Patents

Literature

50results about How to "Not prone to peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of nano-silica sol modified exterior wall latex paint and preparation method thereof

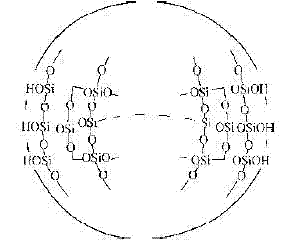

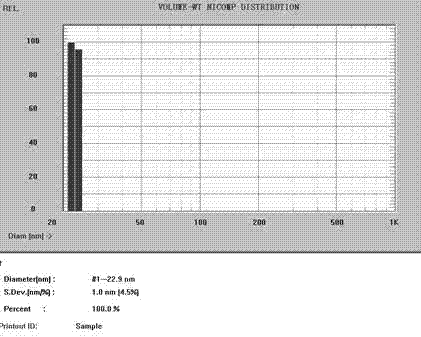

The invention relates to a nanometer silica sol modified exterior wall emulsion paint. The emulsion paint comprises, by mass, 10-30% of water, 15-30% of an emulsion, 5-10% of a nanometer silica sol, 5-15% of heavy calcium, 1-3% of talc, 0.5-1.5% of propylene glycol, 5-25% of titanium dioxide, 0.05-2% of a wetting agent, 0.5-1% of an antifoaming agent, 0.1-0.5% of a dispersant, 1-2% of a thickening agent, and 0.5-2% of a film forming assistant. The preparation method comprises the following steps: dispersion grinding: adding water, powders and early assistants to a dispenser, grinding, and filtering; and post-treating: adding the emulsion, the nanometer silica sol, later water and later assistants to a dispersed slurry, and adjusting the PH value and the viscosity to prepare the emulsion paint. According to the invention, the exterior wall emulsion paint, which is prepared by completing simple technologies of dispersing, sand milling, filtering and the like, has the advantages of no pollution, low VOC (volatile organic compound) discharge, environmental protection, strong adhesion, and good storage stability, washing resistance, contamination resistance and weather resistance.

Owner:SHENYANG SHUNFENG NEW MATERIAL CO LTD

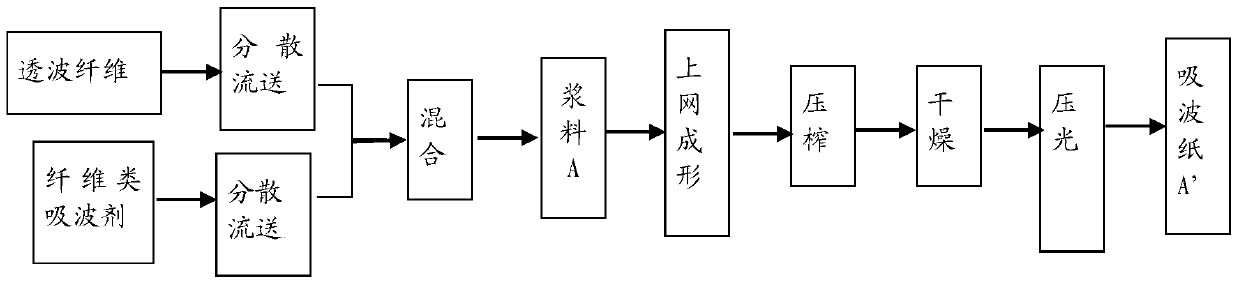

Wave-absorbing paper and preparation method and application thereof

ActiveCN104404814AExcellent electromagnetic attenuation effectImprove mechanical propertiesInorganic fibres/flakesSpecial paperFiberPapermaking

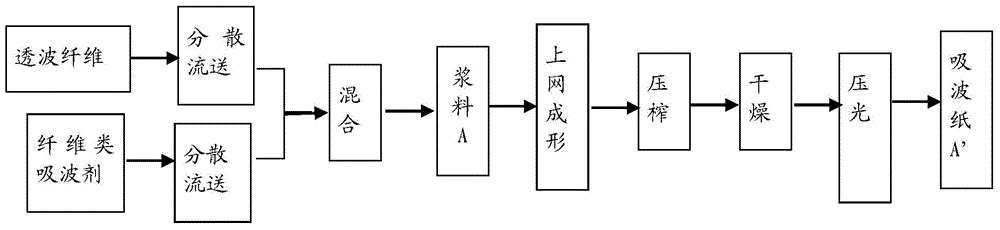

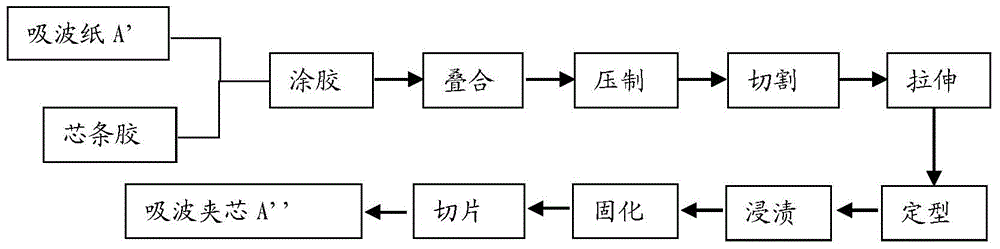

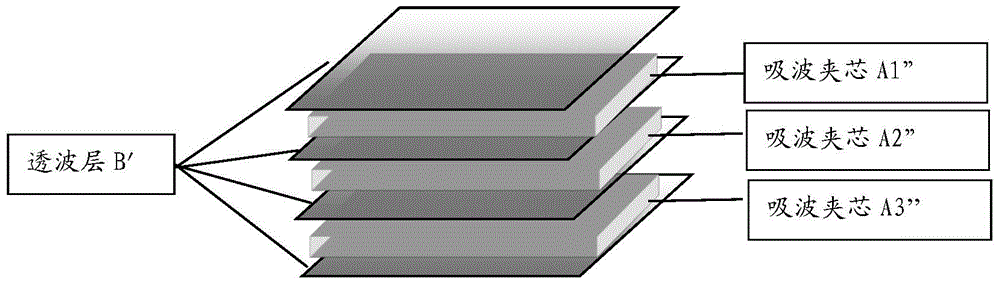

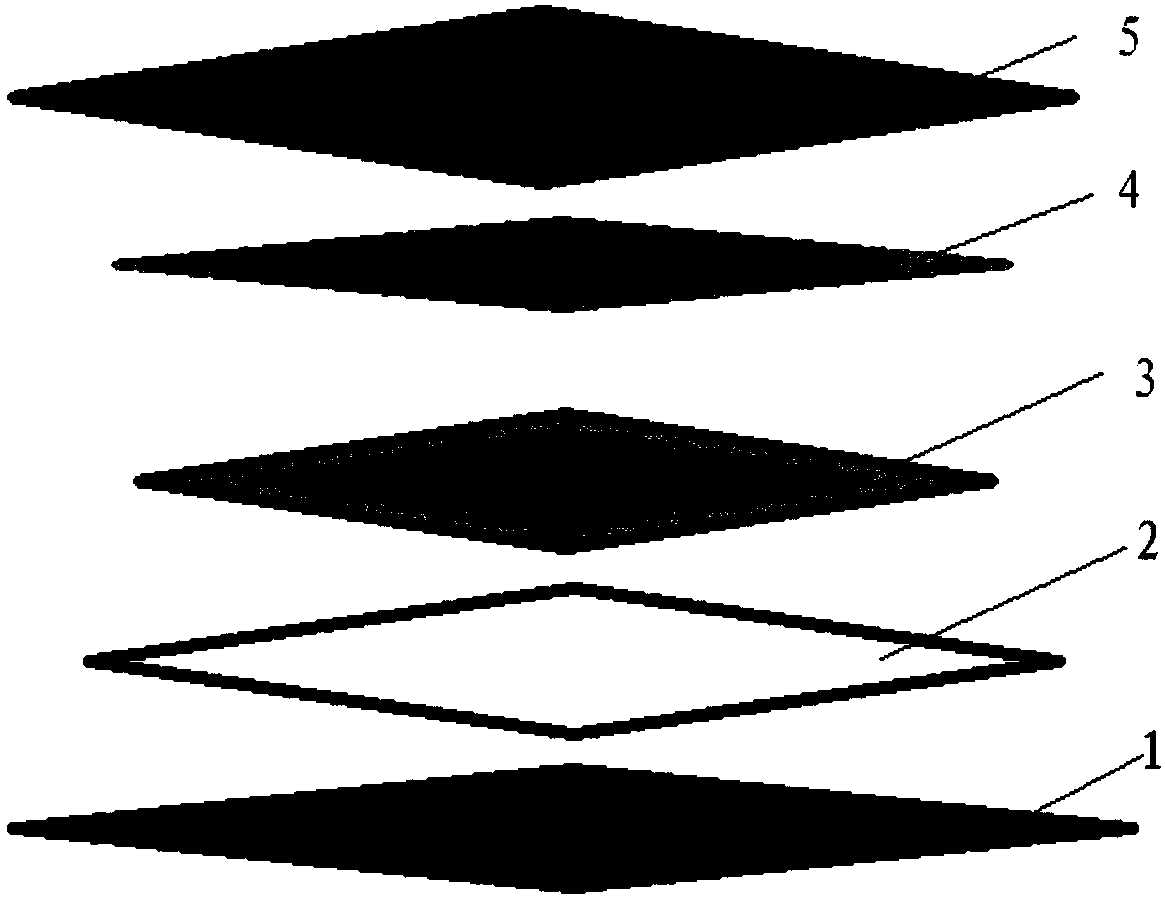

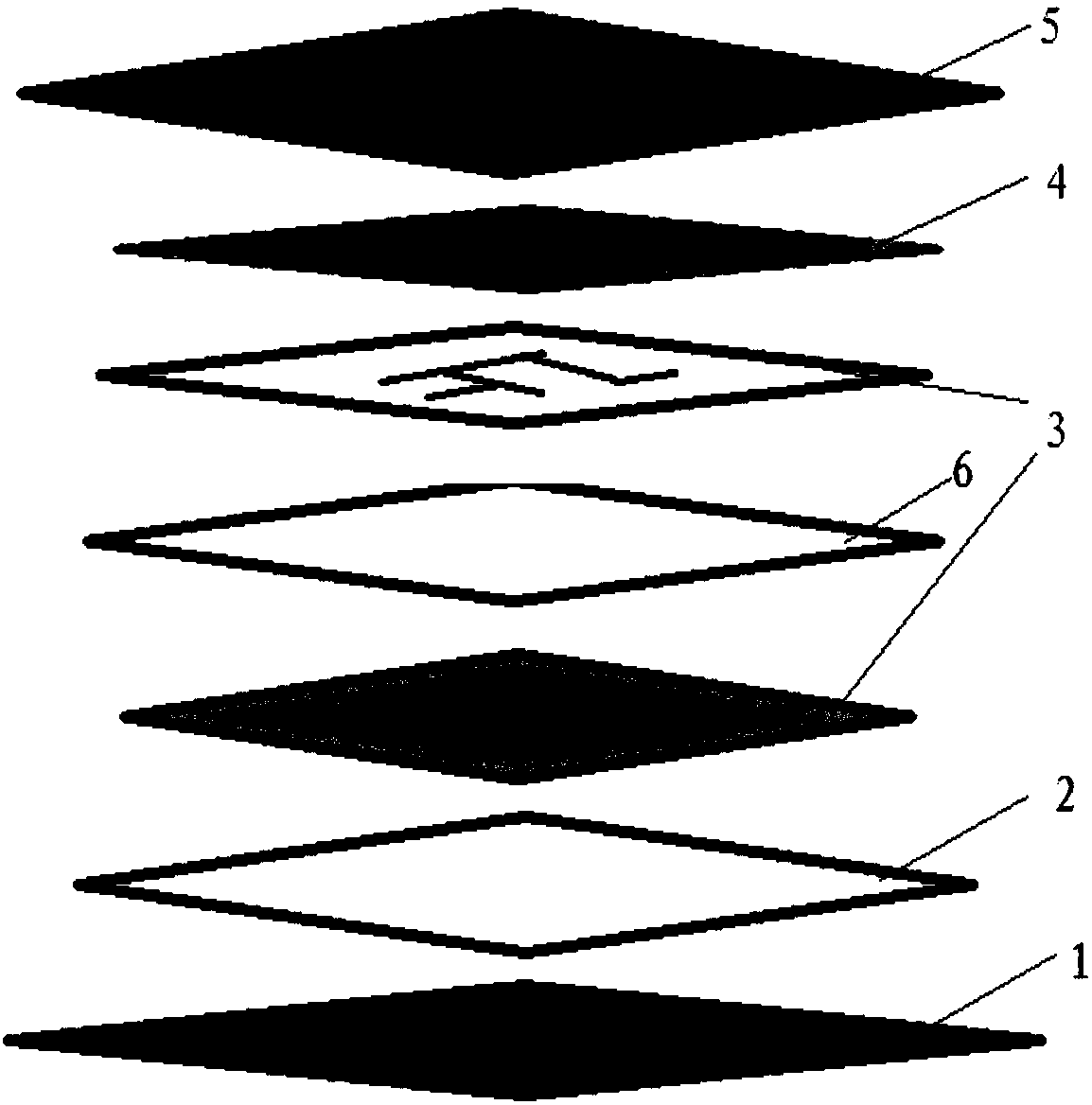

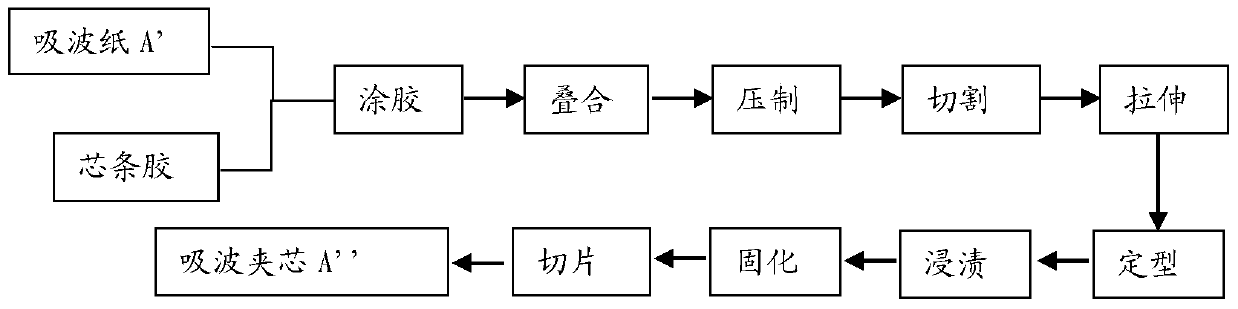

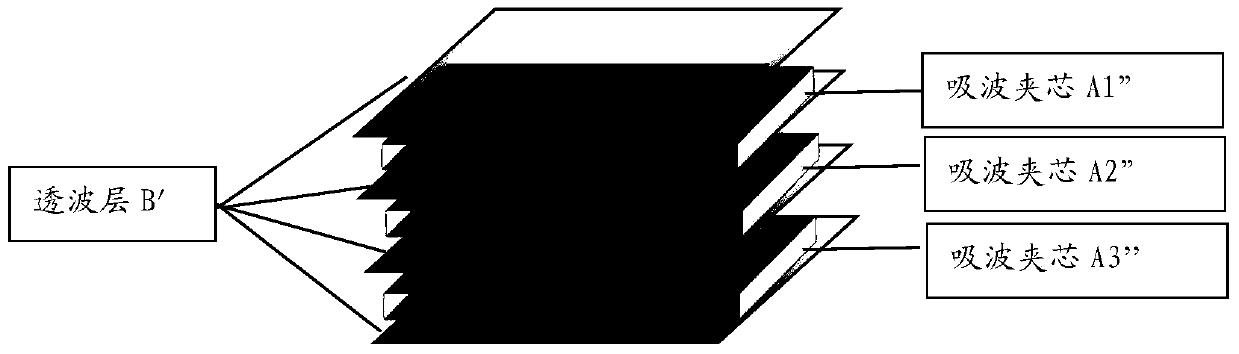

The invention provides wave-absorbing paper and a preparation method and application thereof. The wave absorbing paper contains 0.1-95 wt% of a fiber wave-absorbing agent and 5-99.9 wt% of wave-transparent fiber. The fiber wave-absorbing agent and wave-transparent fiber are mixed and prepared into the wave-absorbing paper by a papermaking process; and then the wave-absorbing paper as a lattice wall material is prepared into a wave-absorbing core sandwich; and then the wave-absorbing core sandwiches prepared from wave-absorbing paper with different fiber wave-absorbing agent content are separated by wave-permeable layers; and finally the entire structure is impregnated and cured to obtain the wave-absorbing material. The wave-absorbing material of the invention has the advantages of high wave-absorbing efficiency, stable wave-absorbing property, wide absorption band, and light weight and high strength.

Owner:SOUTH CHINA UNIV OF TECH

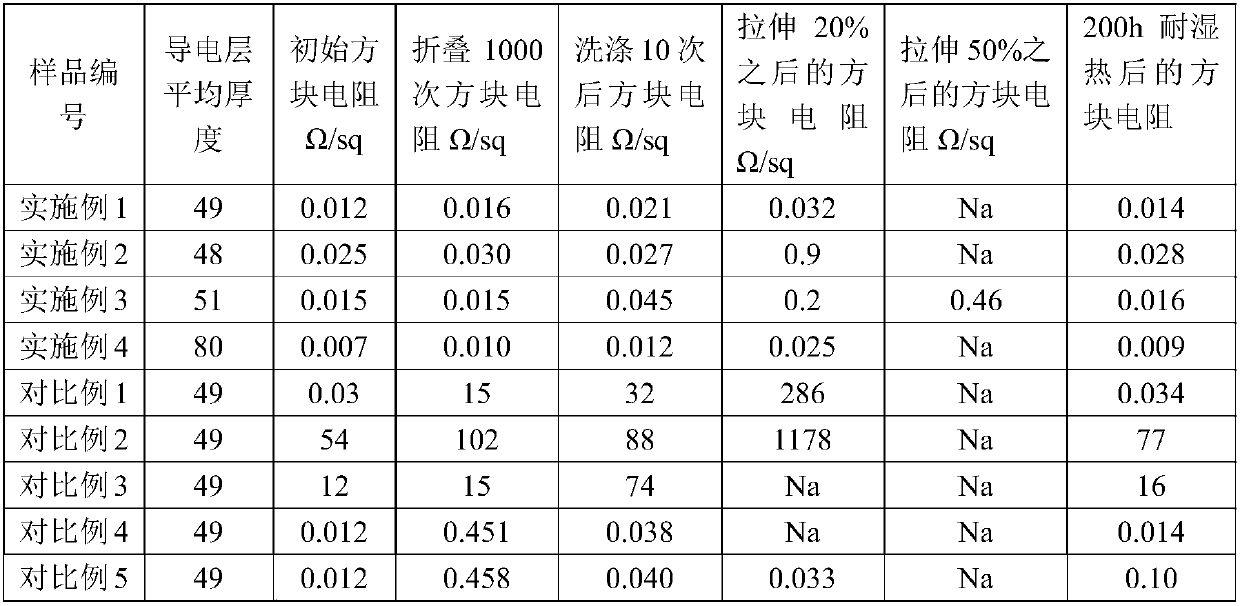

Conductive fabric and preparation method thereof

ActiveCN107938369AImprove wash resistanceImprove tensile propertiesTextiles and paperSurface layerLiquid metal

The invention provides a conductive fabric and a preparation method thereof. The conductive fabric comprises, from inside to outside, an adhesive force improving layer attached to the surface layer ofa fabric substrate, a liquid metal layer, an oxygen isolation protective layer and a packaging protective layer. The preparation method comprises: applying the adhesive force improving layer to the surface layer of a fabric substrate, coating the adhesive force improving layer with the liquid metal layer, coating the liquid metal layer with the oxygen isolation protective layer, and coating the oxygen isolation protective layer with the packaging protective layer. The coating manner includes spraying, brush coating, flow coating or printing. Compared with a conductive fabric in the prior art,the conductive fabric is excellent in conductivity, fold resistance, laundering durability and tensile property. The preparation method is simple and reliable.

Owner:BEIJING DREAM INK TECH CO LTD

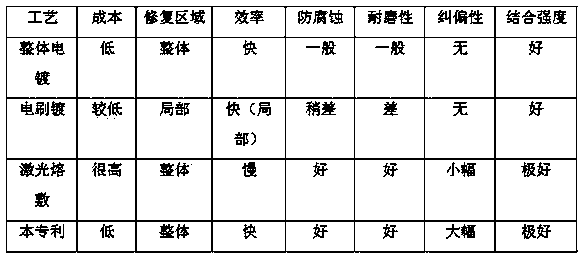

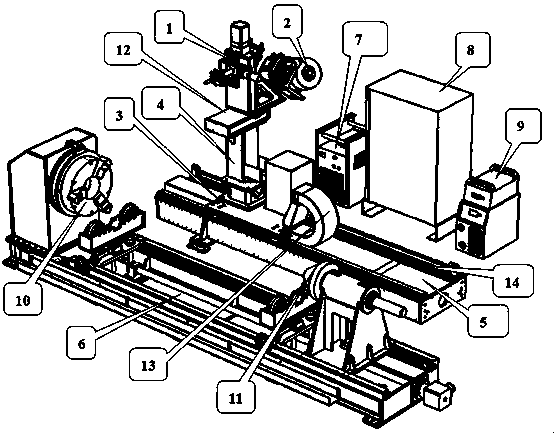

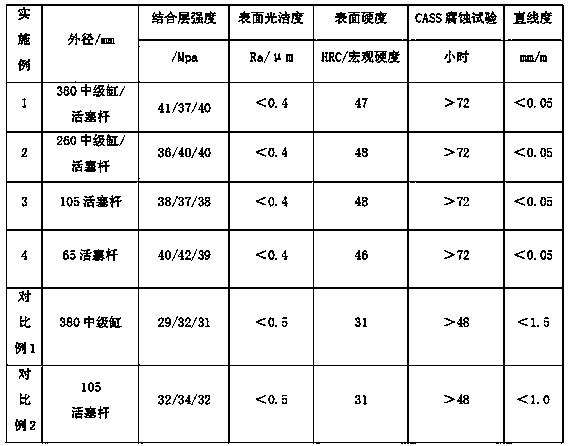

Method for repairing and remanufacturing outer surface of piston rod of hydraulic cylinder or outer surface of intermediate cylinder

ActiveCN104191152AHigh surface macrohardnessImprove wear resistanceArc welding apparatusHydraulic cylinderMetal filament

The invention provides a method for repairing and remanufacturing the surface of a piston rod of a hydraulic cylinder or the outer surface of an intermediate cylinder for coal mines. Aiming at remanufacturing after the surface of the piston rod of the hydraulic cylinder or the outer surface of the intermediate cylinder for the coal mines is damaged and fails, the long-term practice is combined, a metal wire adopting the specific metal powder proportion is creatively designed to serve as a powder core wire, and namely the metal wire is formed by wrapping the metal powder with Cr, Ni and Fe as the main ingredients through a stainless steel foil layer; based on the arc thermal spraying process method, the surface is repaired and remanufactured creatively, and on the premise that the corrosion resistance and the hardness of the repaired layer of the surface are equal to those of the surface treated through the surface laser cladding technology, consideration is given to the good economic applicability and the good practical production efficiency; an existing electroplating technology can be completely replaced, and the method has the wide application and popularization prospects in repairing of the piston rod of the hydraulic support oil cylinder and the intermediate cylinder for the coal mines.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

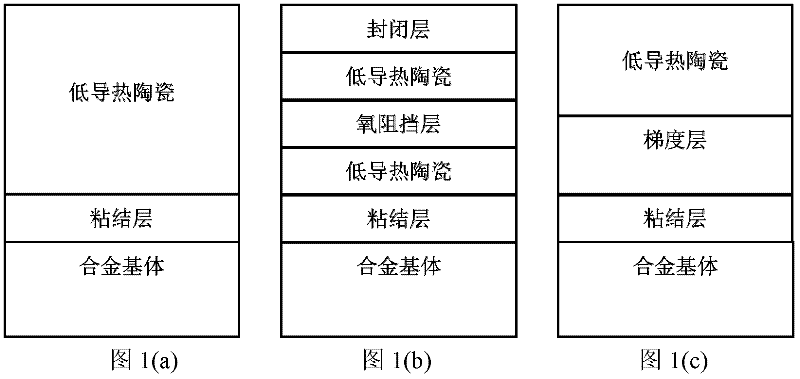

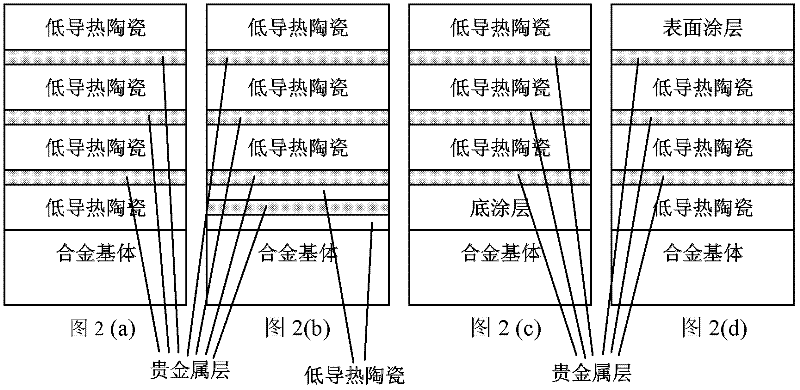

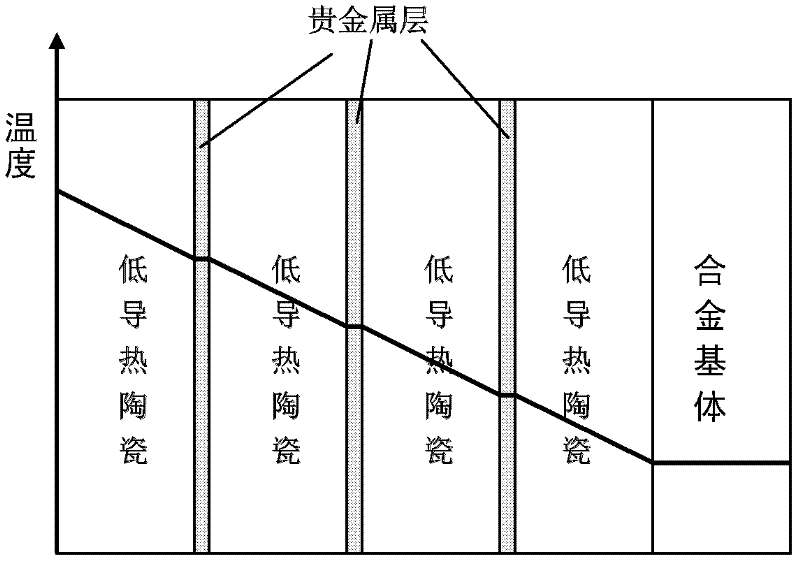

Multipurpose low-conductivity ceramic/noble metal lamellar composite thermal barrier coating

InactiveCN102345122AGood heat insulationNo insulationBlade accessoriesEfficient propulsion technologiesAviationThermal insulation

The invention discloses a multipurpose low-conductivity ceramic / noble metal lamellar composite thermal barrier coating, relating a composite material and coating technology. The coating is divided into four types: (1) regularly and alternatively depositing low-conductivity ceramic layers and noble metal layers; (2) irregularly and alternatively depositing low-conductivity ceramic layers and noblemetal layers; (3) exerting low-conductivity ceramic and noble metal lamellar composite thermal barrier coatings on antioxidant protection layers deposited on the surface of a basic alloy; and (4) depositing other functional coatings on the outer surface of the low-conductivity ceramic / noble metal lamellar composite thermal barrier coating. According to the invention, the lamellar composite thermal barrier coating formed by alternatively depositing the low-conductivity ceramic layers and the noble metal layers has the advantages of excellent thermal insulation performance and thermal shock resistance, stable coating structure and long service life and can be applied to the high temperature protection of hot end components of refractory alloys or high temperature alloys such as an aircraft engine, a marine engine, a ground gas turbine, a rocket engine, and the like.

Owner:UNIV OF SCI & TECH BEIJING

High-density ultrahigh-purity magnesia-calcium brick and preparation method thereof

The invention discloses a high-density ultrahigh-purity magnesia-calcium brick and a preparation method thereof. The high-density ultrahigh-purity magnesia-calcium brick is prepared from 9 to 16% of magnesia-calcium sand having particle sizes of 5-7mm, 9 to 16% of magnesia-calcium sand having particle sizes of 3-5mm, 9 to 16% of magnesia-calcium sand having particle sizes of 1-3mm, 13 to 32% of magnesia-calcium sand having particle sizes of 0.5-1mm, 5 to 25% of magnesia-calcium sand having particle sizes less than or equal to 0.5mm, 5 to 10% of high-purity magnesia sand fine powder having particle sizes less than or equal to 0.044mm, 2 to 5% of tar resin or paraffin, and 2 to 5% of fused zirconia. The preparation method comprises the following steps of raw material proportioning, raw material blending, mixing, molding, sintering, waxing and vacuum aluminium foil package. The high-density ultrahigh-purity magnesia-calcium brick has a high product compact degree and excellent hydration resistance. The high-density ultrahigh-purity magnesia-calcium brick has high purity and thus high slag corrosion resistance and high flushing resistance are obtained. Compared with other like products, the high-density ultrahigh-purity magnesia-calcium brick has better thermal shock resistance. The high-density ultrahigh-purity magnesia-calcium brick contains a large amount of dissociative CaO and thus the high-density ultrahigh-purity magnesia-calcium brick has excellent molten steel cleaning performances and is especially suitable for production of high cleanliness steel such as stainless steel.

Owner:PERFECT WORLD CO LTD

Unburned magnesium-calcium-carbon brick and preparation method thereof

The invention discloses an unburned magnesium-calcium-carbon brick and a preparation method thereof. The unburned magnesium-calcium-carbon brick comprises 9-16 wt% of MgO-CaO clinker with the particle size of 5-7 mm, 9-16 wt% of MgO-CaO clinker with the particle size of 3-5 mm, 9-16 wt% of MgO-CaO clinker with the particle size of 1-3 mm, 13-32 wt% of MgO-CaO clinker with the particle size of 0.5-1 mm, 5-25 wt% of fused magnesia with the particle size of no larger than 0.5 mm, 2-5 wt% of modified asphalt bonding agent, 3-5 wt% of flake graphite, and 2-5 wt% of metal magnesium powder additive. The preparation method comprises the following steps: according to the raw material, carrying out combination of the formula, preparing materials, mixing, molding, sintering, and waxing, and then carrying out vacuum aluminum foil packaging. The unburned magnesium-calcium-carbon brick has high hydration resistance property, high slag resistance property because of high purity, and better thermal shock resistance than other like products. Simultaneously, the method has the advantages of simple process and low cost. The brick contains free CaO, so that the brick has excellent performance of purifying molten steel, and is very suitable for preparing stainless steel and other high cleaness steel.

Owner:PERFECT WORLD CO LTD

Environment-friendly latex paint and preparation method thereof

InactiveCN108329765AStrong adhesionLight smellAntifouling/underwater paintsPaints with biocidesFiberWeather resistance

The invention discloses an environment-friendly latex paint and a preparation method thereof, and relates to the technical field of latex paint. The latex paint is prepared from the following raw materials in parts by weight: 85-105 parts of styrene-acrylic emulsion, 35-45 parts of nano-silica sol, 20-25 parts of diatom ooze, 10-15 parts of nano-TiO2, 10-15 parts of tourmaline anion powder, 10-15parts of glutinous rice glue, 7-8 parts of plant dehydrated filaments, 7-8 parts of antibacterial powder, 4-6 parts of active powder, 4-6 parts of essential oil components, 20-22 parts of an aid and 70-75 parts of deionized water. The latex paint has relatively powerful adhesive force, a paint film has light smell, low VOC and high adhesive force and is combined with the wall stably, peeling and bursting of the paint surface are not easily produced, and weather resistance of the latex paint is greatly improved.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

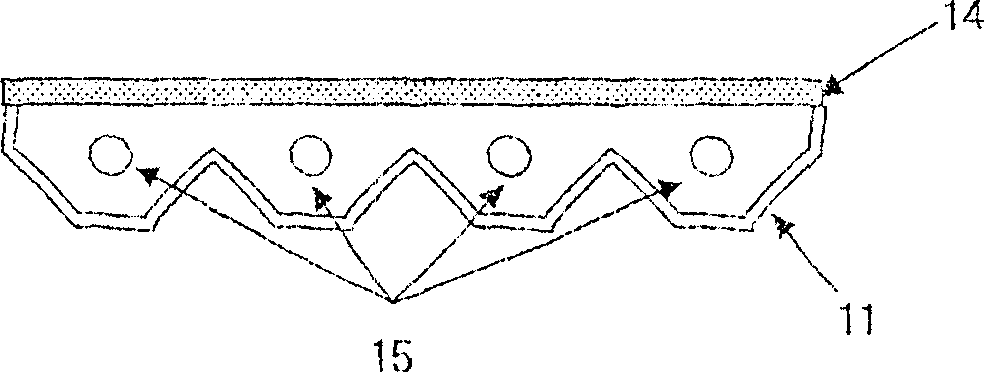

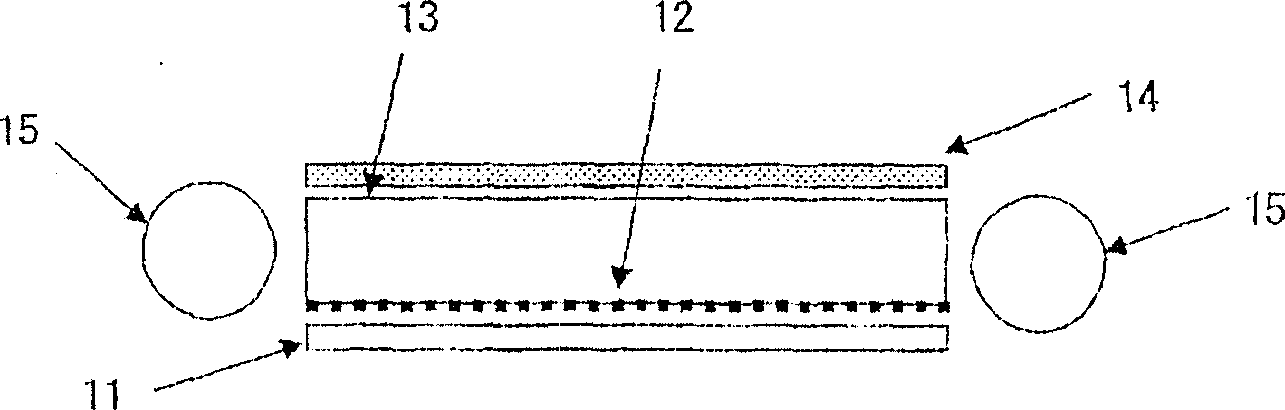

Light-reflector and planar light source using same

ActiveCN1809768AExcellent optical propertiesIncrease brightnessMechanical apparatusMirrorsOptical propertyOptoelectronics

A light reflector having a laminate film that comprises a substrate layer (A) containing a thermoplastic resin and a filler and stretch in at least one direction to have an areal draw ratio of from 1.3 to 80 times and a thermoplastic resin-containing layer (B), wherein the light reflector has a whole ray reflectance of at least 95% and a surface strength of at least 250 g. The light reflector has good optical properties and good workability in that, when stuck to various plates and shaped, it hardly looses, drops and peels from the substrate plates.

Owner:MITSUBISHI CHEM CORP

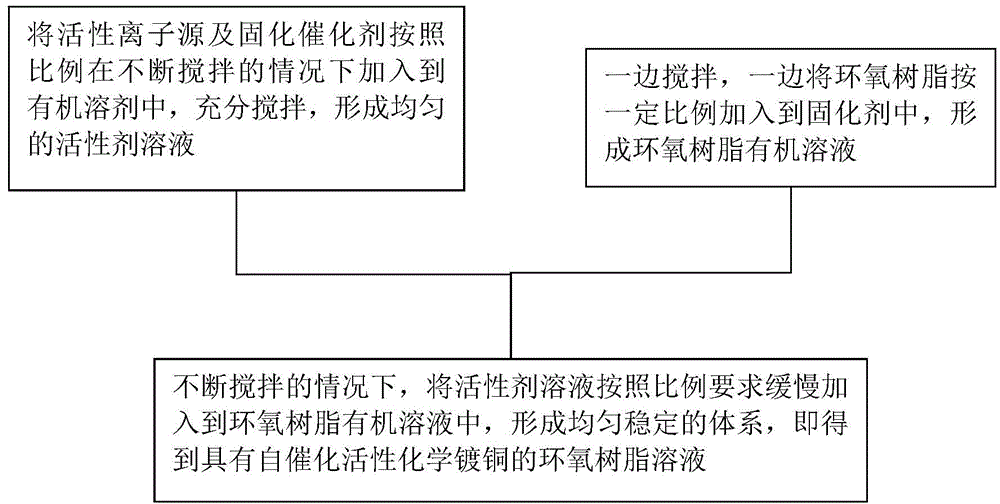

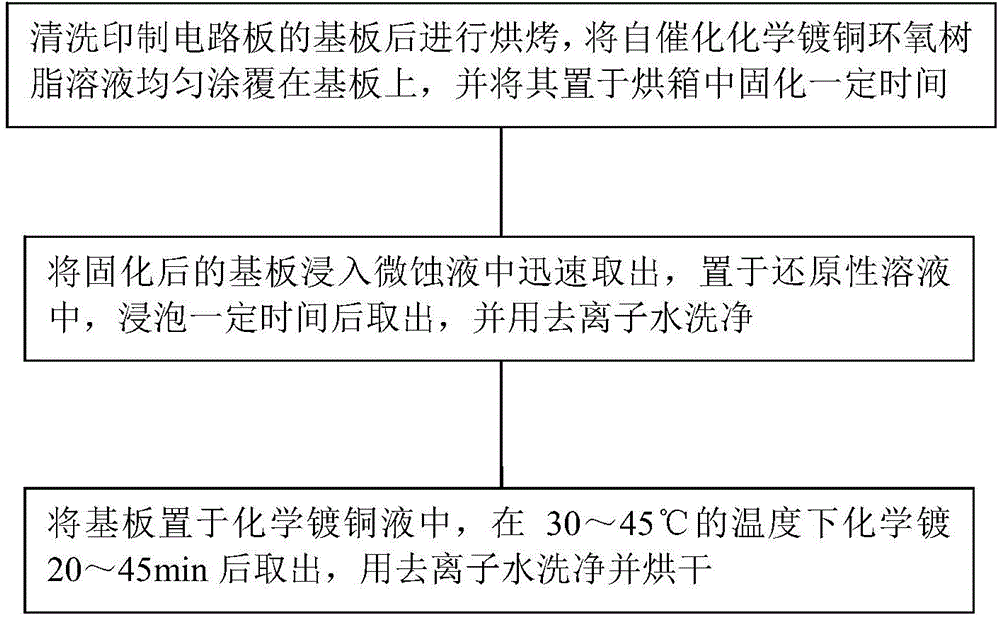

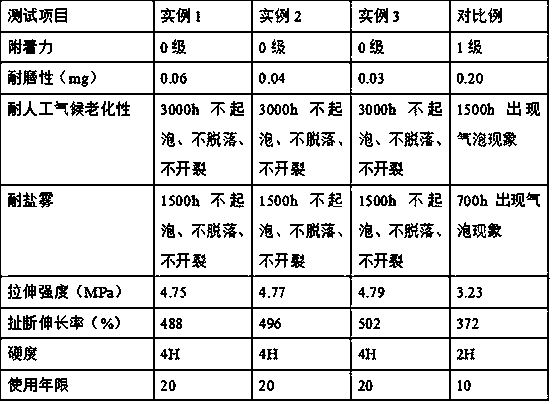

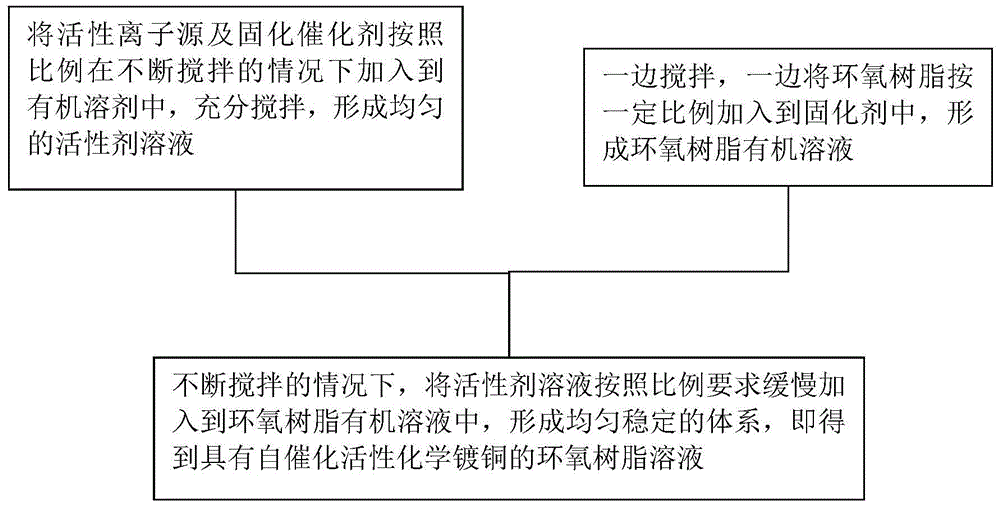

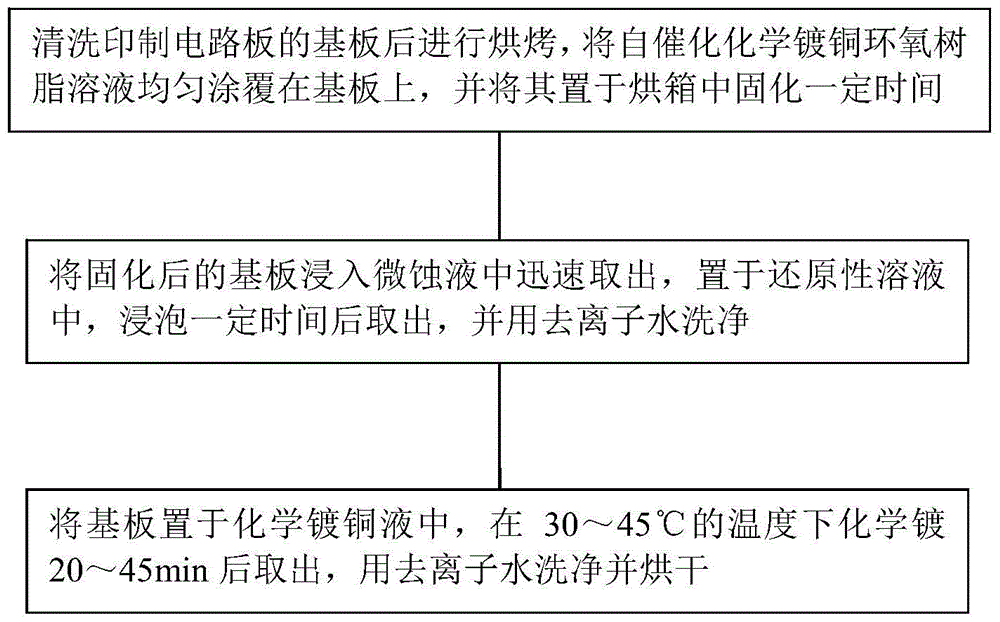

Compounding method of epoxy resin solution with autocatalysis chemical copper plating activity and chemical copper plating method

InactiveCN104789949AImprove stabilityEvenly distributedLiquid/solution decomposition chemical coatingEpoxyChemical plating

The invention relates to a compounding method of an epoxy resin solution with autocatalysis chemical copper plating activity and a chemical copper plating method, and belongs to the technical field of material surface treatment. The compounding method comprises the following steps: adding an activity ion source to an organic solvent under the circumstance of unceasingly stirring, adding a given number of curing catalysts, and sufficiently stirring the activity ion source, the organic solvent and the curing catalysts so as to form a uniform active agent solution; adding epoxy resins to a curing agent according to a certain proportion in a stirring manner so as to form an epoxy resin organic solution; unceasingly stirring the epoxy resin organic solution, and besides, slowly adding the active agent solution to the epoxy resin organic solution so as to form a uniform stable system, namely obtaining a chemical copper plating epoxy resin solution with autocatalysis activity; enabling a compounded resin solution to form a uniform coating on a basal board of a printed circuit board by a casting method or a silk screen printing method, and performing the procedures of solidification, microetch, reduction, chemical plating and the like so as to obtain a plating piece with a bright pink copper plating layer. Through performance test, the copper layer-resin binding force and the electrical conductivity of samples are excellent, and the compounding method and the chemical copper plating method are suitable for a chemical copper plating technology.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Zirconia-mullite-containing material based on kyanite tailings and preparation method of zirconia-mullite-containing material

The invention particularly relates to a preparation method of zirconia-mullite-containing material based on kyanite tailings. According to the technical scheme, the preparation method comprises the steps that 70-80wt% of kyanite tailing particles, 22-32wt% of alpha-alumina micro powder and 0.4-0.8wt% of beryllium oxide are taken as raw materials, the raw materials are added into a ball mill, thenwater with the weight being 300-400wt% of that of the raw materials is added into the ball mill, ball milling is conducted for 4-6 h, and slurry is obtained; the slurry is dried under the condition of80-120 DEG C, crushed and levigated to obtain fine powder; a polyvinyl alcohol solution with the weight being 3-5wt% of that of the fine powder is added into the fine powder, even stirring is conducted, material ageing is conducted for 20-24 h; then compression moulding is conducted, and drying is conducted under the condition of 80-140 DEG C for 14-24 h; and heat preservation is conducted underthe condition of the oxidizing atmosphere and the temperature of 1200-1600 DEG C for 2-5 h, and thus the zirconia-mullite-containing material based on the kyanite tailings is prepared. The preparationmethod has the characteristics that the cost is low, technology is simple, and resources can be comprehensively utilized, and the prepared product is good in thermal shock performance.

Owner:WUHAN UNIV OF SCI & TECH

Fireproof material for steel ladle bottom and preparation method thereof

InactiveCN103482992AEnhanced resistance to molten steel erosionStrong resistance to molten steel erosionGranularityRefractory

The invention discloses a fireproof material for a steel ladle bottom. The fireproof material is made of a framework and castable. The framework is made of large clinkers of which granularity ranges from 50mm to 400m, and the castable is made of aluminum-magnesium auto-flowing castable in which rho-aluminum oxide is used as a binding agent. According to the fireproof material, the large clinkers which are well sintered and are compact in structure are used as the ladle bottom refractory framework, and therefore molten steel washing resistance of the framework is effectively enhanced; the aluminum-magnesium auto-flowing castable in which rho-aluminum oxide is used as the binding agent belongs to non-cement castable, and the castable has the advantages that an integrative system is pure and liquid phase amount generated under high temperature is small; the aluminum-magnesium auto-flowing castable generates spinels in situ under the high temperature condition, the in-situ generated spinels are used as a binder phase, and then the castable has the advantages of being good in thermal shock stability performance and not prone to peeling in the using process, the castable and the framework are encapsulated and poured into a whole, and therefore the fireproof material has the advantages of being high in molten steel washing resistance, good in peeling resistance, long in service life and the like. The fireproof material can have the good using effect in various steel ladle bottoms.

Owner:TANGSHAN GUOLIANG SPEICAL REFRACTORY MATERIAL

Emulsion paint capable of effectively purifying air and preparation method of emulsion paint

InactiveCN107236375ASmooth appearanceNo lumpsAntifouling/underwater paintsPaints with biocidesFiberEmulsion

The invention discloses emulsion paint capable of effectively purifying air and a preparation method of the emulsion paint, and belongs to the technical field of emulsion paint. The emulsion paint comprises, by weight, 65-68 parts of styrene acrylic emulsion, 45-55 parts of modified bamboo pulp fibers, 32-34 parts of reinforced particles, 27-29 parts of citronella oil, 24-26 parts of ricinoleic acid, 22-23 parts of plant dehydration fiber filaments, 19-20 parts of additives and 36-38 parts of water. According to the emulsion paint, a paint film is flat in appearance, free from hard lump and good in hand feeling and glossiness, and formaldehyde and other harmful volatile organic compounds can be effectively removed.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

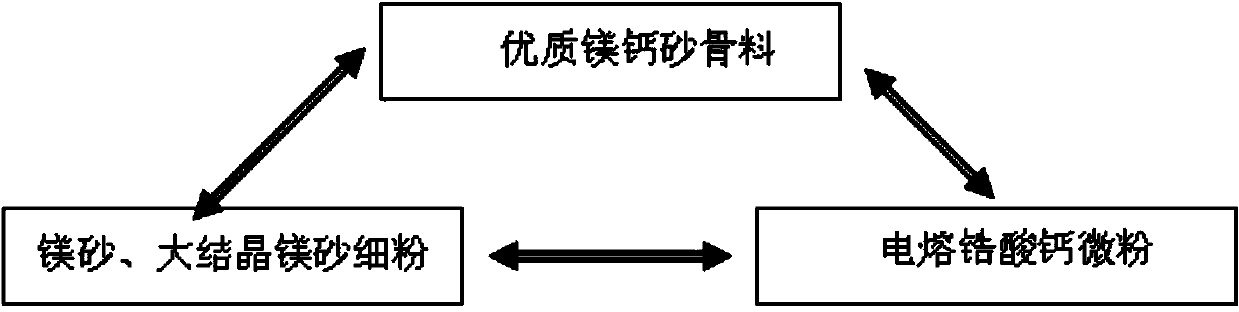

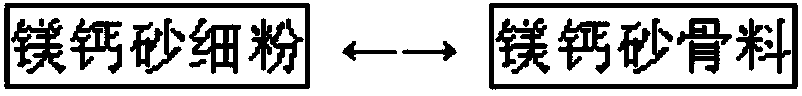

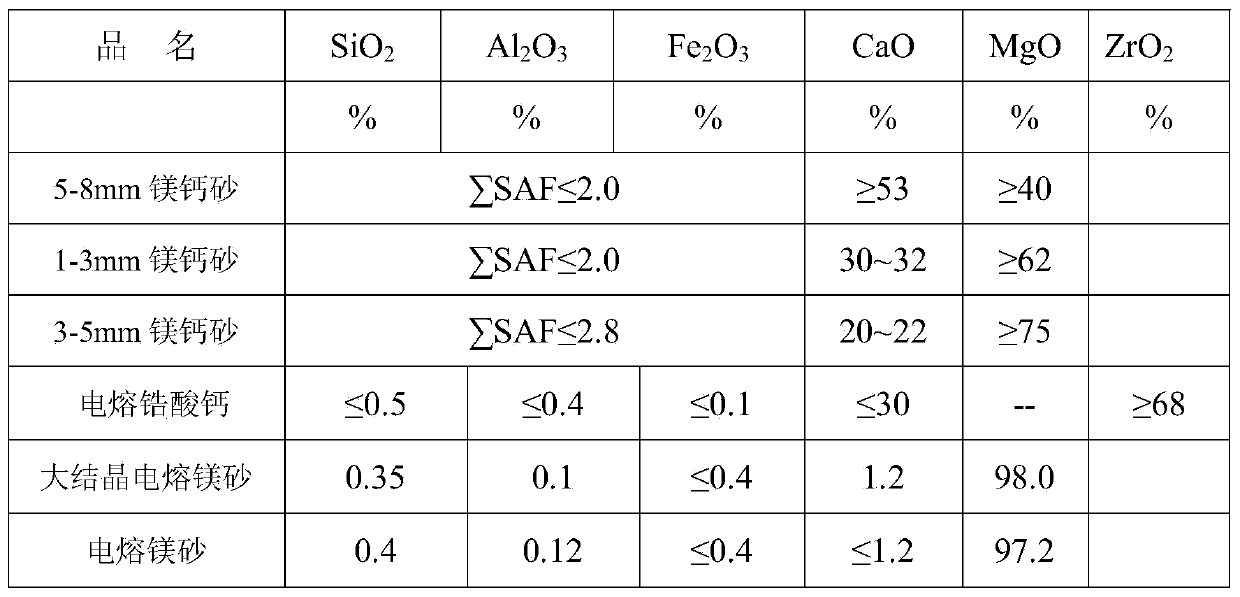

Dolomite-periclase-calcium zirconate composite fireproof material and preparation method thereof

The invention relates to a high-quality dolomite-periclase-calcium zirconate composite fireproof material suitable for smelting stainless steel, special steel AOD furnace and refining ladles. The adopted raw materials mainly comprise, by weight, 8-10% of magnesium calcium sand with a particle size of 5-8 mm, 9-18% of magnesium calcium sand with a particle size of 3-5 mm, 10-22% of magnesium calcium sand with a particle size of 1-3 mm, 5-10% of calcium zirconate with a particle size of 0.5-1 mm, 5-10% of magnesia with a particle size of 0.5-1 mm, 3-10% of 600 mesh electric melting calcium zirconate, 15-24% of magnesia with a particle size of less than or equal to 0.5 mm, 3-10% of 400 mesh 98 large crystal magnesia, 1-3% of a binding agent, and 1-2% of a sintering agent, wherein the raw materials are subjected to mixing, molding, sintering, finished product inspection, package and other steps to prepare the material.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

Hot-galvanized aluminum-magnesium alloy steel plate and production process thereof

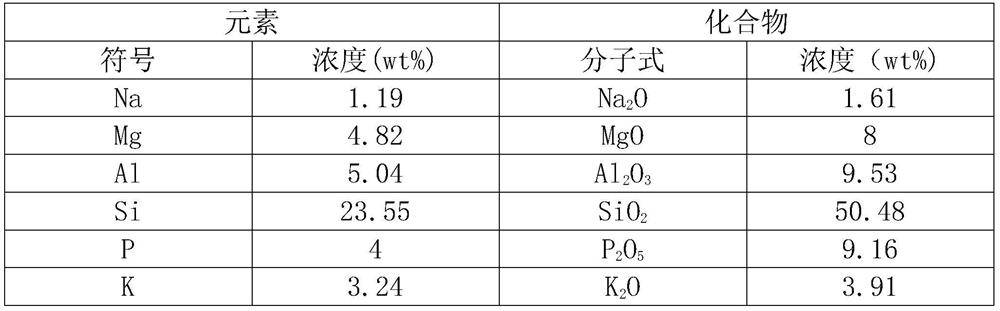

ActiveCN108441796AImprove corrosion resistanceHigh surface hardnessHot-dipping/immersion processesCeriumZinc alloys

The invention discloses a hot-galvanized aluminum-magnesium alloy steel plate and a production process thereof. The hot-galvanized aluminum-magnesium alloy steel plate comprises a steel plate body anda plating layer on the surface of the steel plate body. The plating layer comprises the following components of aluminum, magnesium, cerium, lanthanum, antimony and zinc. A zinc ingot is placed in azinc pot to be heated and molten; a magnesium-zinc alloy ingot, an aluminum-zinc alloy ingot and rare earth are placed in, sampling is carried out after melting, a sample is subjected to spectral analysis, various chemical components are measured, the zinc ingot, the magnesium-zinc alloy ingot, the aluminum-zinc alloy ingot and the rare earth continue to be added according to the actual contents of the components, uniform stirring is carried out, and then spectral analysis of the sample is carried out till the content requirement of the components is met; the steel plate body is subjected to finishing, and then the front face is subjected to passivating treatment; and galvanization of the steel plate body is carried out, the steel plate body is preheated before being put in the pot, and the steel plate body is annealed after being galvanized. In this manner, according to the hot-galvanized aluminum-magnesium alloy steel plate and the production process thereof, corrosion resistance ofthe hot-galvanized aluminum-magnesium alloy steel plate is improved, and the plating layer is not prone to peeling off.

Owner:江苏克罗德科技有限公司

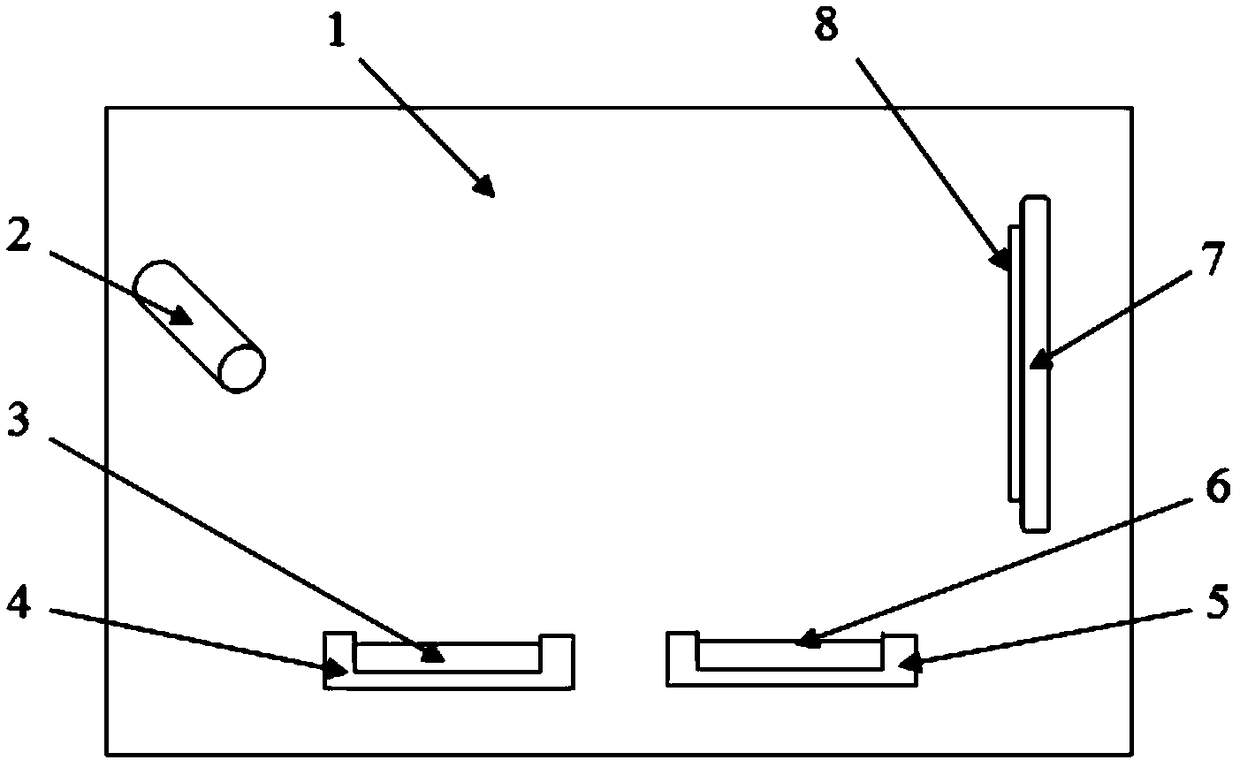

Method for preparing lithium-sulfur battery positive plate by means of ion beam sputtering technology

InactiveCN108493402AWell mixedImprove conductivityCell electrodesCarbon compositesLithium–sulfur battery

The invention discloses a method for preparing a lithium-sulfur battery positive plate by means of an ion beam sputtering technology. Preparation of the positive plate is conducted in an ion beam sputtering chamber, aluminium foil is used as a substrate, quantitative block sulfur and block carbon are used as target materials, after the ion beam sputtering chamber is vacuumized, an argon ion beam is adopted to bombard the block sulfur and the block carbon with different power alternately, sulfur atoms and carbon atoms are sputtered respectively and deposit on the surface of the aluminium foil,and then the lithium-sulfur battery positive plate with a sulfur / carbon composite material is obtained. The preparation method has the advantage that the alternate sputtering amounts of sulfur and carbon can be precisely controlled, so that the sulfur / carbon composite material is evenly mixed.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

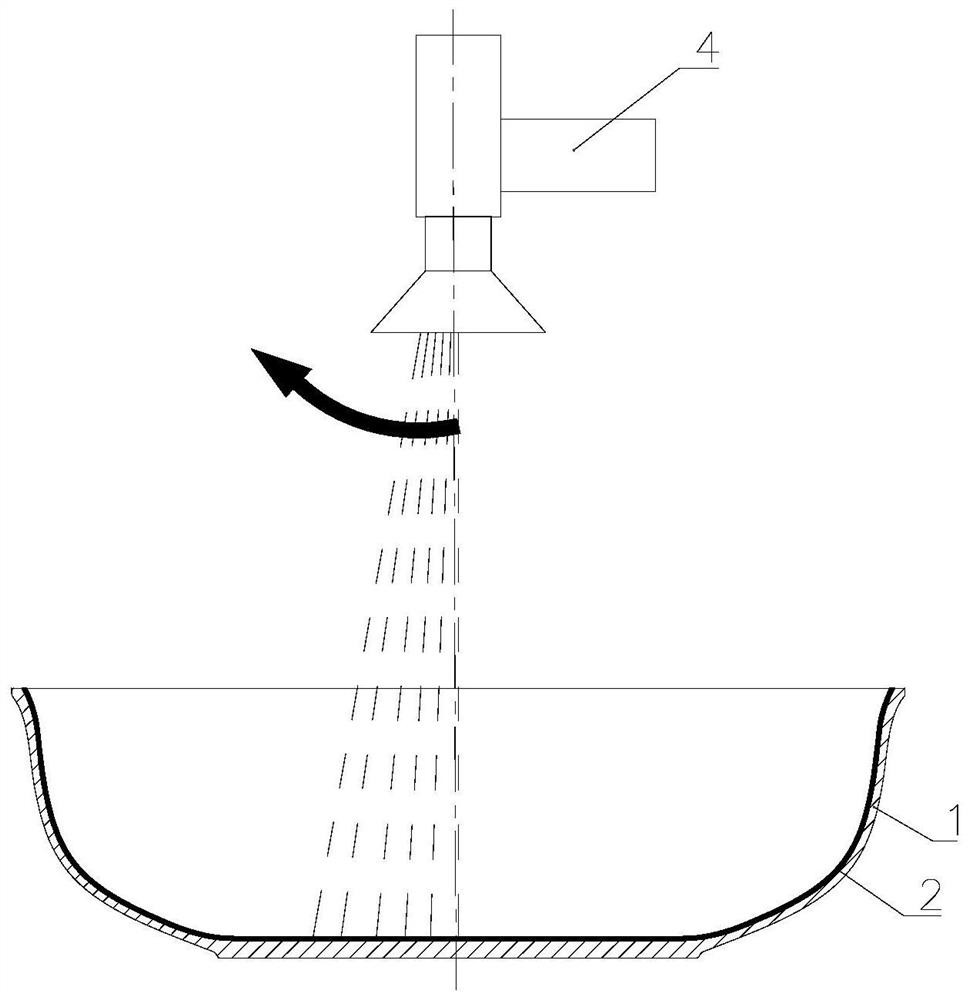

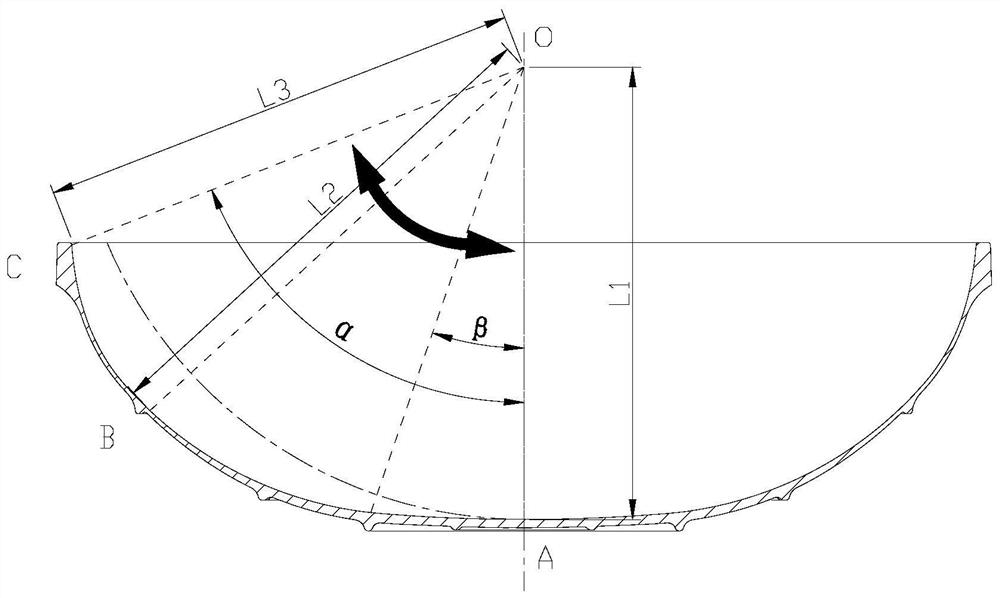

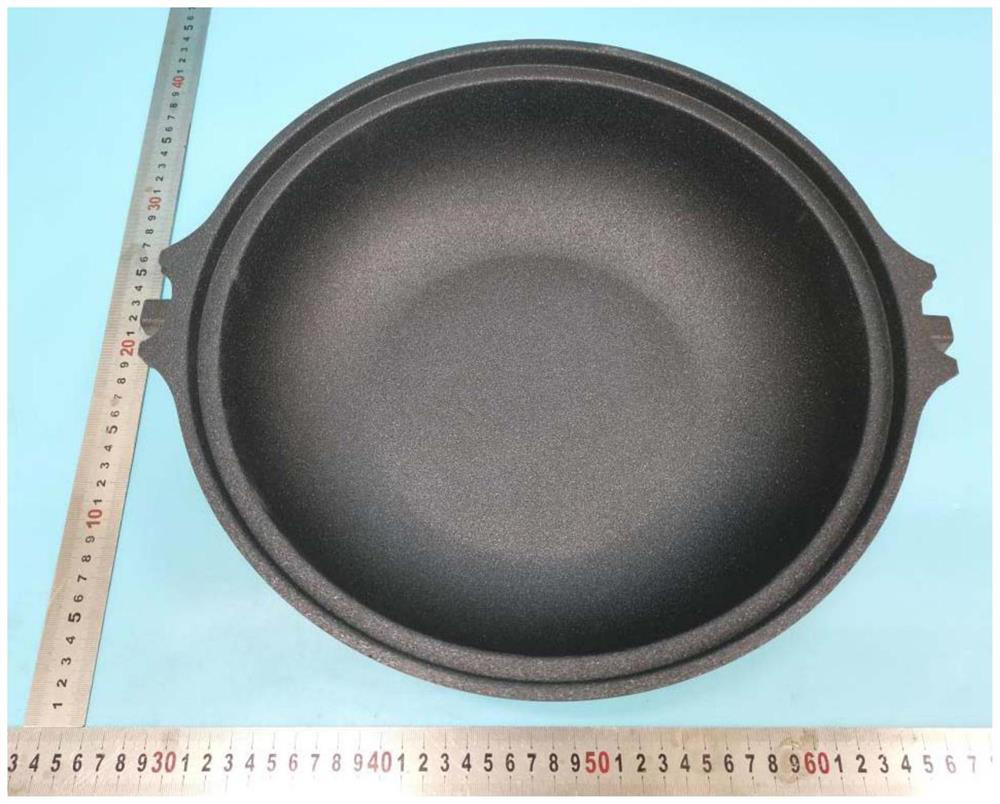

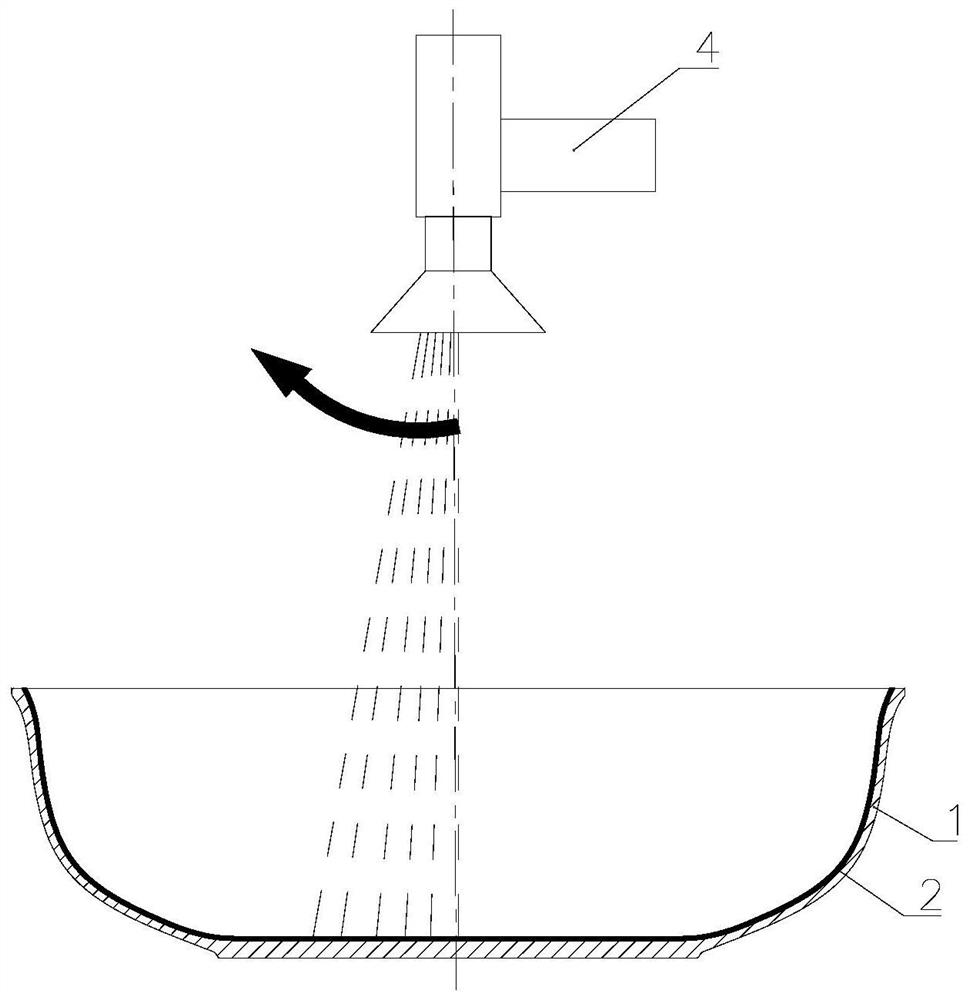

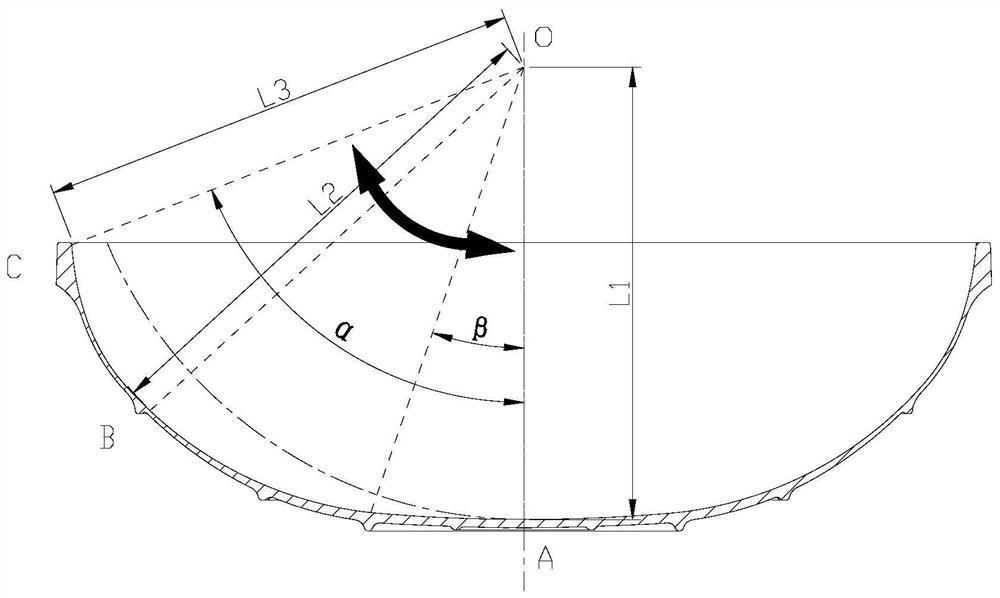

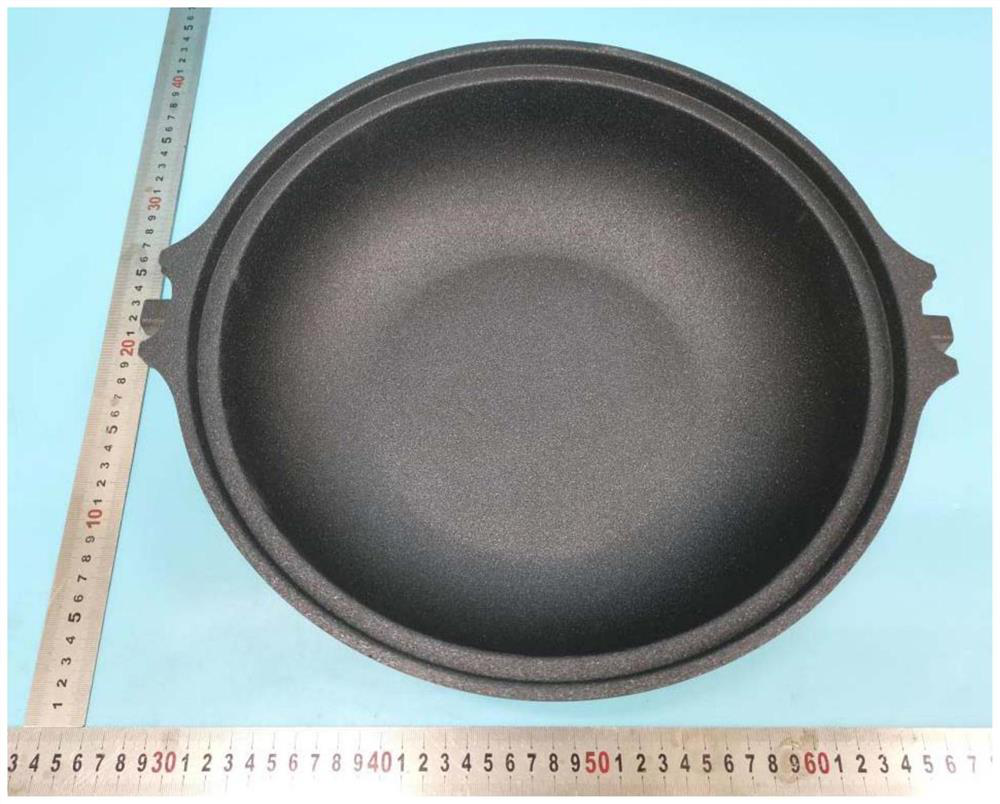

Cooking container and manufacturing method thereof

ActiveCN113215516AHigh bonding strengthHigh hardnessCooking-vessel materialsMolten spray coatingSand blastingRaw material

The invention discloses a cooking container and a manufacturing method thereof, and belongs to the field of kitchen ware. The manufacturing method of the cooking container comprises the steps that a cooking container base material is formed into a cooking container base body; the inner surface of the cooking container base body is subjected to sand blasting roughening; a meltallizing raw material of an alloy composition is provided; the meltallizing raw material is arranged on the inner surface of the cooking container base body through meltallizing to form a meltallizing layer, and the cooking container is manufactured; and a material spray outlet of a spray gun used for meltallizing is opposite to an opening of the cooking container, the material spray outlet swings towards the edge of the cooking container with the central axis of the cooking container as a base point, the cooking container rotates around the central axis of the cooking container, and the meltallizing layer is formed by covering the inner surface of the cooking container base body with the meltallizing raw material of the alloy composition in a multi-layer thermal spraying mode. The thickness distribution mode of the meltallizing layer manufactured through the manufacturing method of the cooking container is beneficial to more uniform heating of the cooking surface of the cooking container, and the meltallizing layer formed through meltallizing is high in bonding strength, high in hardness, low in porosity and low in residual tensile stress.

Owner:HONGYANG HOME APPLIANCES

Absorbing paper and its preparation method and application

ActiveCN104404814BExcellent electromagnetic attenuation effectImprove mechanical propertiesInorganic fibres/flakesSpecial paperFiberPapermaking

The invention provides wave-absorbing paper and a preparation method and application thereof. The wave absorbing paper contains 0.1-95 wt% of a fiber wave-absorbing agent and 5-99.9 wt% of wave-transparent fiber. The fiber wave-absorbing agent and wave-transparent fiber are mixed and prepared into the wave-absorbing paper by a papermaking process; and then the wave-absorbing paper as a lattice wall material is prepared into a wave-absorbing core sandwich; and then the wave-absorbing core sandwiches prepared from wave-absorbing paper with different fiber wave-absorbing agent content are separated by wave-permeable layers; and finally the entire structure is impregnated and cured to obtain the wave-absorbing material. The wave-absorbing material of the invention has the advantages of high wave-absorbing efficiency, stable wave-absorbing property, wide absorption band, and light weight and high strength.

Owner:SOUTH CHINA UNIV OF TECH

Blended elastic knitted fabric and preparation method thereof

ActiveCN111321508AGood breathability and moisture permeabilityIncrease elasticityMechanical cleaningPressure cleaningYarnCellulose

The invention discloses a blended elastic knitted fabric and a preparation method thereof. The preparation method comprises the steps of: a step A of uniformly mixing polyvinyl chloride, ethylene propylene rubber, sodium stearate, bamboo charcoal powder and nanometer titania, heating into a molten state, adding a coupling agent, cellulose ester and sodium alga acid, continuing to uniformly mix, and extruding from a spinneret plate to obtain synthetic fibers; a step B of alternatively arranging the synthetic fibers, cotton fibers and modal fibers according to a sequence of 2:(1 to 3):(1 to 3),and obtaining single yarns by a spinning process; a step C of carrying out cabling on the single yarns to form folded yarns; a step D of carrying out weaving on composite yarns by a rib knitting machine to obtain a gray fabric; a step E of carrying out high-temperature presetting on the gray fabric; and a step F of carrying out ball wool opening and shearing treatment on the gray fabric to obtainthe blended elastic knitted fabric. The blended elastic knitted fabric prepared by the preparation method has high elasticity, is comfortable to wear, excellent in moisture permeability and air permeability, simple in preparation process and easy in operation of a production process, and has wide application prospect.

Owner:石狮市聚宝针纺织品织造有限责任公司

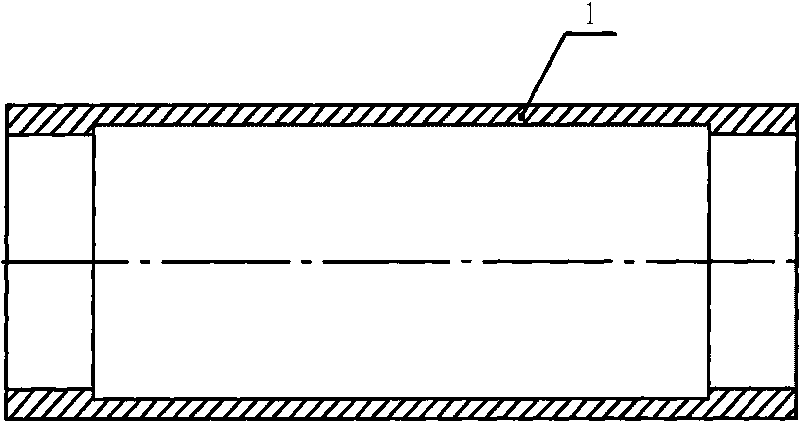

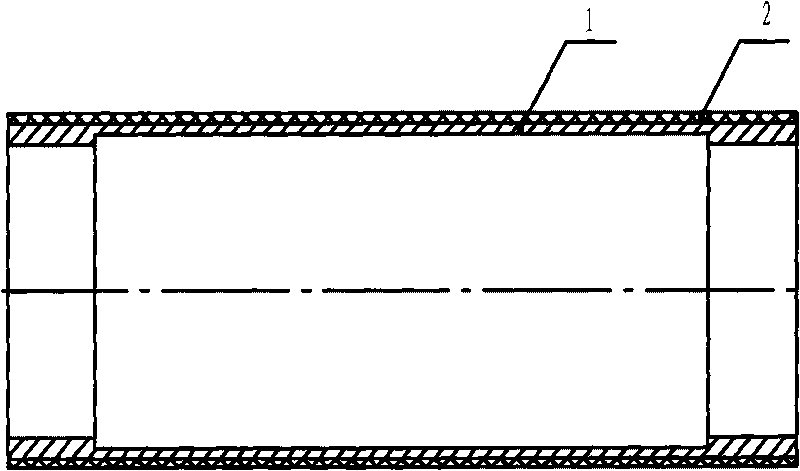

Method for processing high-precision thin-wall metal shell coated with glass fibre reinforced plastics

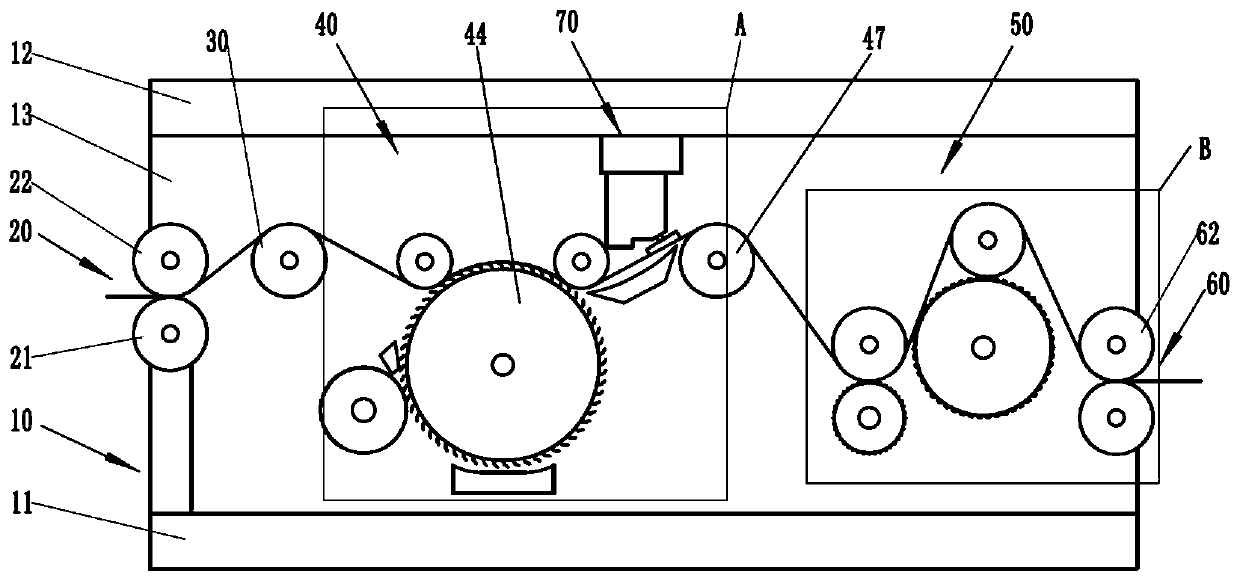

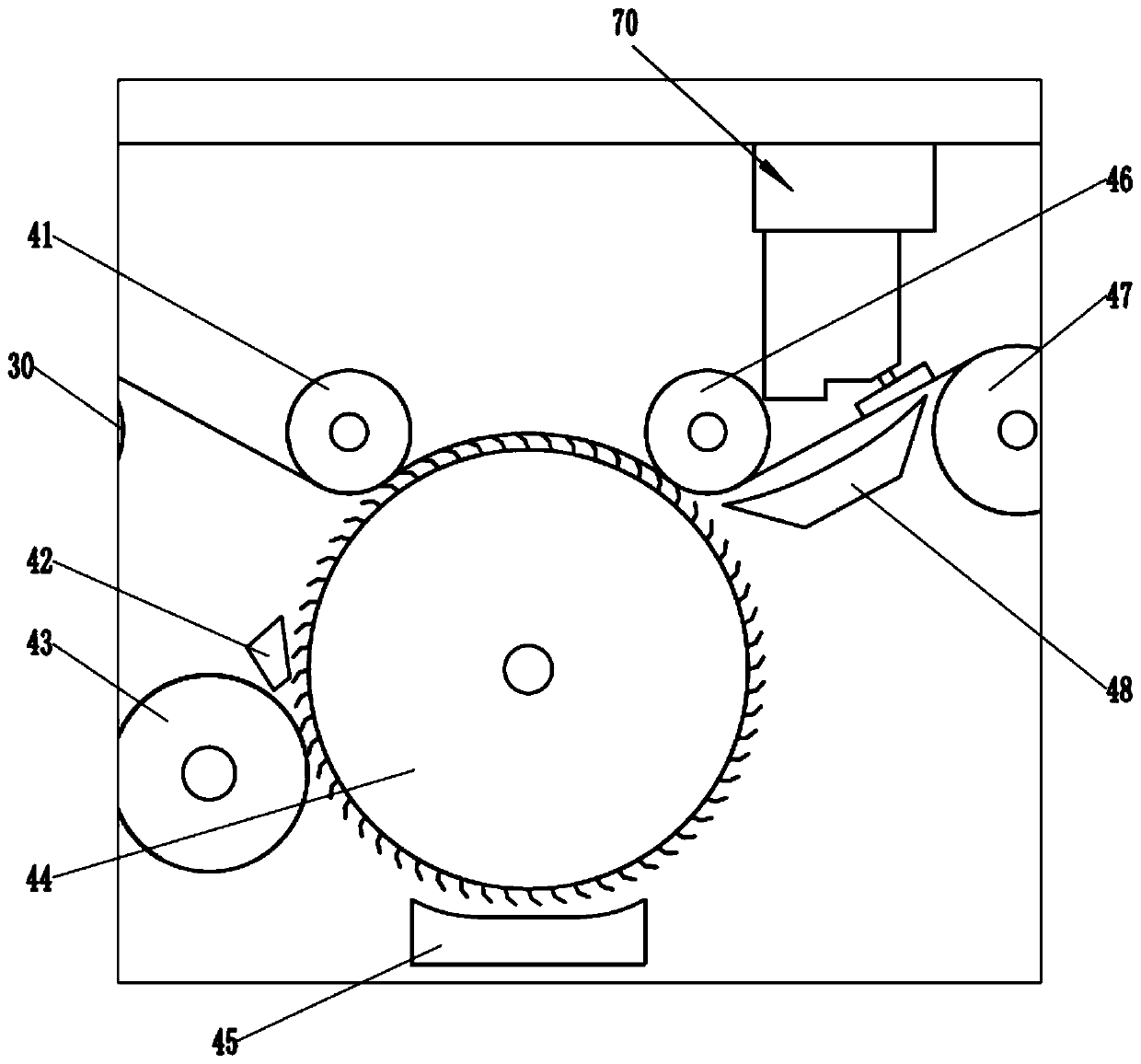

ActiveCN101700704AImprove surface qualityPrevent peelingAutomatic control devicesLaminationMetal machiningFibre-reinforced plastic

The invention relates to a method for processing metal coated with glass fibre reinforced plastics, in particular to a method for processing a high-precision thin-wall metal shell coated with glass fibre reinforced plastics. The method solves the problems that the binding force and the adhesive force between the glass fibre reinforced plastics and the metal are small, phenomena of peeling, scaling off and expanding are easy to generate in processing, the planeness of a plane formed by two materials of the glass fibre reinforced plastics and the metal is poor and the like existing in metal shells coated with the glass fibre reinforced plastics and processed by the prior method. The method comprises the following processing steps of: (1) winding and coating: making the glass fibre reinforced plastics into a strip shape, and then winding to the surface of the metal shell layer by layer after the surface is coated with rubber; (2) solidifying the glass fibre reinforced plastics; (3) cutting the surface of the glass fibre reinforced plastics; (4) and finishing. The strip-shaped glass fibre reinforced plastics are utilized to coat the metal shell, the processing procedure is reasonable, and the glass fibre reinforced plastics coated outside the metal shell has small deformation and are not easy to generate the phenomena of peeling, scaling off, expanding and the like; and the end surface of the processed shell has good planeness.

Owner:SHANXI PINGYANG IND MACHINERY

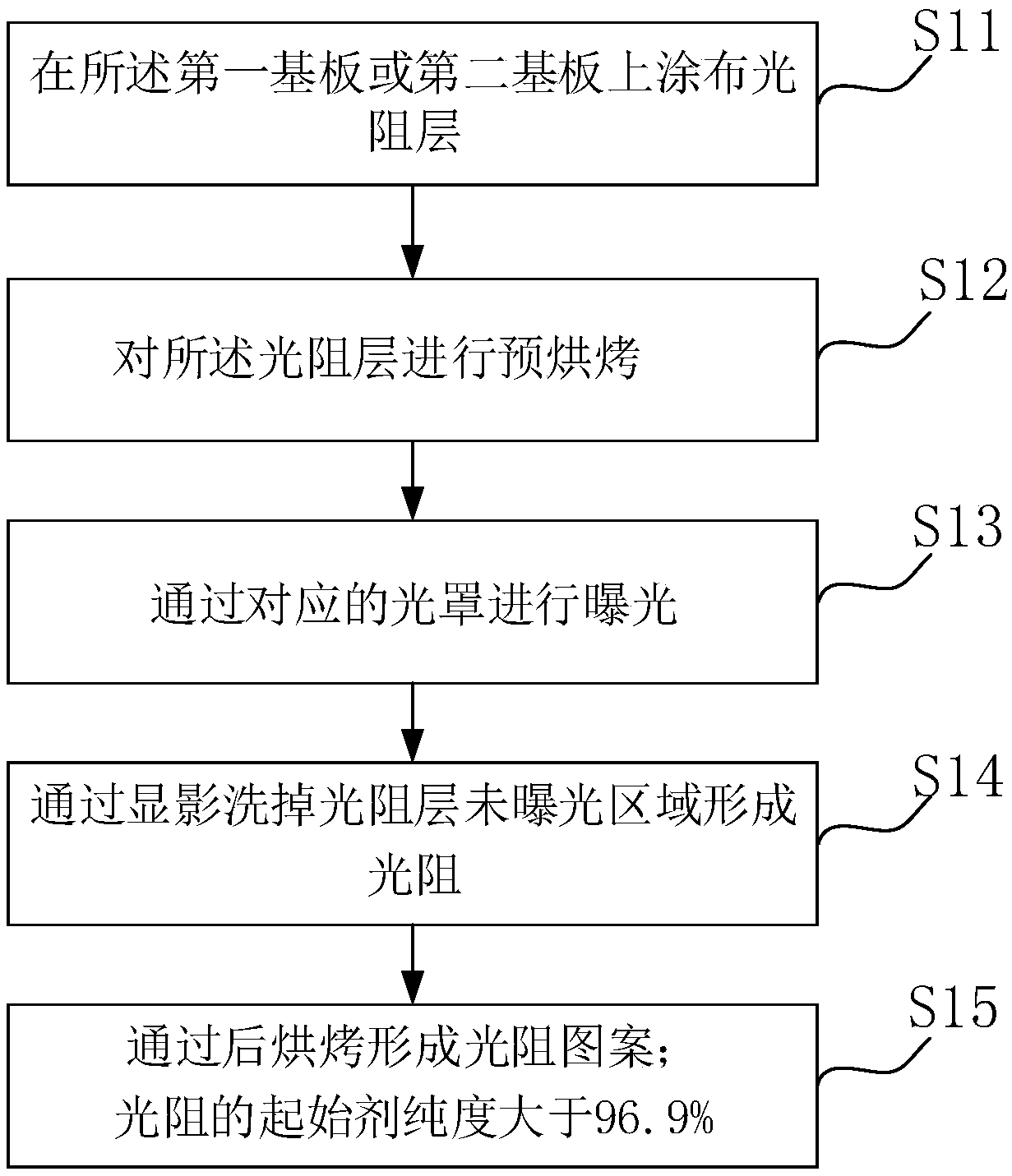

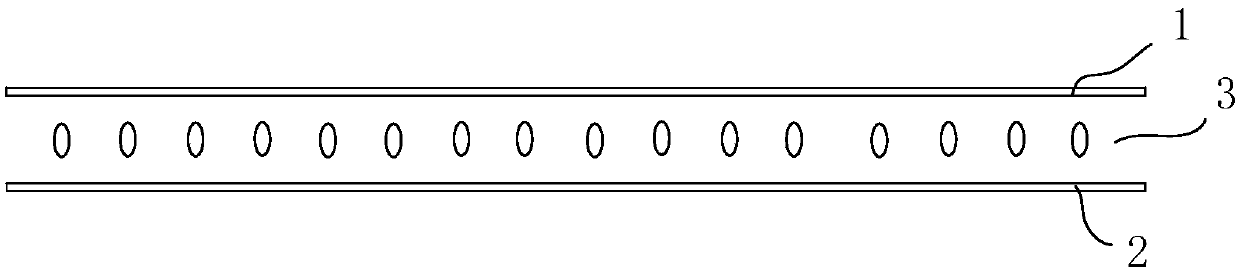

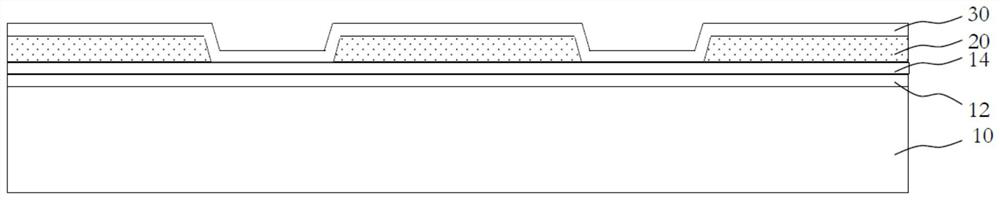

Display panel and manufacture method thereof

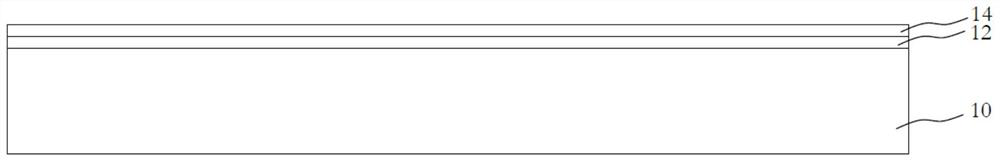

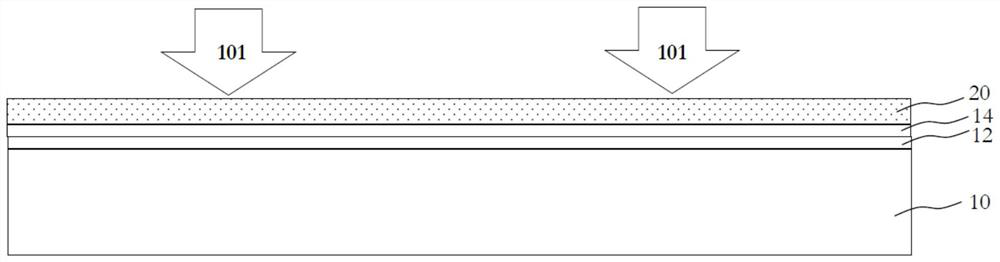

ActiveCN109597227ANot prone to peeling offIncrease the degree of cross-linkingNon-linear opticsCooking & bakingLiquid-crystal display

The invention discloses a display panel and a manufacture method thereof. The display panel comprises a first substrate, a liquid crystal layer and a second substrate, wherein the first substrate andthe second substrate are oppositely arranged, and the liquid crystal layer is arranged between the first substrate and the second substrate. The manufacture method comprises the following steps that:coating the first substrate or the second substrate with a photoresistance layer; pre-baking the photoresistance layer; through a corresponding photomask, carrying out exposure; through developing, washing the unexposed area of the photoresistance layer to form photoresistance; and through post-baking, forming a photoresistance pattern, wherein the initiator purity of the photoresistance pattern is greater than 96.9%. By use of the display panel and the manufacture method, the initiator purity of the photoresistance pattern is improved, the stripping of the photoresistance pattern can be reduced, and a light leakage phenomenon is reduced.

Owner:HKC CORP LTD

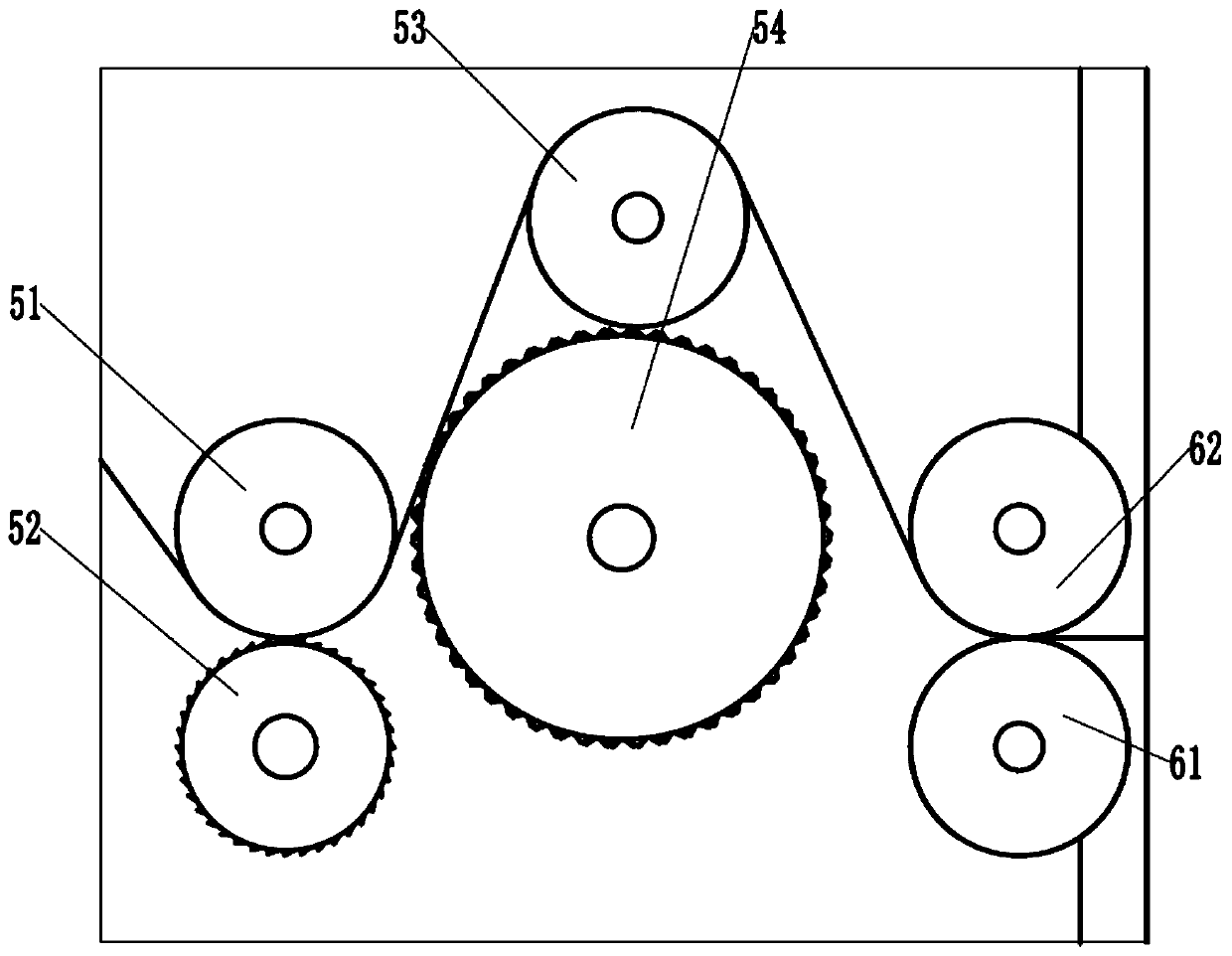

Manufacturing method for high-strength composite coating piston ring for internal combustion engine

InactiveCN106222563AHigh bonding strengthImprove wear resistanceMolten spray coatingPiston ringsPlasma technologyBonding strength

The invention discloses a manufacturing method for a high-strength composite coating piston ring for an internal combustion engine. The manufacturing method comprises the specific steps that a base body of the piston ring is prepared, a coating material is prepared, and a coating is applied to the surface of the base body through an atmospheric plasma technology, wherein the piston ring base body comprises, by weight percentage, 0.3-0.5% of C, 0.2-0.5% of Nb, 0.5-1% of W, 1.0-1.5% of Ni, 0.5-1% of Si, 0.3-0.5% of B and the balance Fe. The piston ring has high abrasion resistance and high damage resistance, meanwhile bonding strength of the coating and the base body is high, the coating is not likely to peel off, and meanwhile the coating is high in mechanical strength, good in durability and long in service life.

Owner:安庆市德奥特汽车零部件制造有限公司

Red copper crystalline glaze and firing method thereof

ActiveCN111977980ANot prone to peelingNot prone to crackingCeramic materials productionCrystallographyGlaze

The invention relates to a red copper crystalline glaze and a firing method thereof. The red copper crystalline glaze is formed by firing the following raw materials in parts by weight: 45 to 52 weight parts of porcelain stone s, 3 to 5 weight parts of limestone, 5 to 7 weight parts of talc, 8 to 12 weight parts of potassium feldspar, 10 to 15 weight parts of iron oxide red, 12 to 16 weight partsof bovine bone ash and 4 to 6 weight parts of kaolin. The red copper crystalline glaze disclosed by the invention has good bondability of a glaze surface and a body, is difficult to generate strippingand cracking of the glaze surface, has good temperature variation resistance, is complete in growth of crystal flowers in the firing process, is difficult to generate a sagging phenomenon, is high infinished product ratio and is suitable for batch production; the red copper crystalline glaze disclosed by the invention is flat in glaze surface, high in glossiness and bright in color; a glaze color is red copper with iron red crystallized crystal flowers; the crystal flowers are uneven in density and size and are of a shape of beautiful and colorful snowflake-shaped crystals; and the red copper crystalline glaze has a very high artistic impression and is very suitable for fields of a tasting tea set, art ornaments and daily tableware porcelains.

Owner:吴利军

Semiconductor packaging structure

PendingCN114256164AHigh strengthNot prone to peelingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The invention provides a semiconductor packaging structure. The semiconductor packaging structure comprises a first dielectric layer; a bonding pad having a protruding portion protruding from the first dielectric layer; the convex part is embedded into the solder bump; and a first barrier layer sandwiched between the bonding pad and the first dielectric layer, in which there is a gap between the first barrier layer and the solder bump, and the bonding pad and the first dielectric layer are separated by the gap. On the other hand, the invention provides a method for forming the semiconductor packaging structure so as to at least enhance the strength of the semiconductor packaging structure.

Owner:ADVANCED SEMICON ENG INC

A kind of cooking container and its manufacturing method

ActiveCN113215516BHigh bonding strengthHigh hardnessCooking-vessel materialsMolten spray coatingKitchen utensilsRaw material

The application discloses a cooking container and a manufacturing method thereof, belonging to the field of kitchen utensils. The manufacturing method of the cooking container comprises: forming the base material of the cooking container into a base body of the cooking container; sandblasting and roughening the inner surface of the base of the cooking container; providing a fusion injection raw material of the alloy composition; A spray layer is formed on the inner surface of the substrate to obtain a cooking container; wherein the spray outlet of the spray gun used for spraying is set opposite to the opening of the cook container, and the spray outlet swings to the edge of the cook container with the central axis of the cook container as the base point. The container rotates around its central axis, and the sprayed layer is formed by multi-layer thermal spray coating of the molten sprayed raw material of the alloy composition covering the inner surface of the base of the cooking container. The thickness distribution mode of the sprayed layer prepared by the cooking container manufacturing method is beneficial to the cooking surface of the cooking container to heat more evenly, and the sprayed layer formed by spraying has high bonding strength, high hardness, low porosity and low residual tensile stress.

Owner:HONGYANG HOME APPLIANCES

Preparation method of two-component high-adhesion pollution flashover-prevention fluorocarbon coating for hard mask

InactiveCN108219602AHigh hardnessNot prone to peelingAntifouling/underwater paintsMicroorganismsCellulosePhosphate

The invention relates to the technical field of preparation of electronic component paint, in particular to a preparation method of a two-component high-adhesion pollution flashover-prevention fluorocarbon coating for a hard mask. The preparation method comprises the following steps: with waxberries, grapes and tea leaves as raw materials, degrading cellulose in the raw materials into glucose withcellulose and fermenting, and mixing a fermentation filtrate with fluorocarbon resin, water glass, magnesium oxide, monopotassium phosphate and the like to prepare the two-component fluorocarbon coating, wherein a proper amount of MgO powder is mixed in the water glass in a component A, then a layer of coating component B is coated, and phosphate in the component B is in an acid-base neutralization reaction with the MgO powder on the surface of an insulator. The fluorocarbon resin is taken as a film forming matter, so that the oxidation resistance of the coating is further improved; an organic acid composition and silicon dioxide generated by sodium carbonate in the component A improve the adhesion of a film; silicon dioxide is mixed to improve the hardness of the coating and the mechanical property of the film; and therefore, the two-component high-adhesion pollution flashover-prevention fluorocarbon coating has a wide application prospect.

Owner:CHANGZHOU DAAO NEW MATERIAL TECH CO LTD

Configuration method of self-catalyzed electroless copper plating epoxy resin solution and electroless copper plating method

InactiveCN104789949BImprove stabilityEvenly distributedLiquid/solution decomposition chemical coatingEpoxyCopper plating

The invention relates to a configuration method of self-catalyzed electroless copper-plating epoxy resin solution and an electroless copper-plating method, belonging to the technical field of material surface treatment. It includes the following steps: adding the active ion source into the organic solvent under constant stirring, and adding a certain amount of curing catalyst, stirring fully to form a uniform active agent solution; and then stirring the epoxy resin in a certain proportion Add to the curing agent to form an epoxy resin organic solution; while stirring continuously, slowly add the active agent solution to the epoxy resin organic solution to form a uniform and stable system, that is, to obtain an epoxy resin solution with self-catalytic active electroless copper plating . The prepared resin solution is uniformly coated on the printed circuit board substrate by casting method or screen printing method, and then through curing, micro-etching, reduction, chemical plating and other processes, the bright pink copper coating can be obtained. After the performance test, the copper layer-resin bonding force and electrical conductivity of the sample are excellent, and it is suitable for the electroless copper plating process.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

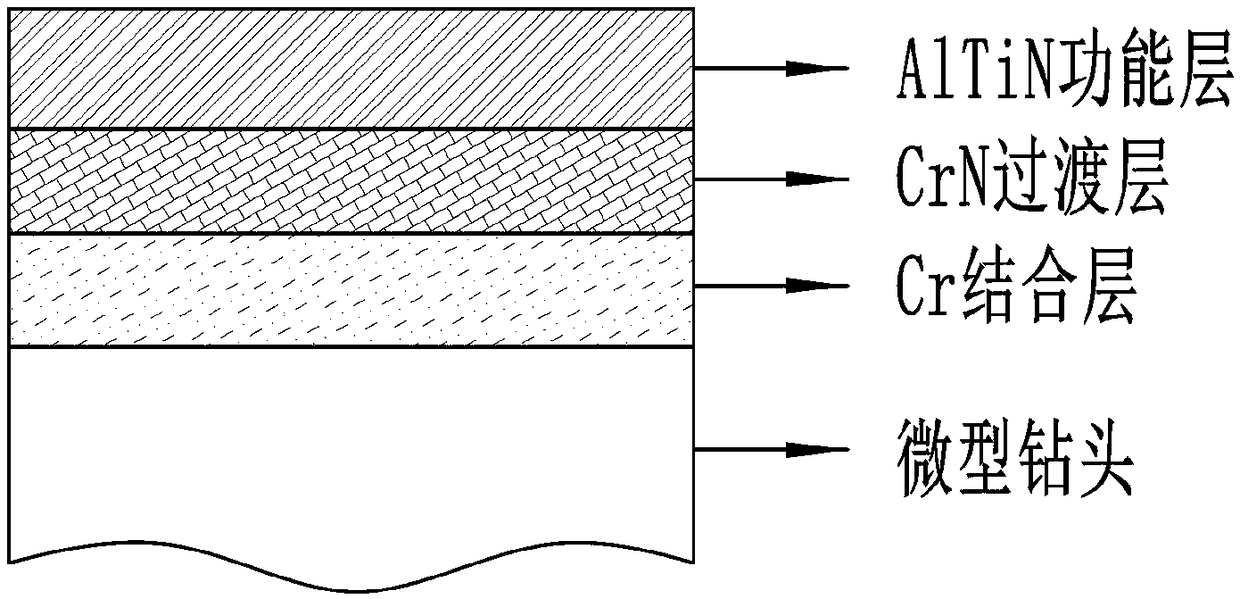

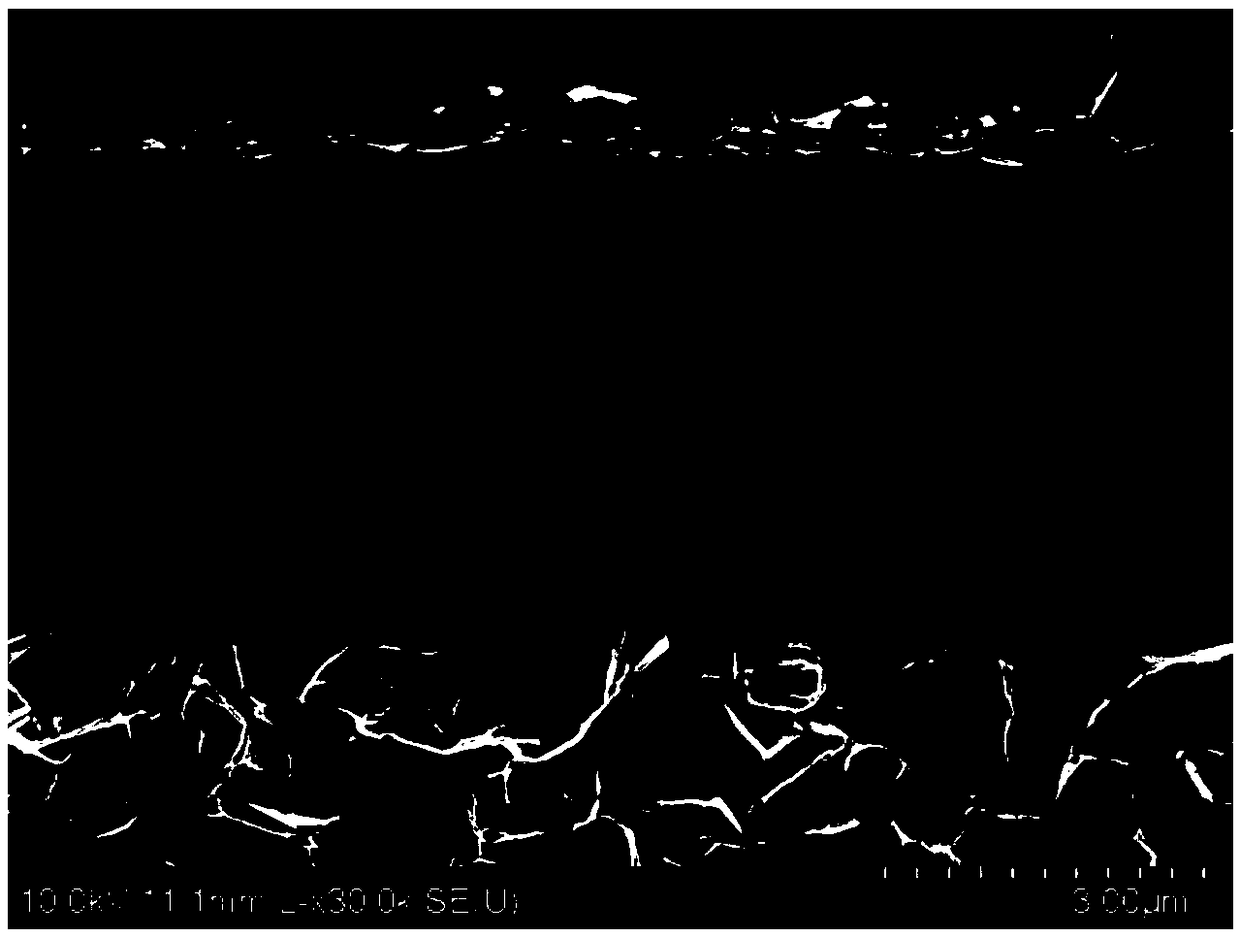

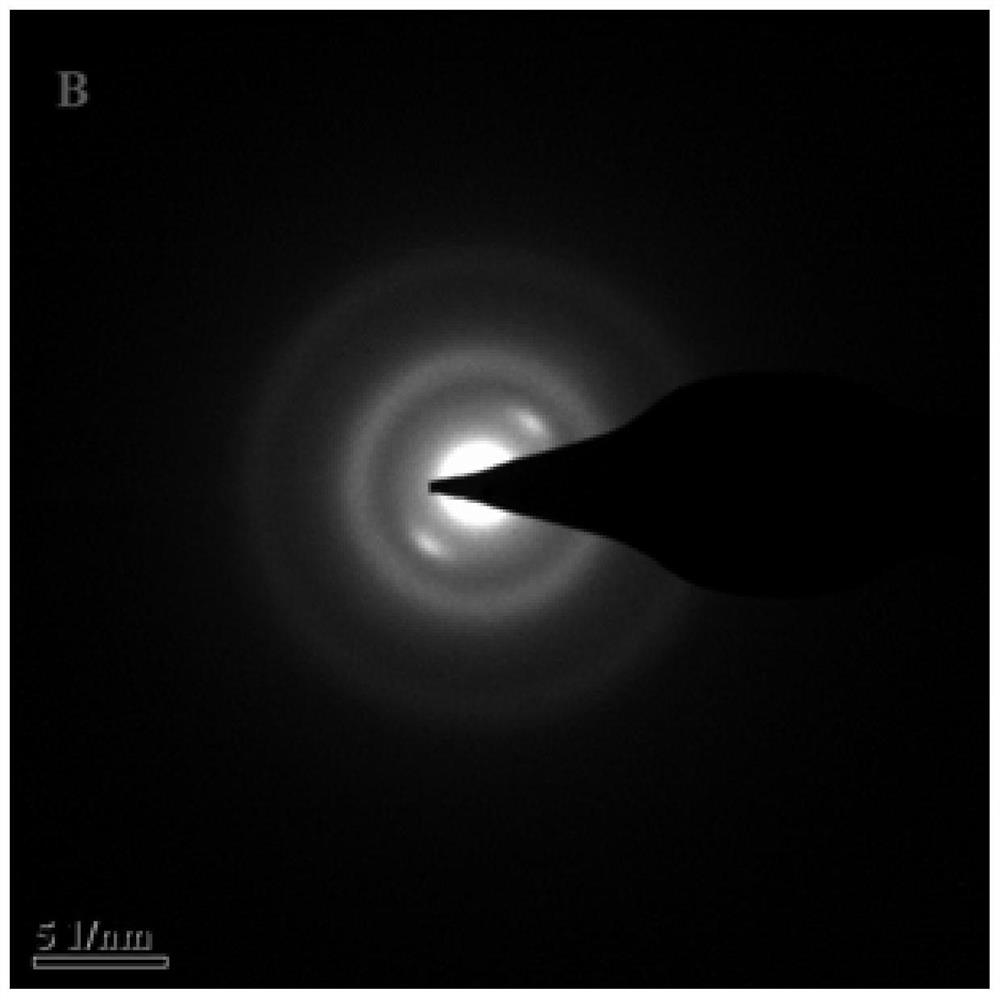

Microbit deposited with AlTiN coating, and preparation method thereof

InactiveCN109023266AImprove bindingHigh hardnessVacuum evaporation coatingSputtering coatingPeak valueNitrogen gas

The invention discloses a microbit deposited with an AlTiN coating. The microbit deposited with the AlTiN coating comprises the AlTiN coating, wherein the AlTiN coating comprises a Cr binding layer, aCrN transition layer and an AlTiN function layer stacked sequentially; and the AlTiN coating has a high binding force, can be firmly combined on the surface of the microbit, is not easy to flake, issmooth in surface, and less in large particle quantity, so that the microbit has high hardness and high temperature wearability, and can maintain the high performance during long-time high-speed operation. The invention further discloses a preparation method of the microbit deposited with the AlTiN coating. The AlTiN coating is prepared on the surface of the microbit by utilizing a plused arc technology, and a high-density plasma can be produced during the pulse discharge period through controlling the nitrogen and argon flow, the pulsed arc peak value, the duty ratio and the frequency, so that the deposition speed of the function layer is fast, and the deposition process is simple, good in repeatability, can be applied to mass production in industry, and has a favorable economic benefit.

Owner:GUANGDONG UNIV OF TECH

Superhard DLC cutter coating of amorphous gradient structure, preparation method of superhard DLC cutter coating and cutter

PendingCN113862613AHigh hardnessReduce internal stressVacuum evaporation coatingSputtering coatingHeat stabilityHardness

The invention relates to the technical field of superhard coatings, and discloses a superhard DLC cutter coating of an amorphous gradient structure, a preparation method of the superhard DLC cutter coating and a cutter. The cutter coating comprises a transition layer and a DLC (sp3 gradient layer) which are sequentially deposited on a cutter base material layer by layer, the transition layer contains Cr and C elements, the contents of the Cr and C elements are set in a gradient manner, and sp3 gradient setting is achieved in the DLC. The internal stress of the DLC (sp3 gradient layer) is relatively low, toughness is enhanced, a crack arrest effect is achieved, and meanwhile the coating has high hardness, reaches the hardness value of a superhard coating and has relatively good thermal stability and chemical stability; the Cr / C gradient transition layer effectively enhances the bonding strength of pure Cr of the transition layer and the DLC of the upper layer, the structure is of a nano composite structure with nanocrystalline CrC wrapped by amorphous C, and the toughness of the coating is greatly improved while the hardness is improved; and due to the existence of the pure Cr transition layer serving as the bonding layer and the Cr / C transition layer, the film-substrate bonding strength of the coating is high, and the coating is not prone to peeling off in the machining process.

Owner:美戈利浙江轨道交通研究院有限公司

Preparation method for piston rings with high-lubricity composite coatings for internal combustion engines

InactiveCN106086628AImprove wear resistanceExtended service lifeMolten spray coatingPiston ringsHigh resistanceCombustion

The invention discloses a preparation method for piston rings with high-lubricity composite coatings for internal combustion engines. The preparation method specifically includes the steps of preparing base bodies of the piston rings, preparing materials of the coatings and applying the coatings to the surfaces of the base bodies through the air plasma technology. The base bodies of the piston rings comprise, in mass percentage, 0.3-0.5% of C, 0.5-1% of Si, 0.5-1% of Mn, 0.3-0.5% of Pb, 0.3-0.5% of Cu, 0.05-0.1% of Ce, 0.05-0.1% of Co and the balance Fe. The piston rings have high wear resistance and high damage resistance, the bonding strength of the coatings and the base bodies is high, and the coatings do not peel off easily. In addition, the coatings are good in lubricity, high in sealing property and long in service life.

Owner:安庆市德奥特汽车零部件制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com