Microwave plasma method for sintering calcium, phosphor bioceramic

A technology of microwave plasma and bioceramics, applied in prosthesis, medical science and other directions, can solve the problems of large energy loss, high sintering temperature, long sintering time, etc., and achieve fast speed, low sintering temperature, and small grain size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

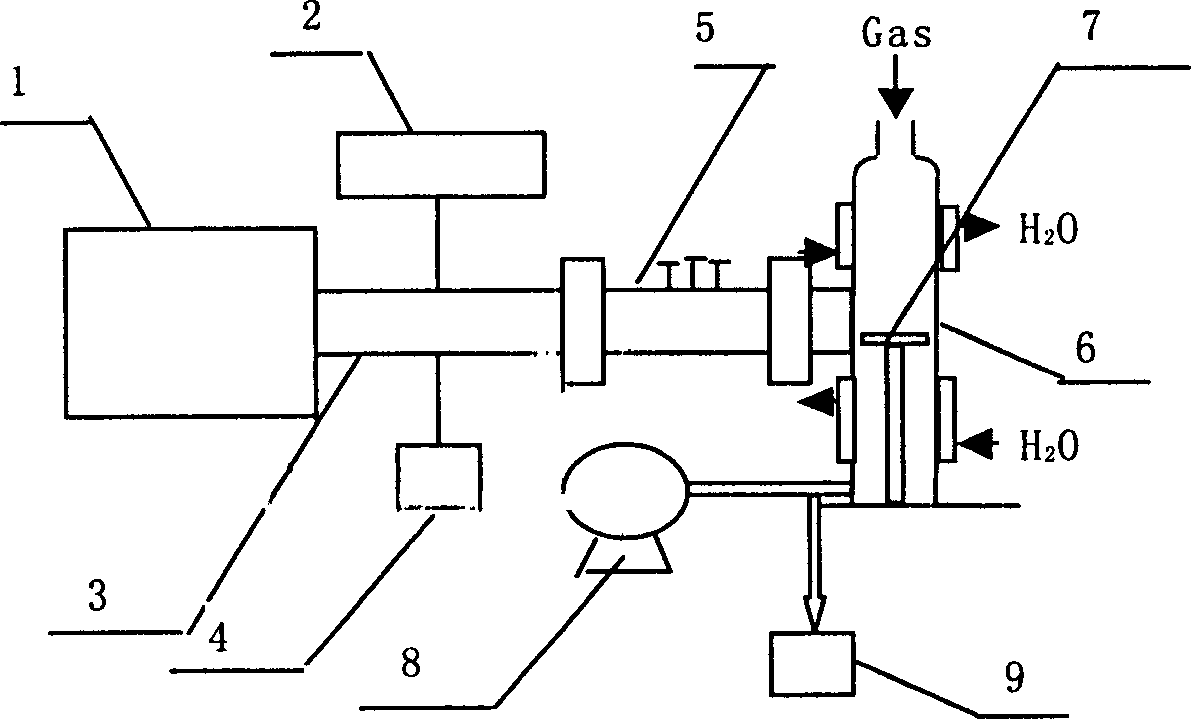

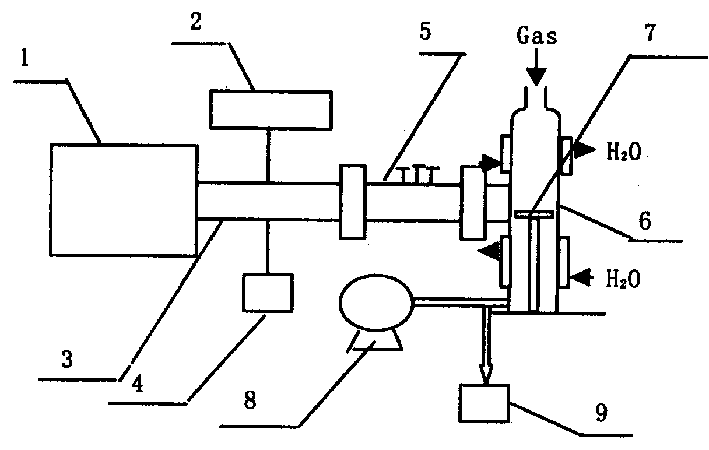

Method used

Image

Examples

Embodiment 1

[0022] Put the formed and degummed hydroxyapatite sample on the abutment of the sintering chamber, pour in cooling water, vacuumize, turn on the microwave generator, and control the CO 2 +O 2 (CO 2 :O 2 =30∶70) The mixed gas flow rate is 100mL / min, the microwave frequency used is 2.45GHz, increase the power to 350W at a speed of 15W / min, gradually adjust the vacuum degree to 8000Pa, keep warm for 20min, and then use a speed of 30W / min Reduce the power, turn off the flame, cool naturally to room temperature and discharge. The linear shrinkage of the obtained sample is 15.8%, and the grain size is 210nm.

Embodiment 2

[0024] Put the formed and degummed tricalcium phosphate sample on the abutment of the sintering chamber, pour in cooling water, vacuumize, turn on the microwave generator, and control O 2 The flow rate is 150mL / min, the microwave frequency used is 2.45GHz, increase the power to 300W at a speed of 10W / min, gradually adjust the vacuum degree to 2000Pa, keep warm for 10min, and then reduce the power at a speed of 30W / min until the flame is turned off. Cool to room temperature and discharge, the linear shrinkage of the obtained sample is 14.8%, and the grain size is 195nm.

Embodiment 3

[0026] Put the formed and degummed hydroxyapatite / tricalcium phosphate (hydroxyapatite: tricalcium phosphate = 60:40) dual-phase sample on the abutment of the sintering chamber, pour in cooling water, vacuumize, and turn on the microwave generator, control O 2 +N 2 (O 2 :N 2 =30∶70) The mixed gas flow rate is 300mL / min, the microwave frequency used is 2.45GHz, increase the power to 300W at a speed of 8W / min, gradually adjust the vacuum degree to 5000Pa, keep warm for 10min, and then decrease at a speed of 30W / min Power, until the material is turned off, the linear shrinkage of the obtained sample is 16.0%, and the grain size is 235nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com