Wave-absorbing paper and preparation method and application thereof

A technology of wave paper and wave absorbing agent, applied in the field of papermaking, can solve problems such as difficult electromagnetic parameter gradient control, affecting the stability of wave absorbing performance, and unsatisfactory broadband wave absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Mix 5wt% of carbon fiber and 95wt% of para-aramid fibrillated pulp to prepare slurry A1, mix 10wt% of carbon fiber and 90wt% of para-aramid fibrillated pulp to prepare slurry A2, and mix 15wt% of carbon fiber Mixed with para-aramid fiber fibrillated pulp 85wt% to prepare slurry A3, and slurry A1, A2, A3 were respectively formed by filtration to obtain wave-absorbing paper A1', A2', A3'. The fibrous wave-absorbing agent is carbon fiber (domestic), with a diameter of 10 μm and a length of 8 mm, and the wave-transmitting fiber is para-aramid fibrillated pulp.

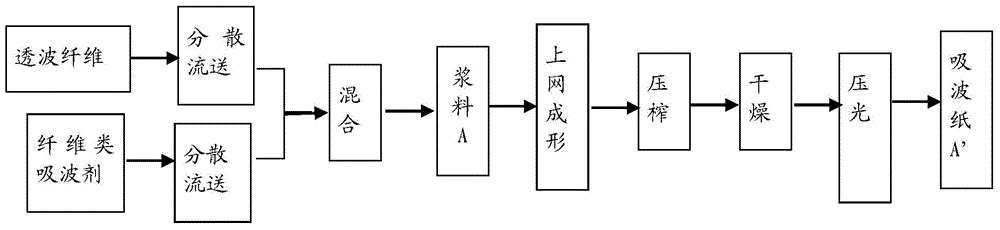

[0075] Such as figure 1 In the preparation process shown, the above-mentioned carbon fiber is dispersed in water with a disintegrator, and the above-mentioned para-aramid fibrillated pulp is dispersed in water with a pulper to obtain two uniformly dispersed suspensions, and then the two suspensions are The liquid was mixed and stirred evenly to obtain a slurry with a concentration of 0.03%. Slurries A1, A2, and A3...

Embodiment 2

[0083] Mix 40wt% of silicon carbide fiber and 60wt% of para-aramid precipitated pulp to prepare slurry A1, mix 50wt% of silicon carbide fiber and 50wt% of para-aramid precipitated pulp to prepare slurry A2, and carbonize 60wt% of silicon fiber and 40wt% of para-aramid precipitated pulp were mixed to prepare slurry A3, and slurry A1, A2, and A3 were respectively formed by filtration to prepare wave-absorbing papers A1', A2', and A3'. The fiber absorbing agent is silicon carbide fiber (domestic), with a diameter of 12 μm and a length of 6 mm, and the wave-transmitting fiber is para-aramid precipitated pulp.

[0084] Such as figure 1 In the preparation process shown, the above-mentioned silicon carbide fiber is dispersed in water with a disintegrator, and the above-mentioned para-aramid precipitated pulp is dispersed in water with a pulper to obtain two uniformly dispersed suspensions, and then the two The suspensions were mixed and stirred evenly to obtain a slurry with a conce...

Embodiment 3

[0087] Mix polycrystalline iron fiber 35wt%, carbon black 5wt% and PBO fibrillated pulp 60wt% to prepare slurry A1, polycrystalline iron fiber 37.5, carbon black 6wt%wt% and PBO fibrillated pulp 56.5wt % mixed to obtain slurry A2, 40wt% of polycrystalline iron fiber, 7wt% of carbon black and 53wt% of PBO fibrillated pulp were mixed to obtain slurry A3, and slurry A1, A2, and A3 were respectively filtered and formed to obtain Absorbing paper A1', A2', A3'. The fibrous wave-absorbing agent is polycrystalline iron fiber with a diameter of 5 μm and a length of 1 mm. The granular wave-absorbing agent is carbon black with a particle size of 5-10 μm. The wave-transmitting fiber is PBO fibrillated pulp.

[0088] Such as figure 1 In the preparation process shown, the above-mentioned polycrystalline iron fiber and carbon black are dispersed in water with a disintegrator, and the above-mentioned PBO fibrillation pulp is dispersed in water with a pulper to obtain three uniformly disperse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com