Multipurpose low-conductivity ceramic/noble metal lamellar composite thermal barrier coating

A thermal barrier coating, layered composite technology, applied in the direction of metal material coating process, coating, superimposed layer plating, etc., to achieve the effect of inhibiting high-temperature evaporation, avoiding instability, and improving anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

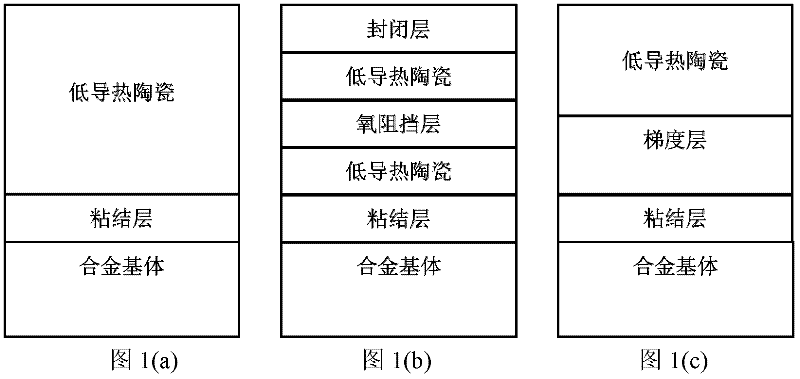

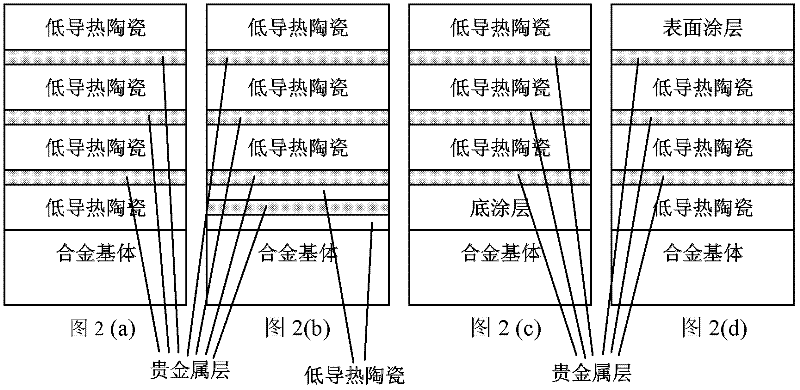

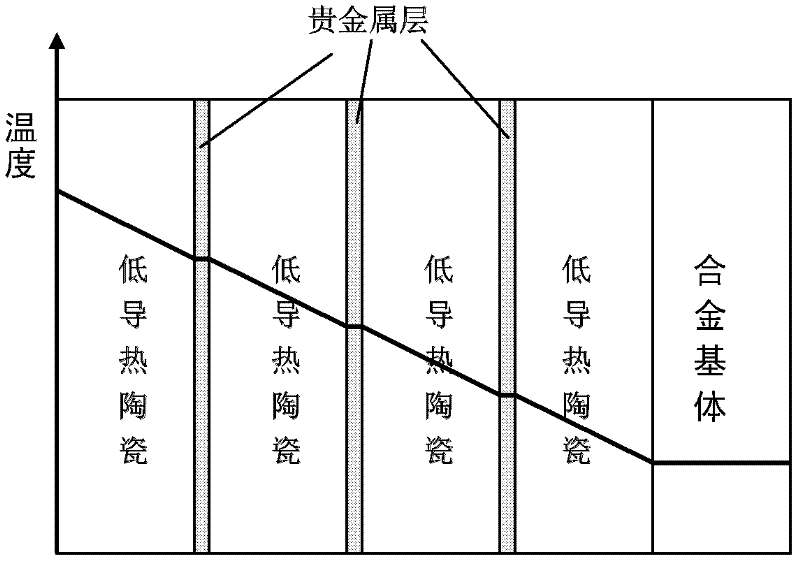

[0035] Example 1: YSZ / Pt layered composite thermal barrier coating

[0036] according to figure 2 In the way shown in (a), the YSZ layer is deposited by electron beam physical vapor deposition and the Pt layer is deposited by magnetron sputtering alternately on the surface of DZ125 superalloy. The thickness of the YSZ layer is 20 mm, the thickness of the Pt layer is 1 mm, and 10 layers are alternately deposited. The prepared YSZ / Pt layered composite thermal barrier coating was tested in an air environment of 1200°C for 200 hours, which proved to have excellent heat insulation effect, as well as excellent resistance to peeling, cracking, thermal shock and high temperature oxidation.

Embodiment 2

[0037] Example 2: YSZ / Pt-20%Au Layered Composite Thermal Barrier Coating

[0038] according to figure 2 In the way shown in (b), the YSZ layer is deposited by electron beam physical vapor deposition and the Pt-20%Au layer is deposited by magnetron sputtering alternately on the surface of DZ125 superalloy. First alternately deposit 2 layers of 1mm YSZ layer and 1mm Pt-20%Au layer, and then alternately deposit 10 layers of 20mm YSZ layer and 1mm Pt-20%Au layer. The prepared YSZ / Pt-20%Au layered composite thermal barrier coating was tested in an air environment of 1200°C for 200 hours, which proved to have excellent heat insulation effect, as well as excellent resistance to peeling, cracking, thermal shock and high temperature oxidation performance.

Embodiment 3

[0039] Example 3: Deposition of YSZ / Pt-20%Au Layered Composite Thermal Barrier Coating on MCrAlY Alloy Coating

[0040] according to figure 2 In the way shown in (c), magnetron sputtering is used to deposit a layer of 30mm MCrAlY alloy coating on the surface of DZ125 superalloy (the specific composition is 10%Co, 25%Cr, 5%Al, 0.1%Y, and the rest is Ni) , and then alternately deposit a 20mm layer of YSZ by electron beam physical vapor deposition and a 1mm layer of Pt-20%Au by magnetron sputtering, 10 layers each. The prepared MCrAlY alloy coating+YSZ / Pt-20%Au layered composite thermal barrier coating was tested in an air environment of 1200°C for 200 hours, which proved to have excellent heat insulation effect, as well as excellent resistance to peeling, cracking and thermal shock performance and high temperature oxidation resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com