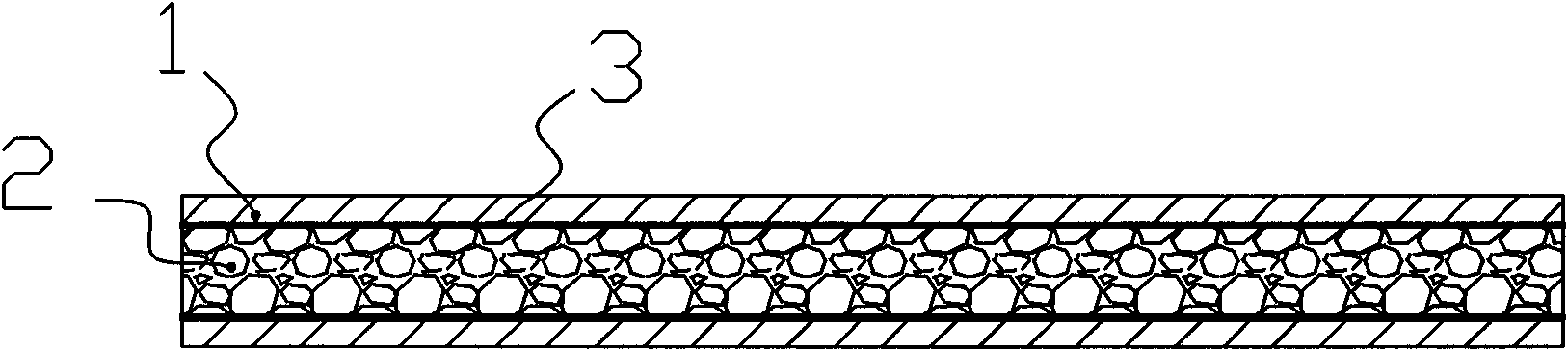

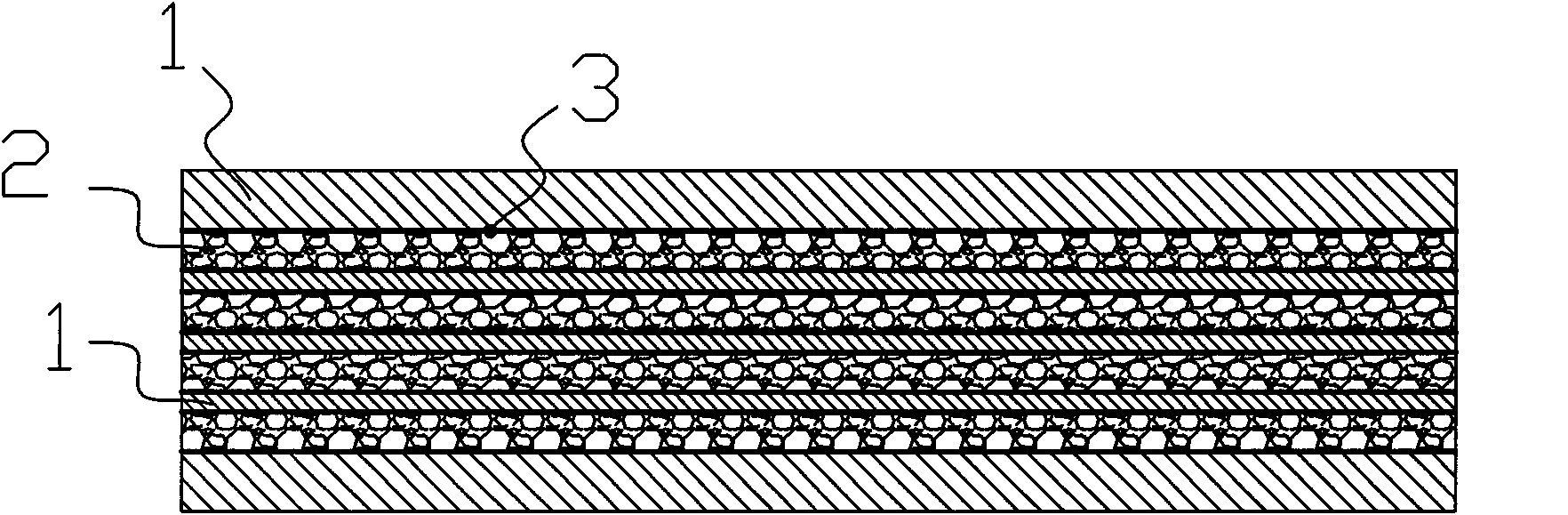

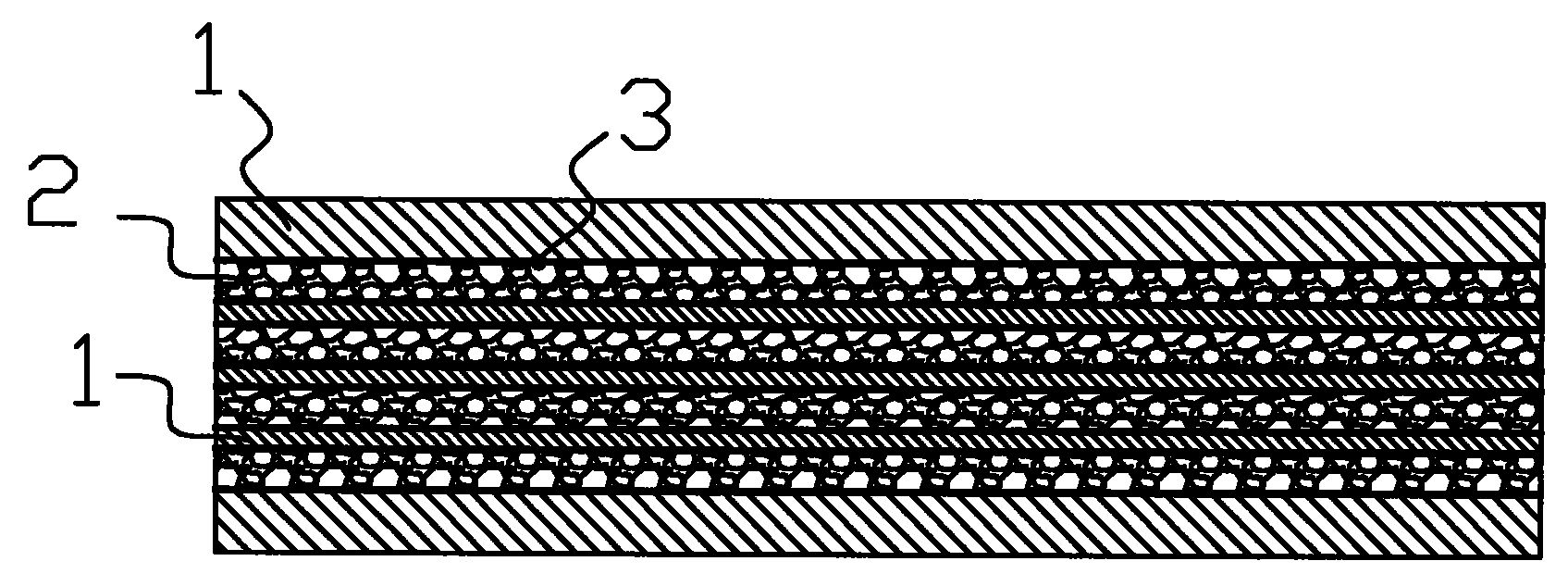

Multilayer perlite composite flame-retardant sheet and preparation method thereof

A technology of composite flame retardant and manufacturing method, which is applied to the multi-layer perlite composite flame-retardant board, the above-mentioned multi-layer perlite composite flame-retardant board manufacturing field, can solve the problems of fire prevention, environmental pollution, insect pests, etc., and achieve saving Effect of wood, light weight and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture Embodiment 1

[0039] Flame-retardant layer manufacturing embodiment 1 is:

[0040] 1. Prepare materials according to the following composition weight ratio: 10kg of expanded perlite with particle diameter between 1.5-3mm; 25kg of magnesium chloride, 10kg of magnesium oxide, 100kg of sodium phosphate, 150kg of lithopone, 0.1kg of emulsifier, binder 50kg;

[0041] 2. Proportioning magnesium chloride with water into a liquid with a density of 15%;

[0042] 3. Mix the liquid with other raw materials and pour into the blender to stir for 5 minutes to form a paste slurry;

[0043] 4. Pour into the specified mold and pressurize 5 tons to make a 1 cm thick sheet, take it out and dry it.

manufacture Embodiment 2

[0044] Flame-retardant layer manufacturing embodiment 2 is:

[0045] 1. Prepare materials according to the following composition weight ratio: 20kg of expanded perlite with particle diameter between 1.5-3mm; 40kg of magnesium chloride, 25kg of magnesium oxide, 300kg of sodium phosphate, 350kg of lithopone, 0.2kg of emulsifier, binder 200kg;

[0046] 2. Proportioning magnesium chloride with water into a liquid with a density of 30%;

[0047] 3. Pour the liquid and other raw materials into the mixer and stir for 20 minutes to form a paste slurry;

[0048] 4. Pour into the specified mold and pressurize 15 tons to make a 120 cm thick sheet, take it out and dry it.

manufacture Embodiment 3

[0049] Flame-retardant layer manufacturing embodiment 3 is:

[0050] 1. Prepare materials according to the following composition weight ratio: 15kg of expanded perlite with particle diameter between 1.5-3mm; 30kg of magnesium chloride, 15kg of magnesium oxide, 200kg of sodium phosphate, 250kg of lithopone, 0.15kg of emulsifier, Dosage 125kg;

[0051] 2. Proportioning magnesium chloride with water into a liquid with a density of 18%;

[0052] 3. Pour the liquid and other raw materials into the mixer and stir for 10 minutes to form a paste slurry;

[0053] 4. Pour into the specified mold and pressurize 10 tons to make a 60 cm thick sheet, take it out and dry it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com