Preparation method for gold-tin eutectic alloy foil having uniform structure

A technology of eutectic alloy and uniform structure, which is applied to the preparation of gold-tin eutectic alloy foil with uniform structure and the processing technology of difficult-to-deform alloy foil, and achieves reduction of production cost, uniform deformation and stress of welding piece, and good welding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Precisely configure the gold-tin eutectic alloy whose composition is 20% by mass of tin and 80% by mass of gold. Air in the body, and then evacuate until the vacuum degree reaches 10 -3 After Pa, under the working current of 900A, the arc is smelted, the smelting peak temperature is 1300 ℃, and the gold-tin alloy melt is obtained, and the melt is electromagnetically stirred, and the electromagnetic stirring speed is 1100r / min, and the stirring time is 1-2 minutes. Then, use Cool the water-cooled copper crucible to room temperature, and control the cooling rate to 1.0-1.1*10 3 K / min; repeat the process of smelting, stirring, and cooling 4 times; take out the ingot and hold it at 240°C for 2 hours. After homogenizing annealing, the ingot is then thermally compressed at 240°C. The pressure is 0.02mm / s, the holding time is 2 minutes, the deformation of each pass is controlled at 17-19%, annealing is performed at 240-260°C between passes, the annealing holding time is 10 mi...

Embodiment 2

[0035] Precisely configure the gold-tin eutectic alloy whose composition is 20% by mass of tin and 80% by mass of gold. Air in the body, and then evacuate until the vacuum degree reaches 10 -3After Pa, under the working current of 950A, the arc is smelted, the smelting peak temperature is 1300 ℃, and the gold-tin alloy melt is obtained, and the melt is electromagnetically stirred, and the electromagnetic stirring speed is 1300r / min, and the stirring time is 1-2 minutes. Then, use The water-cooled copper crucible is cooled to room temperature, and the cooling rate is controlled to be 1.2-1.3*10 3 K / min; repeat the process of smelting, stirring, and cooling 5 times; take out the ingot and hold it at 250°C for 3 hours. After homogenizing annealing, the ingot is then thermally compressed at 250°C. The pressure is 0.01mm / s, the holding time is 2 minutes, the deformation of each pass is controlled at 16-18%, annealing is performed at 240-260°C between passes, the annealing holding ...

Embodiment 3

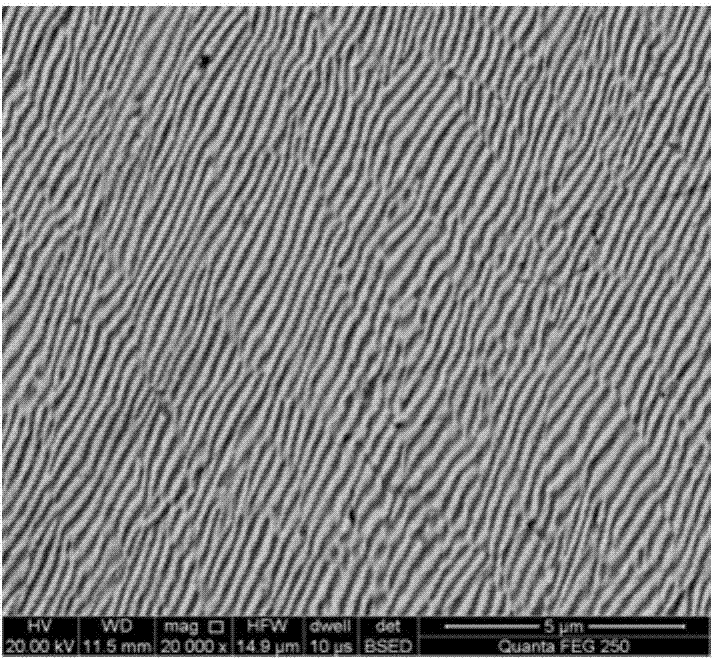

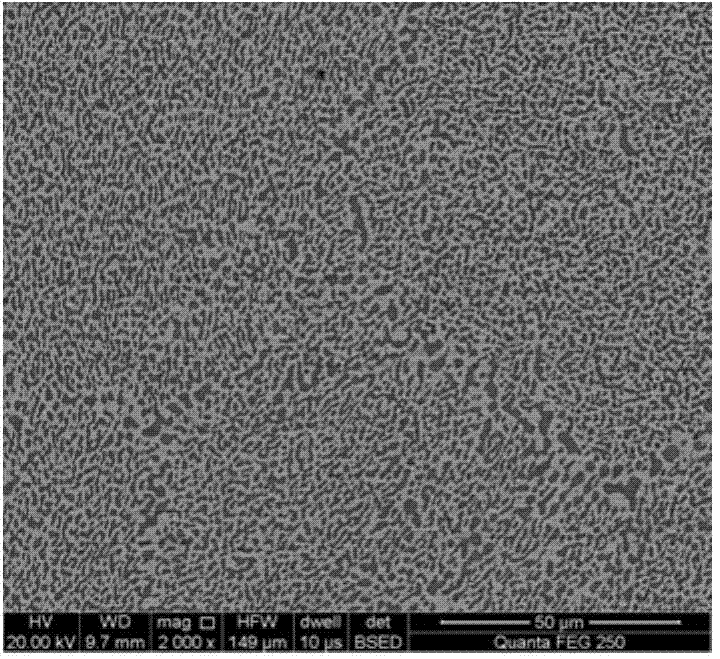

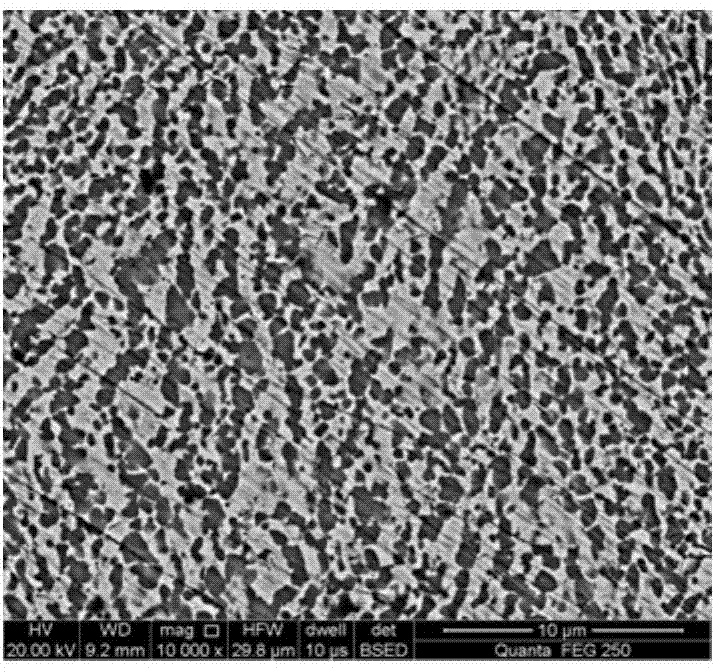

[0038] Precisely configure the gold-tin eutectic alloy whose composition is 20% by mass of tin and 80% by mass of gold. Air in the body, and then evacuate until the vacuum degree reaches 10 -3 After Pa, arc melting under the working current of 1000A, the melting peak temperature is 1300 ℃, and the gold-tin alloy melt is obtained, and the melt is electromagnetically stirred, and the electromagnetic stirring speed is 1500r / min, and the stirring time is 1-2 minutes. Then, use Cool the water-cooled copper crucible to room temperature, and control the cooling rate to 1.4-1.5*10 3 K / min; repeat the process of smelting, stirring and cooling 6 times; the solidified structure after smelting is as follows figure 1 As shown, it is a full-sheet lamellar eutectic structure without primary phase; the ingot is taken out and kept at 260°C for 5 hours for homogenization annealing. The microstructure of the ingot after homogenization heat treatment is as follows: figure 2 As shown, it is an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com