Bamboo-wood composited container floor and production method thereof

A bamboo-wood composite and container technology, which is used in the manufacture of tools, wood-layered products, and the joining of wooden veneers, can solve problems such as the reduction of floor strength, and achieve the effects of good flatness, improved strength, and structural symmetry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

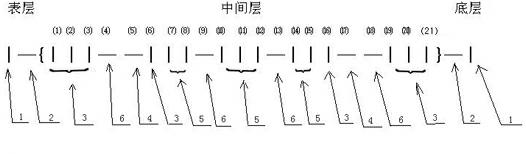

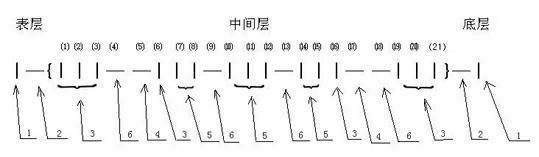

[0019] As shown in the figure, the present invention comprises surface layer, bottom layer and middle layer, is characterized in that:

[0020] The surface layer is composed of longitudinal adhesive film 1, horizontally restructured veneer 2 or horizontal non-woven fabric 2, and the longitudinal adhesive film 1 is placed on the upper surface of horizontally restructured veneer 2 or horizontal non-woven fabric 2;

[0021] The bottom layer is composed of longitudinal adhesive film 1, horizontally restructured veneer 2 or horizontal non-woven fabric 2, and the longitudinal adhesive film 1 is placed on the lower surface of the horizontally restructured veneer 2 and horizontal non-woven fabric 2;

[0022] The middle layer is a composite symmetrical structure of 21 layers of bamboo curtains and wood veneers. The middle layer is respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com