Integral insulating joint

An insulating joint and integral technology, applied in the direction of pipes/pipe joints/pipes, passing components, mechanical equipment, etc., can solve the problems of difficult sealing effect of insulating gasket 4, difficult sealing effect of insulating gasket 4, easy damage, etc. , to achieve the effect of excellent insulation and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

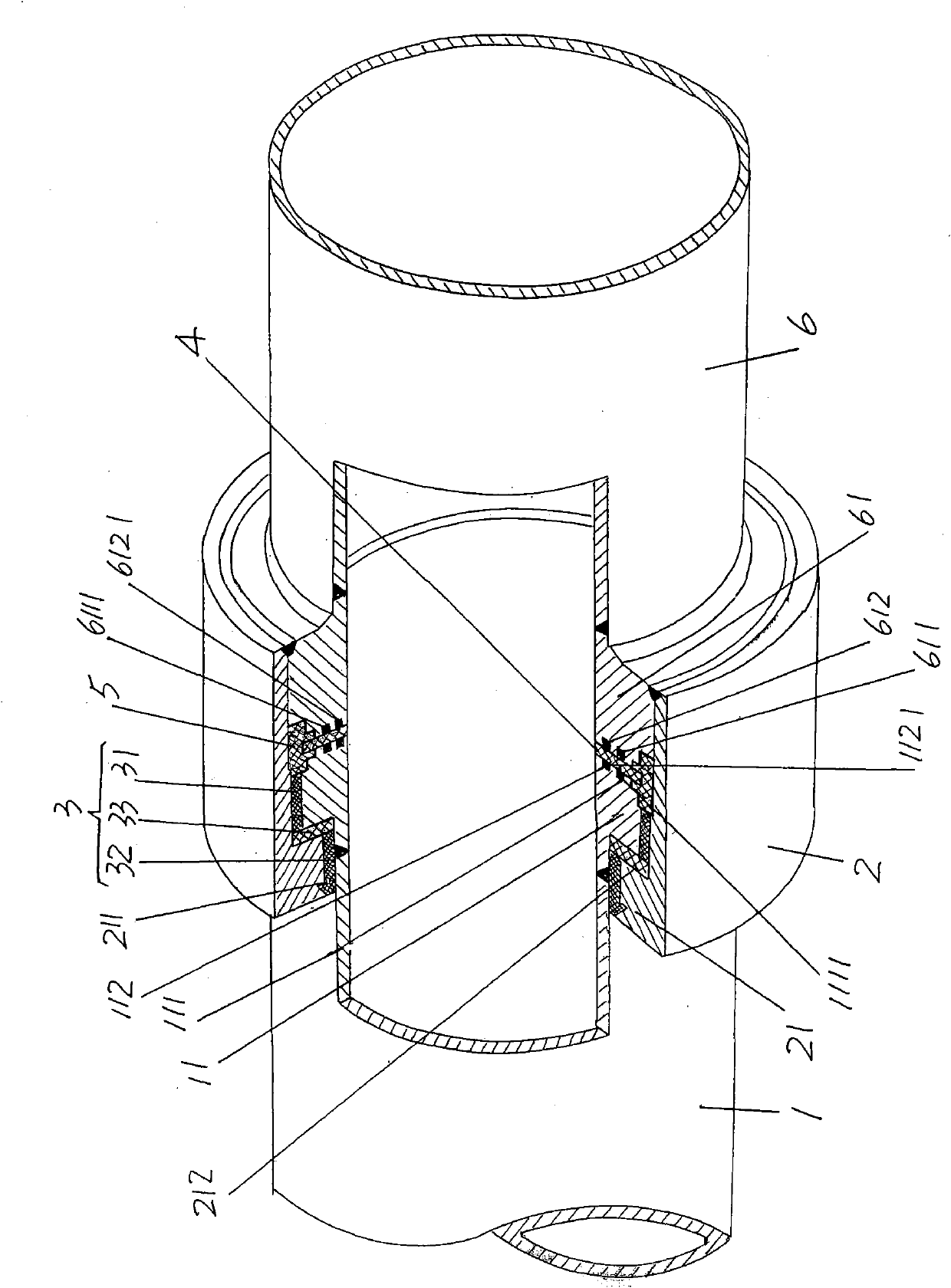

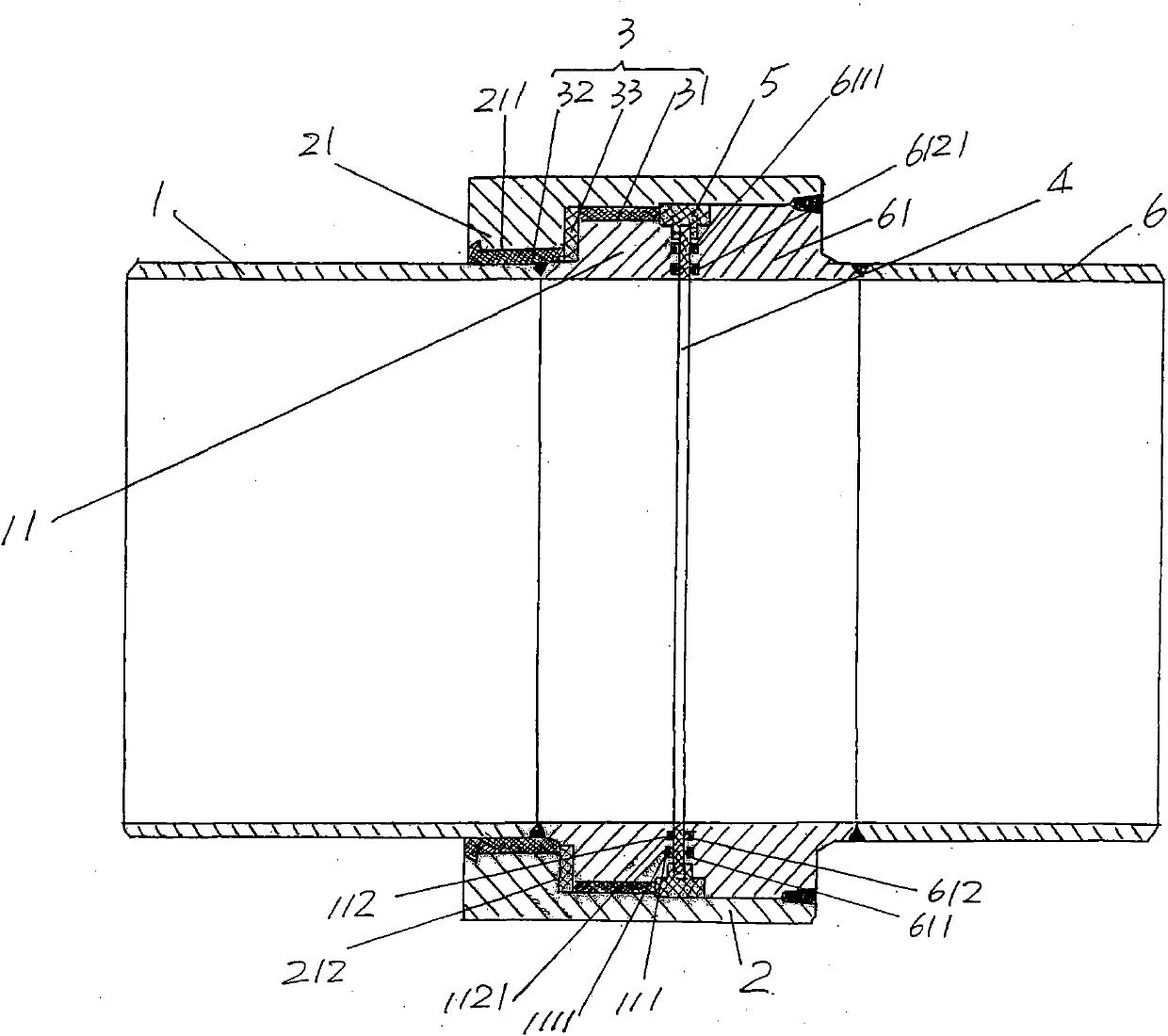

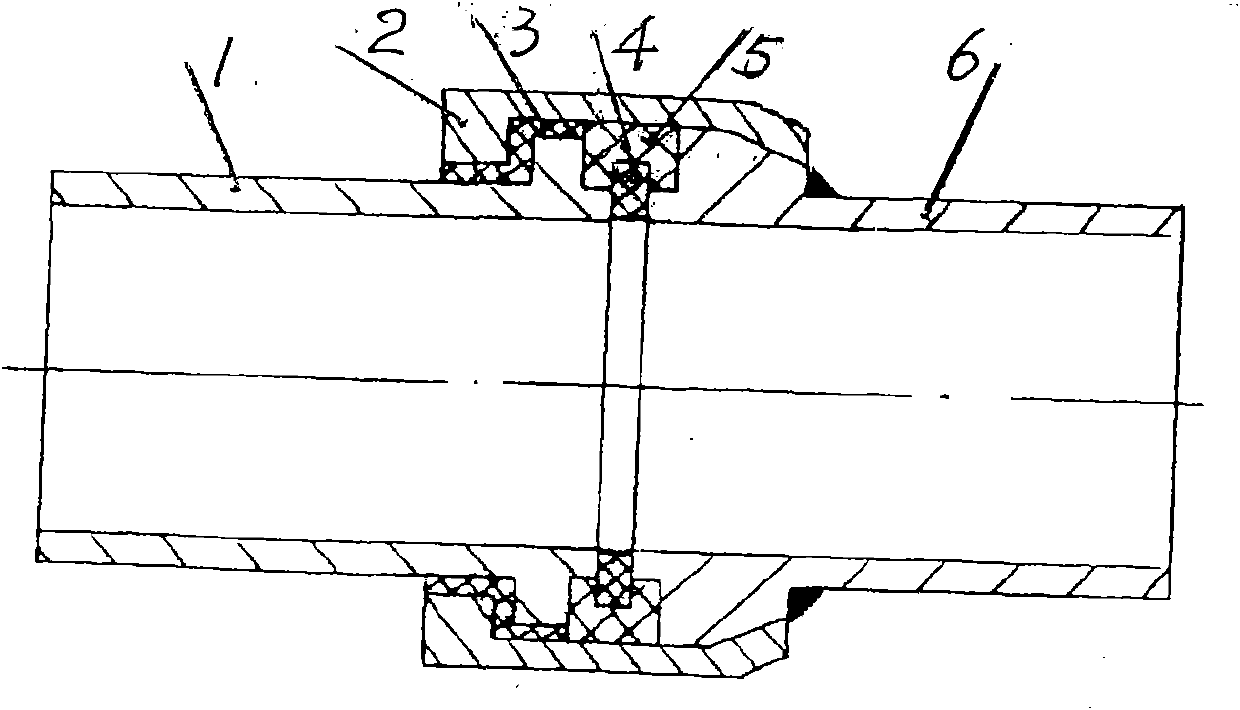

[0017] please see figure 1 and figure 2 , the upper and lower conduits 6, 1 are provided, the end of the lower conduit 1 towards the end of the upper conduit 6 is formed with a lower conduit flange 11 by welding, and at the side of the lower conduit flange 11 facing the upper conduit 6 The surface is provided with a first sealing ring groove 111 and a second sealing ring groove 112 , the first sealing ring groove 111 is embedded with a first sealing ring 1111 , and the second sealing ring groove 112 is embedded with a second sealing ring 1121 . Similarly, an upper conduit flange 61 is formed by welding at the end of the upper conduit 6 towards the end of the lower conduit 1, and the surface on the side of the upper conduit flange 61 facing the lower conduit 1 is toward the side of the lower conduit flange 11. A third sealing ring groove 611 and a fourth sealing ring groove 612 are opened on one side surface, a third sealing ring 6111 is embedded in the third sealing ring gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com