Wood drying remote monitoring system based on DSP (digital signal processor)

A remote monitoring system, wood drying technology, applied in the direction of drying solid materials, drying, lighting and heating equipment, etc., can solve the problems of complex operation, waste, outdated equipment energy, etc., achieve uniform heating, short drying cycle, and realize the solution simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

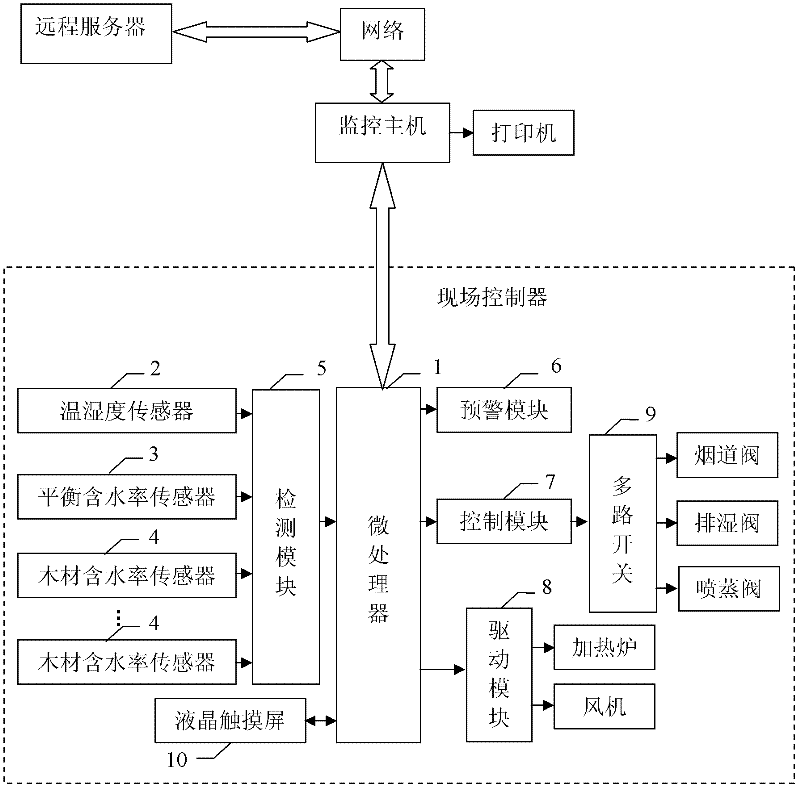

[0017] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the wood drying remote monitoring system based on DSP described in this embodiment includes a remote server, a monitoring host and a field controller, and the field controller includes a microprocessor 1, a temperature and humidity sensor 2, a balance moisture content Sensor 3, detection module 5, early warning module 6, control module 7, multi-way switch 9, drive module 8, and n wood moisture content sensors 4, n is a natural number,

[0018] The temperature and humidity sensor 2 collects the temperature and humidity signal of the drying kiln, and the temperature and humidity signal output end of the temperature and humidity sensor 2 is connected with the temperature and humidity signal input end of the detection module 5;

[0019] The balanced moisture content sensor 3 collects the balanced moisture content signal of the drying kiln, and the balanced moisture content signal ...

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this specific embodiment and the wood drying remote monitoring system based on DSP described in specific embodiment one is that the field controller can further include a liquid crystal touch screen 10, which can communicate with the microprocessor 1 through the liquid crystal touch screen 10 For data interaction.

[0025] In this embodiment: the current state of the drying kiln can be displayed through the liquid crystal touch screen 10, and some drying parameters can also be set.

[0026] In terms of hardware design: the field controller adopts DSP2812 core board LT8504 embedded development board for development and design, mainly completes the design of external storage circuit, touch screen interface circuit, signal input and output drive circuits, and connects with the serial port of the monitoring host to achieve reliable communication .

[0027] In terms of software design: the monitoring host uses the object-orien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com