Compounding method of epoxy resin solution with autocatalysis chemical copper plating activity and chemical copper plating method

A technology of epoxy resin solution and chemical copper plating, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as electrical performance change, achieve high flatness, good stability and good quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

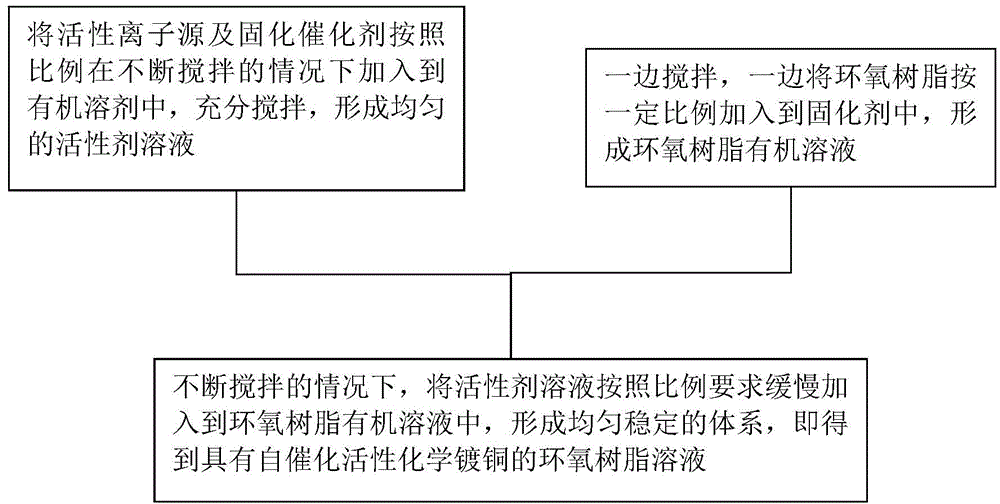

Method used

Image

Examples

Embodiment 1

[0028] The configuration method of the self-catalyzed electroless copper plating epoxy resin solution of this example comprises the following steps:

[0029] 1. Prepare a new active agent solution.

[0030] (1) Weigh 0.1-0.5 g of active ion source, while stirring, add the active ion source into a beaker filled with 10-20 mL of organic solvent, and fully stir to form a uniform active agent solution;

[0031] The active ion source refers to a metal salt that can form catalytic electroless copper plating particles after being reduced, and the active ion source includes organic acid salts, metal carbonyl compounds, metal alkoxides, and acetylacetone complexes soluble in organic solvents. One or more active ion sources specifically include palladium acetate, palladium oxalate, silver benzoate, silver acetate, silver oxalate, copper formate, copper acetate, copper oxalate, copper carbonyl, silver carbonyl, copper alkoxide, silver alkoxide, One or more of copper acetylacetonate or s...

Embodiment 2

[0048] 1. Weigh 0.1g of copper formate and add it into a butanone-ethylene glycol (1:1) system with a mass of 3g, wherein the volume ratio of butanone-ethylene glycol is 1:1, stir well to make it evenly mixed , and a small amount of ethylenediamine was added dropwise as a dispersant, and an epoxy resin curing catalyst was added dropwise, and stirred evenly.

[0049] 2. Take 1 g of bisphenol A glycidyl ether, add 0.8 g of methyl hexahydrophthalic anhydride, and stir mechanically for 20 minutes to form a glycidyl ether epoxy resin solution.

[0050] 3. Use a dropper to slowly drop the copper formate-butanone / ethylene glycol solution obtained in step 1 into the stirred glycidyl ether epoxy resin solution, and continue stirring for 30 minutes after the drop is completed to obtain a copper-containing epoxy resin solution .

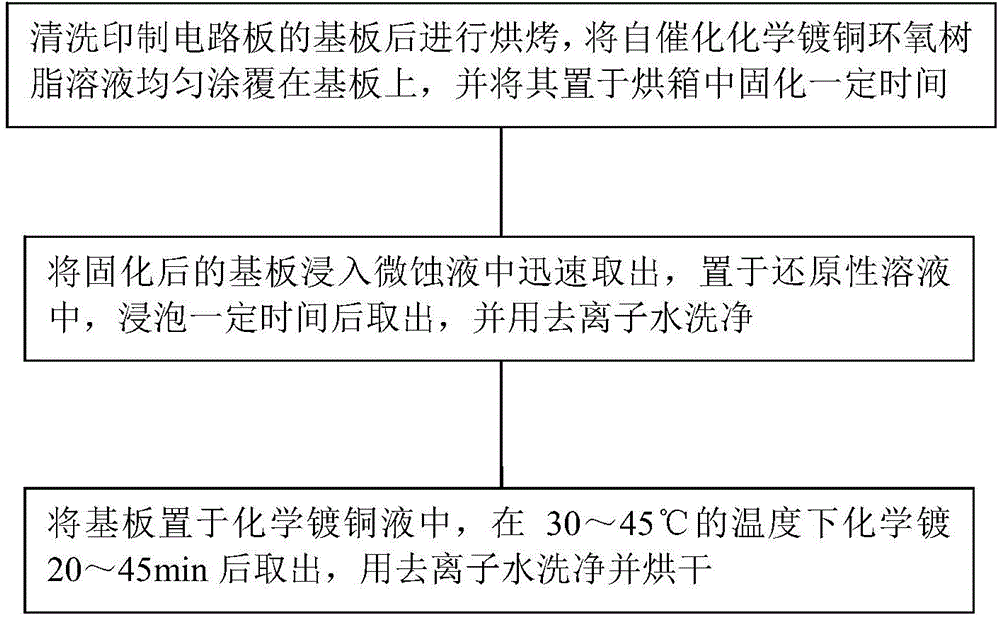

[0051] 4. Select the FR-4 substrate as the substrate of the printed circuit board, ultrasonically clean the FR-4 substrate with absolute ethanol and deionized...

Embodiment 3

[0056] 1. Weigh 0.1g of silver acetate, add it to 3g of methyl ethyl ketone, stir well to make it evenly mixed, and drop a small amount of ethylenediamine as a dispersant, add dropwise an epoxy resin curing catalyst, and stir evenly.

[0057] 2. Take 1 g of bisphenol A glycidyl ether, add 0.8 g of methyl hexahydrophthalic anhydride, and stir mechanically for 20 minutes to form a glycidyl ether epoxy resin solution.

[0058] 3. Use a dropper to slowly drop the solution obtained in step 1 into the epoxy resin solution obtained in step 2 under stirring, and continue stirring for 30 minutes after the drop is completed to obtain a silver-containing epoxy resin solution.

[0059] 4. Clean the FR-4 substrate ultrasonically with absolute ethanol and deionized water, bake it in an oven at 100°C for 1 hour, and apply the silver-containing epoxy resin solution in step 3 evenly and thinly on the dry FR-4 substrate. 4 on the substrate, and put it in an oven at 130°C for 10 minutes to cure....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com