Super duplex stainless steel used on pump valve product and preparation method thereof

A duplex stainless steel, super technology, applied in the field of stainless steel, can solve the problems of not being able to further improve the corrosion resistance and mechanical properties of duplex stainless steel, limit the corrosion resistance and mechanical properties, reduce the corrosion resistance of duplex stainless steel, and achieve blunt The effect of changing the range of chemical current, improving corrosion resistance and mechanical properties, and not being easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] The super duplex stainless steel used in the pump valve product described in this embodiment is characterized in that its composition and weight percentage of each component are as follows: nickel: 6.5%, chromium: 25%, molybdenum: 4%, copper: 0.8 %, nitrogen: 0.25%, carbon ≤ 0.02%, manganese ≤ 1%, silicon ≤ 1%, phosphorus ≤ 0.03%, sulfur ≤ 0.025%, cerium: 0.05%, the balance is iron.

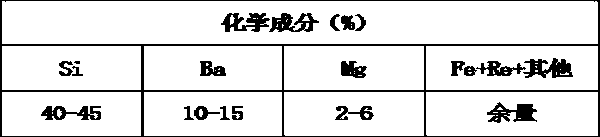

[0010] The preparation method of the above-mentioned super duplex stainless steel is as follows: put the relevant materials used in the intermediate frequency furnace for smelting, and after the materials are completely melted to form a molten metal melt, the molten metal melt is sampled and analyzed and the carbon content is adjusted so that the carbon content is low The weight percentage does not exceed 0.02%, and then pour the covering agent into the intermediate frequency furnace. The scientific name of the covering agent in this embodiment is: slagging agent. The main raw material of the ...

Embodiment 2

[0015] The super duplex stainless steel used in the pump valve product described in this embodiment is characterized in that its composition and weight percentage of each component are as follows: nickel: 8.5%, chromium: 24%, molybdenum: 3.5%, copper: 0.5 %, Nitrogen: 0.3%, Carbon ≤0.01%, Manganese ≤1%, Silicon ≤1%, Phosphorus ≤0.03%, Sulfur ≤0.02%, Cerium: 0.2%, the balance is iron.

[0016] The preparation method of the above-mentioned super duplex stainless steel is as follows: put the relevant materials used in the intermediate frequency furnace for smelting, and after the materials are completely melted to form a molten metal melt, the molten metal melt is sampled and analyzed and the carbon content is adjusted so that the carbon content is low The weight percentage does not exceed 0.02%, and then pour the covering agent into the intermediate frequency furnace to completely cover the surface of the molten metal and increase the furnace temperature to 1500°C for deoxidation an...

Embodiment 3

[0019] The super duplex stainless steel used in the pump valve product described in this embodiment is characterized in that its composition and weight percentage of each component are as follows: nickel: 7%, chromium: 26%, molybdenum: 3%, copper: 1 %, nitrogen: 0.2%, carbon ≤ 0.02%, manganese ≤ 1%, silicon ≤ 1%, phosphorus ≤ 0.02%, sulfur ≤ 0.025%, cerium: 0.1%, and the balance is iron.

[0020] The preparation method of the above-mentioned super duplex stainless steel is as follows: put the relevant materials used in the intermediate frequency furnace for smelting, and after the materials are completely melted to form a molten metal melt, the molten metal melt is sampled and analyzed and the carbon content is adjusted so that the carbon content is low The weight percentage does not exceed 0.02%, and then pour the covering agent into the intermediate frequency furnace to completely cover the surface of the molten metal melt and increase the temperature in the furnace to 1505°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com