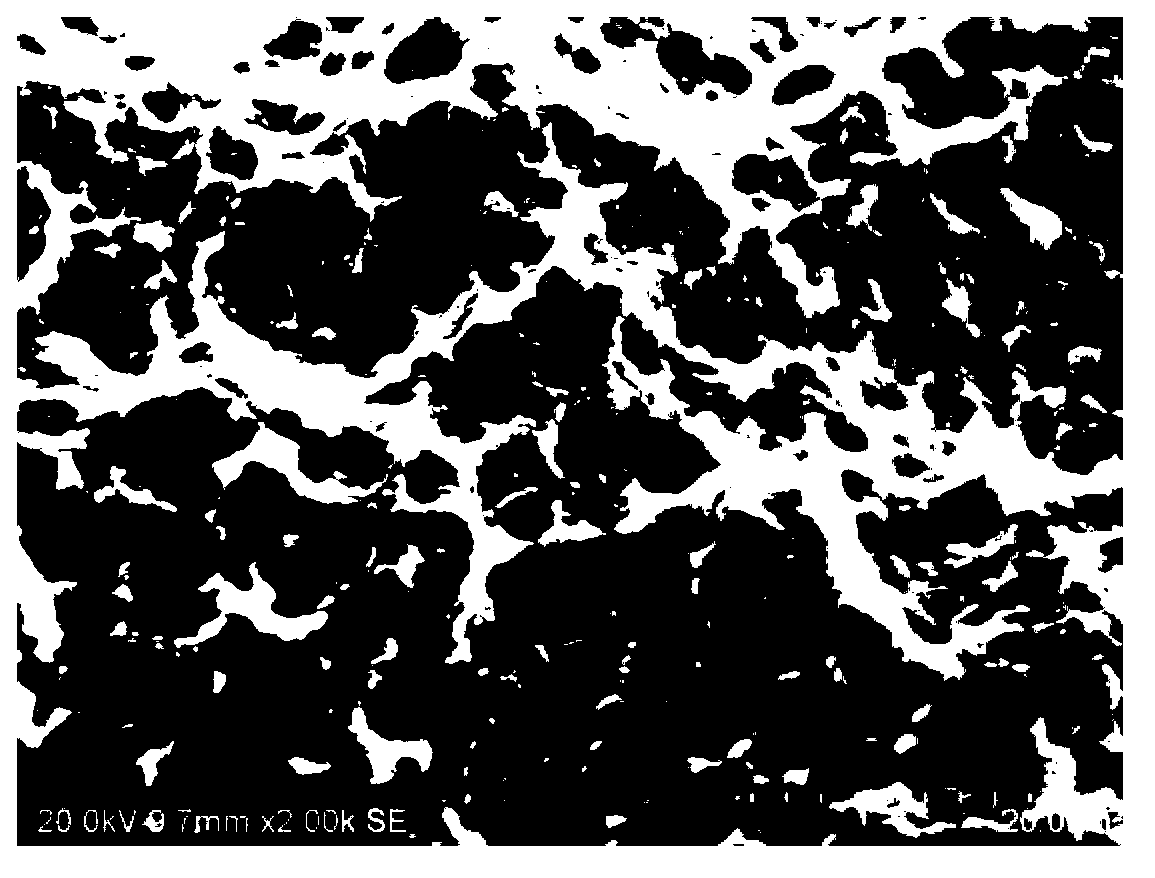

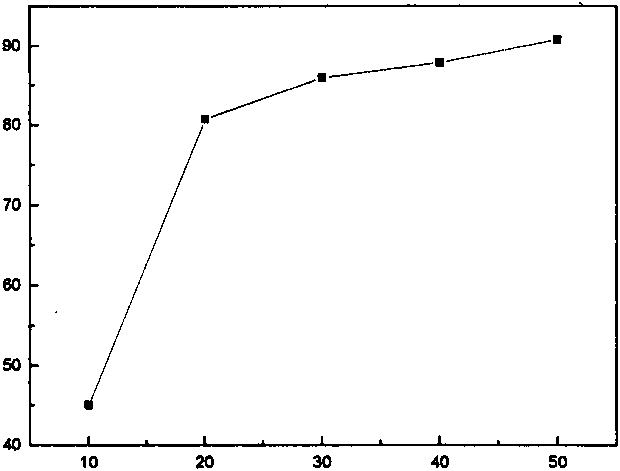

Surface treatment process of bioactive metallic titanium implant having multistage micro-pit structure

InactiveCN103451602ANot easy to fall offInhibit sheddingVacuum evaporation coatingSputtering coatingAcid etchingDrug biological activity

The invention relates to a surface treatment process of a bioactive metallic titanium implant having a multistage micro-pit structure, and the surface treatment process comprises the following steps: pretreatment, sandblasting treatment, acid etching treatment, sputtering treatment and glow discharge treatment; according to the surface treatment process, a multistage micro-pit three-dimensional structure having a bioactive tantalum coating is formed on the surface of the metallic titanium implant, so that the binding strength between the tantalum coating and the metallic titanium implant is very good, the tantalum coating is not easy to shed, shedding of the tantalum coating during or after an implantation process is avoided, the biological activity of the metal titanium implant can be improved, bone deposition of the surface of the metal titanium implant is accelerated, the tissue healing time is shortened, and through the formation of synostosis between the metal titanium implant and a surrounding bone tissue, the effect of improvement of the stability of the metal titanium implant can be achieved.

Owner:JIANGSU TRAUSIM MEDICAL INSTR

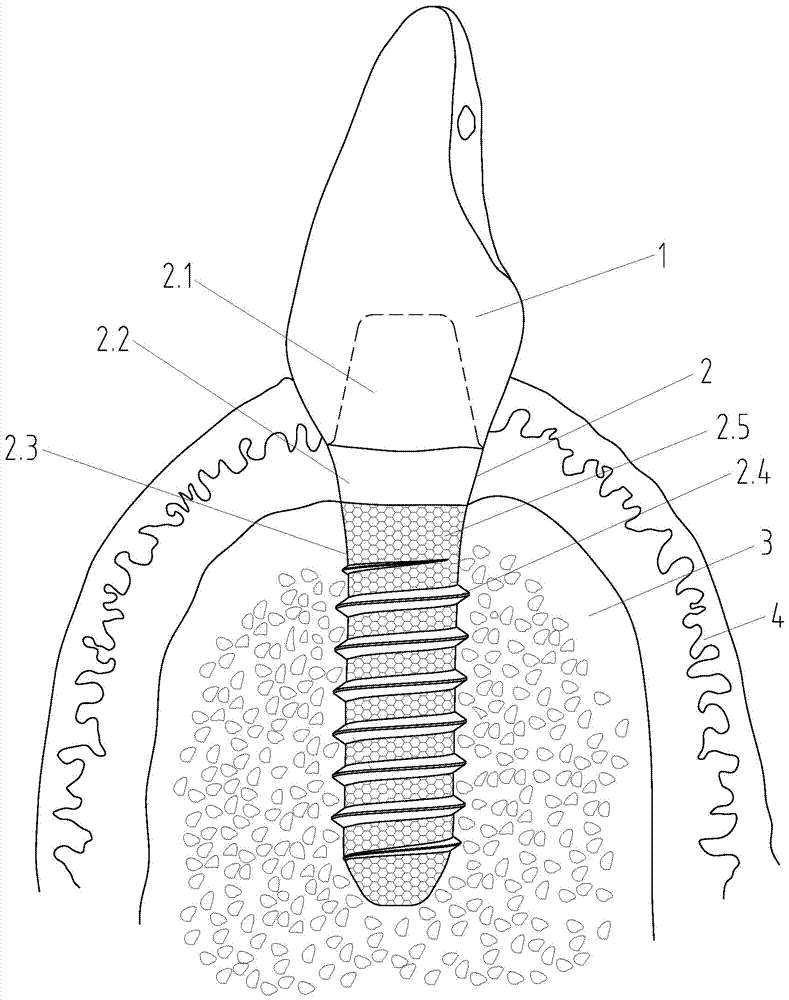

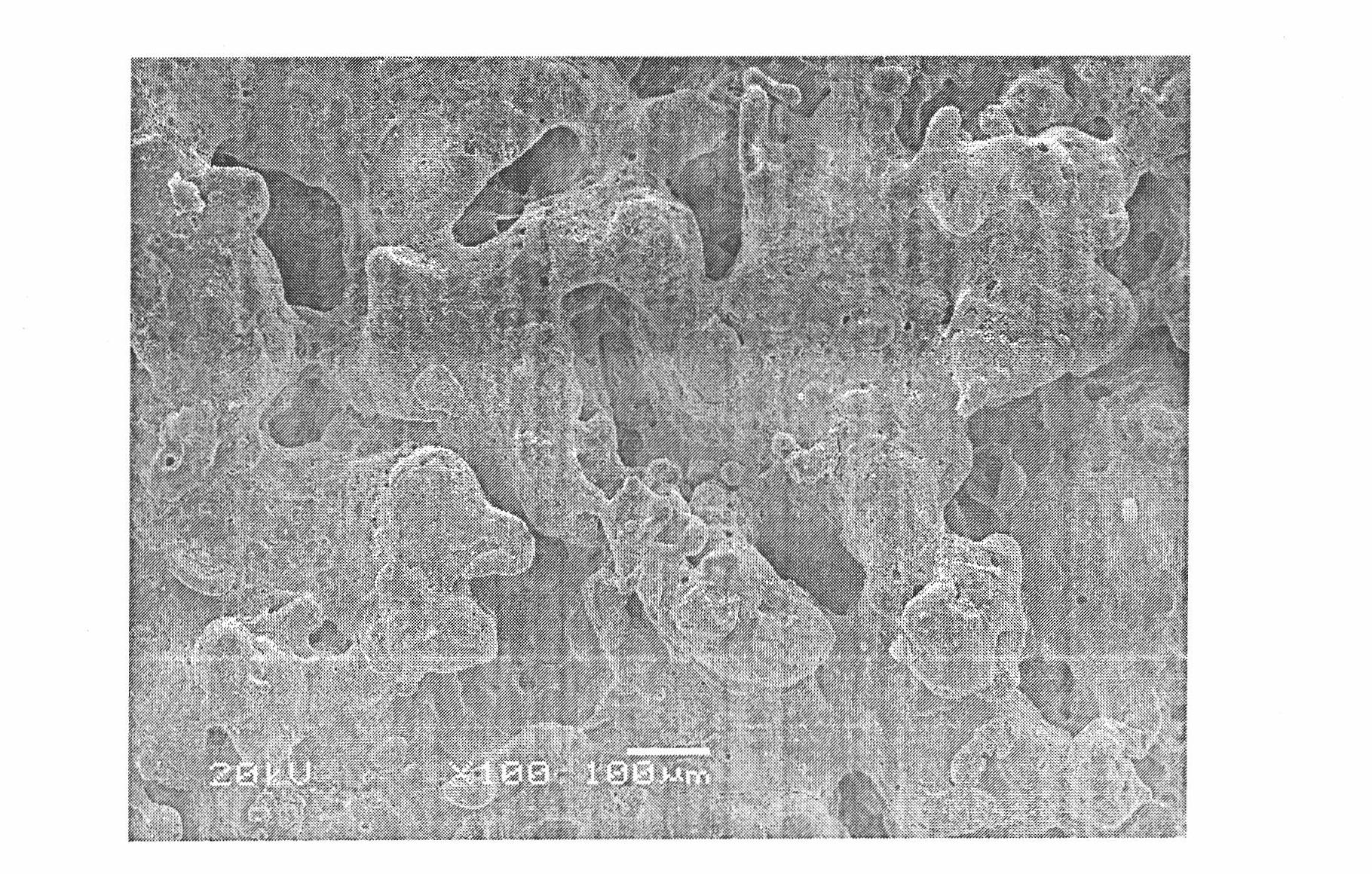

Production method of bone tissue engineering scaffold material artificial tooth root capable of improving synostosis

ActiveCN107961398APromote migrationTo promote metabolismTissue regenerationCoatingsSpray coatingBioactive coating

The invention provides a production method of a bone tissue engineering scaffold material artificial tooth root. The method includes the six steps of: preparing a steel model, preparing an initial green body of the artificial tooth root, processing pores, filling the pores with a PLLA / nHA composite, spray-coating the green body with a PGA / nHA composite coating, and performing surface degradation.In the invention, the initial green body of the artificial tooth root is prepared with a PEEK and HA crystal whisker composite material as a bone tissue engineering scaffold material, wherein at corresponding positions on the green body, pores are processed and are filled with the degradable PLLA / nHA active composite material; finally, the green body is spray-coated with the PGA / nHA bioactive coating and then surface degradation is carried out to produce the bone tissue engineering scaffold material artificial tooth root capable of improving synostosis function. The artificial tooth root can be combined with bone through self-repairing on bones with bone induction cells, so that the elasticity modulus of the tooth root is matched with alveolar bone better, and bone absorption of the alveolar bone is not liable to be caused. The artificial tooth root is greatly better than a common artificial tooth root.

Owner:NANNING YUEYANG TECH

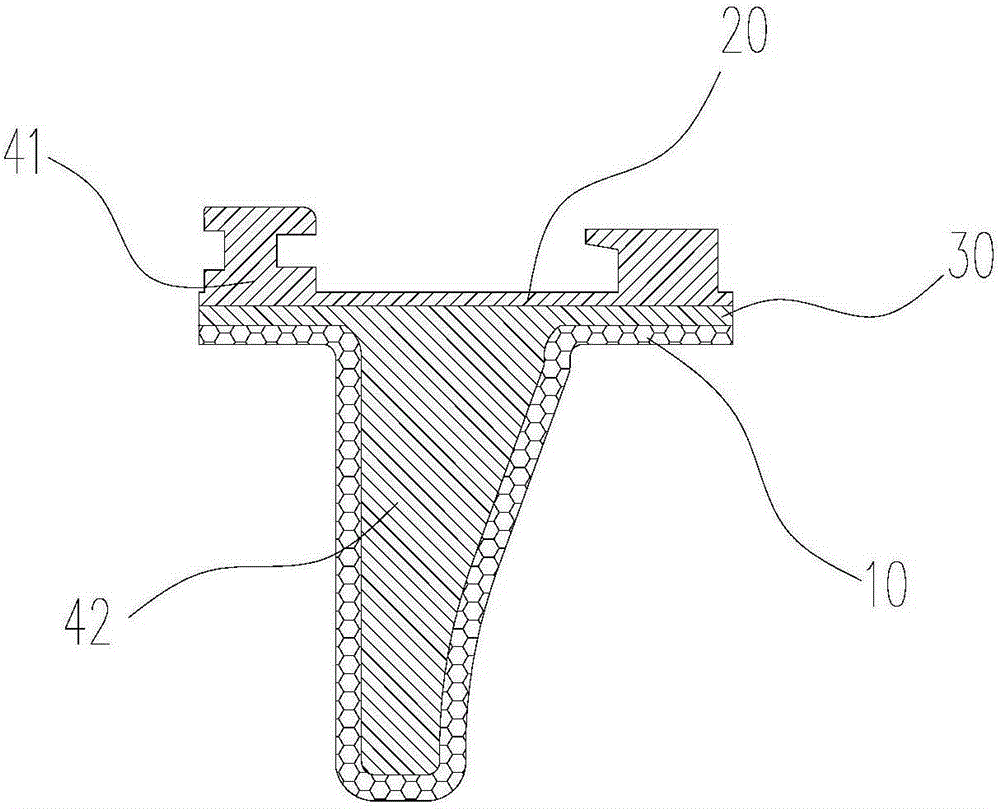

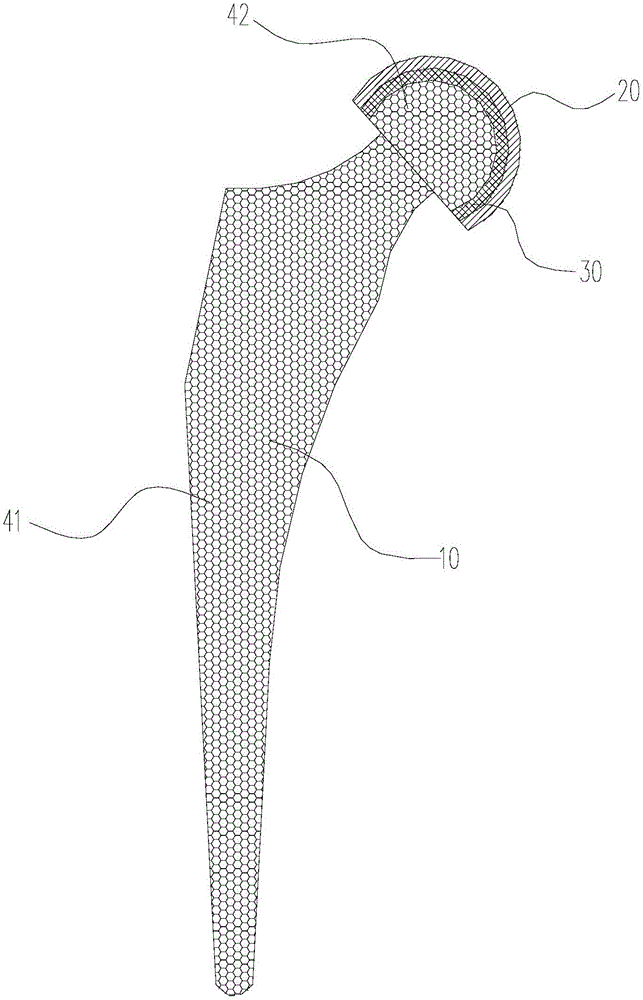

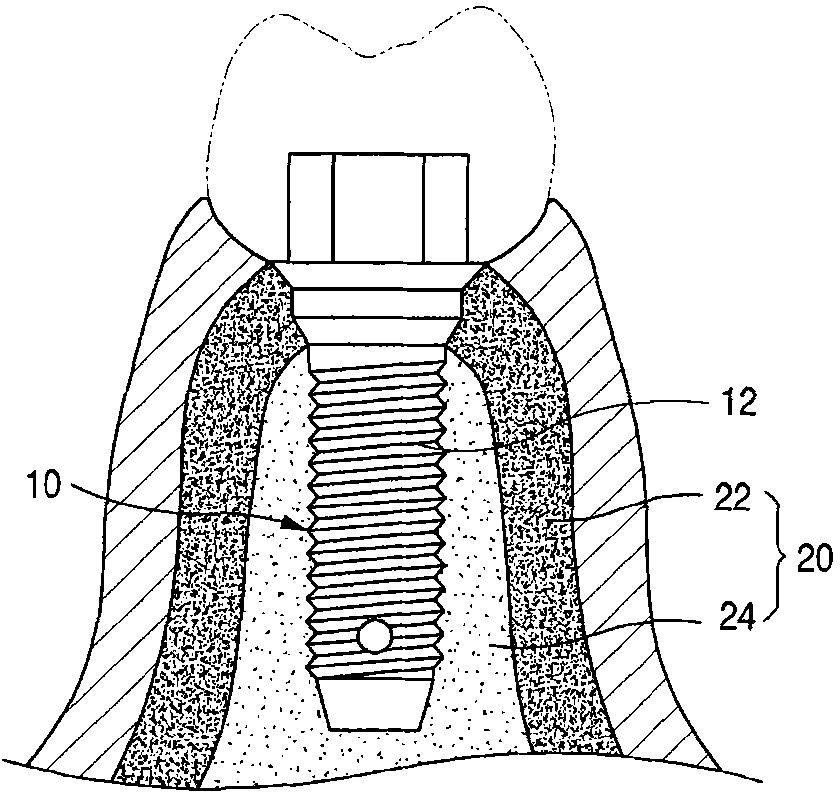

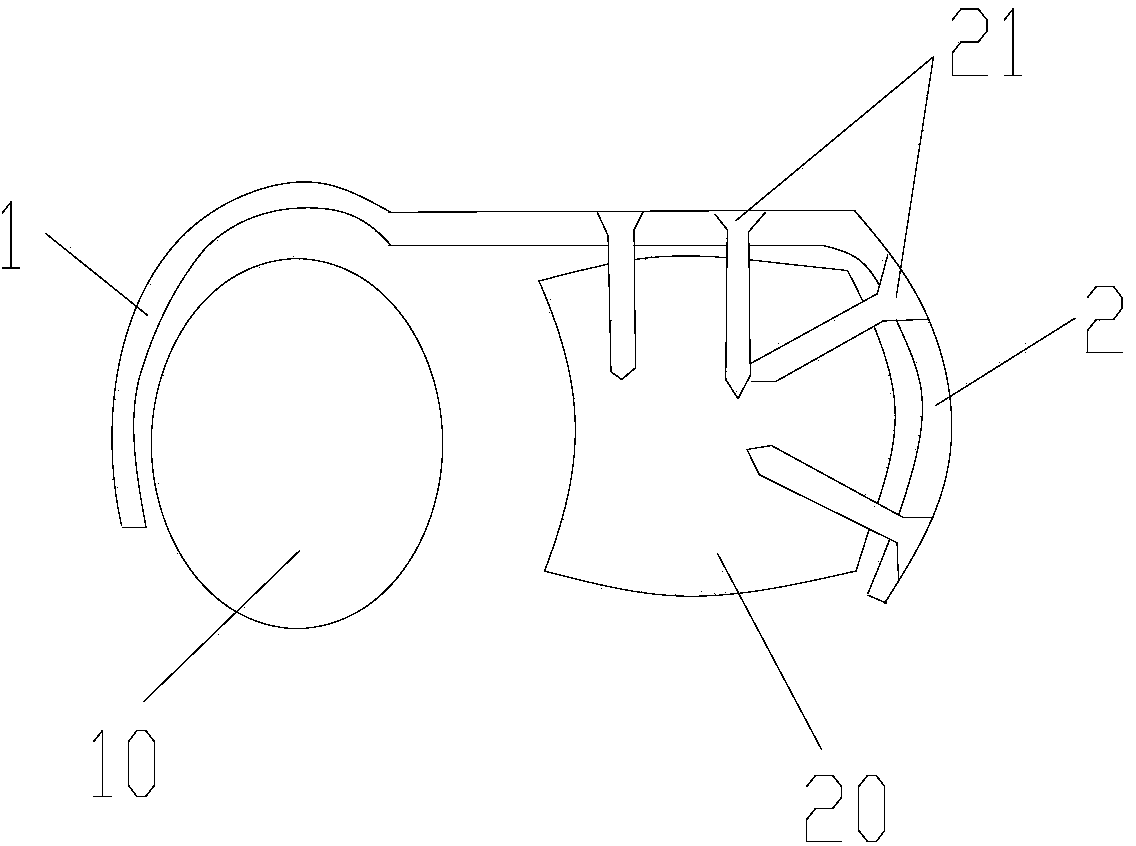

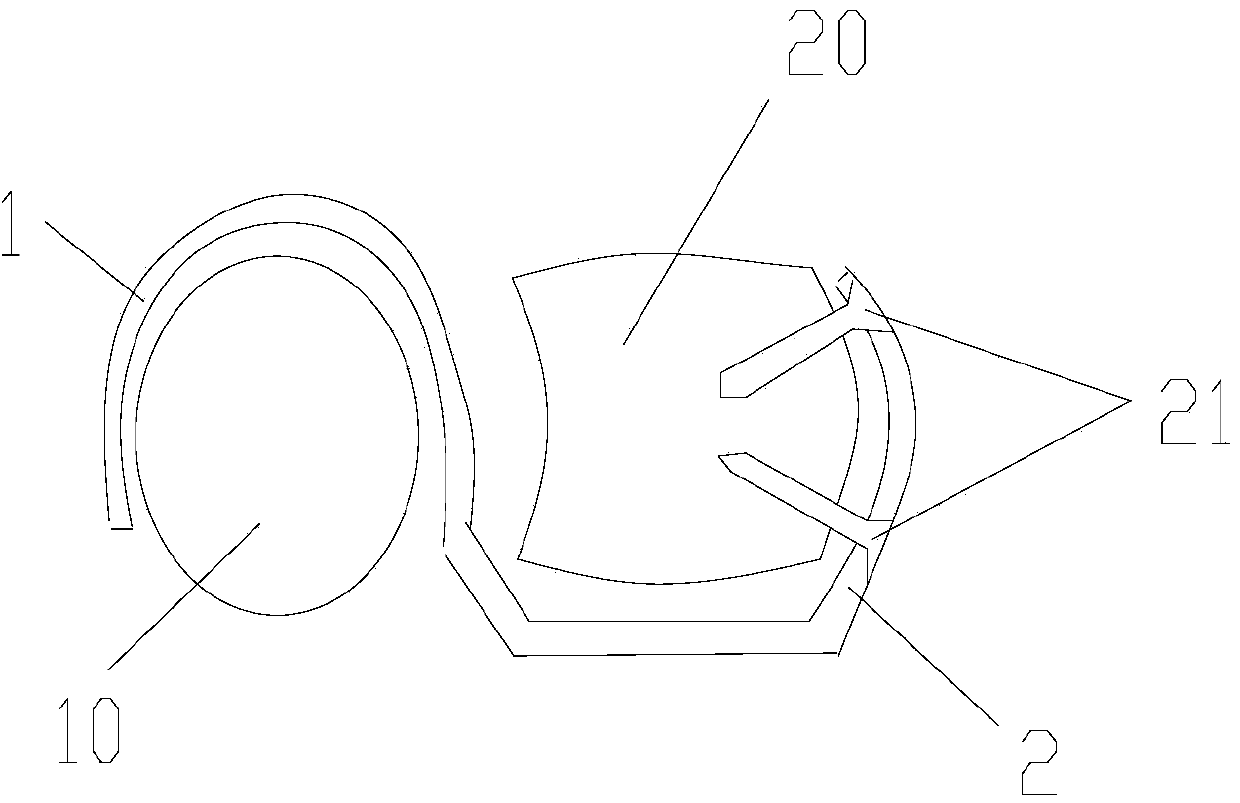

Double-metal prosthesis component

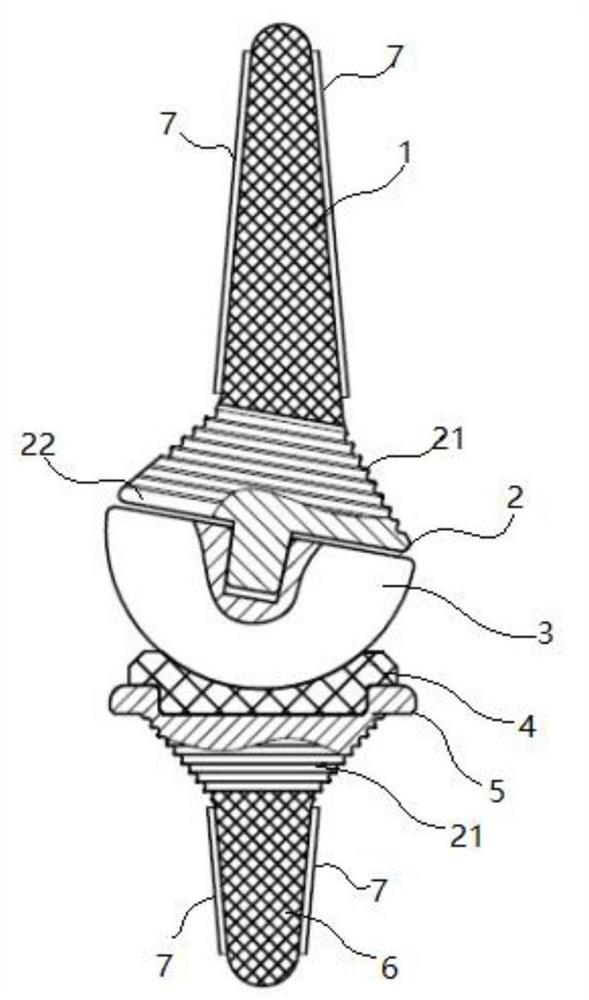

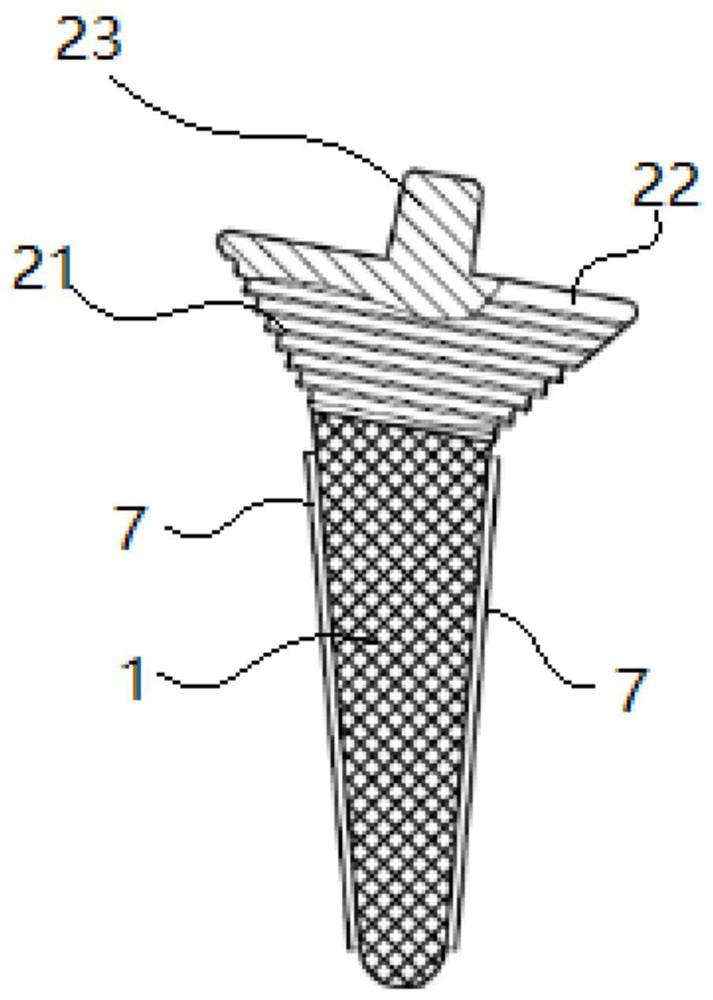

ActiveCN105213069AInhibition of dissolutionNot easy to produceJoint implantsWear resistantProsthesis

The invention provides a double-metal prosthesis component. The double-metal prosthesis component comprises a metal synostosis layer (10), a wear-resistant metal layer (20) and a transition layer (30), wherein the wear-resistant metal layer (20) is arranged on one side of the metal synostosis layer (10), and the transition layer (30) is arranged between the metal synostosis layer (10) and the wear-resistant metal layer (20). The double-metal prosthesis component in the technical scheme is capable of solving the problem of poor metal prosthesis component replacement quality in the prior art effectively.

Owner:BEIJING AKEC MEDICAL

Bioactive bone-repairing cement material

The invention relates to the technology of biological material in the field of biomedical engineering, specifically a preparation technology for bioactive bone-repairing cement material, which is suitable for medical application in the fields of orthopaedics department, thoracic surgery department and reconstructive surgery, such as artificial joint fixation, bone defect filling and implant restoration. The invention relates to a new material which is a combination of powder and liquid with bioactivity for bone repairing and is characterized in that the combination comprises a powder component including homopolymerization powder of methyl methacrylate or copolymerization powder of methyl methacrylate, and a sosoloid powder doped with strontium hydroxyapatite capable of being hardened and solidified to form solid substance with a certain mechanical intensity and synostosis activity when mixed with the liquid component. The main component of the liquid includes methyl methacrylate monomer, which can form bioactive bone-repairing cement when mixed with the powder component. Compared with the prior art, the material can further increase osteoconduction and osteoconduction activity of the combination, and accelerate healing of bone defect part; thus, the material is suitable for orthopaedics department and craniomaxillofacial plastic repair.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

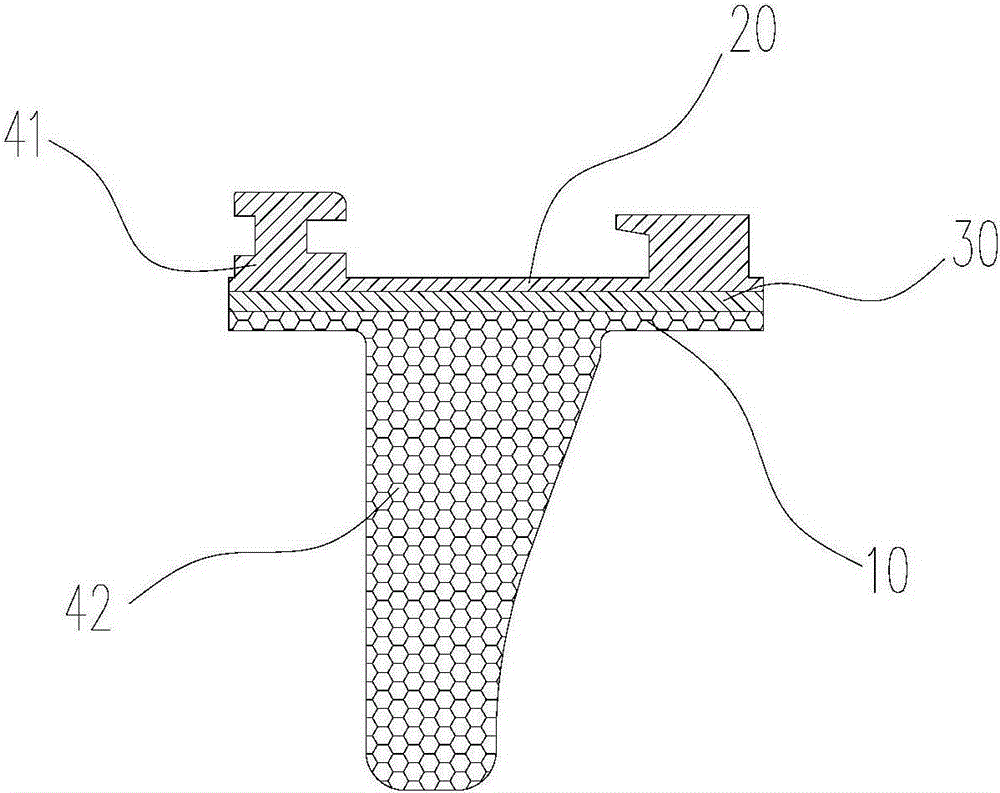

Bimetal prosthesis part

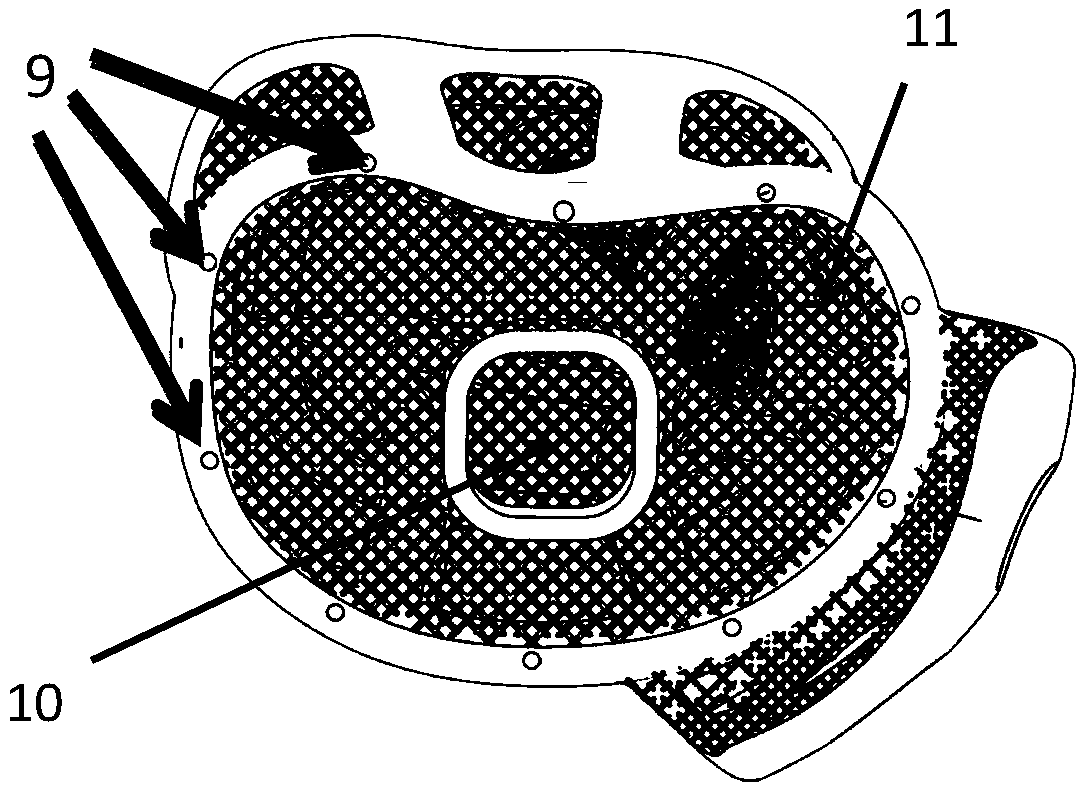

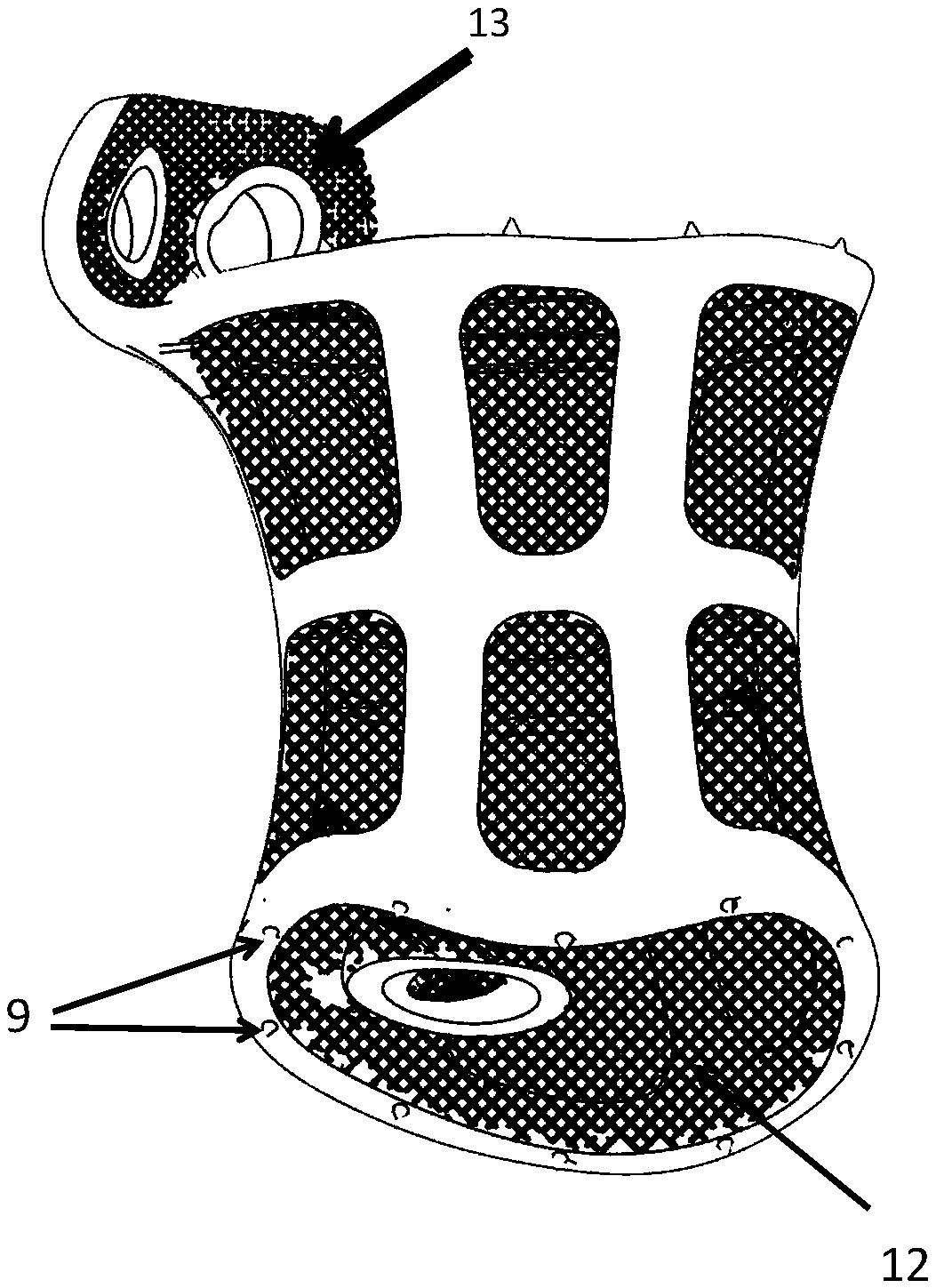

ActiveCN105105871AInhibition of dissolutionNot easy to produceBone implantJoint implantsWear resistantProsthesis

The invention provides a bimetal prosthesis part. The bimetal prosthesis part comprises a synostosis metal layer (10), a metal wear-resistant layer (20) arranged on one side of the synostosis metal layer (10), and a transition layer (30) arranged between the synostosis metal layer (10) and the metal wear-resistant layer (20). According to the technical scheme, the problem that in the prior art, a metal prosthesis part is not good in replacement quality can be effectively solved.

Owner:BEIJING AKEC MEDICAL

Method for preparing rhizoma drynariae/pig bone powder/chitosan compound bracket material

The invention adopts a method for preparing a medicated tissue engineering bracket material by a fully natural material, which overcomes the defects of slower growth of bone tissues at the initial period of implantation and weak synostosis at the initial period in the traditional tissue engineering bracket. The traditional Chinese medicines of rhizoma drynariae and pig bone type hydroxylapatite are introduced into the bracket to obtain a compound tissue engineering bracket material with excellent biological activity. The pig bone type hydroxylapatite is extracted from pig bones, has excellent biological activity and low production cost, is green and innoxious and is pulverized to reach a micron / nano state; the traditional Chinese medicine of the rhizoma drynariae has the functions of promoting the multiplication of osteoblast, accelerating the bone growth, diminishing inflammation and resisting bacteria and is prepared by an effective water extraction solvent method, a pulverization method and a spraying method; and the chitosan is used as a template and is prepared by a vacuum freeze drying method. The porosity of the bracket material is between 45% and 91%, the aperture is adjustable within a range of 40-500mu m, and the compressive strength can reach 0.1-5.6MPa. In the degradation process, the pH value of the bracket is between 6.77 and 7.50.

Owner:JIAMUSI UNIVERSITY

Bone repair implant coated with strontium-doped calcium polyphosphate coating and preparation method thereof

InactiveCN101927034AImprove biological activityGood biocompatibilityImpression capsDentistry preparationsOsteoblastTitanium metal

The invention discloses a bone repair implant coated with a strontium-doped calcium polyphosphate coating and a preparation method thereof. The implant is titanium metal of which a surface is coated with the strontium-doped calcium polyphosphate (SCPP) coating. The preparation method mainly comprises the following steps of: (1) spraying 150 to 300-mesh strontium-doped calcium polyphosphate powder to the surface of a titanium metal substrate to form the coating in a way of blowing the powder over a plasma flame by using plasma spraying equipment, and after coating the surface of the titanium metal substrate fully, cooling the titanium metal substrate naturally to obtain a primary product of the implant material; and (2) cleaning and drying the primary product of the implant material, preserving the heat and annealing the primary product at 700 to 800 DEG C, and after full annealing, cooling the primary product slowly to obtain the prepared implant product. The implant disclosed by the invention has higher bioactivity and the functions of promoting osteocyte growth and vascularization, can improve interface compatibility between the implant and tissues and promote synostosis, can be used as a bone repair material and an oral dental implant, and is easy to popularize commercially.

Owner:成都华西一为生物植体科技有限公司

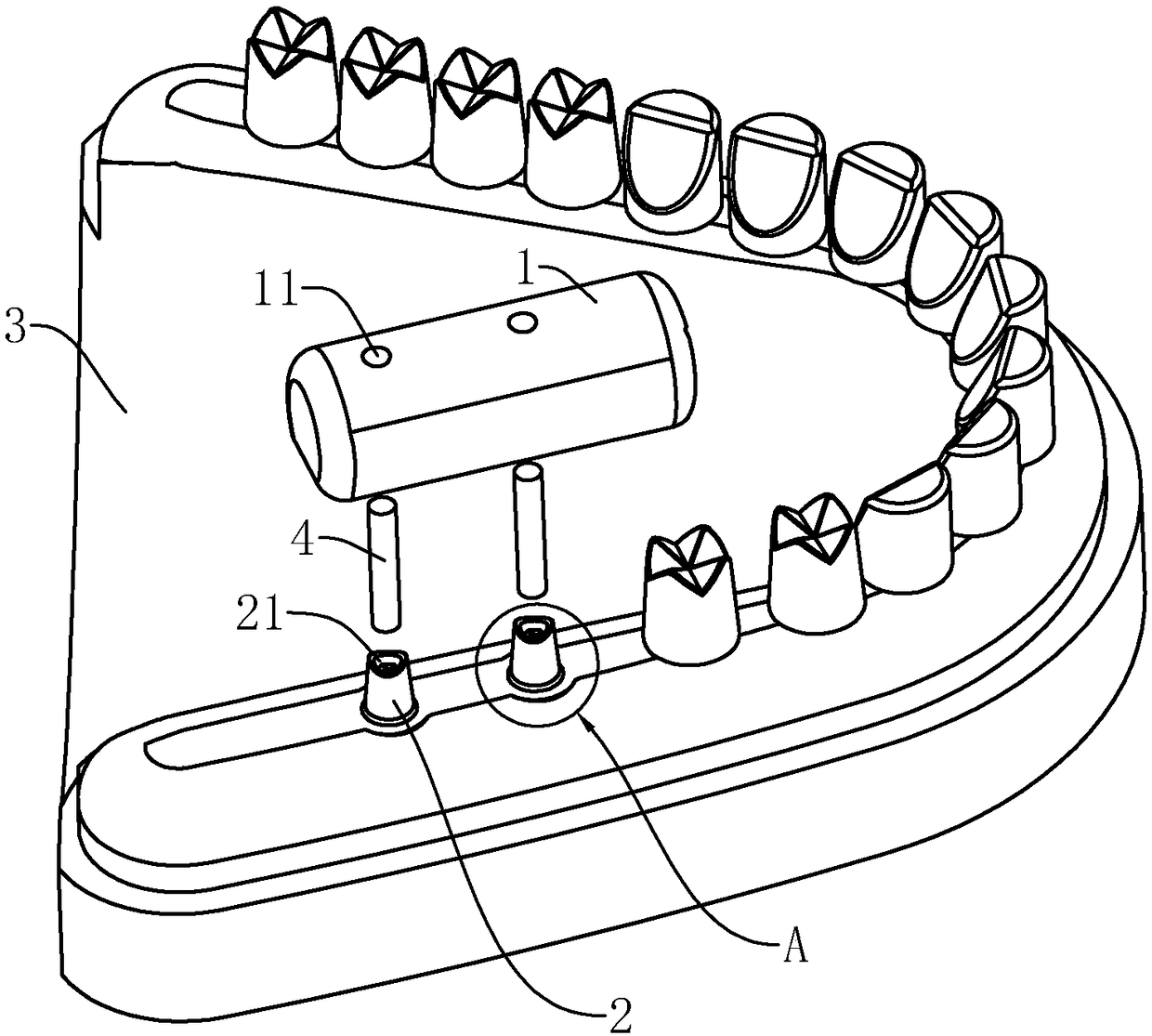

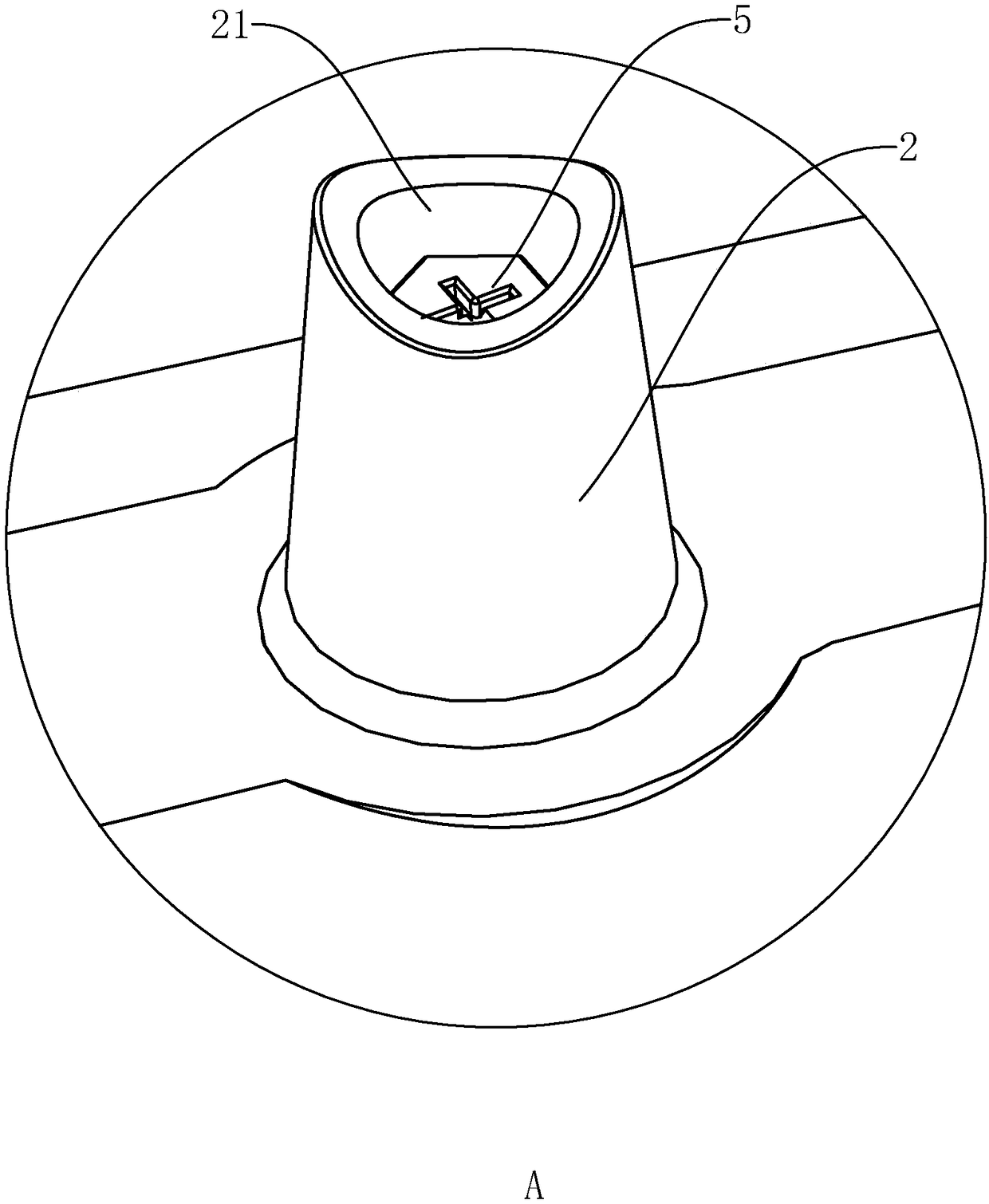

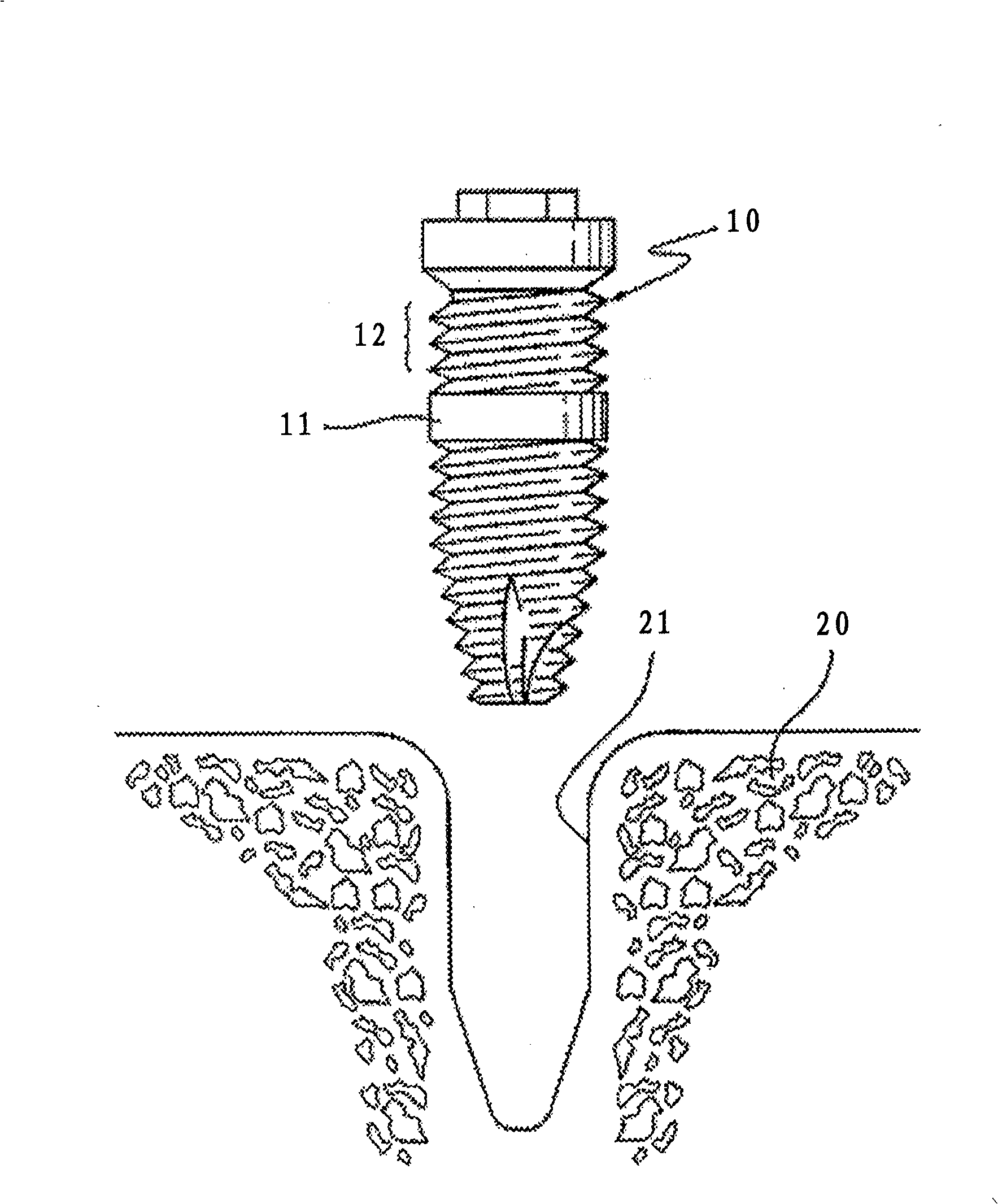

Dental implant implantation method

The invention relates to a dental implant, in particular to a dental implant implantation method which comprises the following steps of S1, rubbing an oral cavity model of a patient; S2, preparing a hole in an alveolar bone, and implanting an artificial implant; S3, waiting for synostosis; S4, installing a healing abutment to enable the implant to penetrates through a gingiva, and waiting for formation of soft tissues; S5, preparing a locator according to the oral cavity model of the patient; S6, after formation of the soft tissues, dismantling the healing abutment, putting the locator and a permanent abutment at the implantation part of the patient after the locator and a permanent abutment are matched to enable the locator to be matched with teeth and the gingivae on the two sides of theimplantation part, and installing an abutment fixing bolt from an installation hole to fix the permanent abutment on the implant; and S7, wearing a dental crown on the permanent abutment. By adoptingthe dental implant implantation method provided by the invention, the locator is adopted to assist location when the permanent abutment is installed, and the effect of accurately locating and installing the position of the permanent abutment is achieved.

Owner:北京康泰健瑞牙科技术有限公司

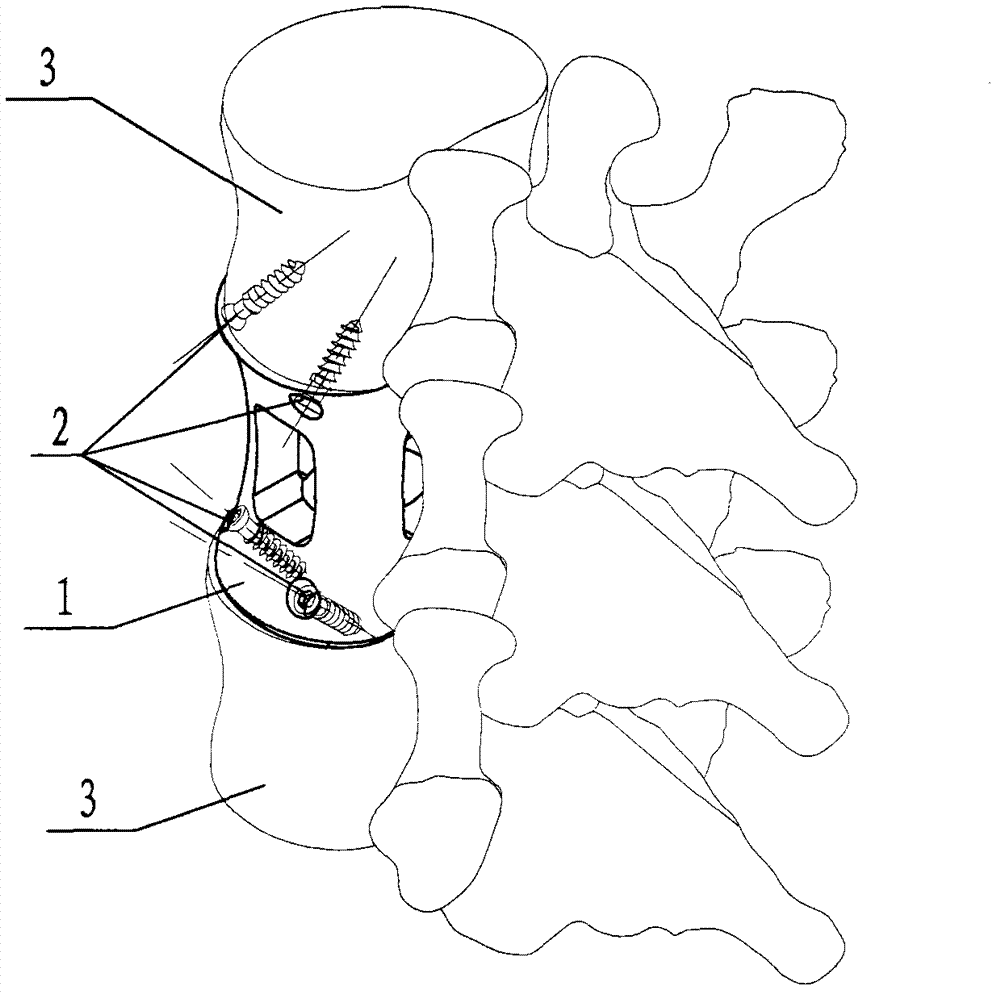

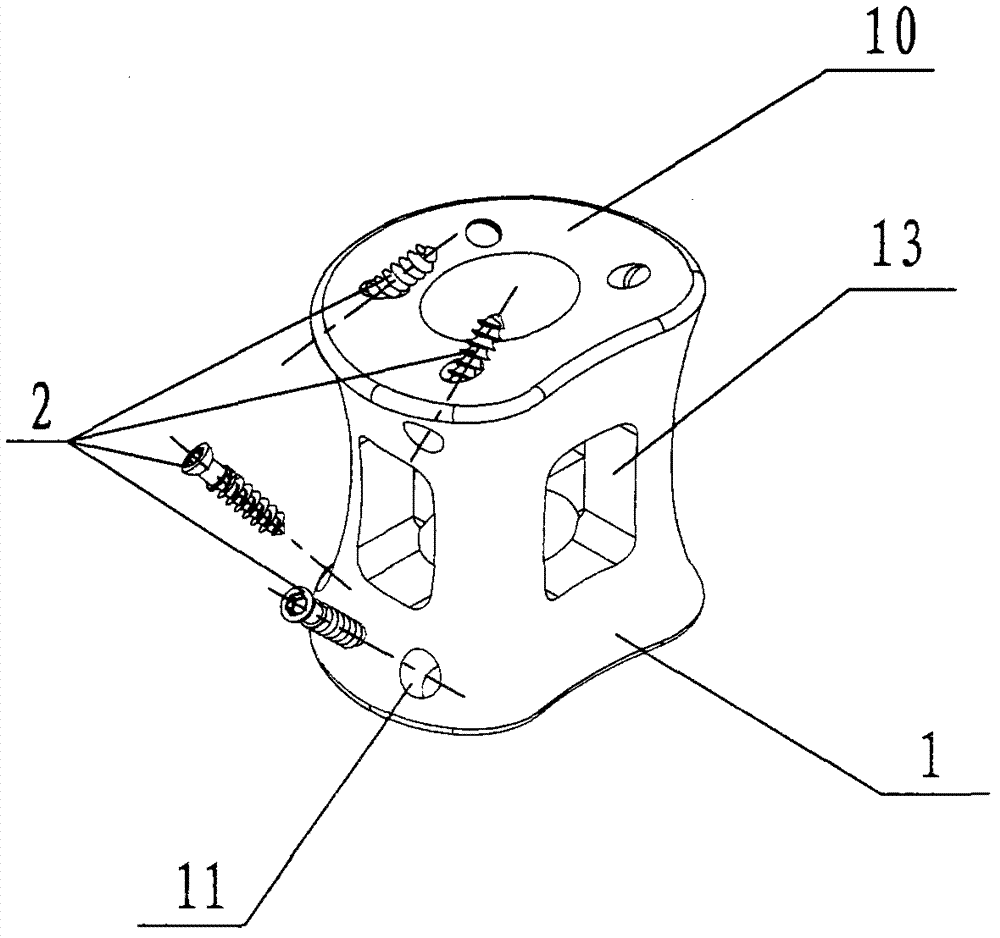

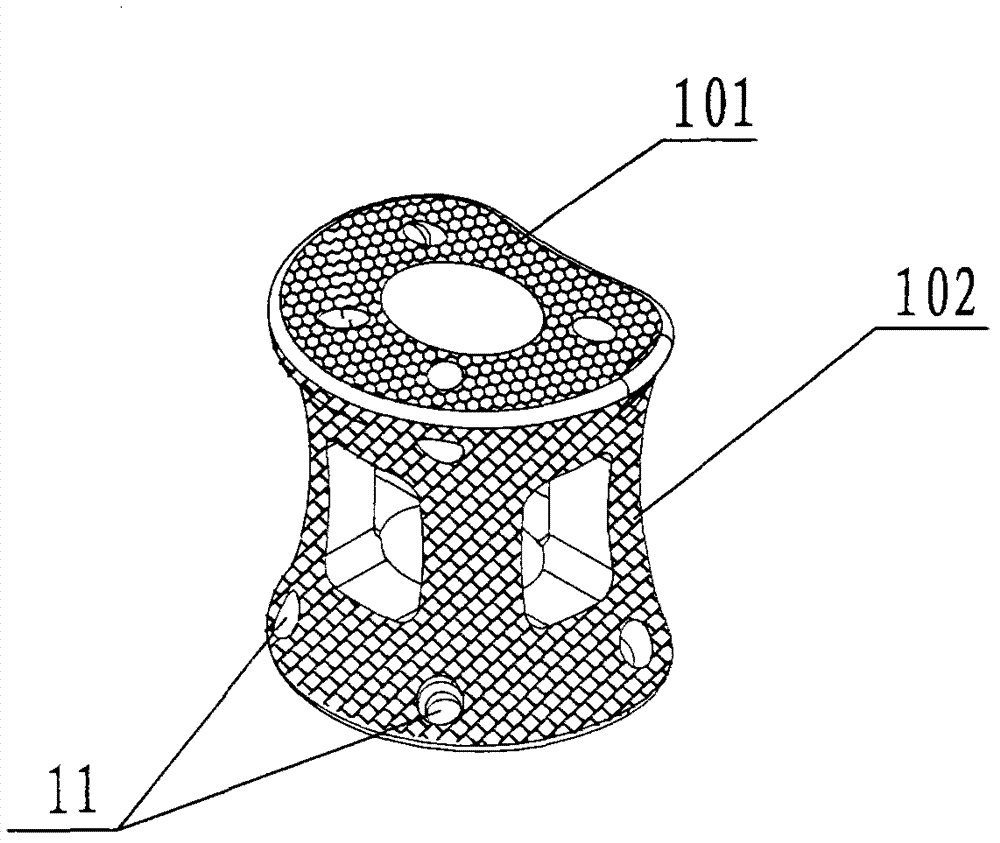

Self-stabilization artificial vertebral body

InactiveCN103239305AAchieve long-term stabilityInternal osteosythesisSpinal implantsSelf-stabilizationSynostosis

The invention relates to a self-stabilization artificial vertebral body which is used for being inserted to replace resected or deleted parasitic vertebral body sections. The self-stabilization artificial vertebral body comprises a vertebral body main body and vertebral body fixing screws. An integration surface of the vertebral body main body and a vertebral body is a microcellular structure which is beneficial to ingrowth of bone cells. In an operation, the vertebral body main body with the suitable height is installed into the position with a damaged parasitic vertebral body section taken out and the vertebral body main body is fixed with an adjacent upper main healthy vertebral body and an adjacent lower main healthy vertebral body through the vertebral body fixing screws by penetrating through vertebral body fixing screw holes. The self-stabilization artificial vertebral body has the advantages of being good in instance stability after the operation and good in synostosis to effectively resist to subsidence, enabling the height of the replaced vertebral body to be continuously kept and being free of incisure after the operation and simple and reliable in operation.

Owner:BEIJING AKEC MEDICAL

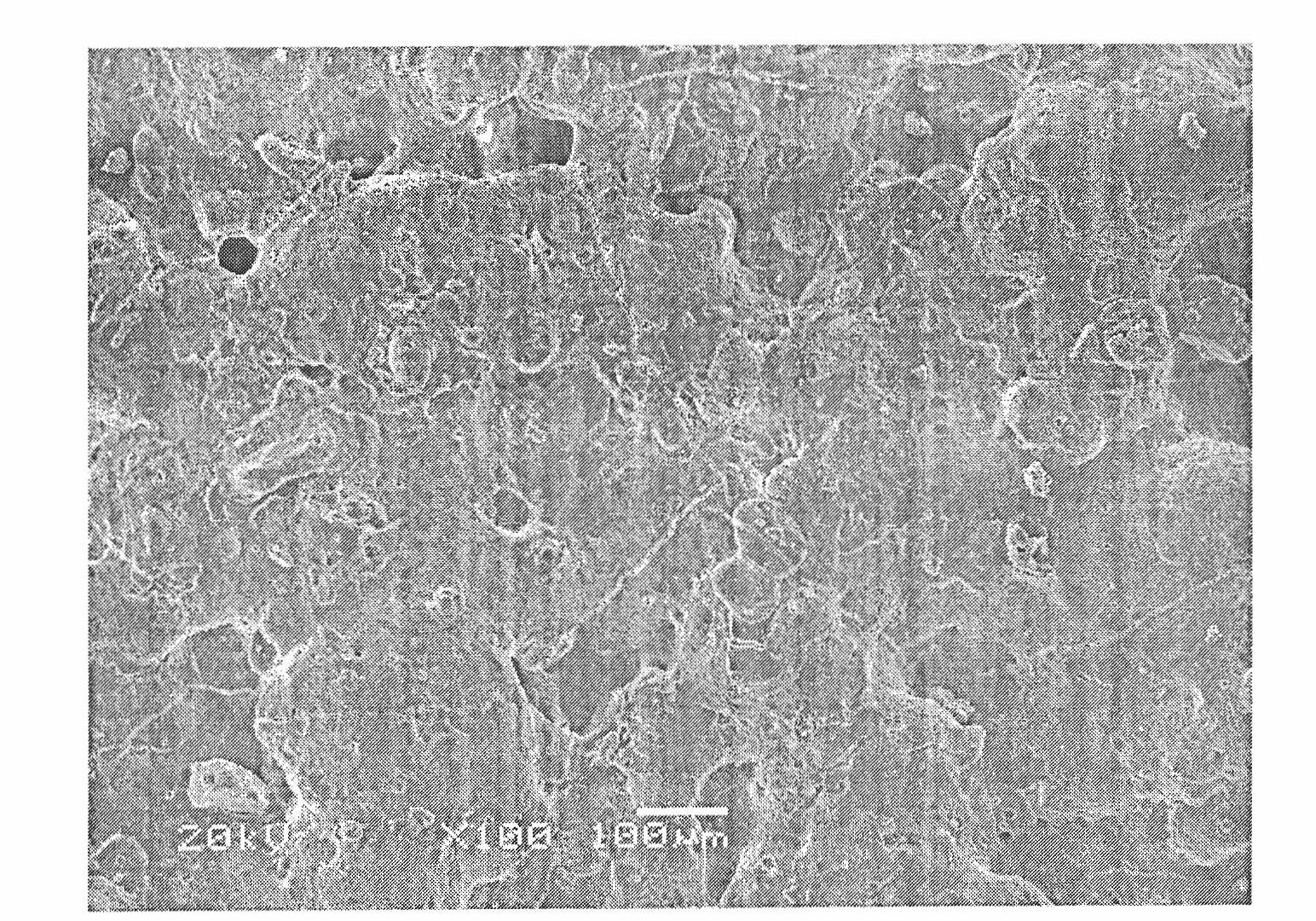

Preparation method of artificial bone tooth with PLLA/nHA (poly-L-lactic acid/nano-hydroxyapatite) surface active coating

ActiveCN106963978AImprove stabilityGive full play to the excellent characteristicsPharmaceutical delivery mechanismArtificial teethApatiteArtificial bone

The invention provides a preparation method of an artificial bone tooth with a PLLA / nHA (poly-L-lactic acid / nano-hydroxyapatite) surface active coating. The preparation method comprises the steps of preparation of an artificial bone tooth blank from a PEEK (polyetheretherketone) composite, preparation of the coating of a PLLA / nHA composite and surface degradation treatment. According to the method, the artificial tooth blank is prepared from a PEEK resin and glass fiber composite; the PLLA / nHA composite is securely applied on the surface of an implantation part of the artificial tooth blank; since poly-L-lactic acid is degraded more quickly than nano-hydroxyapatite, a part of poly-L-lactic acid on the surface of the coating is degraded; more nano-hydroxyapatite particles on the surface of the coating are exposed; bone induction and synostosis are better facilitated. The artificial tooth prepared by the method can fully exert excellent characteristics of the PEEK composite and the PLLA / nHA composite; a Young modulus of elasticity of the artificial tooth is close to that of human bone; a shielding phenomenon can be avoided; the coating is good in stability; the degradation time conforms to a growth cycle of the bone; the artificial tooth can be used for a long term.

Owner:NANNING YUEYANG TECH

Inter vertebral fusing device

InactiveCN1640368AHigh mechanical strengthGood biocompatibilityInternal osteosythesisSpinal implantsMetallic materialsCervical vertebral body

The present invention discloses a cervical synostosis device for front enter operation of cervical vertebrae. Said device is formed from upper and lower two arms, screws and a hollow column body and is prepared by using absorbable material of poly-DL-lactic acid, poly-L-lactic acid and polyglycollic acid or copolymer of them, biological ceramics or composite of hydroxyapatite and the above-mentioned polymer. The side wal of said column body can have or have not open pore, its upper surface is made into the risen form, and its upper and lower surface can have or have not pointed tooth, and its cross-section is polygonal or circular. Said invention also provides its advantages and application range.

Owner:宋跃明 +2

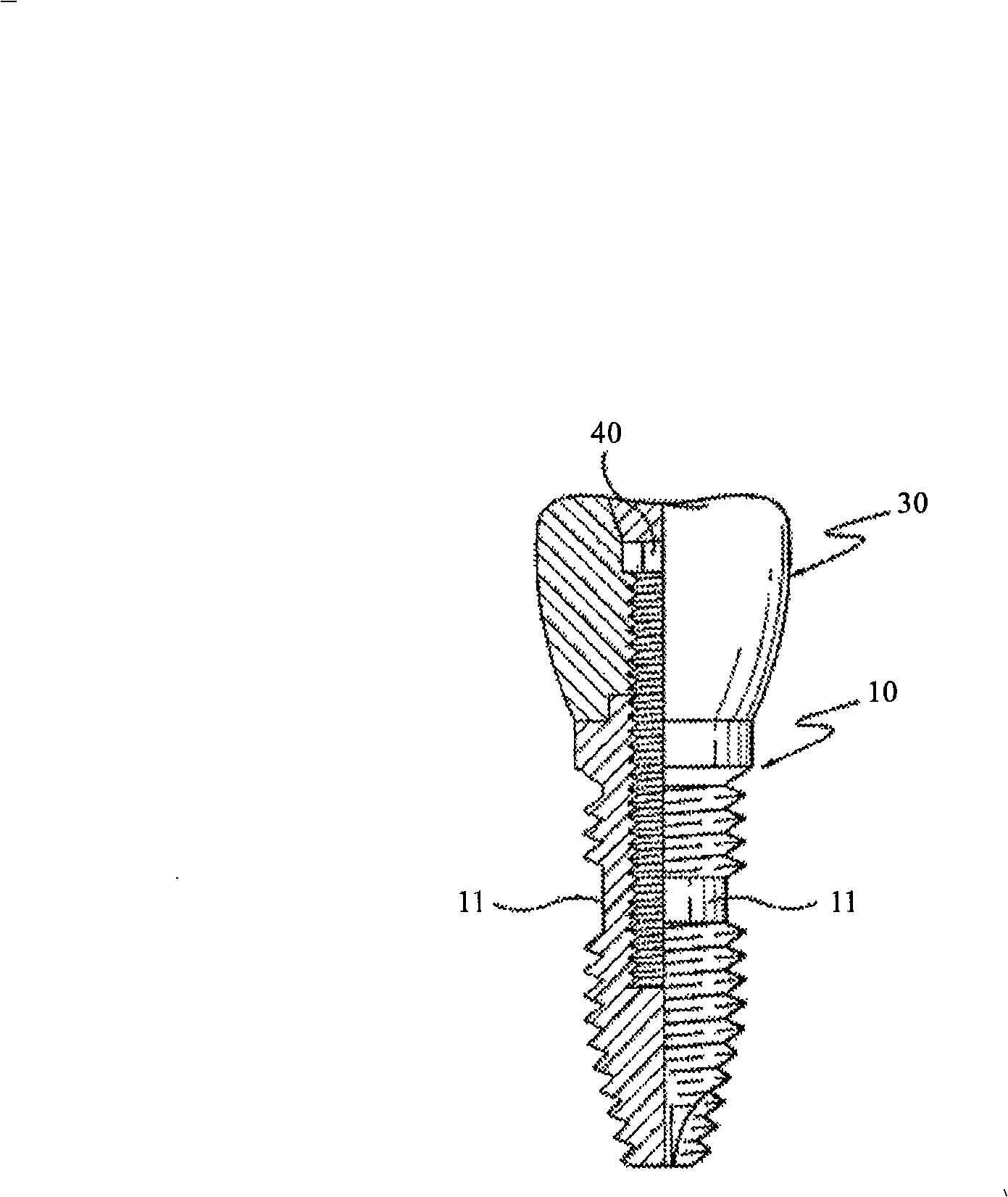

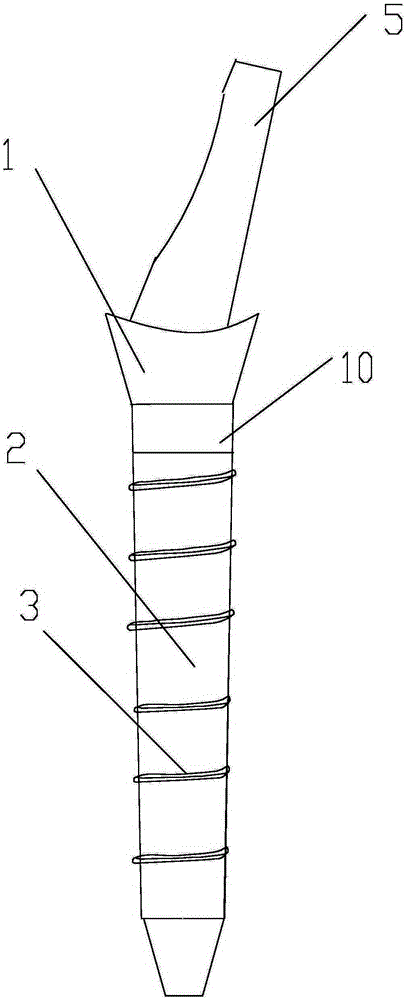

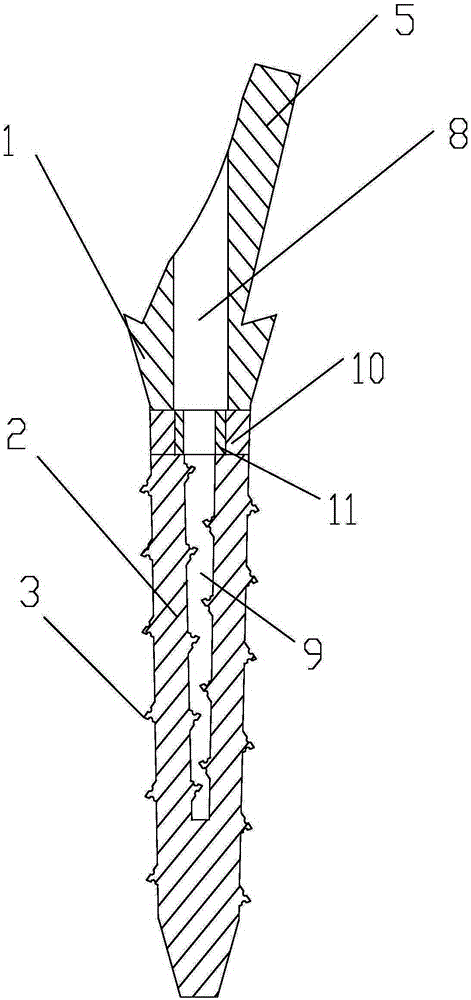

Synostosis artificial tooth

InactiveCN101292906AImprove structural strengthEnsure bone contactDental implantsSurface roughnessSynostosis

The present invention relates to a synostosis artificial tooth, in particular to a synostosis artificial tooth which can enlarge the bone contact quantity and strengthens the structure intensity inside an Osseo-Integrated Dental Implant with a high ground abrasive belt. The synostosis artificial tooth of the present invention has the abrasive belt as follows: the abrasive belt is placed between the position at one third of the total length from the upper part of the fang to the fang and the position at two third of the total length, the abrasive belt is ground with the surface roughness within 0.5 micron along the circle direction, and the abrasive belt has the width between 0.5mm and 1.0mm under the occasion that the length of the fang is less than 8mm; the abrasive belt has the width between 0.5mm and 1.2mm under the occasion that the length of the fang is between 9mm and 12mm; the abrasive belt has the width between 0.5mm and 1.5mm under the occasion that the length of the fang is more than 13mm. The synostosis artificial tooth of the present invention is characterized by also comprising a thread- shaped embossment which is protrudent from the abrasive belt and has the same surface roughness as the abrasive belt.

Owner:玄英根 +1

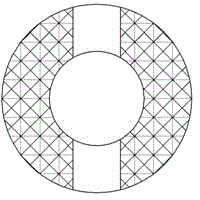

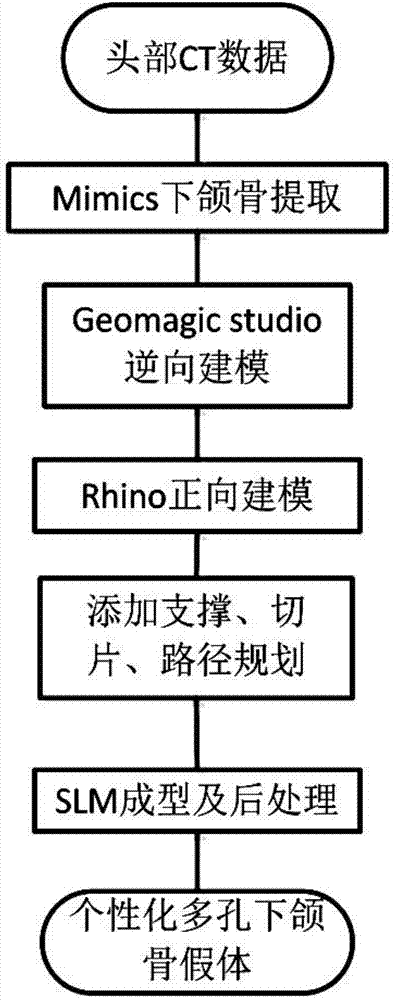

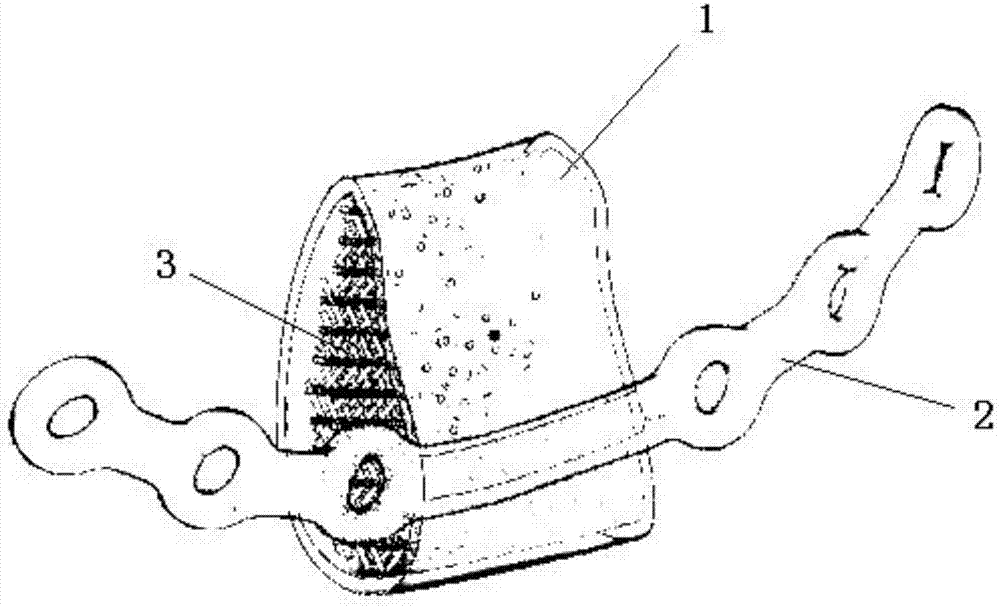

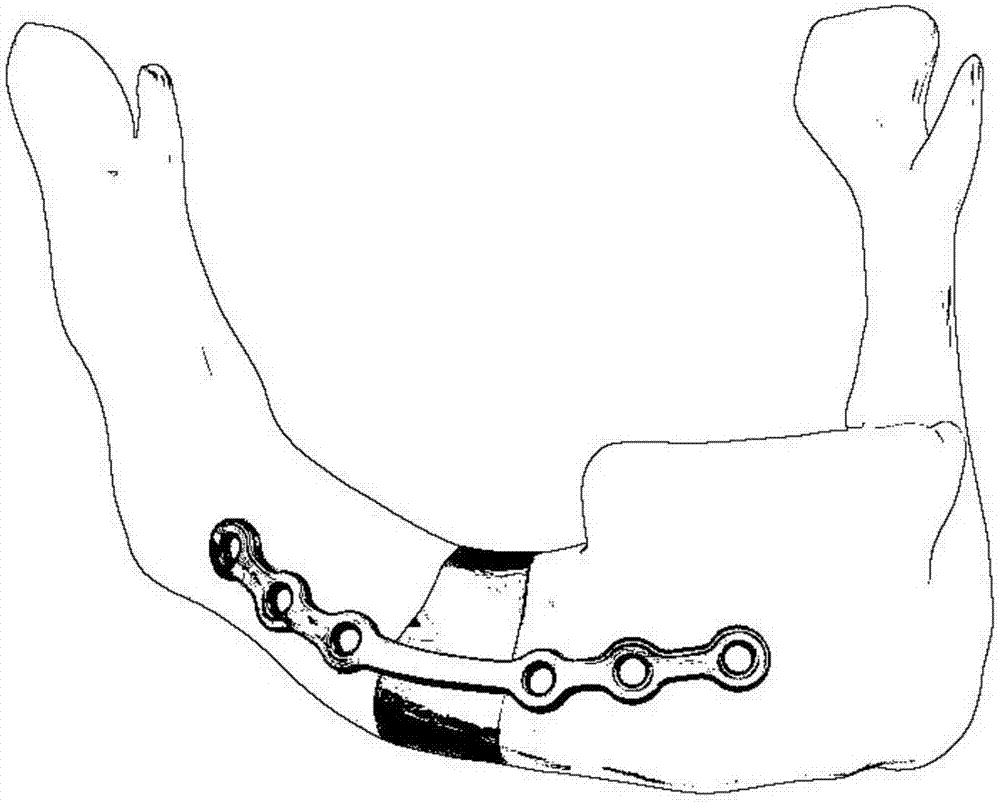

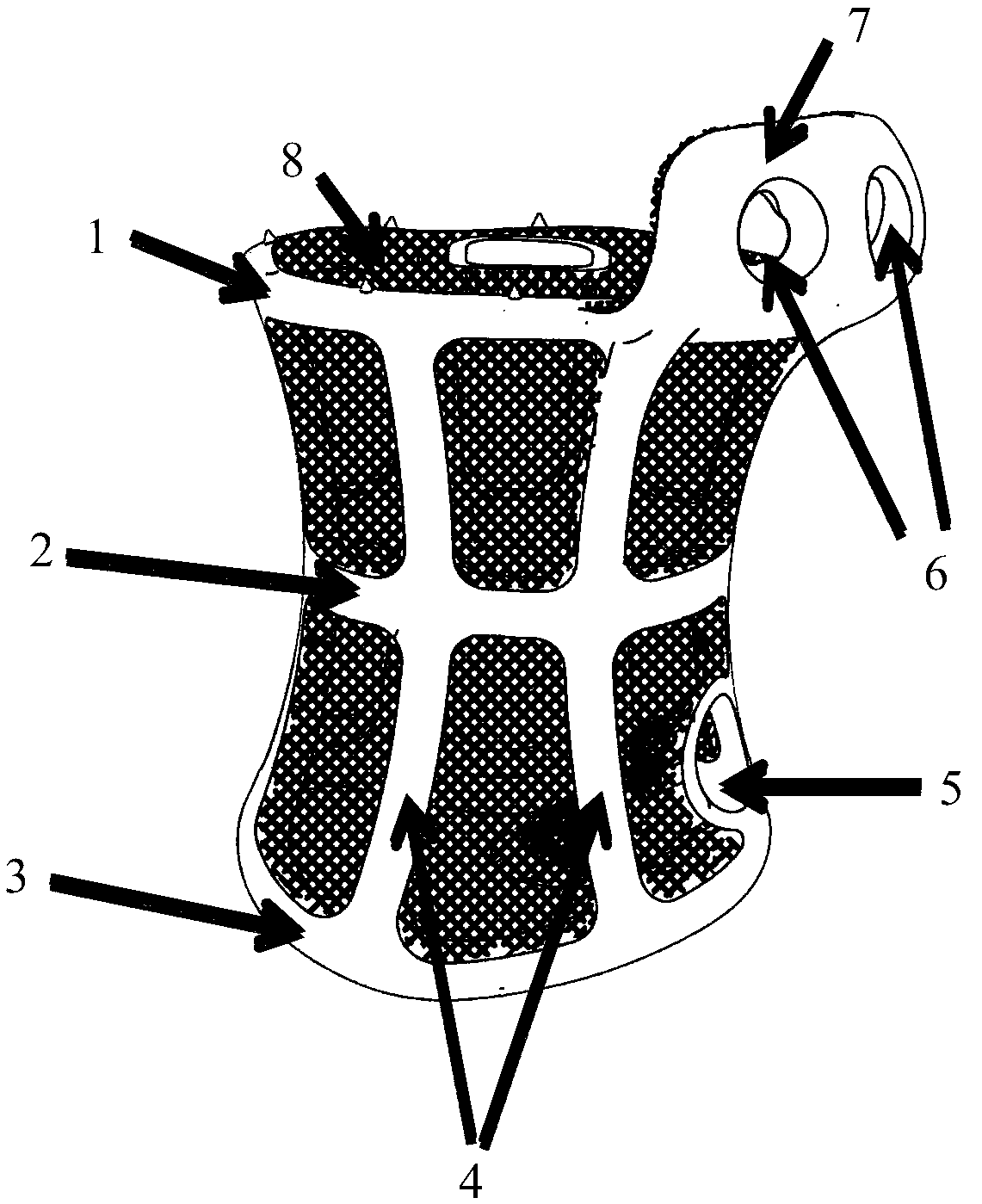

Manufacturing method of individualized prosthesis with porous structure

InactiveCN107374786ARestore facial shapeHigh degree of personalizationTomographySkullSelective laser meltingProsthesis

The invention discloses a manufacturing method of an individualized prosthesis with a porous structure. The method comprises the steps of extracting CT data; reversely modeling; forward designing; adding supports and cutting into slices: importing an acquired design model into Materialise Magics software to add the supports and cut into slices; importing sliced data into RPPPath software to plan a scanning path and importing into selective laser melting molding equipment for molding; and post-processing: post-processing molded prosthesis components for a part to be repaired, so as to finally acquire the individualized titanium alloy prosthesis with the porous structure for the part to be repaired. A selective laser melting molding technology is used for manufacturing, relatively high individualization is achieved, and a face form of a patient can be well recovered; the method provided by the invention adopts a microcosmic porous structure with suitable porous parameters, so that synostosis is facilitated; the method is high in practicability instead of staying in a model level, and relative design content is applicable to different cases and different cut bone forms.

Owner:SOUTH CHINA UNIV OF TECH

Spine prosthesis based on 3D printing and making method thereof

PendingCN108685627AImprove gripEasy to fixAdditive manufacturing apparatusJoint implantsBone tissueProsthesis

The invention discloses a spine prosthesis based on 3D printing and a making method thereof. The spine prosthesis comprises supporting frames, hollowed-out structures and fixing parts; each supportingframe is of a cavity-type main body stress structure formed by multiple transverse beams and longitudinal beams, each transverse beam comprises an upper bearing beam, a lower bearing beam and a middle transverse beam body, the upper bearing beams and the lower bearing beams are matched with the centrum surfaces in contact with the upper bearing beams and the lower bearing beams in dissection shape respectively, multiple longitudinal beams are distributed between the upper bearing beams and the lower bearing beams, and the middle transverse beam bodies are connected among the longitudinal beams; the hollowed-out structures are non-main-stress parts distributed among the supporting frames. According to the spine prosthesis, the upper and lower bearing beams are required to be designed in reference to the dissection shapes of the adjacent upper and lower centrum surfaces and completely attached to each other during installation, conical fixing spine structures are evenly distributed, theholding force is reinforced, and accordingly fixing is more stable; the main body structure is a waisted structure and is beneficial to effective conduction of a load and stress diffusion. The cavitydesign and opening design are adopted for the interior of the supporting frame, the supporting frame is used for containing the bone tissue, and synostosis of the upper and lower centrums is promoted.

Owner:陕西东望科技有限公司

Implantable toe joint prosthesis

PendingCN112754737APromote ingrowthIncrease the binding rateAnkle jointsToe jointsArticular headToe joint prosthesis

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

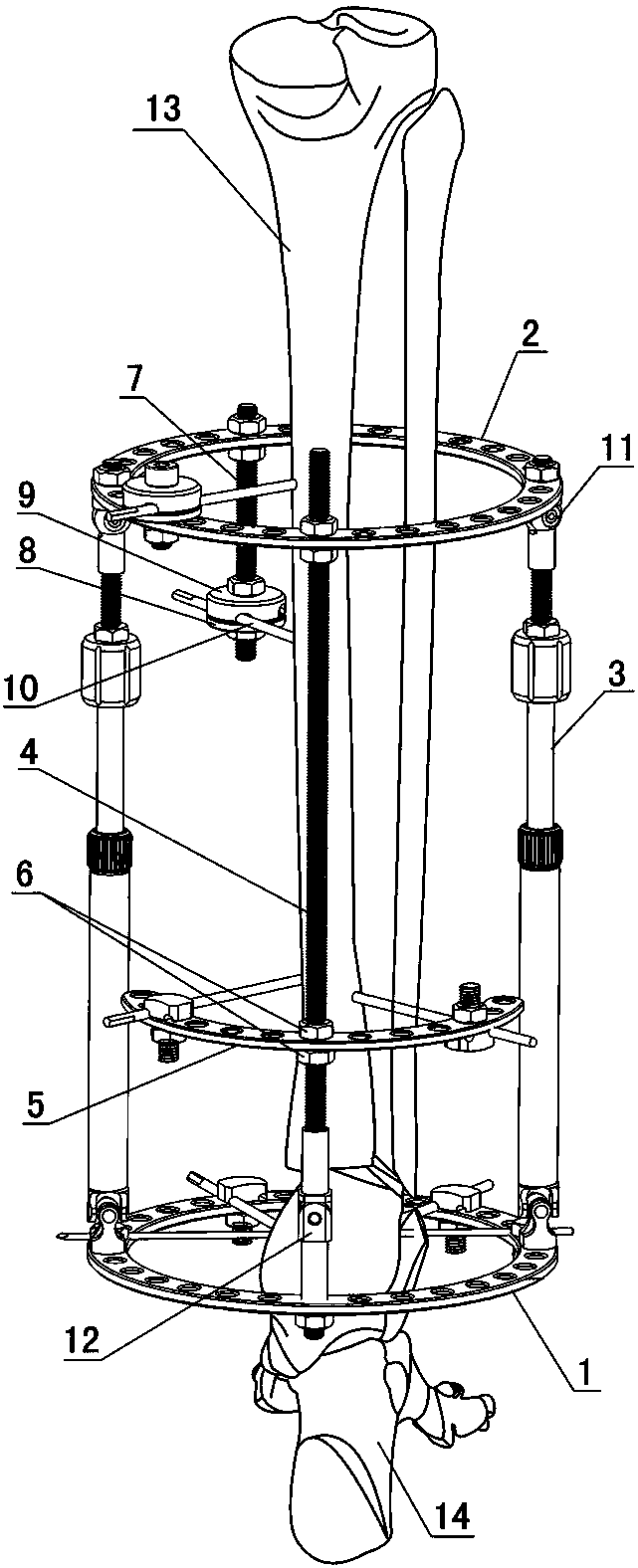

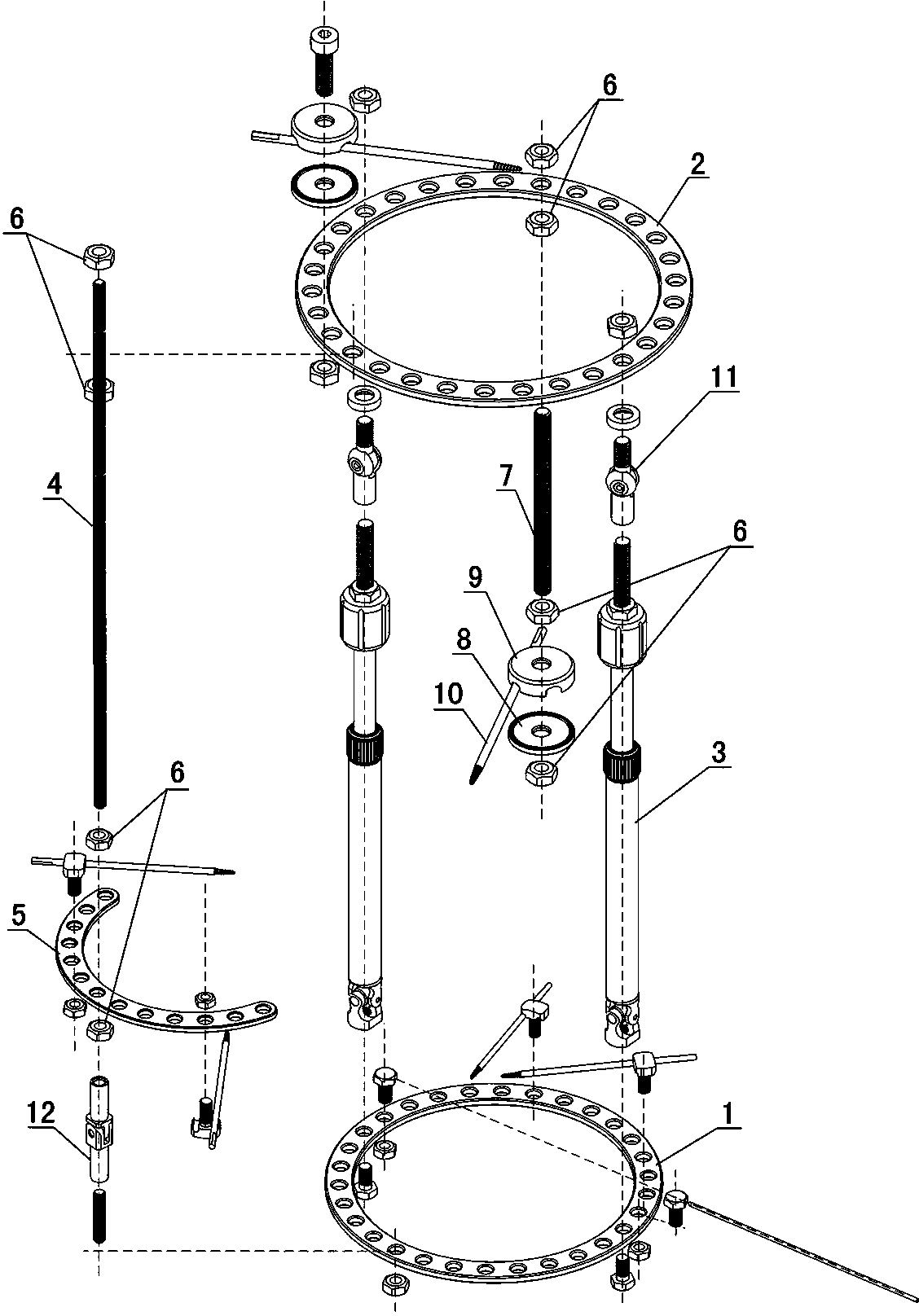

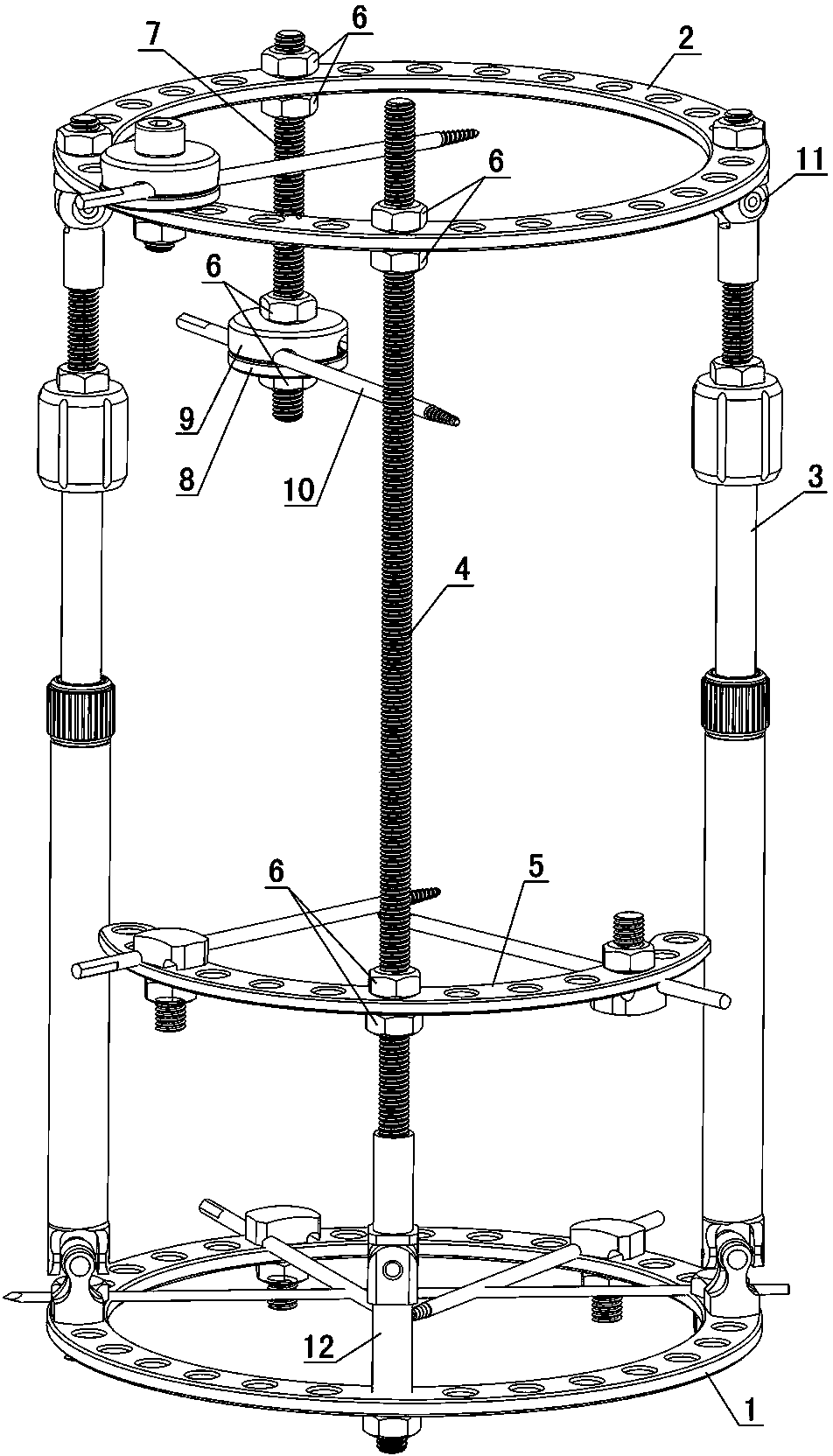

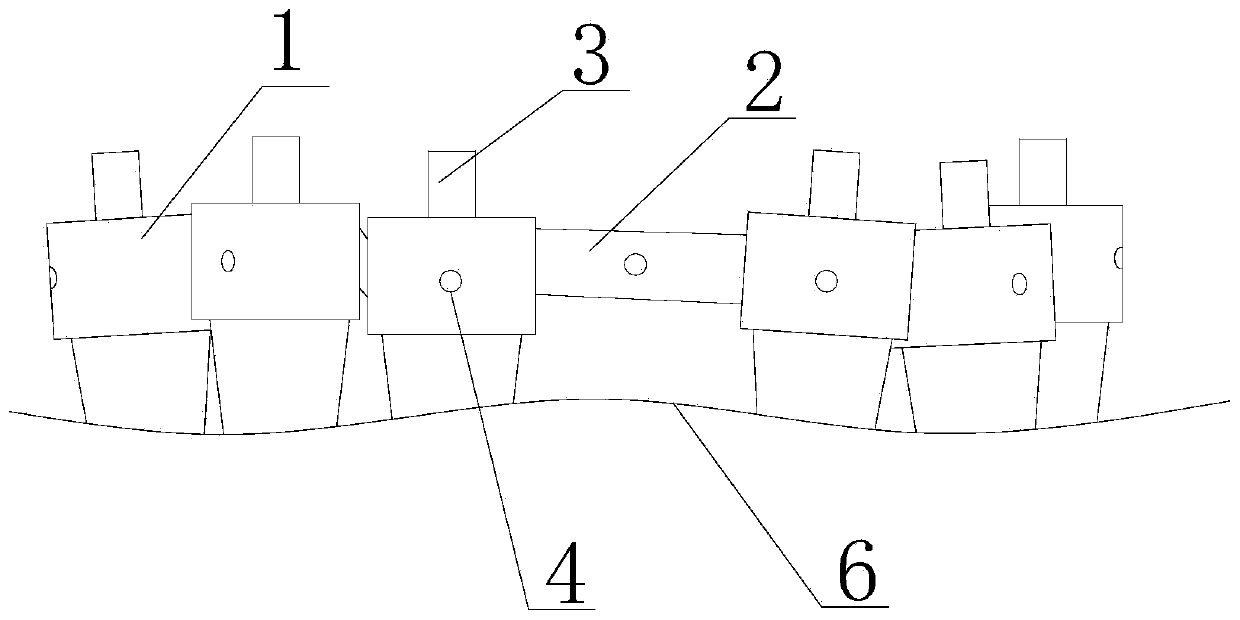

Regulation-control orthosis for coronal plane deformity of ankle

A regulation-control orthosis for coronal plane deformity of an ankle is formed by a bone fixing support, steel needle fixing clamps connected onto the bone fixing support and steel needles clamped in the steel needle fixing clamps; the bone fixing support comprises a far end hole ring, a near end hole full ring arranged at the middle or middle upper section of a tibia, at least two fast extending lengthening rods connected between the far end hole ring and the near end hole full ring, a hole ring connecting rod provided with threads and connected between the far end hole ring and the near end hole full ring, and an arc hole ring adjustably connected to the hole ring connecting rod by an up-and-down adjusting nut and arranged at the middle lower section of the tibia. The regulation-control orthosis coronal plane deformity of the ankle is special for treating the strephexopodia or strephenopodia deformity of the ankle caused by synostosis, can perform traction, resetting, fixing and deformity correcting on fracture or deformity of the ankle in introversion and extroversion spaces, and is suitable for the traction, fixing and correcting on the coronal place of the ankle.

Owner:JIANGSU GUANGJI MEDICAL TECH

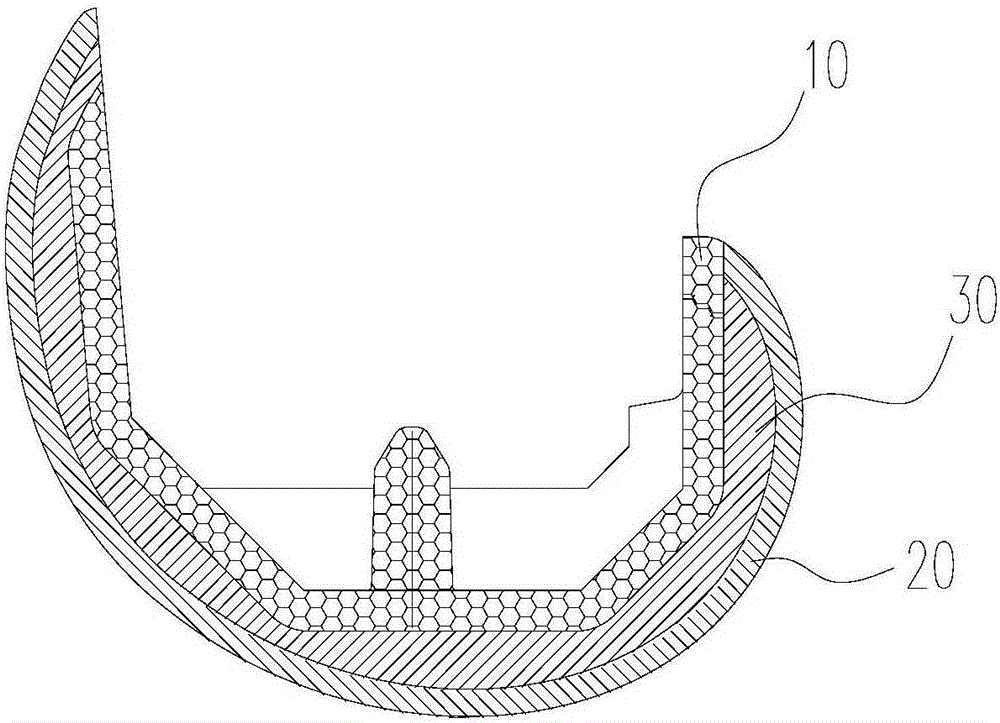

Mucoperiosteal type implant

The invention discloses a mucoperiosteal type implant, which comprises a pure titanium casing matched with the skeleton face of a covered synostosis oral cavity. The longitudinal section of the casing in the extending direction is saddle-shaped, and a gap between the longitudinal section of the casing and covered bones can be filled with materials favorable to guiding of skeletal regeneration. A plurality of papillary concave portions and convex portions are respectively arranged on the edge of the casing, the concave portions and the convex portions are arranged at intervals, and the edge form is apt to enable mucoperiosteal tissue to be implanted and filled. At least two fixing holes and fixing screws matched with the fixing holes are arranged on the casing, the material of the fixing bolts is pure titanium, and the design of the casing with a rough inner surface and a smooth outer surface is favorable to osseointegration and protection of soft tissue. A connecting structure connected with false teeth or artificial crowns to be repaired is arranged outside the sellar crest portion of the casing to be in mechanical connection or cementation with the false teeth or the artificial crowns so as to improve repairing effects.

Owner:施生根 +1

Fluorapatite coating and preparation method thereof

InactiveCN101856511AImprove biological activityGood biocompatibilityCoatingsGel preparationBiocompatibility Testing

The invention discloses a fluorapatite coating which is prepared by ion coated gel preparation, shielding layer gel preparation and biomineralization process. The fluorapatite coating has higher bioactivity, biocompatibility and synostosis capability, and effectively overcomes the defects of the existing implanted materials.

Owner:SHANDONG UNIV

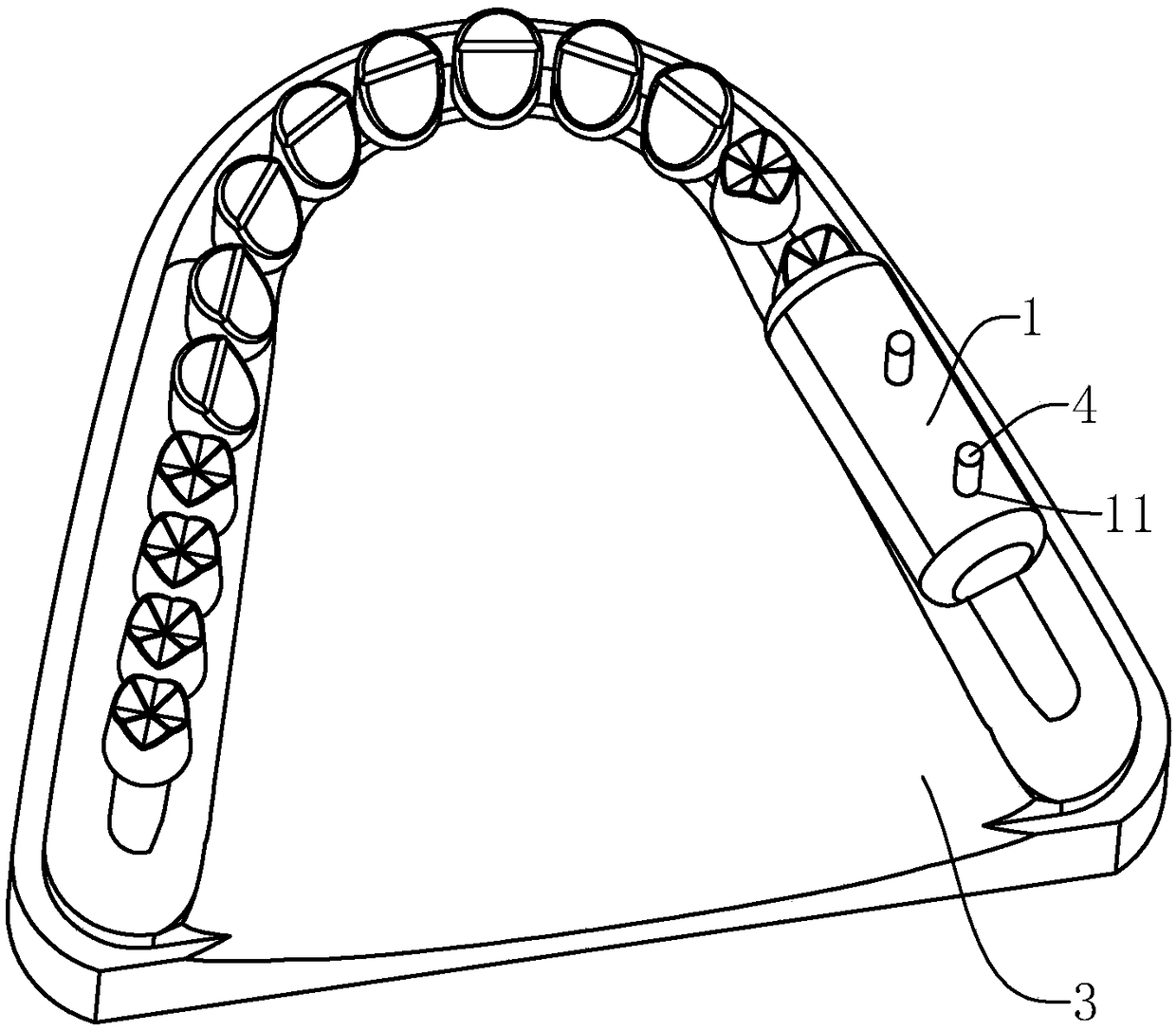

Oral cavity implant stiffener and digital processing method thereof

ActiveCN109717970AGood combination stabilityImprove long-term stabilityDental implantsMedicineTime cost

The invention belongs to the field of oral cavity rehabilitation, and discloses an oral cavity implant stiffener and a digital processing method thereof. The oral cavity implant stiffener comprises aconnecting rod and at least two positioning structural members, wherein the positioning structural members and implanting positions are in corresponding arrangement; each of the positioning structuralmembers is provided with a positioning part, and the running direction of each of the positioning parts is the same as that of the corresponding implanting position; the connecting rod is connected between every two positioning structural members; and the connecting rod and the positioning structural members are made from a rigid material. Compared with steel wires, the oral cavity implant stiffener is higher in rigidity, the force is easier and uniformly transferred to various implants, the entire dispersing action of jaw force is improved, and initial stage synostosis and long-term stability of the implants are facilitated. According to implant pattern digital design, the time cost and the work difficulty can be greatly reduced, a technician does not need special tuning, and the reworkpercentage does not exist almost. Because of the mechanical property and the force conduction advantages, immediate rehabilitation can be realized for more implant cases, and indication is extended.

Owner:CHENGDU DT DENTALLAB CO LTD

Porous dental implant internally combined with biodegradable magnesium alloy and manufacturing method of porous dental implant

InactiveCN108553187AGuaranteed porosityGuaranteed strength of mechanical propertiesDental implantsTissue regenerationPorositySynostosis

The invention discloses a porous dental implant internally combined with biodegradable magnesium alloy and a manufacturing method of the porous dental implant. The dental implant comprises a main bodyand an embedded body, wherein the main body is composed of a bone grafting section and a transgingival section, and the side wall of the bone grafting section is provided with a thread; the embeddedbody is a cylinder prepared from a biodegradable magnesium alloy material, and the surface of the embedded body is provided with an external thread. An internal threaded hole allowing the embedded body to be screwed in is formed in the bottom end of the bone grafting section, a plurality of permeating holes are formed in the bone grafting section, one end of each permeating hole is communicated with the internal threaded hole, and the other end of each permeating hole is communicated with the side wall of the bone grafting section. By means of the dental implant, under the condition that the porosity of the dental implant is ensured, the mechanical property and strength of the dental implant are ensured. The magnesium alloy is mechanically connected with the dental implant body through threads, the operation is simple, and connection is stable and reliable. After implantation, the magnesium alloy is automatically degraded, meanwhile, bone cells are induced to grow into the dental implant, and finally, synostosis is achieved. In the magnesium alloy degradation process, the mechanical property of the dental implant can meet work requirements all the time.

Owner:广东健齿生物科技有限公司

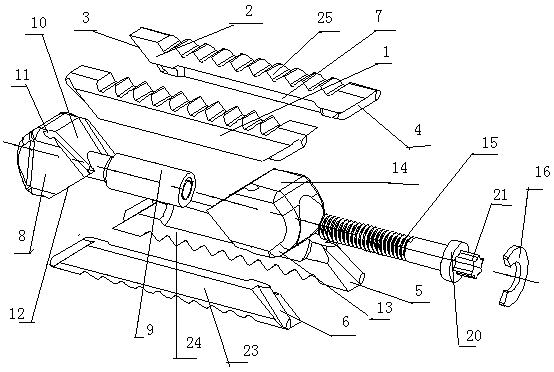

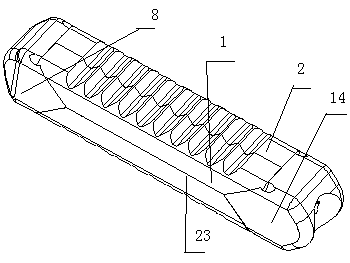

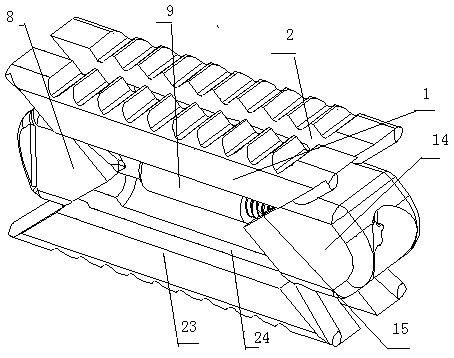

Four-side distractible interbody fusion cage

ActiveCN108095867ARestore tensionRestore physiological curvatureSpinal implantsDistractionSpinal cage

The invention relates to the technical field of interbody fusion cage medical apparatuses, and in particular to a four-side distractible interbody fusion cage. The interbody fusion cage is composed ofa fusion contact mechanism and a driving distraction mechanism, wherein the fusion contact mechanism is composed of an upper fusion contact component and a lower fusion contact component; the upper fusion contact is composed of a front upper fusion block and a rear upper fusion block; the lower fusion contact component is composed of a front lower fusion block and a rear lower fusion block; grooves are kept in the inner sides of the front upper fusion block, the rear upper fusion block, the front lower fusion block and the rear lower fusion block; the driving distraction mechanism is composedof a left push component and a right push component; the left push component is composed of a left push block and a driving pull pipe; the right push component is composed of a right push block, a driving screw rod and a retainer ring. The interbody fusion cage provided by the invention has the advantages of recovering height and tension of a vertebral section, relieving compression, recovering physiological curvature of a spine, promoting synostosis, guaranteeing spine stability and the like.

Owner:博能华医疗器械(北京)有限公司

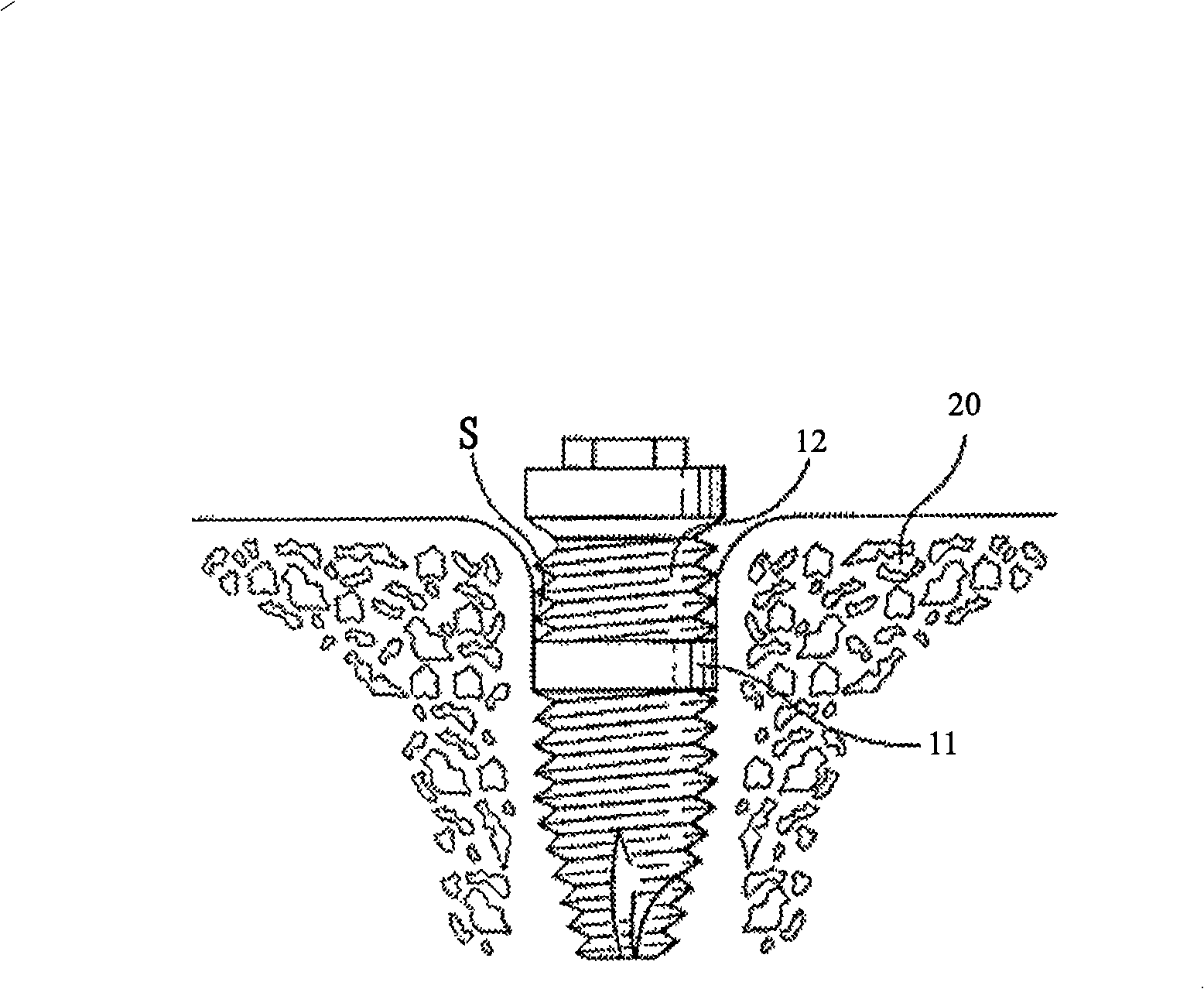

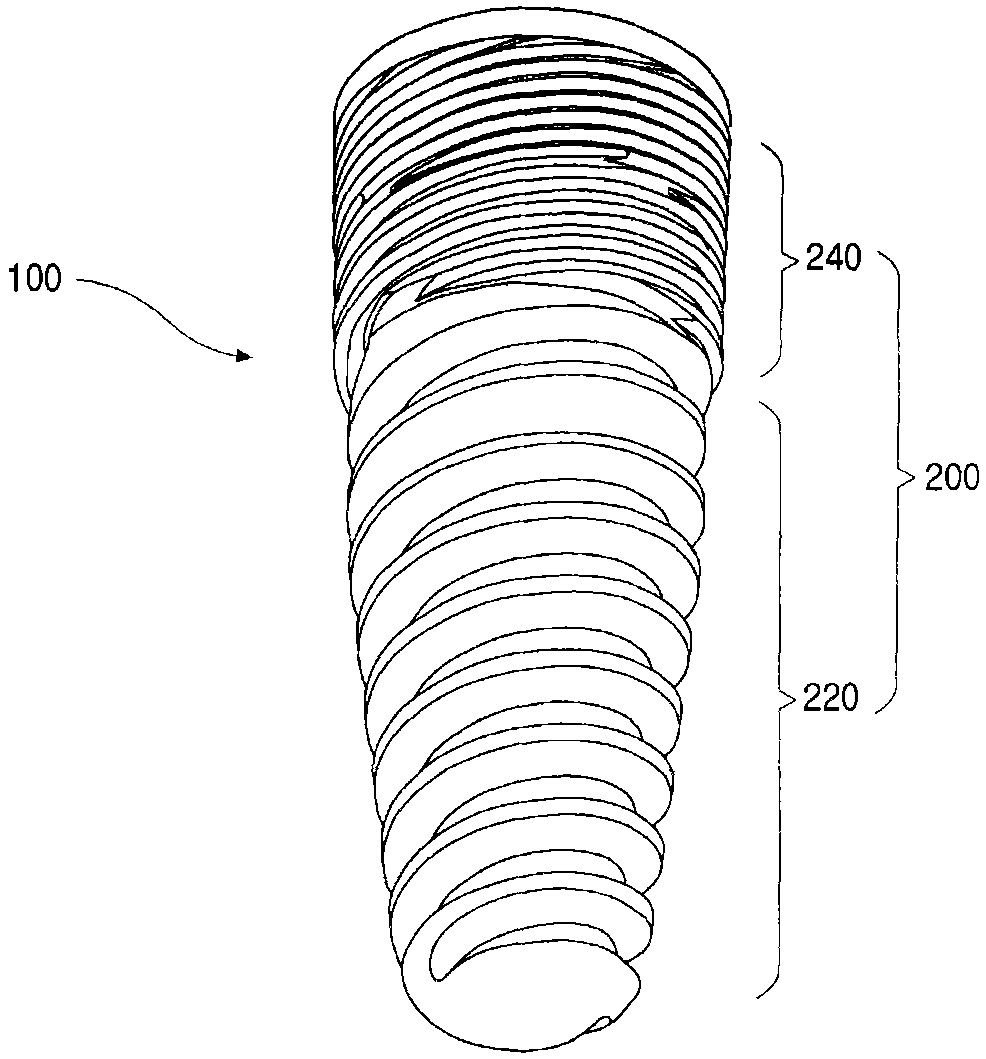

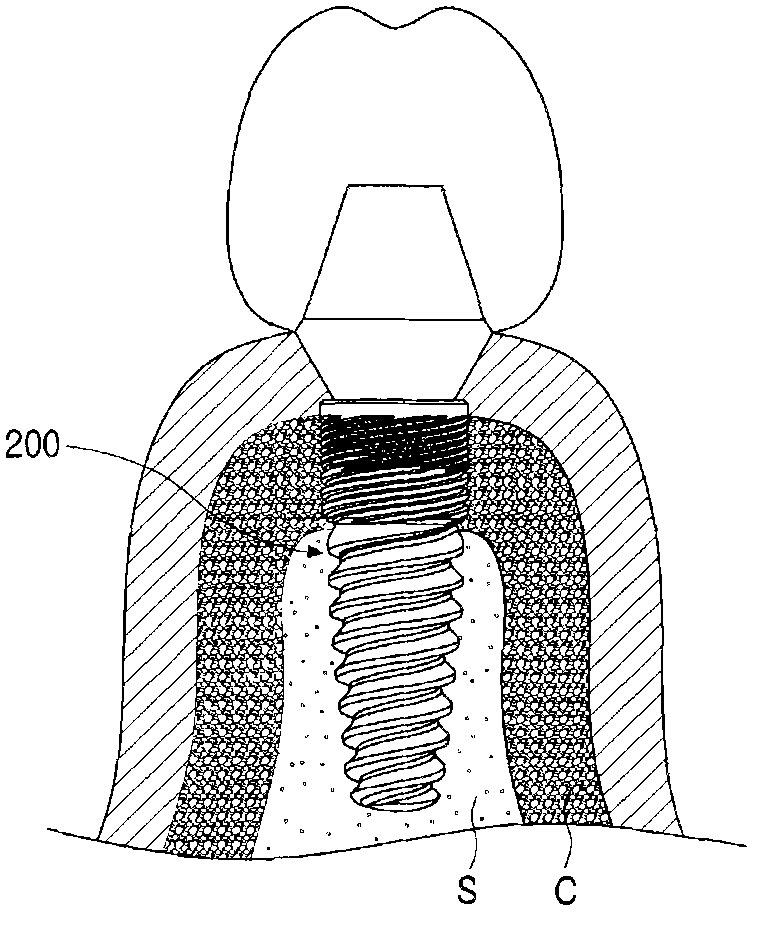

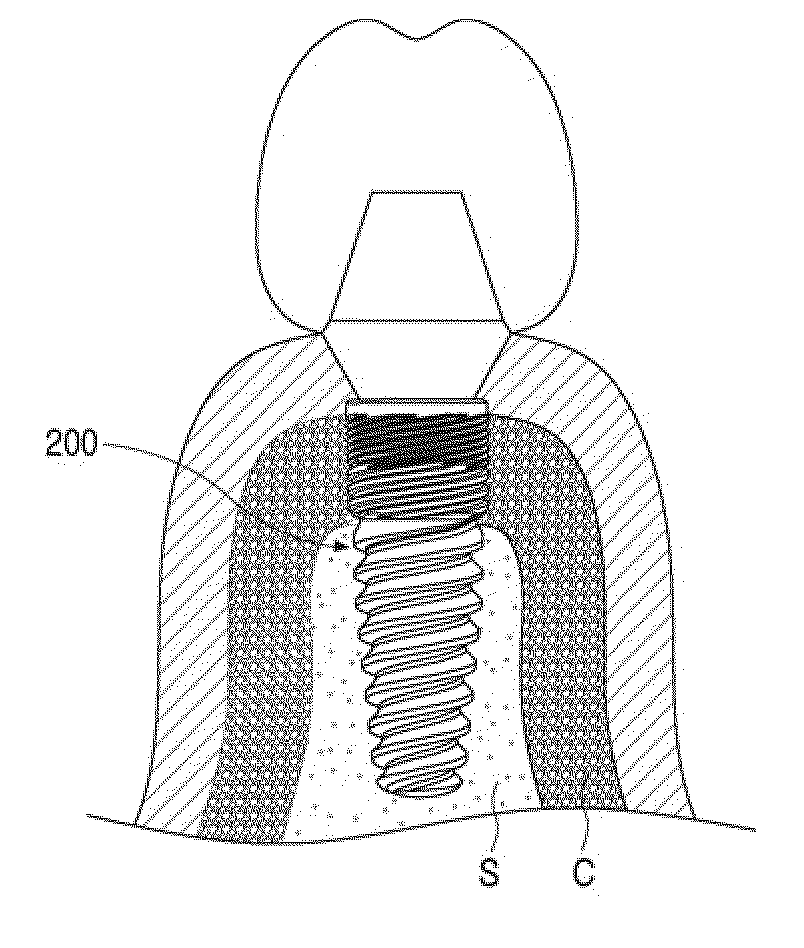

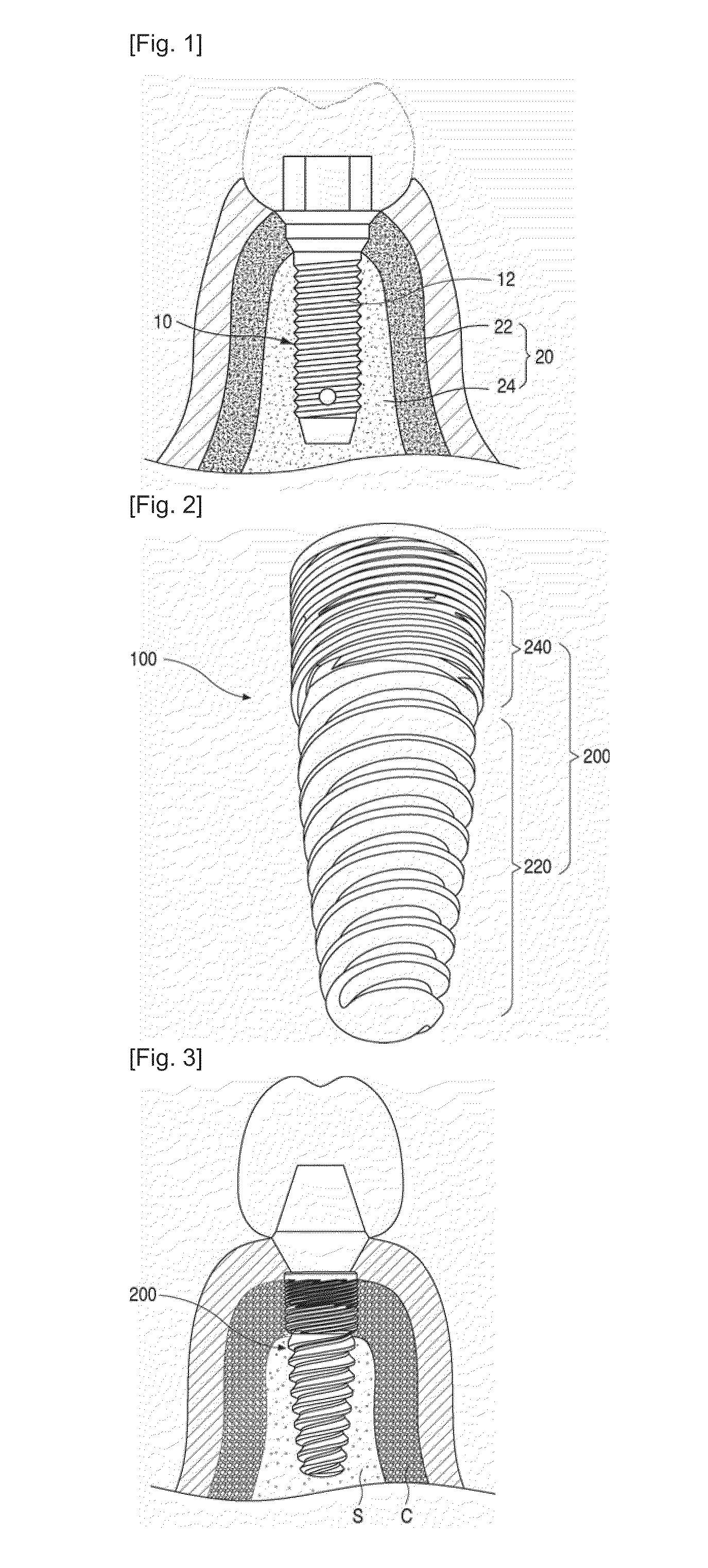

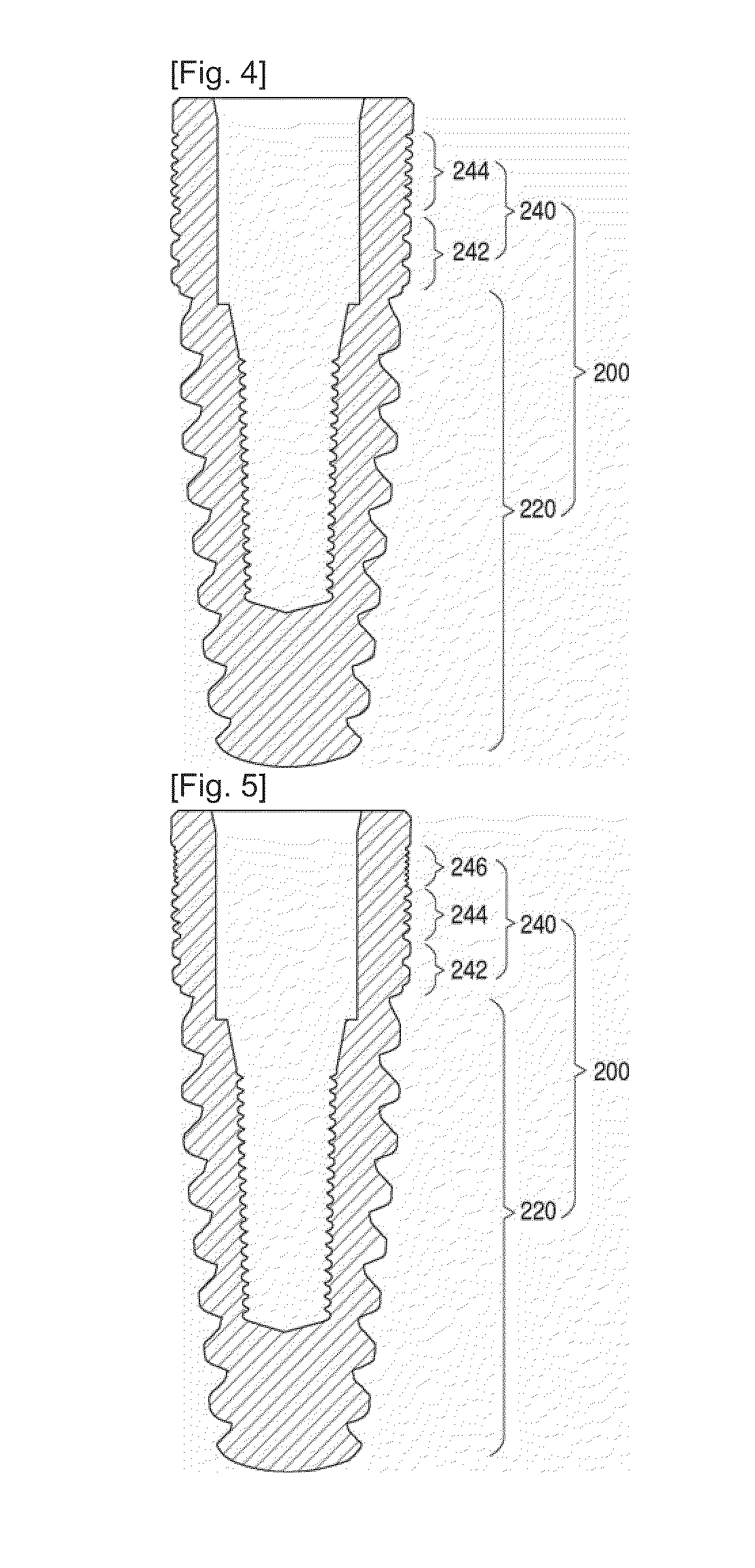

Dental implant fixture

Provided is a dental implant fixture with 3 or more ridged portions having mutually different pitches to distribute load uniformly across osseous tissue. The pitches of the ridged portions (200) progressively decrease in one direction. The ridged portions (200) include a larger ridged portion (220) that contacts spongy bone with low bone density, and a smaller ridged portion (240) that contacts cortical bone with high bone density. The smaller ridged portion (240) is provided with 2 or more threaded regions with respectively different pitches. With this configuration, bone decay and bone damage can be prevented, and synostosis can be improved.

Owner:柯泰克股份有限公司

Distal radioulnar joint reduction fixation plate

InactiveCN103735305ASmall range of activitiesUnlimited rotationBone platesDistal radioulnar jointOrthopedic department

The invention provides a distal radioulnar joint reduction fixation plate, and belongs to the field of internal fixation instruments for clinical medicine orthopedic operations. The distal radioulnar joint reduction fixation plate comprises an ulna hook and a radius fixing portion, wherein the ulna hook surrounds the periphery of an ulna and is used for hooking the ulna, the radius fixing portion is used for fixing a radius, and the ulna hook and the radius fixing portion are positioned at two ends of the distal radioulnar joint reduction fixation plate respectively. The distal radioulnar joint reduction fixation plate is fixed onto the radius through the radius fixing portion, the ulna is hooked by the ulna hook, reduction effects can be enhanced, the shortcoming of loosening caused by suture is overcome, reduction of the movement range of a distal radioulnar joint and complications of synostosis caused by ulna and radius steel needle fixation are avoided, reduction can be reliable by the aid of the distal radioulnar joint reduction fixation plate, rotation of the distal radioulnar joint is limited, natural healing of a distal radioulnar joint ligament or / and a joint capsule is facilitated, surgical effects are improved, and the complications are decreased.

Owner:张文涛

Combined-type soft tissue horizontal dental implant

The invention discloses a combined-type soft tissue horizontal dental implant which comprises a base of the dental implant, an implant root and a fixing screw which connects the base with the implant root. An outer thread is arranged at the implant root, and the surfaces of dental sides of one or more sides of the outer thread are rough surfaces. By means of the combined-type soft tissue horizontal dental implant, 'synostosis' between the dental implant root and the surrounding bone tissue is more facilitated, and meanwhile the phenomenon of spin of the implant under the action of external force can be hindered.

Owner:吴大怡

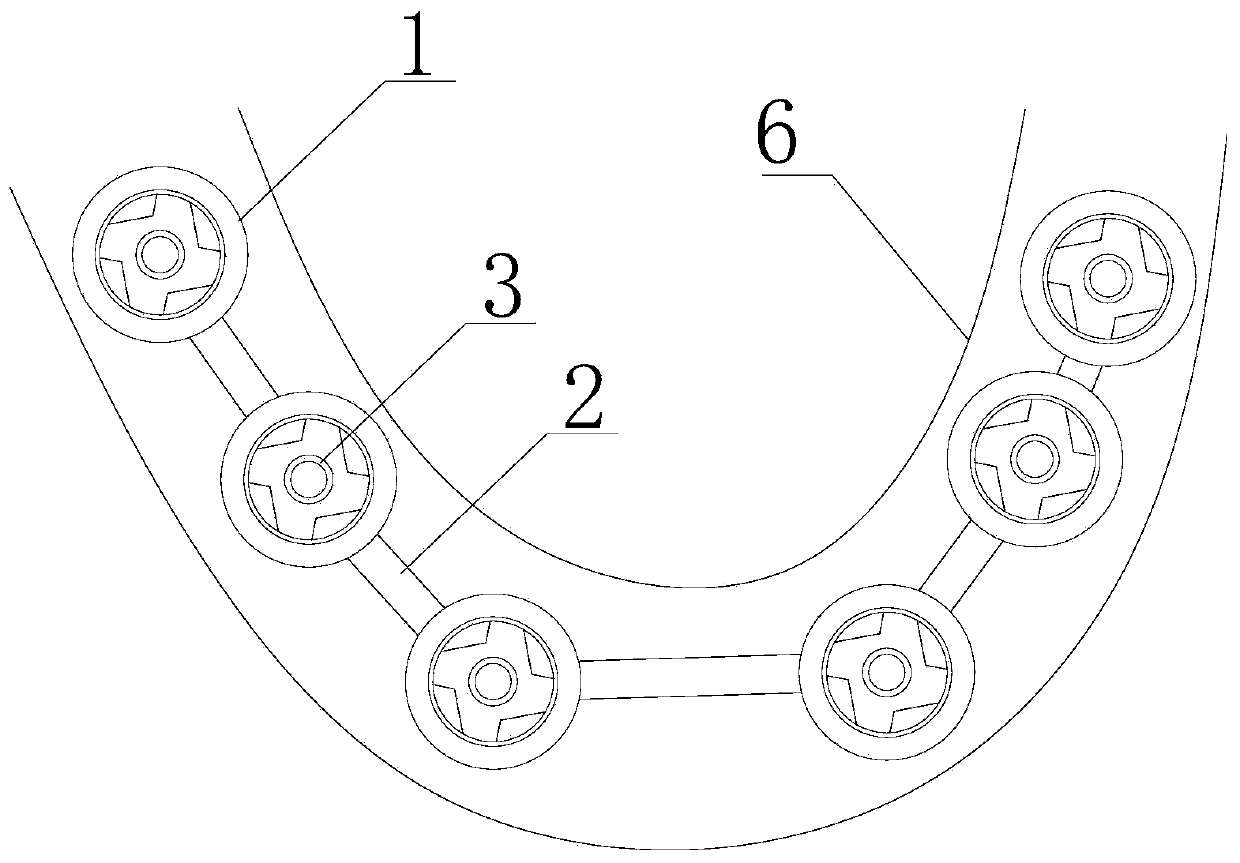

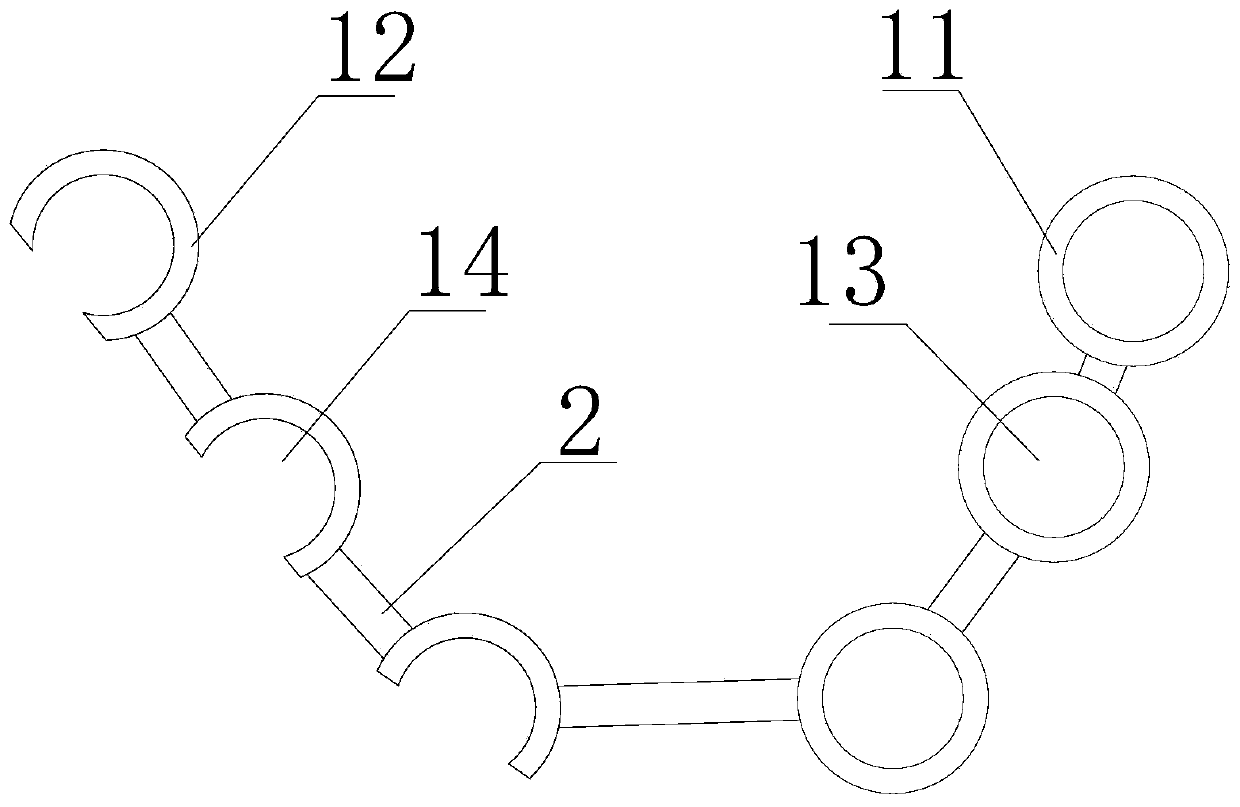

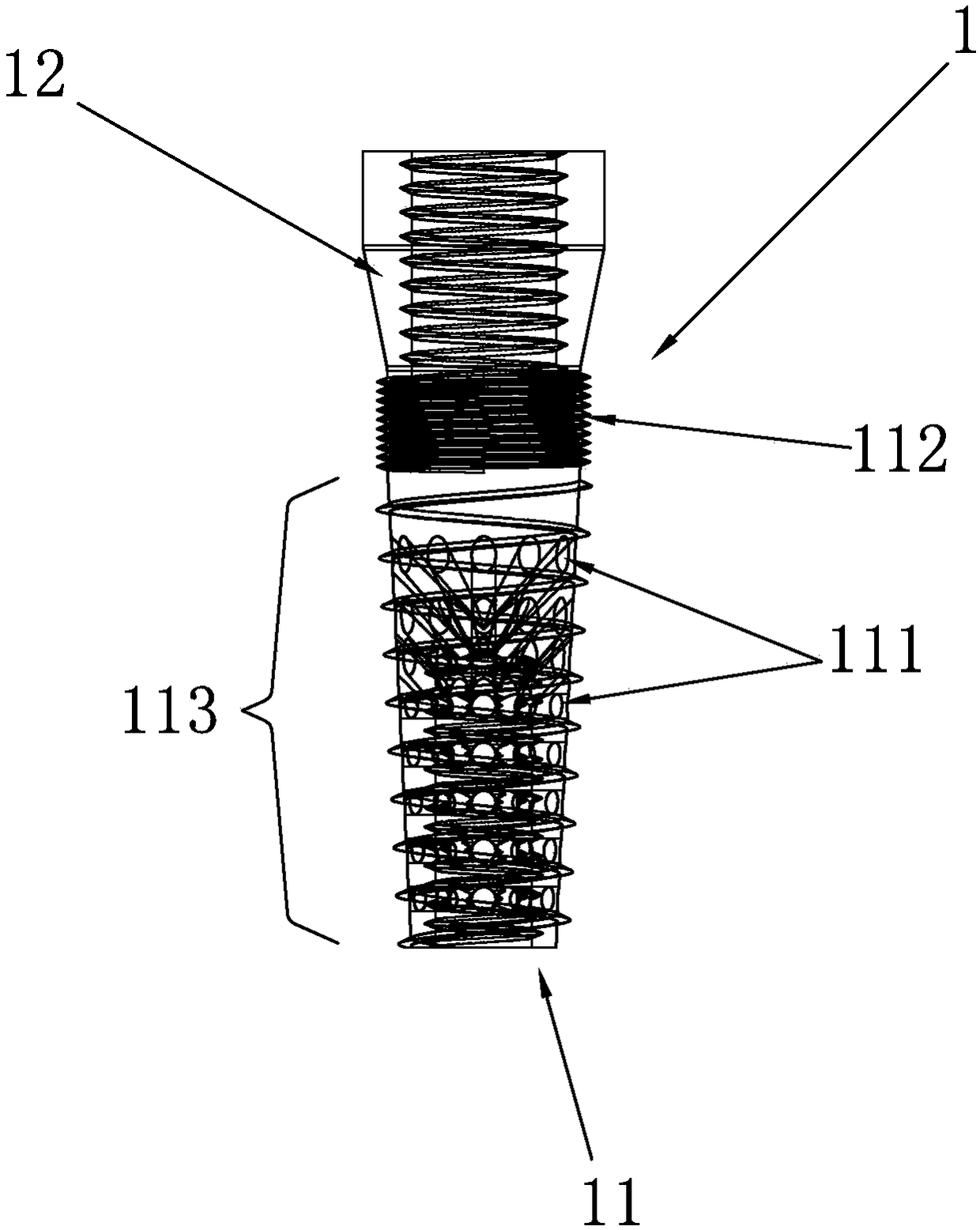

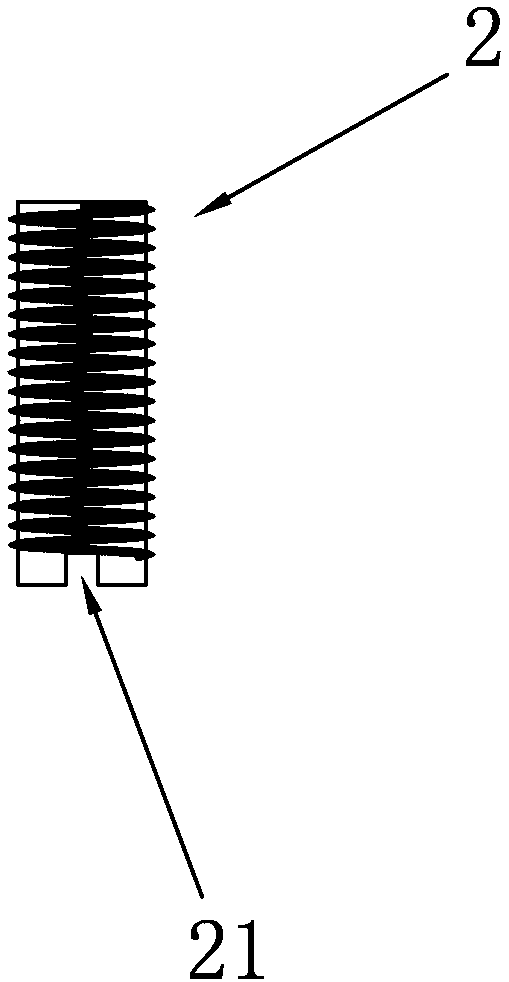

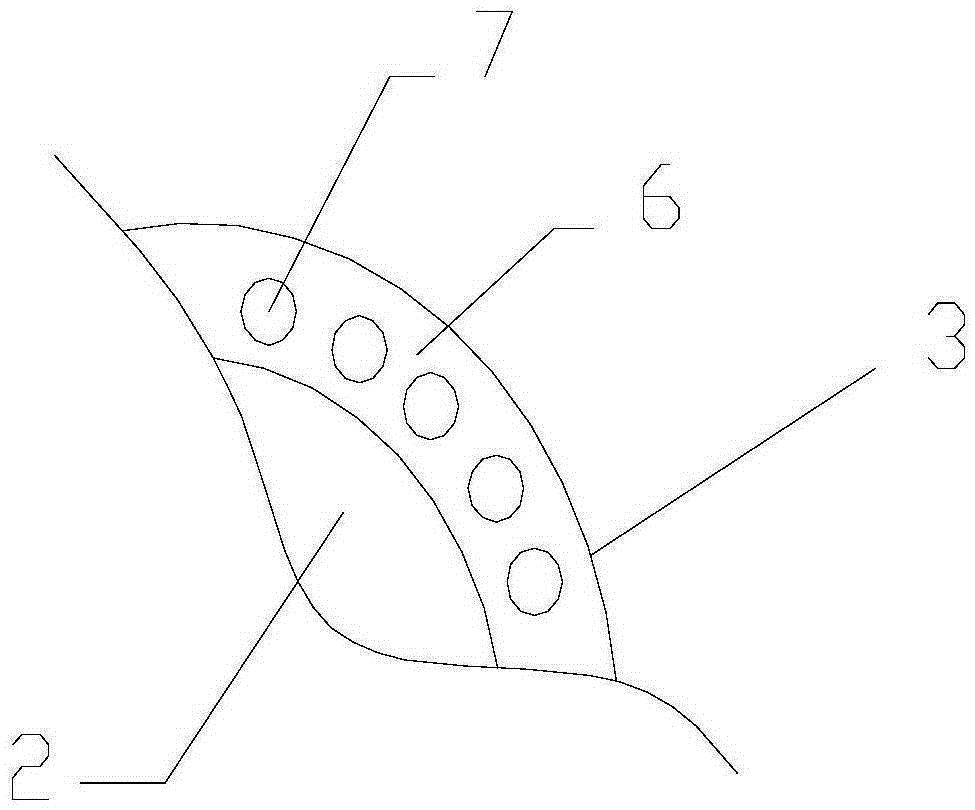

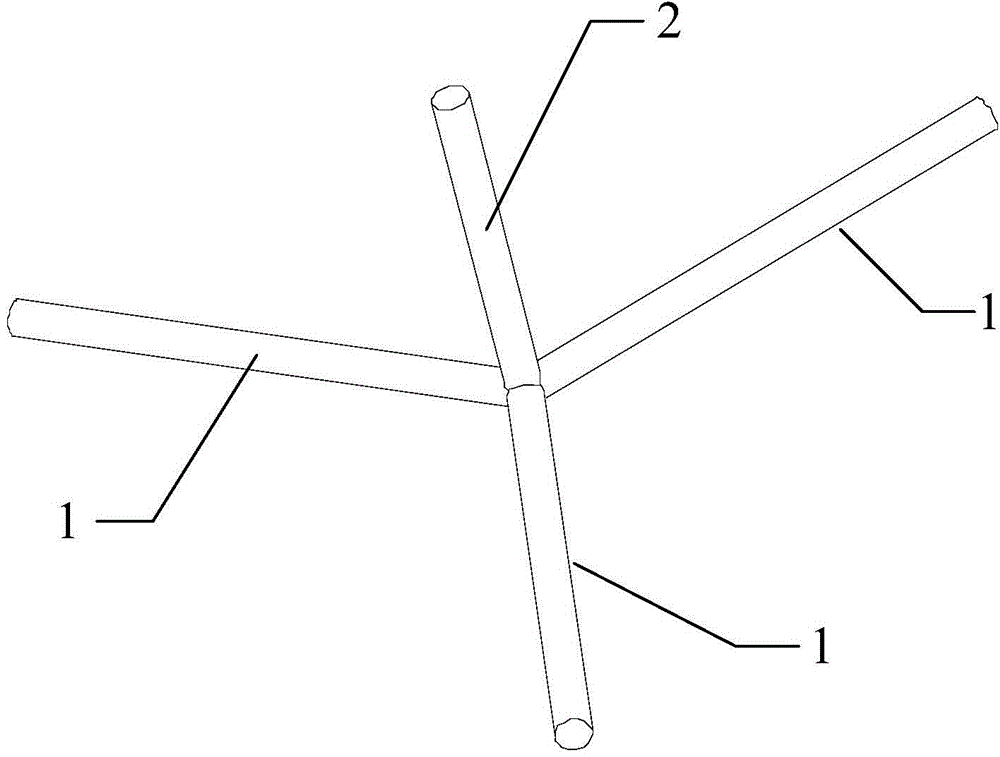

Interface fixing structure for metal bone trabeculae

The invention discloses an interface fixing structure for metal bone trabeculae. The interface fixing structure for the metal bone trabeculae comprises at least three intersected metal bone trabecula supports (1) and a metal bone trabecula projection (2), and one end of the metal bone trabecula projection (2) is arranged at the intersection of the at least three intersected metal bone trabecula supports (1). By the aid of the metal bone trabecula projection which can penetrate into a bone to form a pile driving effect, a bone trabecula prosthesis can be steadily combined with a bone bed, a contact area of a bone trabecula surface and a synostosis surface is unaffected, porosity of the metal bone trabecula is unaffected as well, and bone ingrowth can be induced to the maximum extent so as to realize long-term biological fixation of the prosthesis.

Owner:TRAUSON CHINA MEDICAL INSTR COMPANY

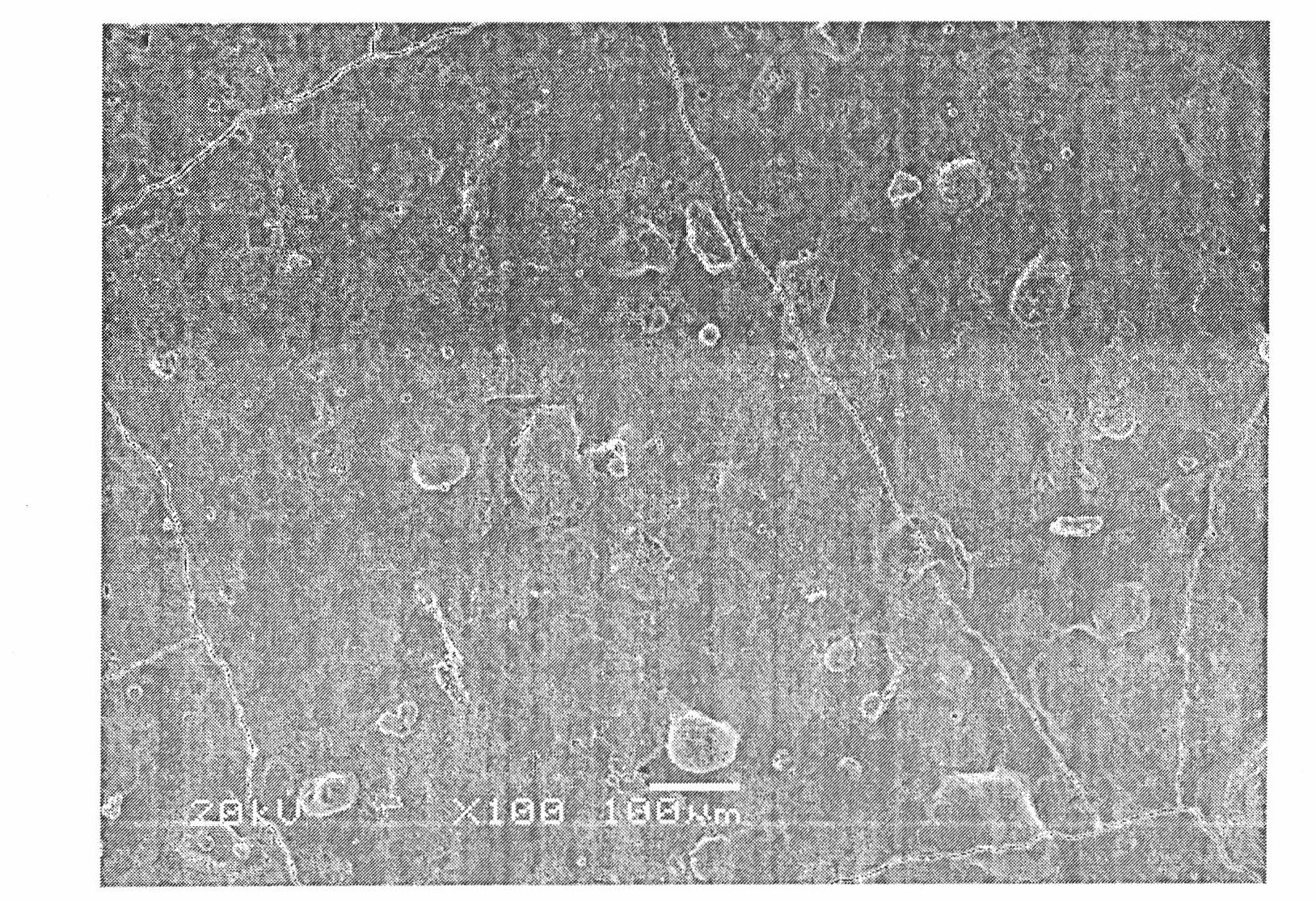

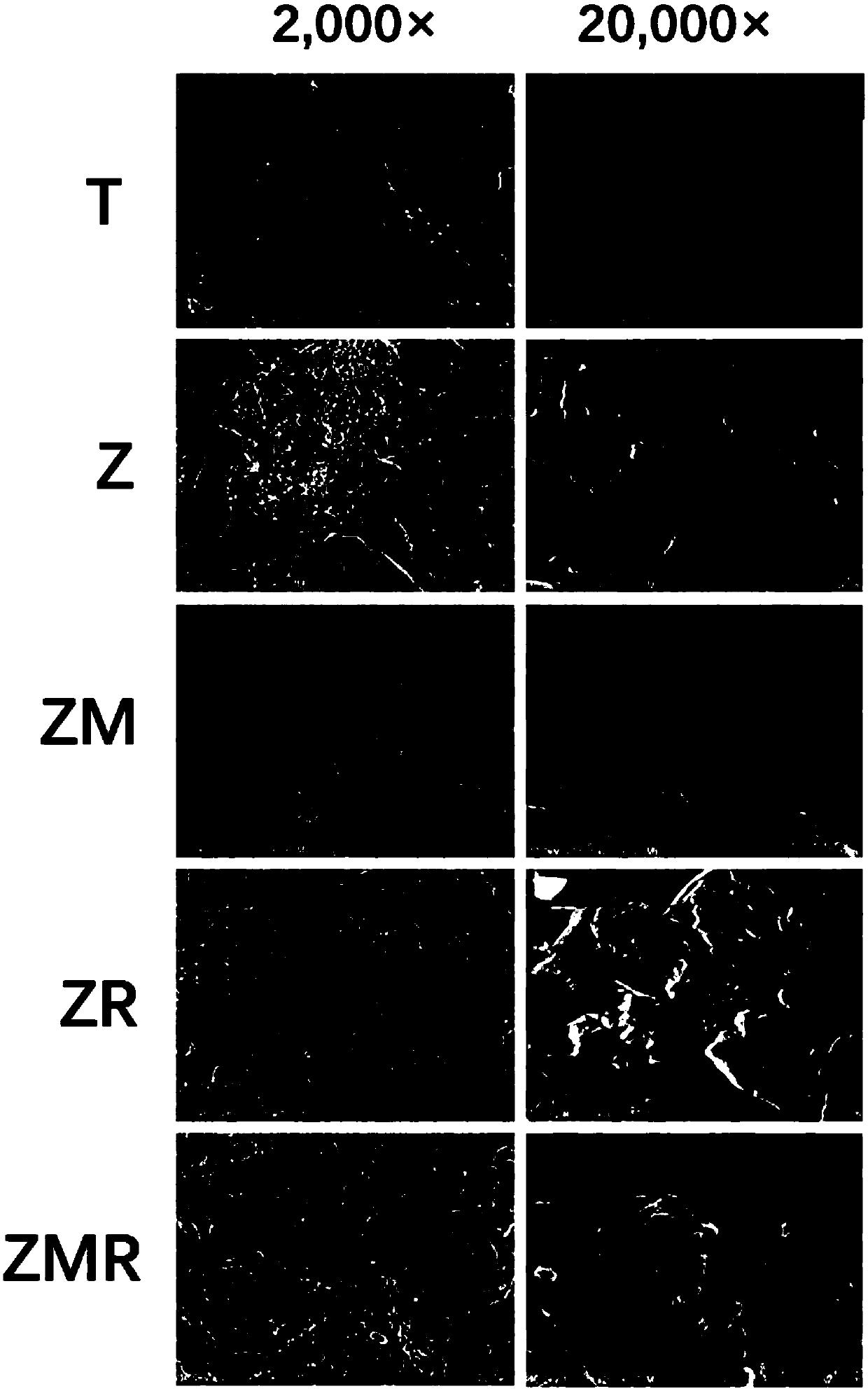

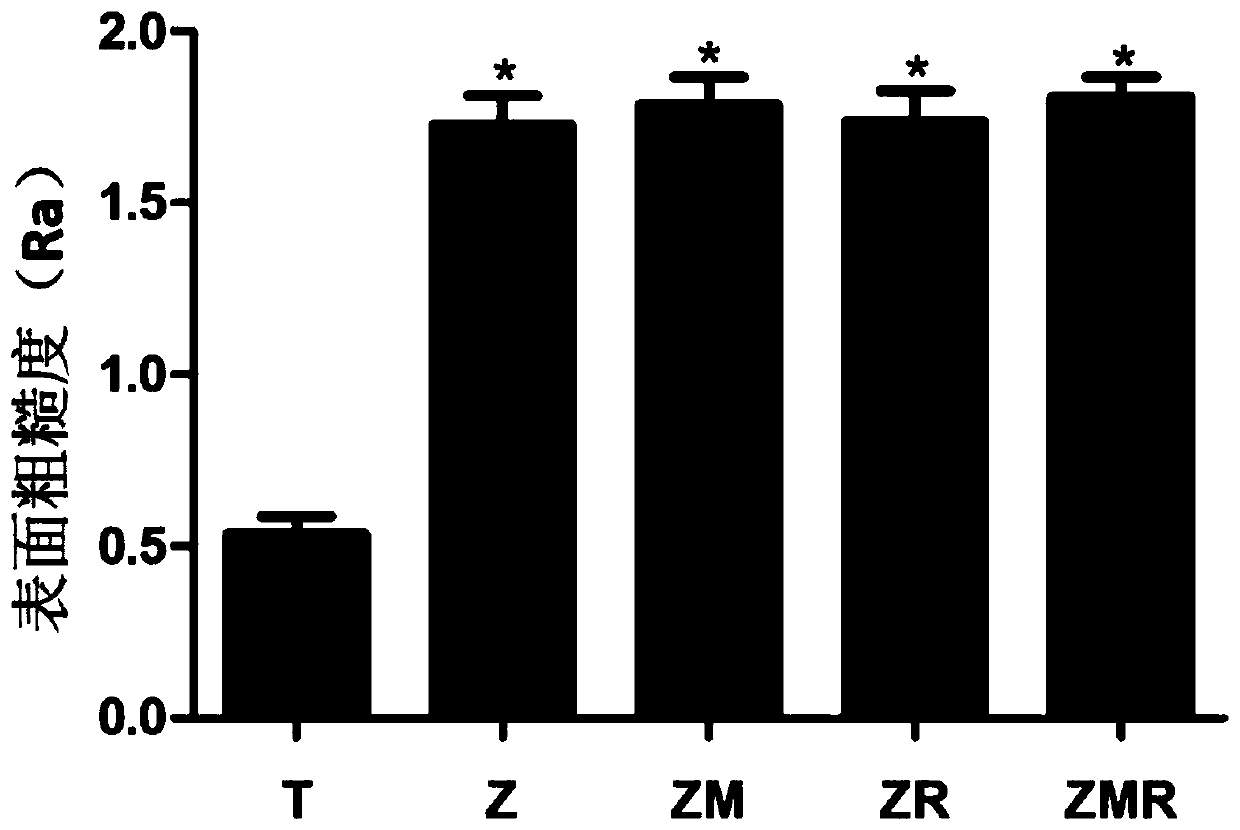

Method for preparing biological active coating layer on surface of zirconia convenient for synostosis

InactiveCN109675098ANo side effectsImprove surface wettabilityPharmaceutical delivery mechanismCoatingsArginineOsteoblast

The invention relates to a method for preparing a biological active coating layer on the surface of zirconia convenient for synostosis. The method comprises the following steps: (1) carrying out magnesium ion implantation after sequentially putting and washing zirconia test pieces, wherein the implantation voltage is 10 to 20 keV, and the magnesium ion concentration is 2 to 3*10<15> ion / cm<2>; (2)carrying out arginine-glycine-aspartic acid tripeptide complex connection on the surface of the zirconia test pieces after the magnesium ion implantation. The test pieces prepared through zirconia for preparing the biological active coating layer are beneficial for adhesion, extension and proliferation of osteoblast, and meanwhile, tissue mineralization can be promoted.

Owner:SHANDONG UNIV

Dental Implant Fixture

InactiveUS20110076642A1Avoid damageReduce spacingDental implantsFastening prosthesisLow bone densityBone Cortex

Provided is a dental implant fixture with 3 or more ridged portions having mutually different pitches to distribute load uniformly across osseous tissue. The pitches of the ridged portions (200) progressively decrease in one direction. The ridged portions (200) include a larger ridged portion (220) that contacts spongy bone with low bone density, and a smaller ridged portion (240) that contacts cortical bone with high bone density. The smaller ridged portion (240) is provided with 2 or more threaded regions with respectively different pitches. With this configuration, bone decay and bone damage can be prevented, and synostosis can be improved.

Owner:COTEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com