Super duplex stainless steel used in pump and valve products and preparation method thereof

A technology of duplex stainless steel and products, applied in the field of stainless steel, can solve the problems of inability to further improve the corrosion resistance and mechanical properties of duplex stainless steel, reduce the corrosion resistance of duplex stainless steel, limit the corrosion resistance and mechanical properties, etc. The effect of changing the chemical current range, not easy to crack, and improving corrosion resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] The super duplex stainless steel used in pump and valve products described in this embodiment is characterized in that its composition and weight percentage of each component are as follows: nickel: 6.5%, chromium: 25%, molybdenum: 4%, copper: 0.8 %, nitrogen: 0.25%, carbon ≤ 0.02%, manganese ≤ 1%, silicon ≤ 1%, phosphorus ≤ 0.03%, sulfur ≤ 0.025%, cerium: 0.05%, and the balance is iron.

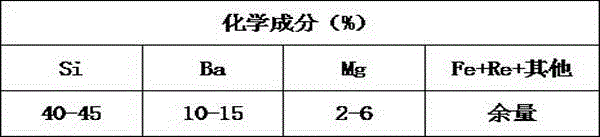

[0010] The preparation method for preparing the above-mentioned super duplex stainless steel is as follows: put the relevant materials used into an intermediate frequency furnace for smelting, and after the materials are completely melted to form a molten metal melt, sample and analyze the molten metal melt and adjust the carbon content to make the carbon content The percentage by weight is not more than 0.02%, and then pour the covering agent into the intermediate frequency furnace. The scientific name of the covering agent described in this embodiment is: slag gathering agent. The ma...

Embodiment 2

[0015] The super duplex stainless steel used in pump and valve products described in this embodiment is characterized in that its composition and weight percentage of each component are as follows: nickel: 8.5%, chromium: 24%, molybdenum: 3.5%, copper: 0.5% %, nitrogen: 0.3%, carbon ≤ 0.01%, manganese ≤ 1%, silicon ≤ 1%, phosphorus ≤ 0.03%, sulfur ≤ 0.02%, cerium: 0.2%, and the balance is iron.

[0016] The preparation method for preparing the above-mentioned super duplex stainless steel is as follows: put the relevant materials used into an intermediate frequency furnace for smelting, and after the materials are completely melted to form a molten metal melt, sample and analyze the molten metal melt and adjust the carbon content to make the carbon content The weight percentage does not exceed 0.02%, and then pour the covering agent into the intermediate frequency furnace so that the covering agent completely covers the surface of the molten metal and raises the temperature in t...

Embodiment 3

[0019] The super duplex stainless steel used in pump and valve products described in this embodiment is characterized in that its composition and weight percentage of each component are as follows: nickel: 7%, chromium: 26%, molybdenum: 3%, copper: 1 %, nitrogen: 0.2%, carbon ≤ 0.02%, manganese ≤ 1%, silicon ≤ 1%, phosphorus ≤ 0.02%, sulfur ≤ 0.025%, cerium: 0.1%, and the balance is iron.

[0020] The preparation method for preparing the above-mentioned super duplex stainless steel is as follows: put the relevant materials used into an intermediate frequency furnace for smelting, and after the materials are completely melted to form a molten metal melt, sample and analyze the molten metal melt and adjust the carbon content to make the carbon content The weight percentage does not exceed 0.02%, and then pour the covering agent into the intermediate frequency furnace, so that the covering agent completely covers the surface of the molten metal and raises the temperature in the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com