Cooking container and manufacturing method thereof

A technology for a cooking container and a manufacturing method, applied in the field of kitchen utensils, can solve the problems of poor strength, easy peeling and damage, loss of anticorrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The cooking container of the present application can be any container that can process food, such as a pot, the cup body of a cooking machine or a cooking machine, etc., wherein the pot includes not only a frying pan, an inner pot in an electric rice cooker, etc., it is especially suitable for Frying pan, take the wok utensil of frying pan as an example in the following embodiments for illustration.

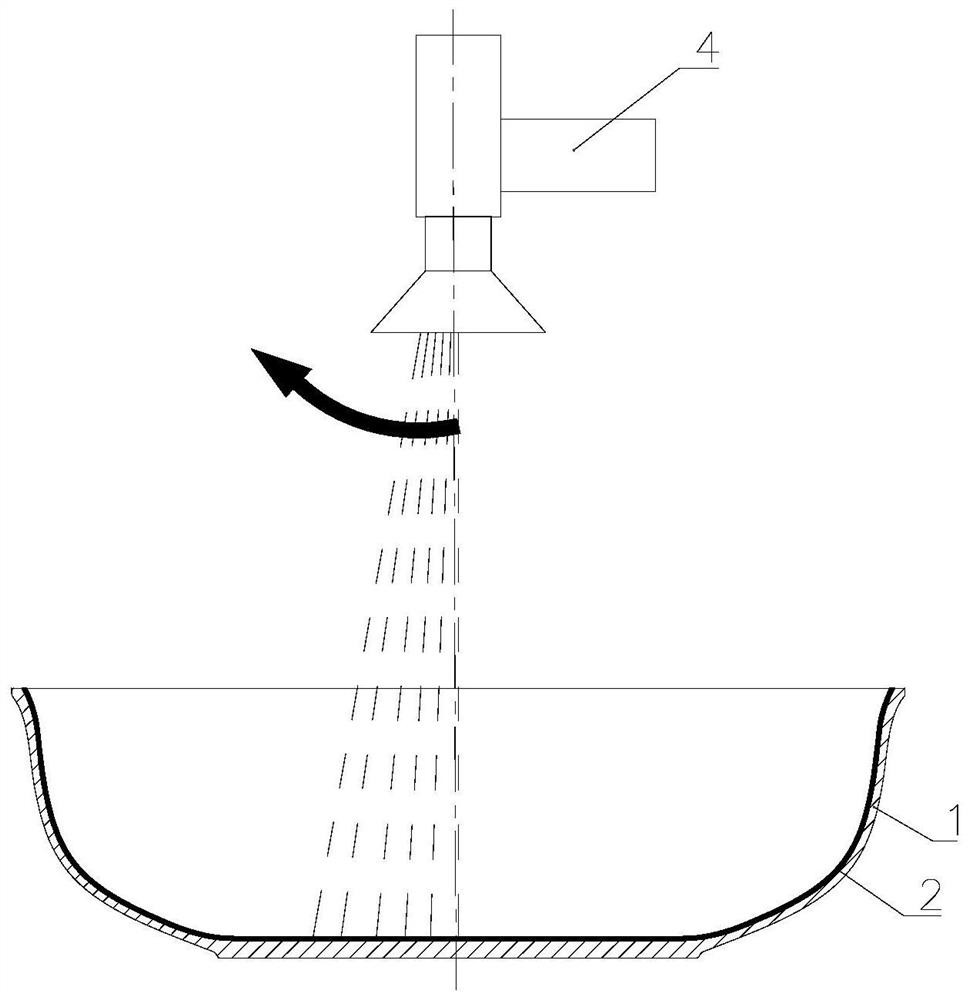

[0074] refer to figure 1 , as an embodiment, the manufacturing method of cooking container comprises the following steps:

[0075] shaping the cooker base material into a cooker base body 1;

[0076] Carry out sandblasting roughening to the inner surface of cooking container base body 1;

[0077] Provide molten injection raw materials for alloy compositions;

[0078] Spraying the raw materials to the inner surface of the cooking container base 1 to form a spraying layer 2, that is, to make a cooking container;

[0079] Wherein, the material injection outlet of the spra...

Embodiment 2

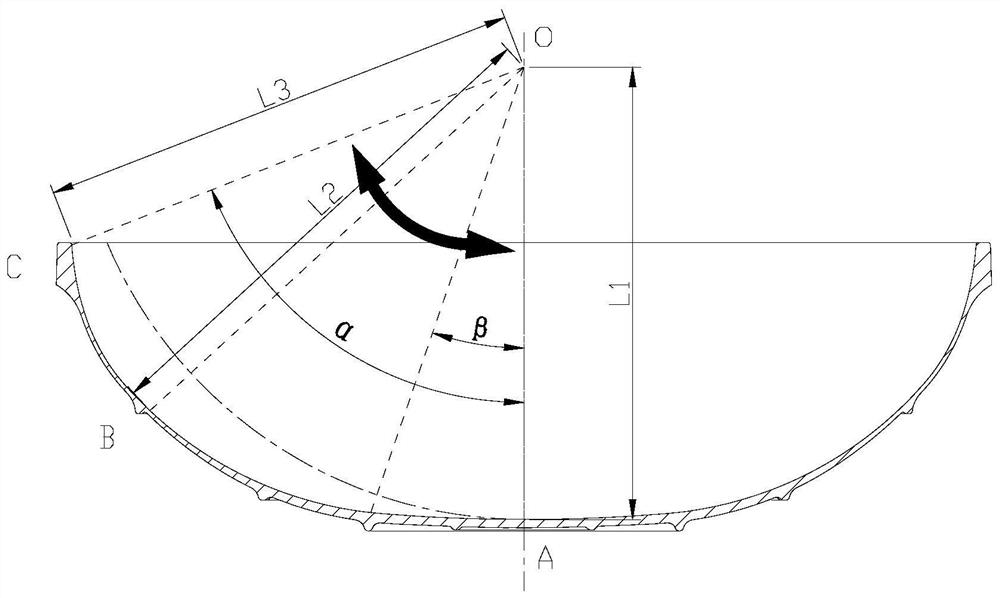

[0083] refer to figure 2 , when the spray outlet is located at the base point where the central axis of the cooking vessel coincides, the distance between the spray outlet and the inner surface of the cooking vessel is L1; The surface distance is L3, and when the spray outlet swings between the base point and the limit position, the distance between the spray outlet and the inner surface of the cooking container is L2, and L1<L3<L2. The way of changing the distance between the spray outlet and the cooking container can make the center of the bottom of the cooking container, such as the bottom of the pot, have the highest hardness and the lowest porosity, and the hardness of the top edge of the cooking container, such as the opening of the pot, is second. The porosity increases, while the transition between the bottom and top openings is the least rigid and most porous. In actual use, for example, the loss of the bottom of the pot is the largest, followed by the opening of th...

Embodiment 3

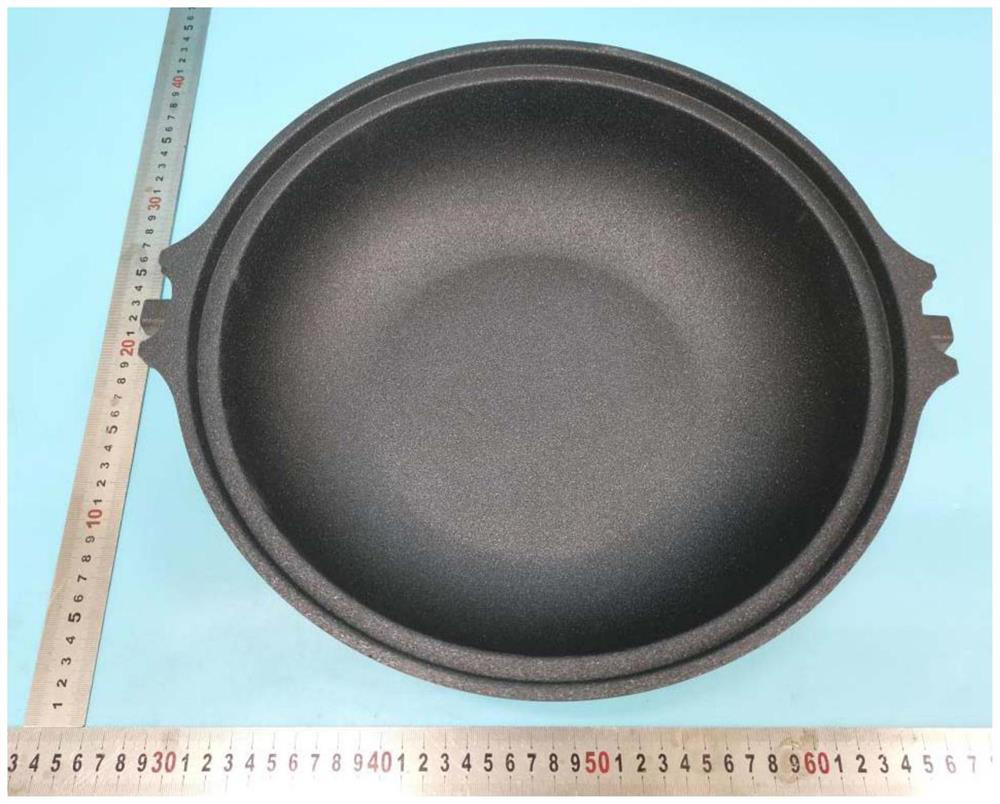

[0094] This embodiment provides a cooking utensil, which is described by taking a pot as an example.

[0095] As an embodiment, the pot includes a pot base, the inner surface of the pot base is attached with a spray layer formed by a melt spraying process, and the spray layer is an iron alloy; the cooking container has a main cooking area and an auxiliary cooking area surrounding the main cooking area. Cooking area; on the main cooking area, the thickness of the spray layer is 0.2 mm to 2 mm; the thickness ratio of the auxiliary cooking area to the main cooking area is 0.25 to 0.9. Under the same heat source, the heating temperature near the center of the pot is higher than that at the edge. By setting the thickness of the main cooking area near the center of the pot to be greater than the thickness of the auxiliary cooking area at the edge, the heating rate of the center of the pot is close to that of the edge. Reduce the temperature difference between the center and the edge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com