Plastic curb and plastic curbstone forming same

A curb stone and plastic technology, which is applied in the direction of side ditch/curb stone, road, road, etc., can solve the problems of difficult construction, poor jointing, difficult maintenance, etc., and achieves convenient and firm installation, convenient transportation and installation, The effect of construction quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

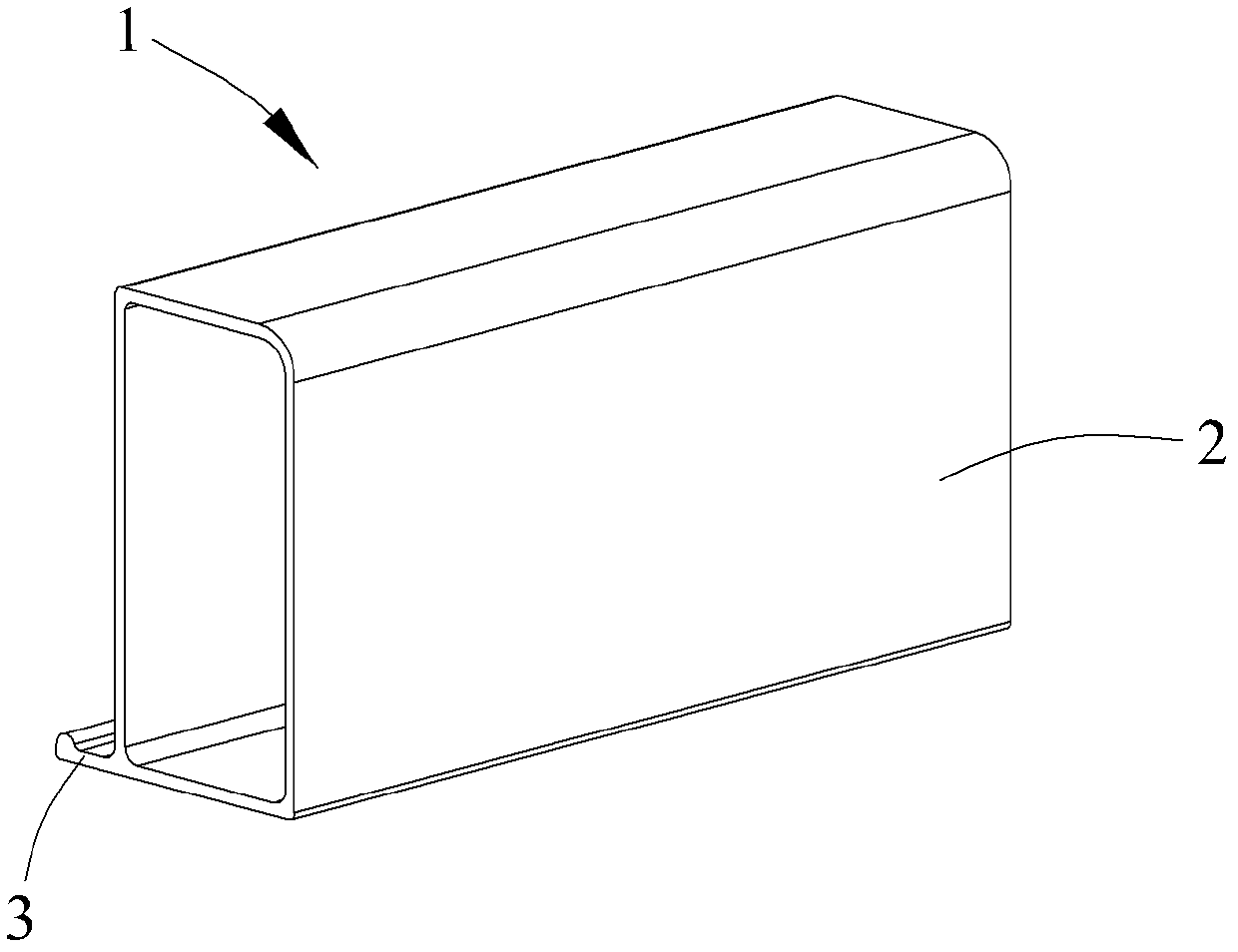

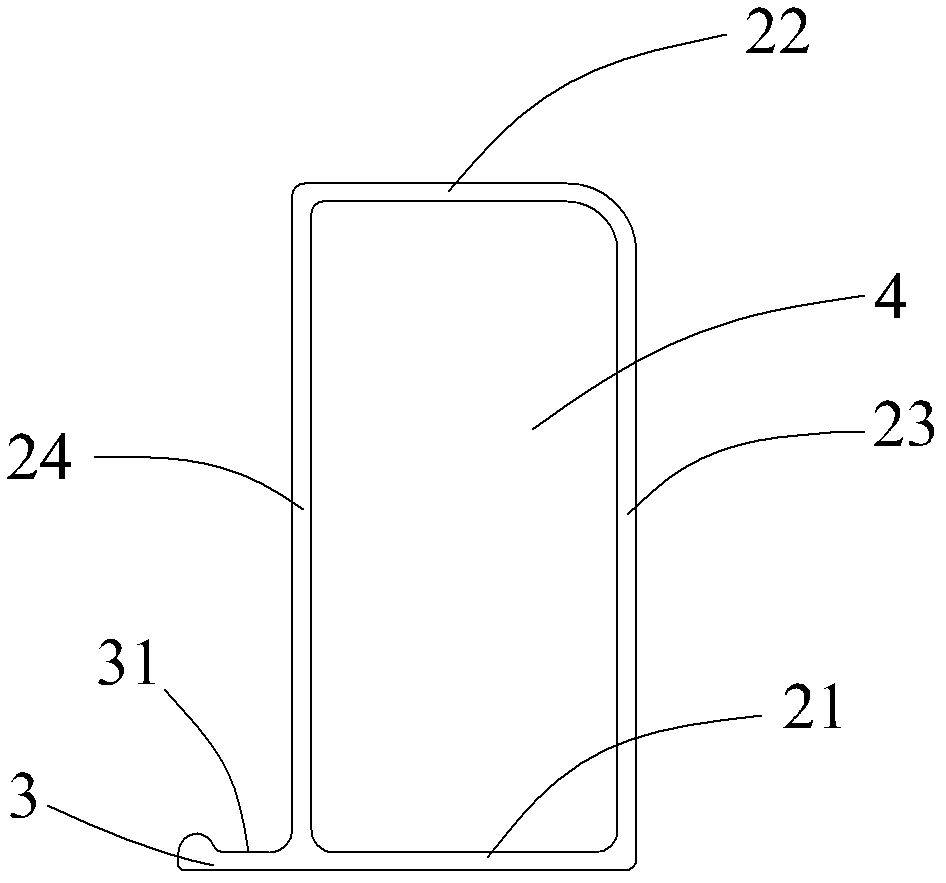

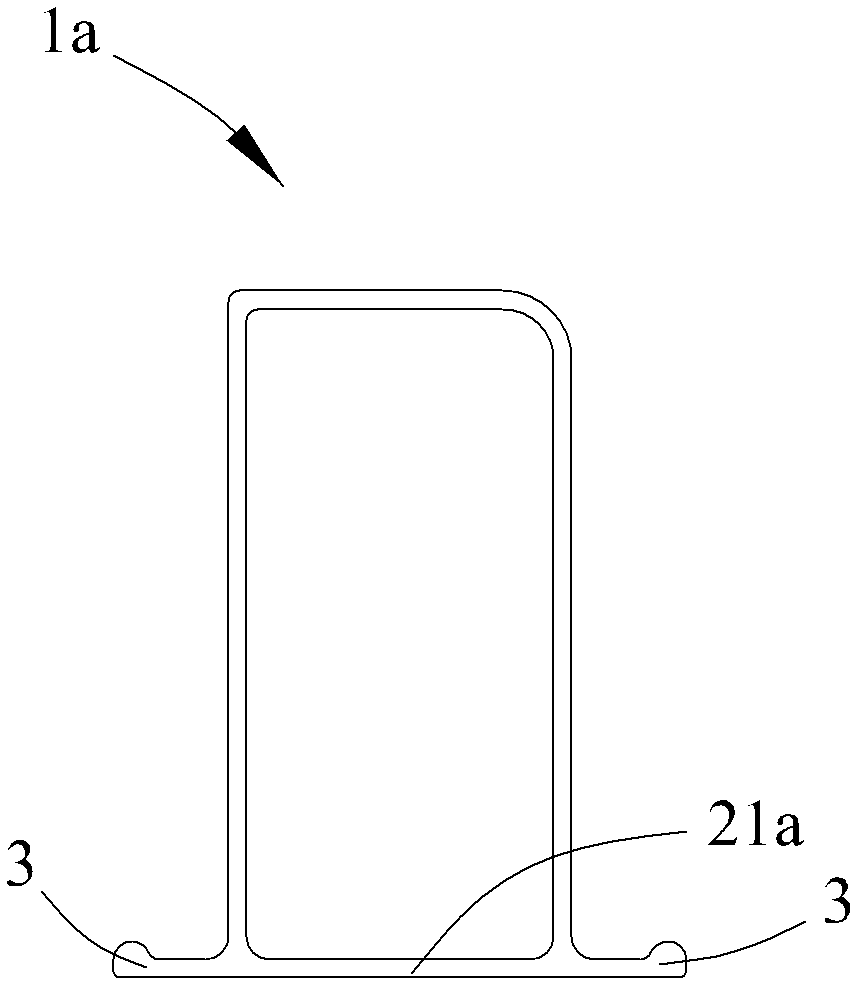

[0035] Such as Figure 1-10 As shown, the plastic curbstone of the present invention is made of plastic material, including a flat hollow body and a flange extending outward from the bottom edge of the hollow body, and the hollow body includes a bottom plate, a top plate, a front side plate and The rear side plate, the top plate is connected between the top end of the front side plate and the top end of the rear side plate, the bottom plate is connected between the bottom end of the front side plate and the bottom end of the rear side plate, by the The bottom plate, the top plate, the front side plate and the rear side plate are enclosed to form a cavity that runs through both ends of the hollow body in a transverse direction.

[0036] The plastic curb of the present invention can be widely used on the edges of roads, flower beds, field surfaces, green belts, etc., to demarcate the range of the road surface, tidy the road capacity, protect the edge of the road surface, and gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com