Manufacturing method of hot forming rim

A manufacturing method, thermoforming technology, applied in transportation and packaging, vehicle parts, etc., can solve the problems of low molding quality, low stability, low precision, etc., to improve the molding quality, reduce the extrusion force, improve the rim structure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

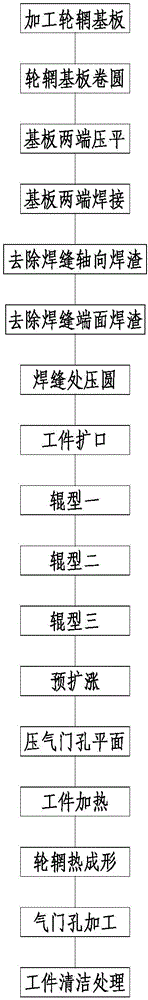

[0039] Embodiment: a kind of manufacturing method of thermoformed rim of the present invention, as attached figure 1 Shown, including the following production steps.

[0040] A1. Formed rim round tube: that is, a closed round tube that is circumferentially closed is made with a metal plate. Specifically include A1-1, A1-2, A1-3, A1-4, a2, A1-5 as described below.

[0041] A1-1. Formed rim substrate: a rim substrate 1 with a strip-shaped sheet structure processed from a metal plate (see figure 2 ).

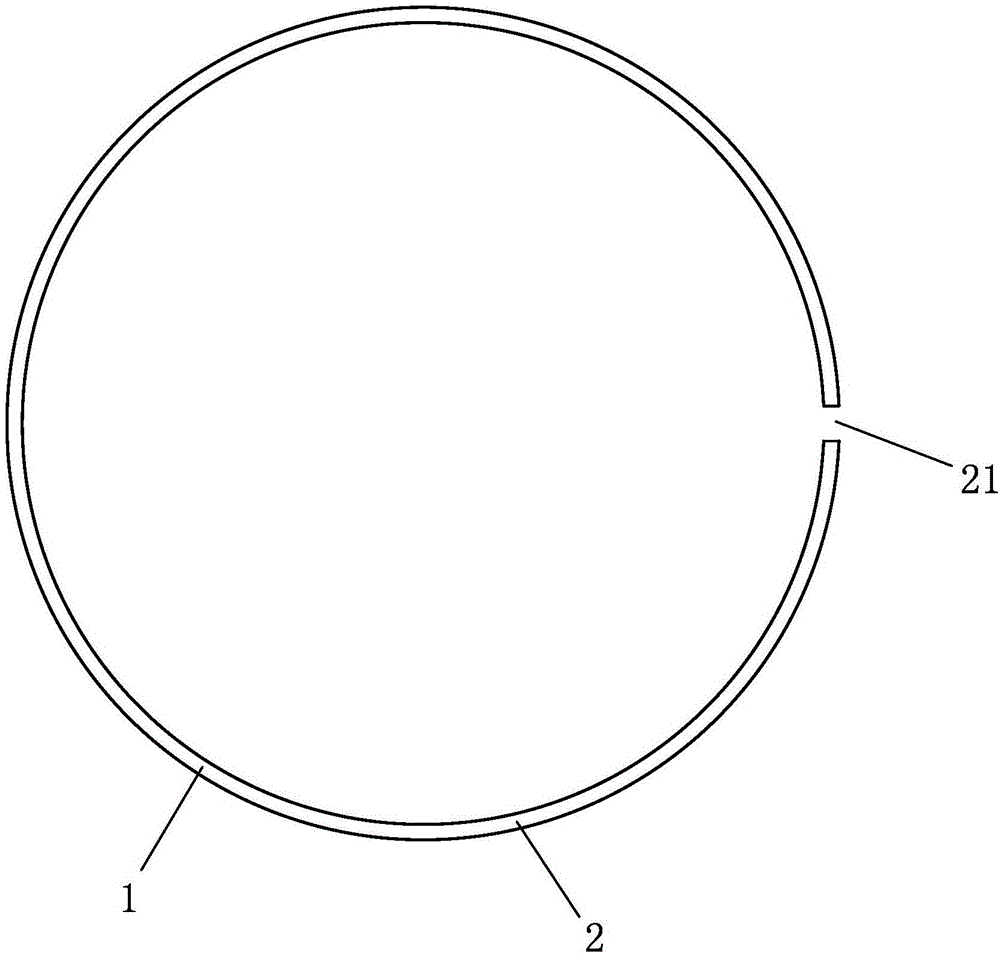

[0042] A1-2. Forming a round tube with a slot: roll the rim substrate 1 into a round tube 2 with a slot with a butt joint gap 21 (see image 3 ).

[0043] A1-3. Forming flat tubes with slots: change the two rim base plate ends 11 of the rim base plate from an arc-shaped structure to a planar structure on the same plane, so that the round tube with slots becomes a planar structure at the butt joint 21 Flat tube with slot 3 (see Figure 4 ).

[0044] A1-4. Forming closed flat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com