Manufacturing method of individualized prosthesis with porous structure

A technology of porous structure and manufacturing method, applied in prosthesis, medical science, bone implants, etc., can solve problems such as limited bone resources, difficult recovery of external shape, and damage to bone harvesting sites, so as to facilitate osseointegration and restore the face Morphological, highly individual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

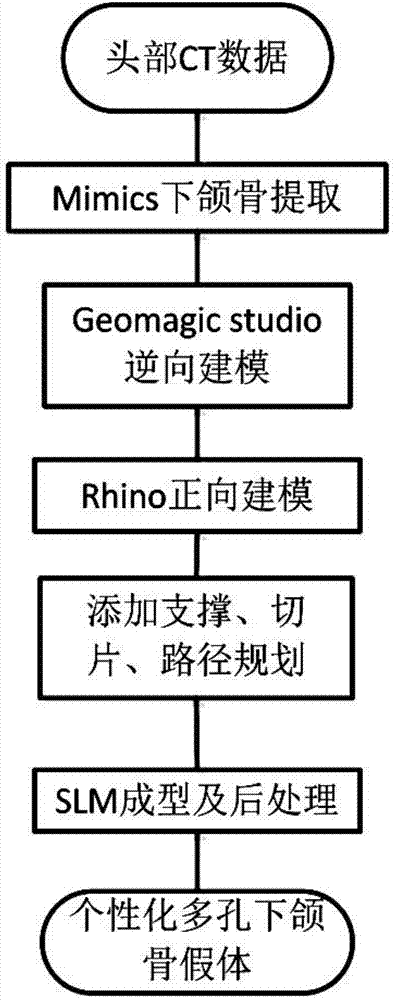

[0025] Select a head CT scan data, import it into mimics10.0 software, set a reasonable gray threshold, and extract the mandible model separately. The mandibular triangular surface model extracted by mimics10.0 software was imported into geomagicstudio software for reverse modeling through smoothing and denoising, contour line editing, surface patch construction, surface fitting and other operations, and the mandibular solid model in IGS format was obtained.

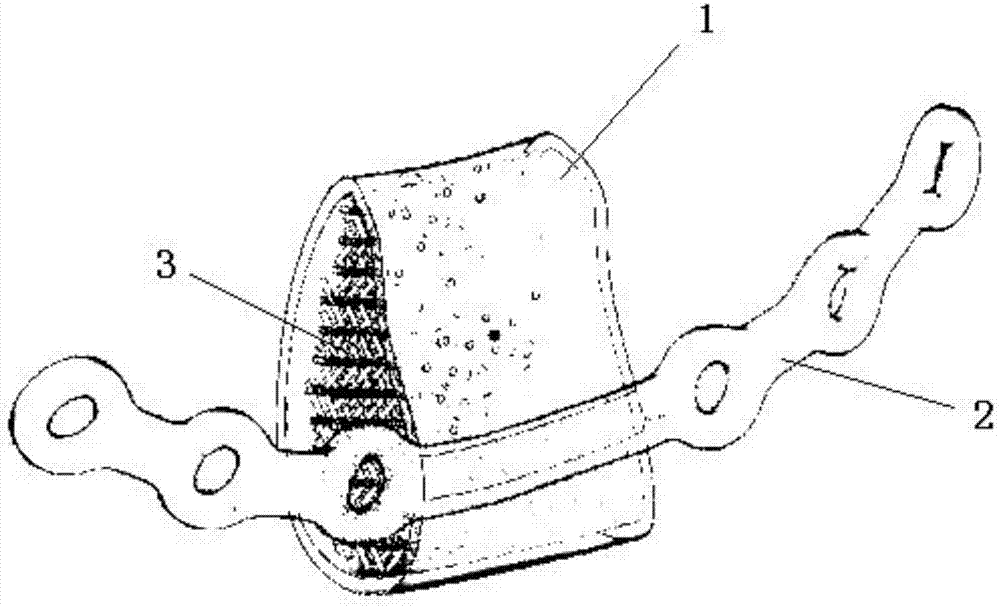

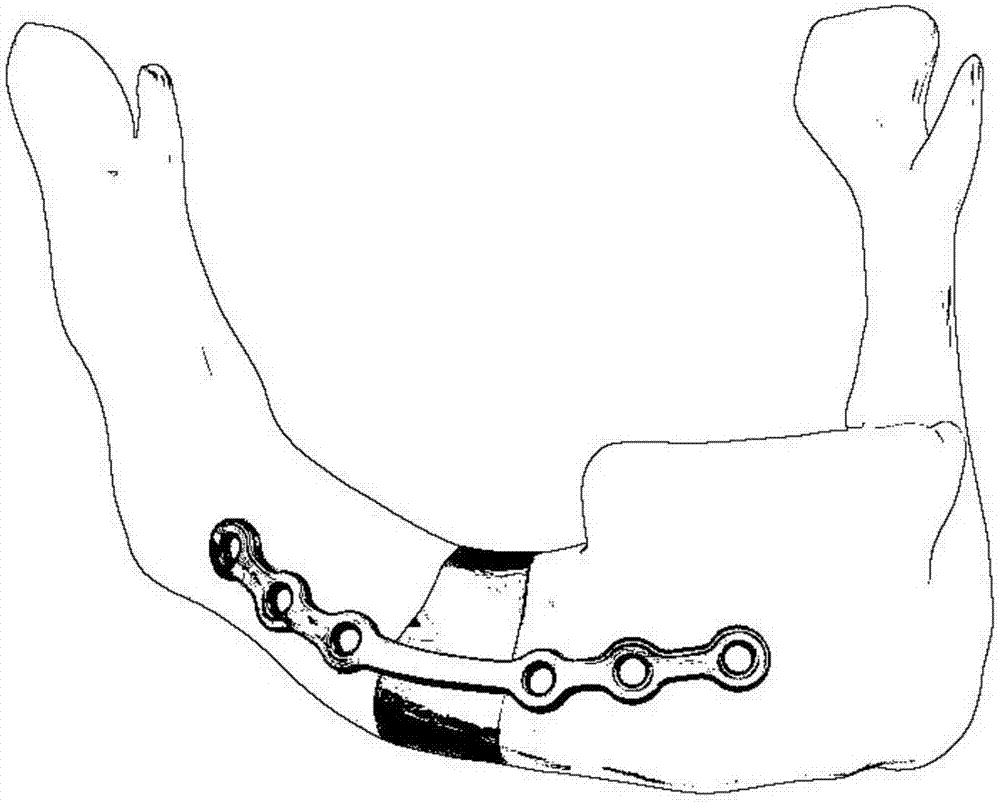

[0026] Import the mandibular solid model in IGS format into rhino software, intercept the part of the diseased mandibular segment to be replaced by the prosthesis, and design the solid shell and fixed wings on both sides of it. Among them, considering the formability of laser selective melting molding equipment and the original thickness (2 mm) of mandibular cortical bone, and considering that the elastic modulus of metal is much higher than that of cortical bone, the thickness of the solid shell is set to 0.5-1 mm. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com