Patents

Literature

64 results about "Wood moisture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

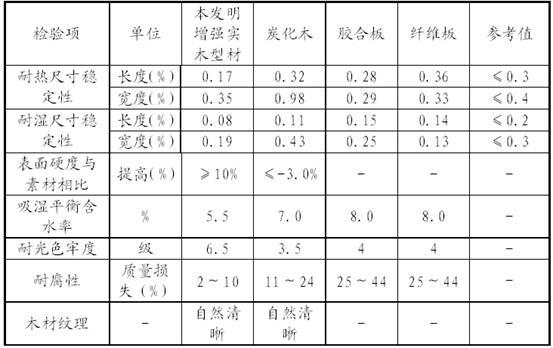

Stable enhanced type solid wood profile and production method thereof

ActiveCN101879736AReduce surface hardnessReduce surface strengthWood impregnation detailsSolid woodWeather resistance

The invention provides a production method of a stable enhanced type solid wood profile improved by a wood carbonization and acetylation process, which belongs woodwork production technique. The production method comprises the following steps of: a, drying treatment, wherein the wood moisture content is reduced to be as low as 5.0 to 8.0 percent, the moisture content deviation in the wood thickness is less than 2.0 percent, and the wood internal residual stress is less than 2.0 percent; b, carbonizing treatment; c, acetylation treatment; and d, equalization treatment. The invention also discloses a stable enhanced type solid wood profile prepared by the production method. The solid wood profile prepared by the method is stable, has high corrosion resistance and weathering resistance, high output, long product service life and wide utilization ways, is favorable for realizing flow line production, and is convenient for industrialization.

Owner:ZHEJIANG SHIYOU TIMBER

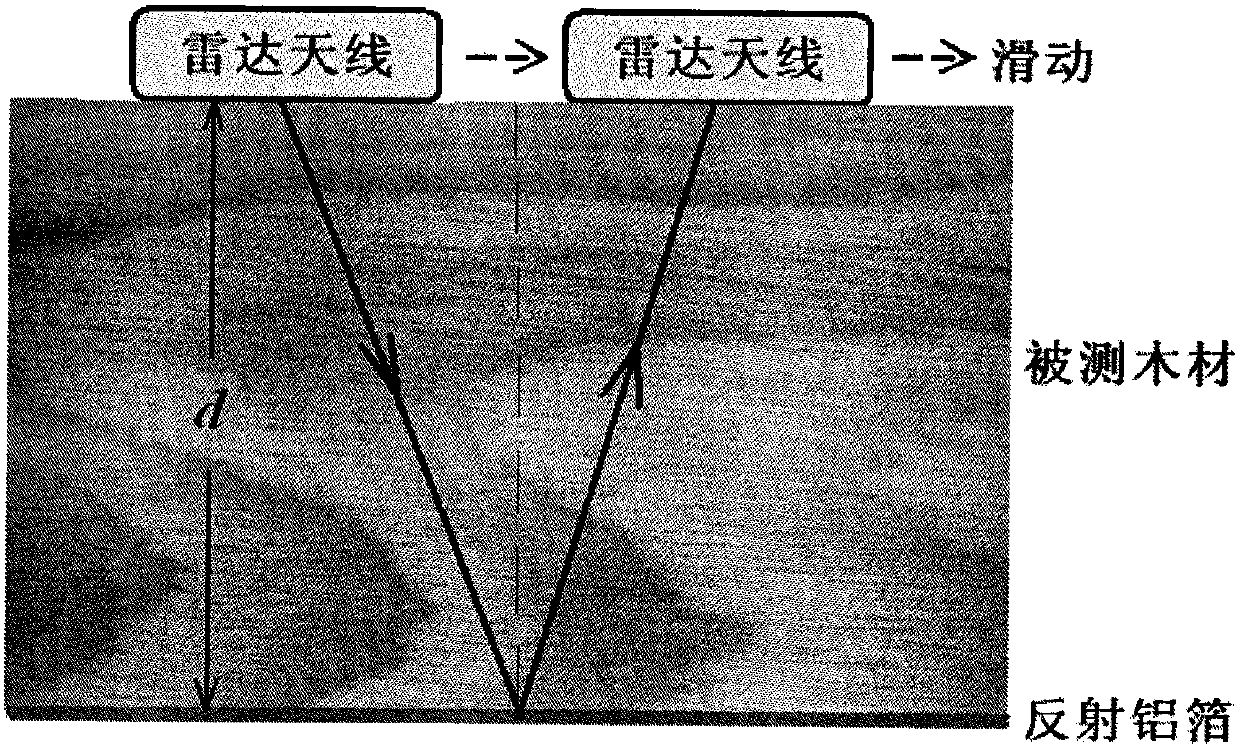

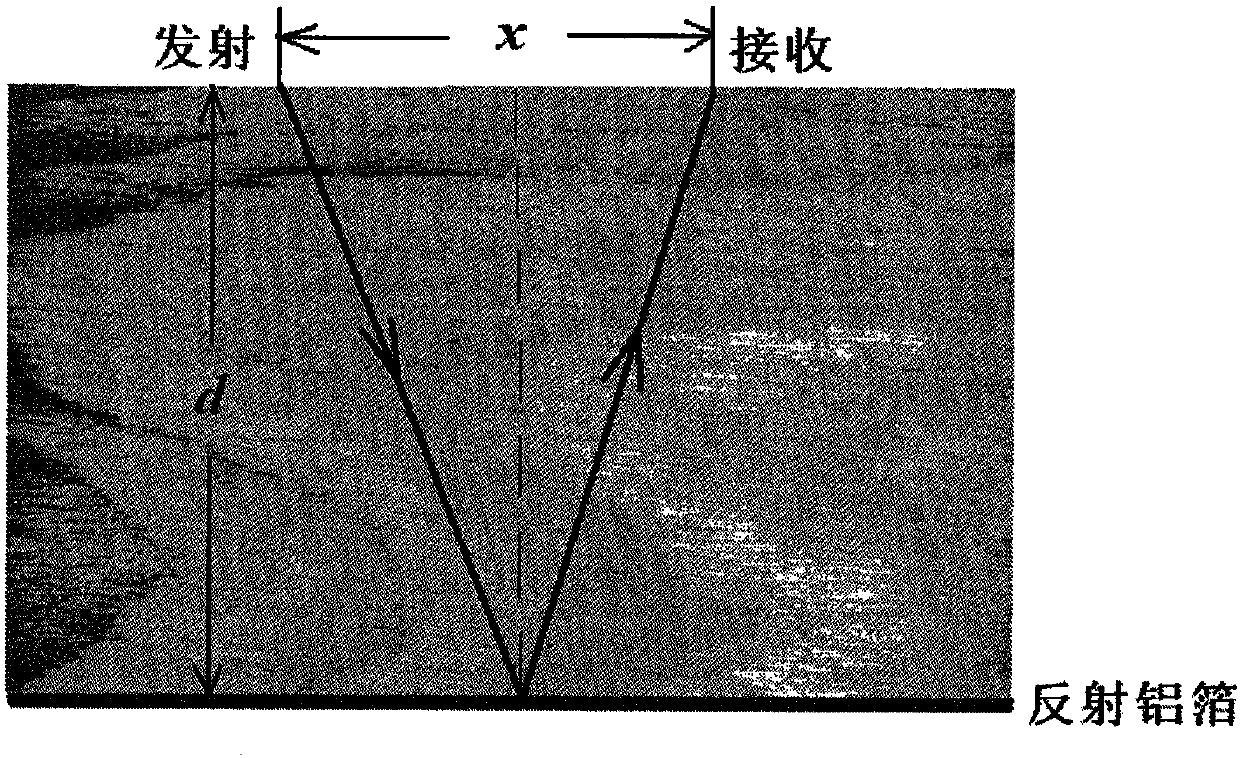

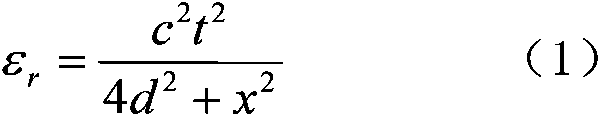

Wood moisture content detection method based on radar waves

InactiveCN103808624ANo damageLarge measuring rangeWeighing by removing componentMoisture content investigation using microwavesElectricitySoil science

The invention discloses a wood moisture content detection method based on radar waves. The wood moisture content detection method overcomes such shortcoming of the conventional weighing method as complicated detection process and is a real-time, continuous and lossless moisture content detection method. When the radar waves are transmitted in wood, the transmission speed, the amplitude intensity, the reflection time and the like of the radar waves are affected due to difference of dielectric constants in the wood, and the dielectric constants in the wood are closely relevant to the moisture content of the wood. The detection method comprises the steps of mounting a radar antenna (containing a radar wave emitting and receiving device, wherein the radar wave frequency is 900Mhz, and the wood which is 1m thick can be detected), a data manager (which can digitalize and store the radar waves emitted and reflected by the radar antenna for analysis and research), and a wood relative dielectric constant and moisture content relation model; emitting the radar waves to the wood with the known thickness through the radar antenna, collecting the reflected waves, calculating the double-journey traveling time of the radar waves in the wood through the data manager, calculating a relative dielectric constant of the wood, and obtaining the moisture content of the wood according to the wood relative dielectric constant and moisture content relation model.

Owner:BEIJING FORESTRY UNIVERSITY

Moisture content measuring method for wood drying process and wood drying method

ActiveCN108802352AAccurate moisture contentReduce drying defectsWeighing by removing componentWood testingNarrow rangeSolid wood

The invention discloses a moisture content measuring method for a wood drying process and a wood drying method. The moisture content measuring method for the wood drying process and the wood drying method include: measuring an initial moisture content and initial weight of to-be-dried wood, and stacking the to-be-dried wood in a drying kiln; measuring temperature and wind speed of media flowing through two sides of the stacked to-be-dried wood, acquiring saturated vapor pressure of moist air according to dry-bulb temperature, acquiring relative humidity of the moist air according to temperatures of wet and dry bulbs, and finally acquiring density and moisture content of the moist air so as to obtain moisture contents of the to-be-dried wood at different times; according to the moisture contents of the to-be-dried wood, drying the to-be-dried word according to wood drying standards so as to obtain high-quality dry wood. The moisture content measuring method is precise, simple, low in input, applicable to any wood moisture content measurement, less in measuring parameters, simple in calculation, systematically stable, capable of overcoming the defects of large measuring error and narrow range of an electric measuring method and improving quality of solid wood plates, high in efficiency and low in cost.

Owner:BEIJING FORESTRY UNIVERSITY

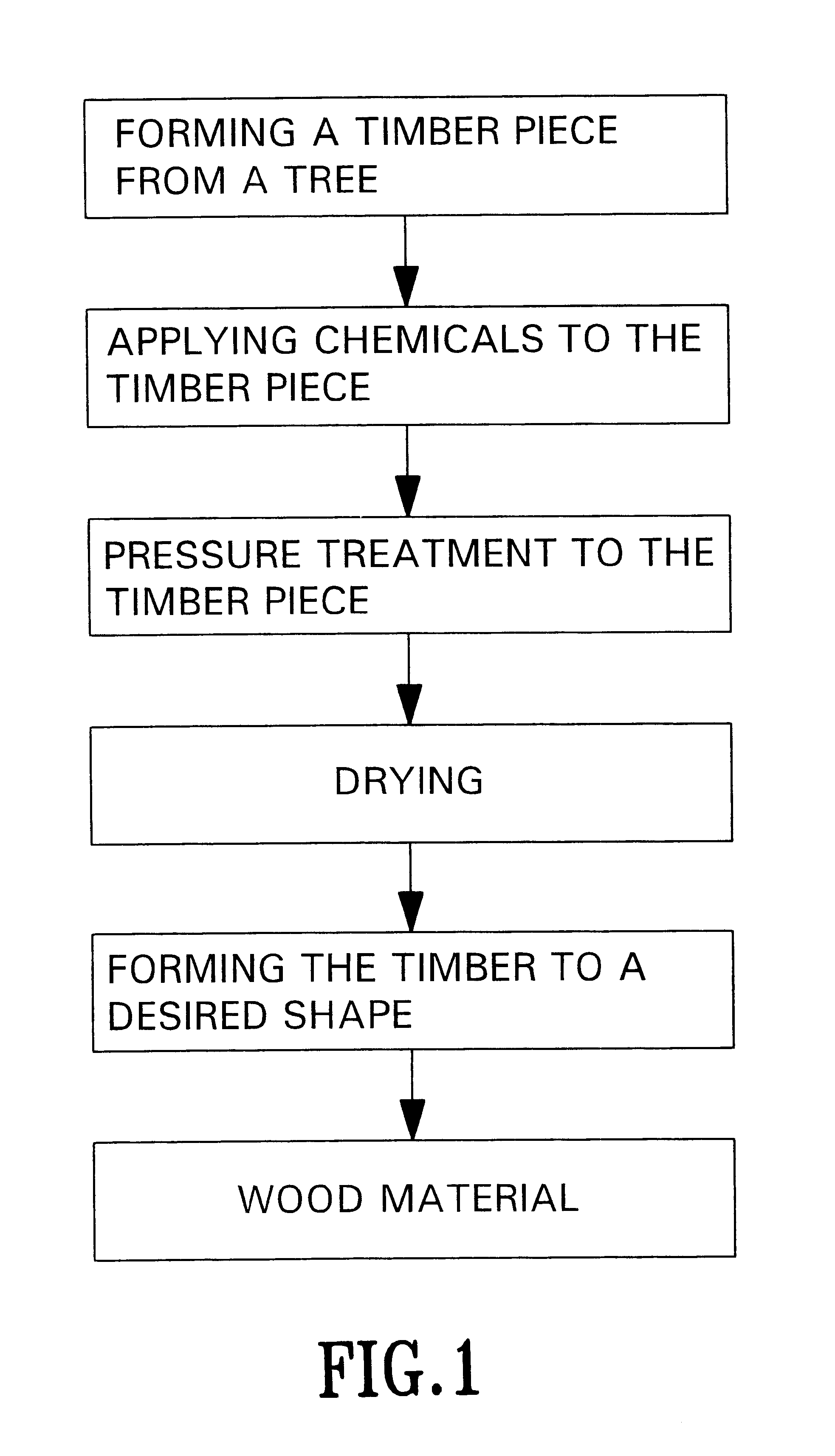

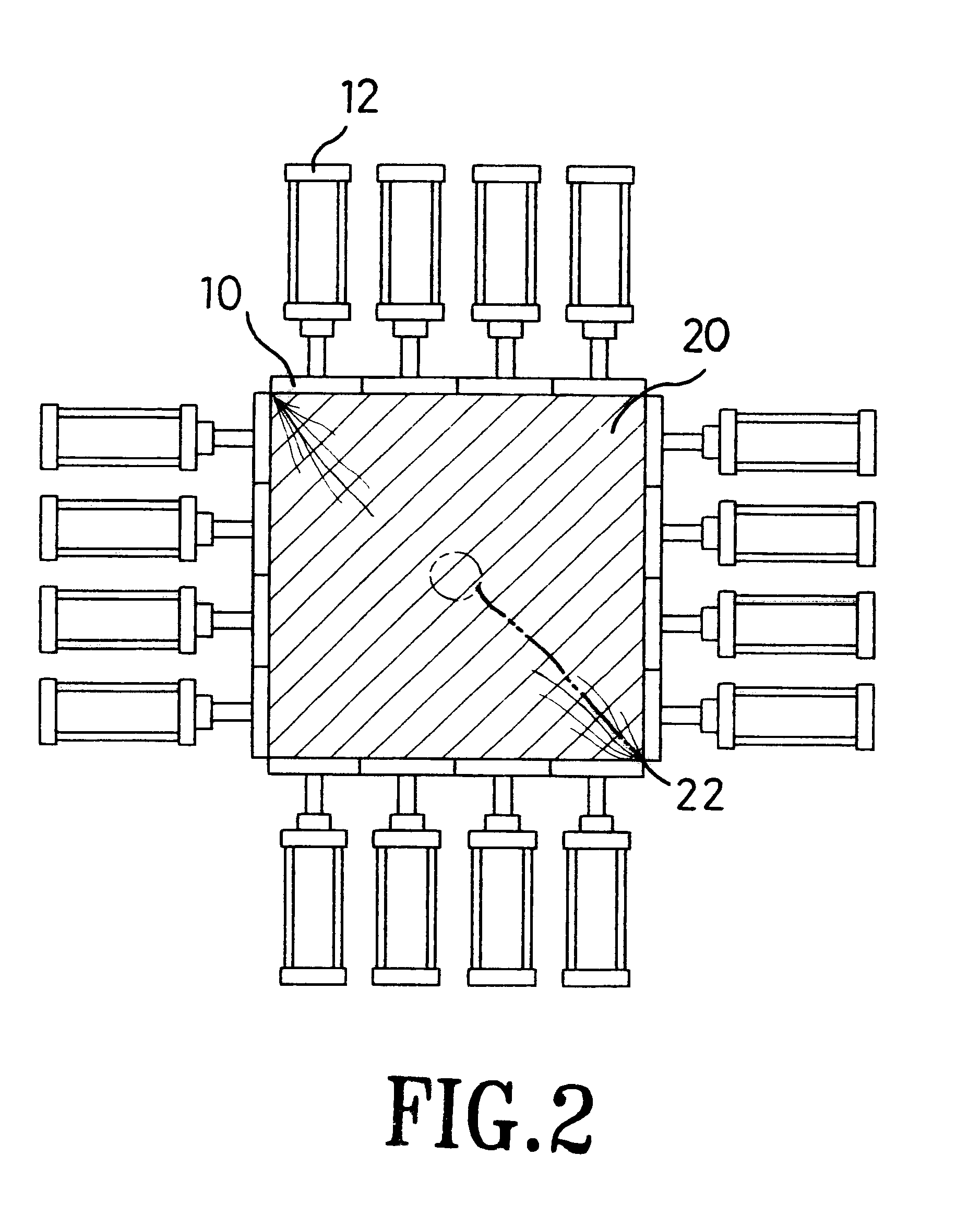

Method for producing a piece of timber including heartwood

A method for making wood with heartwood has steps of forming a wood log with a heartwood from a tree, pressure treatment to the wood log with the heartwood, drying the wood log and forming the wood log to a desired shape. The pressure treatment process is to apply a desired pressure to the wood log to reduce a moisture content of the wood log with the heartwood to an even level. This can avoid the wood log with the heartwood to split, crack or deform during the drying process. The utilization of a tree can be increased, and the process for gain a wood material is simplified.

Owner:LEE SHEN BA

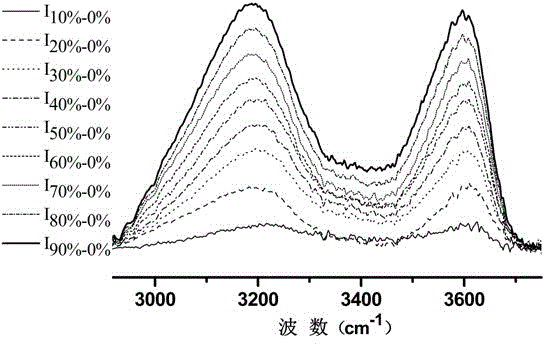

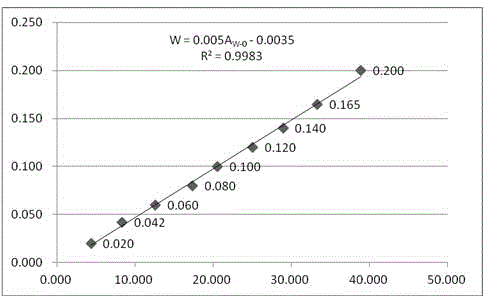

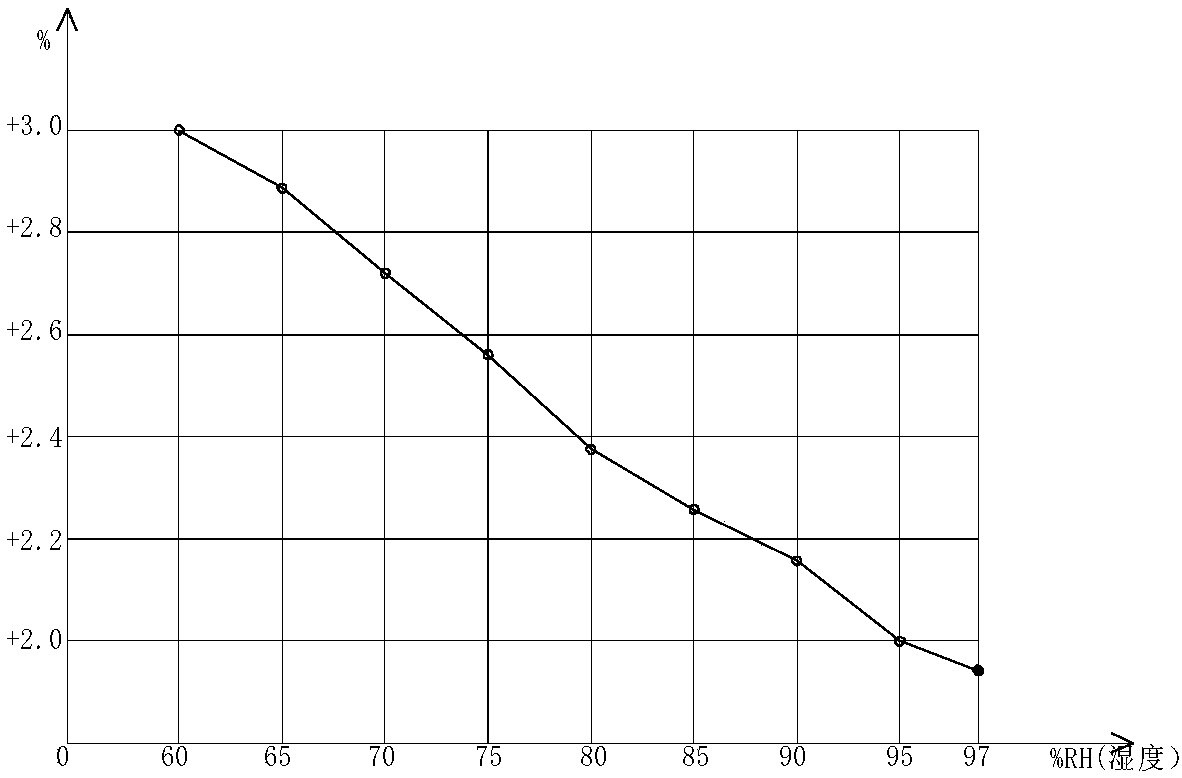

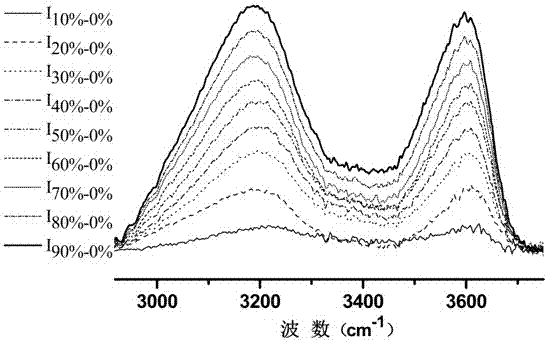

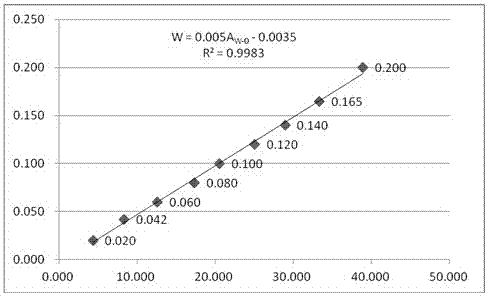

Method for detecting moisture content of wood on basis of infrared differential spectrum technology

InactiveCN104390932AReduced measurement timeOvercoming the lack of high demandMaterial analysis by optical meansDifferential spectrumOptical spectrometer

The invention discloses a method for detecting moisture content of wood on the basis of an infrared differential spectrum technology. The method is characterized by comprising the steps of selecting wood to be detected, preparing an absolutely-dry sample and balance samples of different relative humidity by utilizing the selected wood; measuring an infrared spectrogram I<o> of the absolutely-dry sample and an infrared spectrogram I<w> of each balance sample by utilizing an infrared spectrometer; subtracting the infrared spectrogram I<o> of the absolutely-dry sample from the infrared spectrogram I<w> of the balance sample to obtain an infrared differential spectrogram I<w-o>; solving an area A<w-o> in the range of 2900 to 3750 cm<-1> in the infrared differential spectrogram; determining the moisture content W of the wood samples of different relative humidity by utilizing a traditional drying method; linearly regressing the moisture content W and the area A<w-o> of each sample by utilizing a least square method to establish a model for detecting the moisture content of the wood by utilizing the infrared differential spectrum technology. The model can be used for the mass detection of the wood samples to be detected, each sample is detected only for one second, and the detection time of the wood moisture content is greatly shortened. The method has advantages of short period, rapidness in detection and micro scale and even trace amount of needed sample, is a nondestructive detection technique and can be applied to the field of the evaluation of wood.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

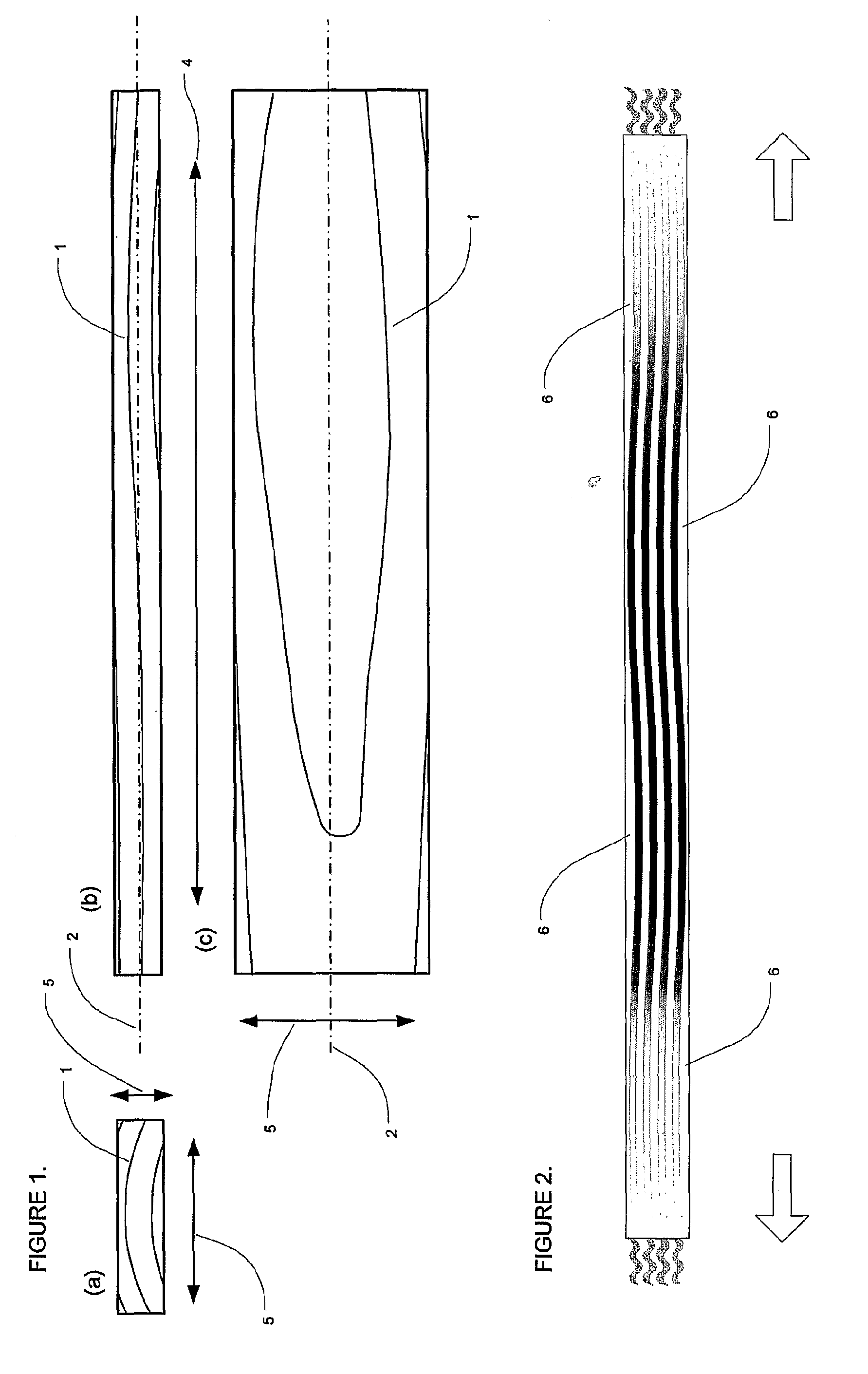

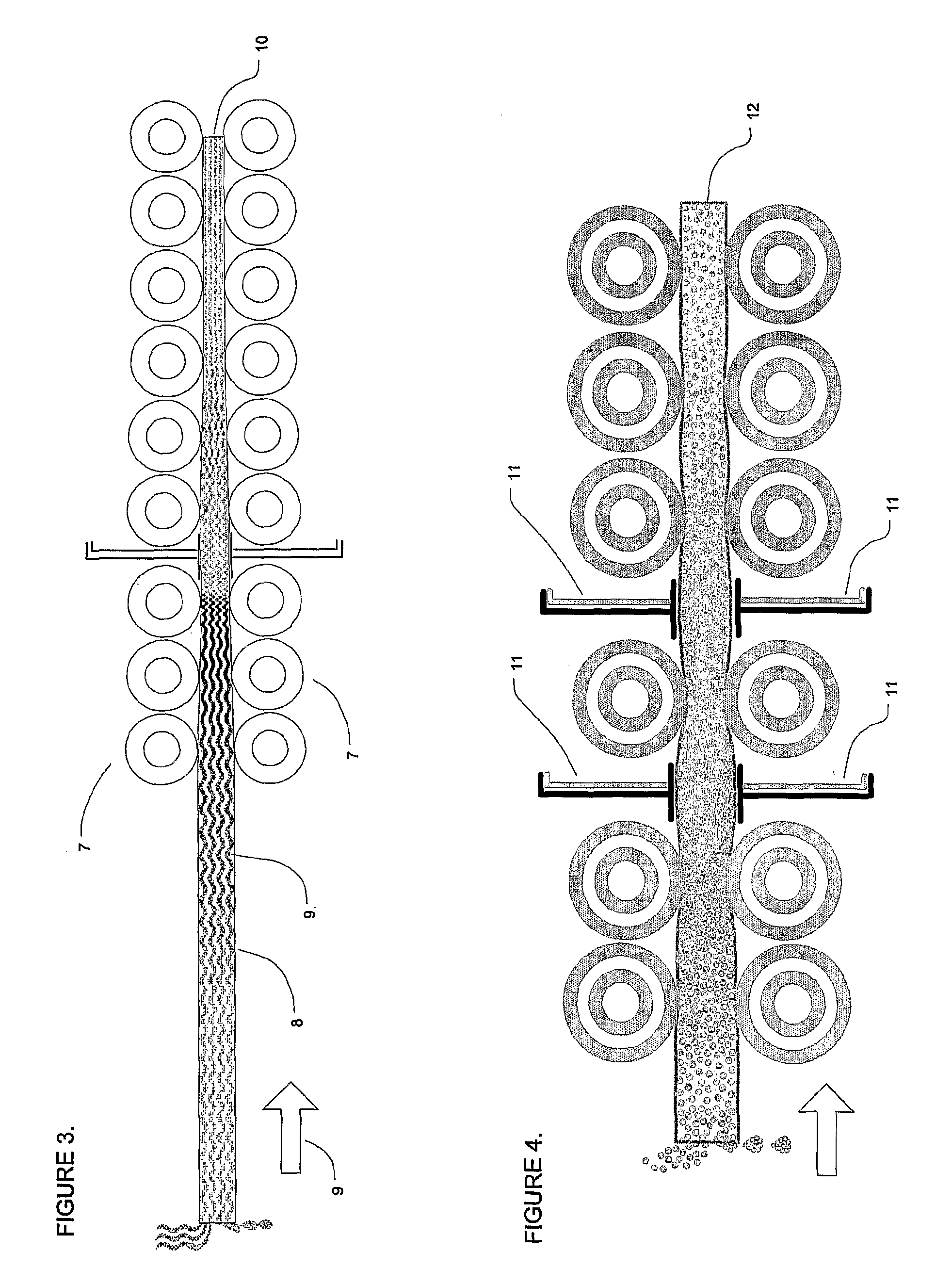

Timber Processing

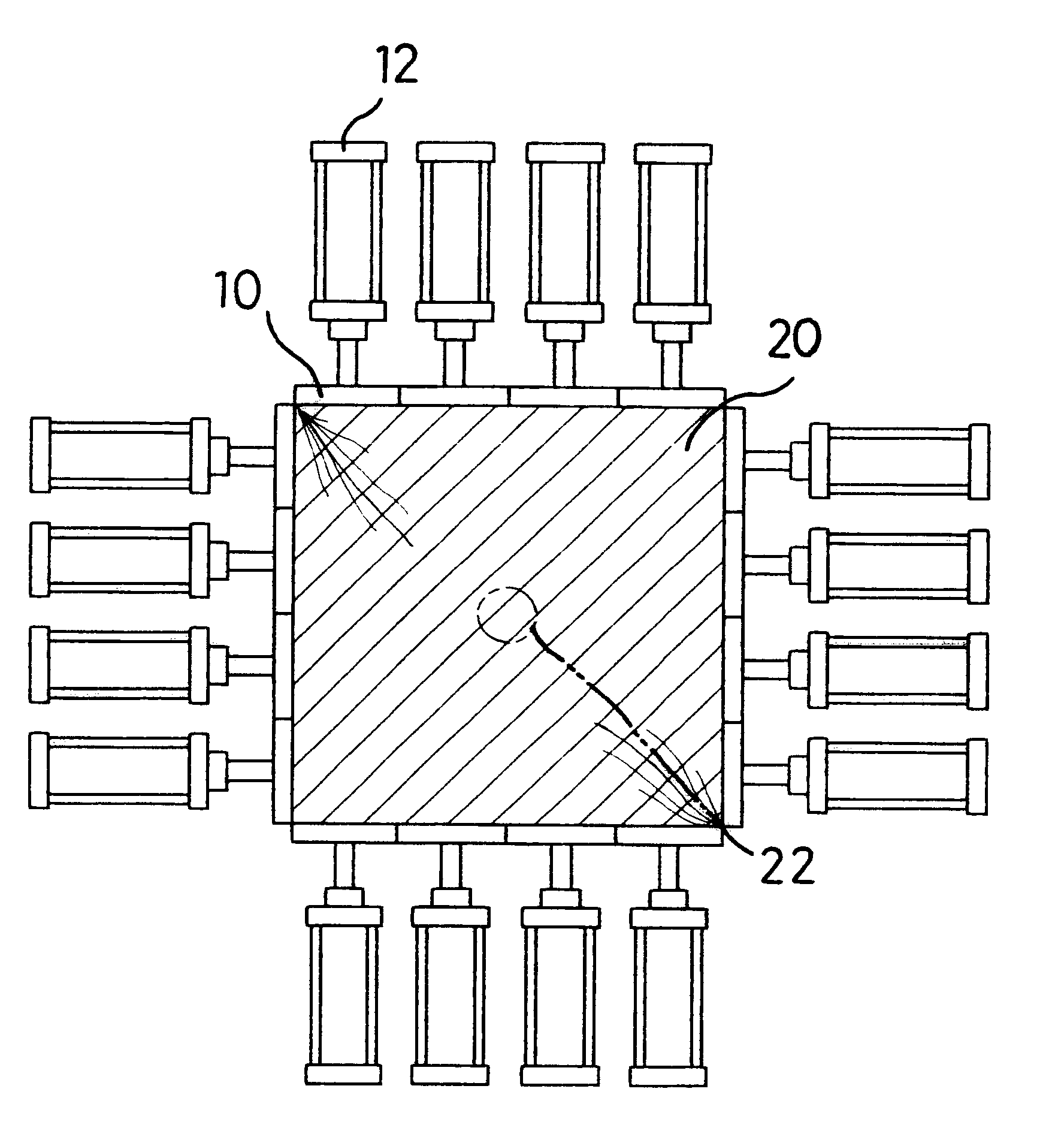

A process for changing the properties of the wood in timber by applying varying pressure progressively along the length of the timber. The timber is caused to contract to facilitate the removal of wood water along the grain of the timber, to bend or straighten the timber, to assist the timber in contracting to its strunk state or to a state of increased density and to facilitate gluing of the processed timber. To facilitate the process timber can be heated by micro or radio waves, by direct heat or an electrical current can be applied to the timber. The heating means is generally also applied progressively along the length of the limber. The planes of pressure contact as applied to timber surfaces are not parallel to each other.

Owner:KNORR ANDREW KARL

Poplar modifying process

InactiveCN103203786AImprove utilizationAchieve ultra-large-scale productionWood treatment detailsWood moistureChemistry

The invention discloses a poplar modifying process, and belongs to the technical field of wood modification treatment. The poplar modifying process comprises processes of poplar acid-base property detection, stewing, wood acid-base neutralization, drying, adding a wood softener for modification, adjusting wood moisture content and the like. The poplar modifying process provided by the invention has the advantages that not only can the desired equipment be simple, but also large-scale production can be realized; and meanwhile, the effectiveness of the wood softener can be improved to the greatest extent, and the cost can be reduced.

Owner:林宪富

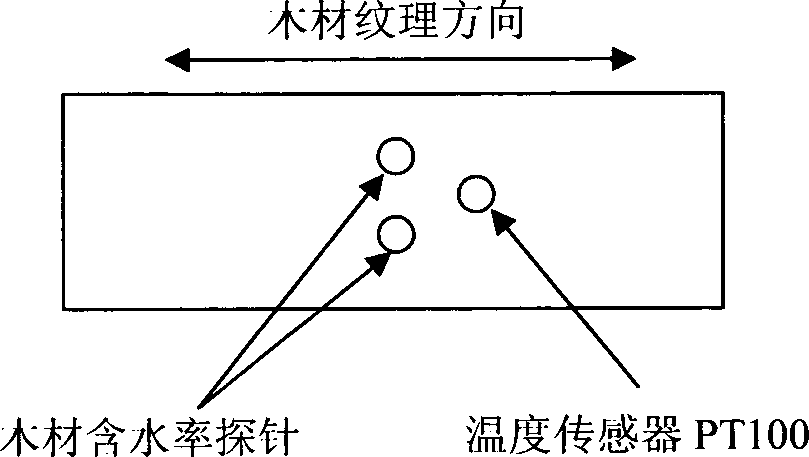

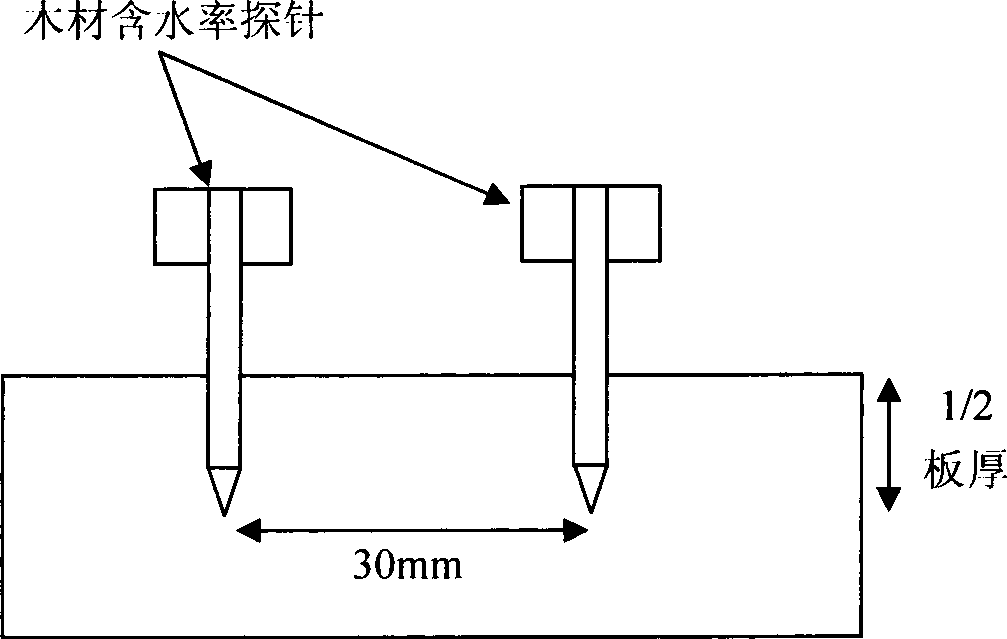

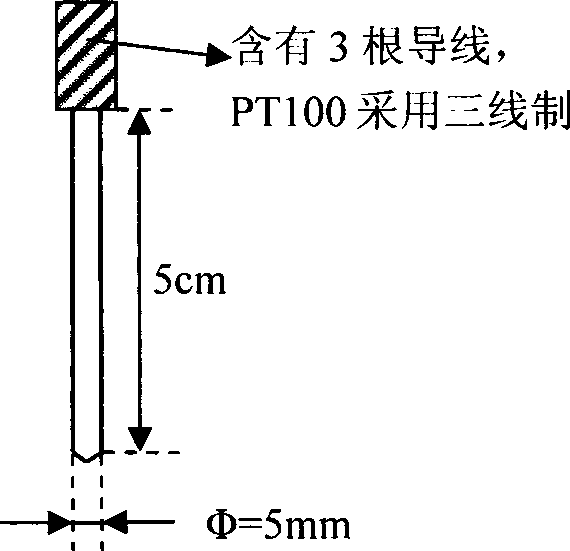

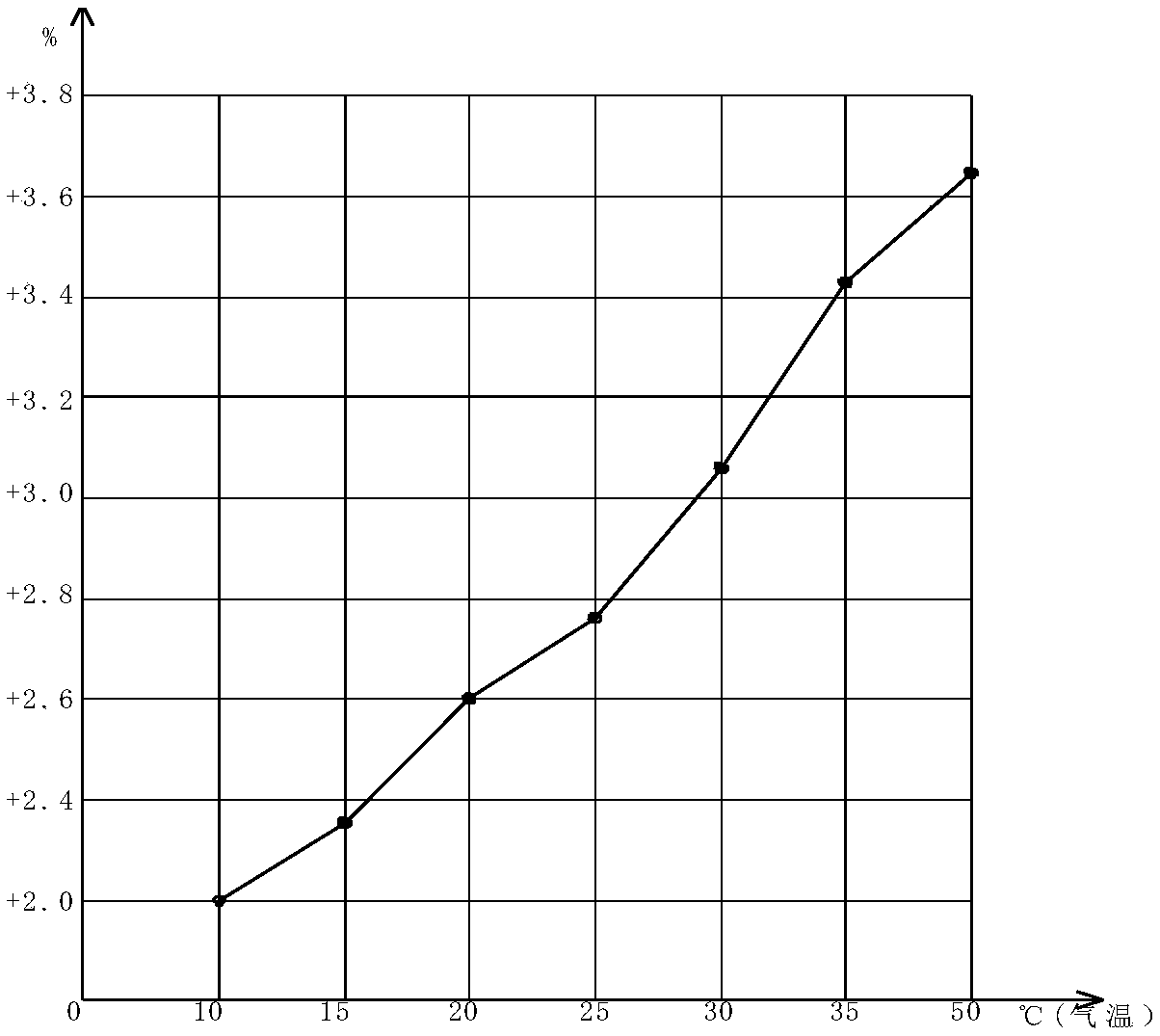

Wood moisture content detection method using wood core temperature compensation

InactiveCN103822946AImprove detection accuracyQuality assuranceMaterial resistanceElectrical resistance and conductanceCore temperature

The invention provides a wood moisture content detection method using wood core temperature compensation, which belongs to the wood processing field. To overcome the problems that usage of ambient temperature of only one point for wood moisture content temperature compensation leads to great errors and is difficult to meet process requirements of drying in measurement of multipoint moisture content of wood in a wood drying kiln by using a resistivity method, the method provided by the invention adopts the following steps: 1, selecting six wood moisture content detection points in a wood drying kiln and arranging a temperature sensor and a wood moisture content sensor at each test point; 2, detecting wood core moisture content of a board by using two probes of the wood moisture content sensor at each test point and detecting wood core temperature of the board by using the temperature sensors; and 3, respectively carrying out temperature compensation of moisture content of the board on detection points based on corresponding wood core temperature detected by each corresponding temperature sensor. According to the method, wood core moisture content values of the board are compensated by wood core temperature, so detection precision of wood moisture content can be effectively improved, and wood processing quality is guaranteed.

Owner:NORTHEAST FORESTRY UNIVERSITY

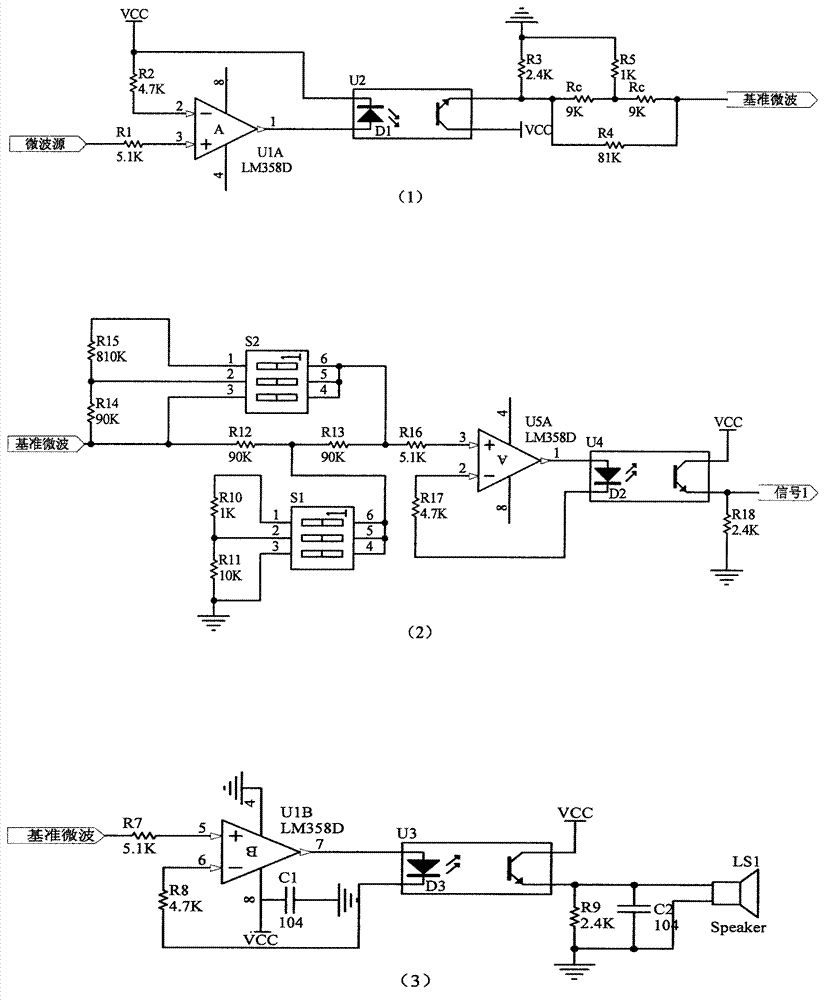

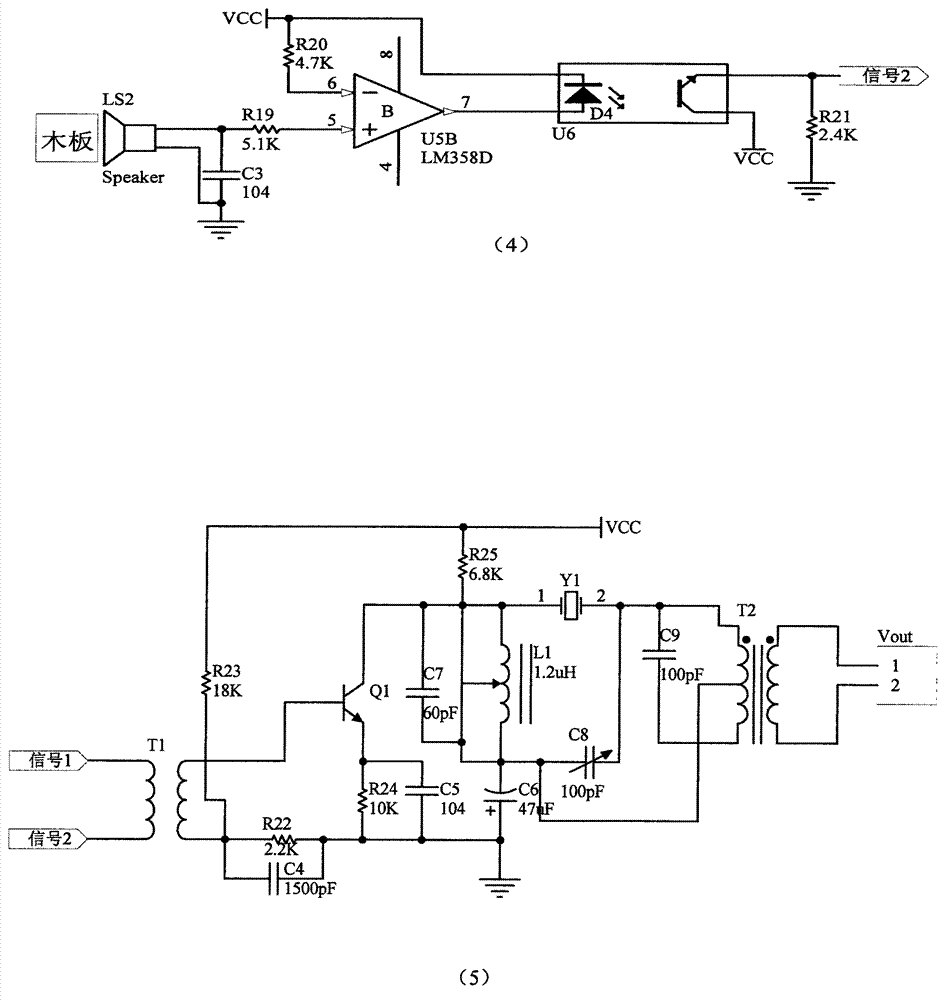

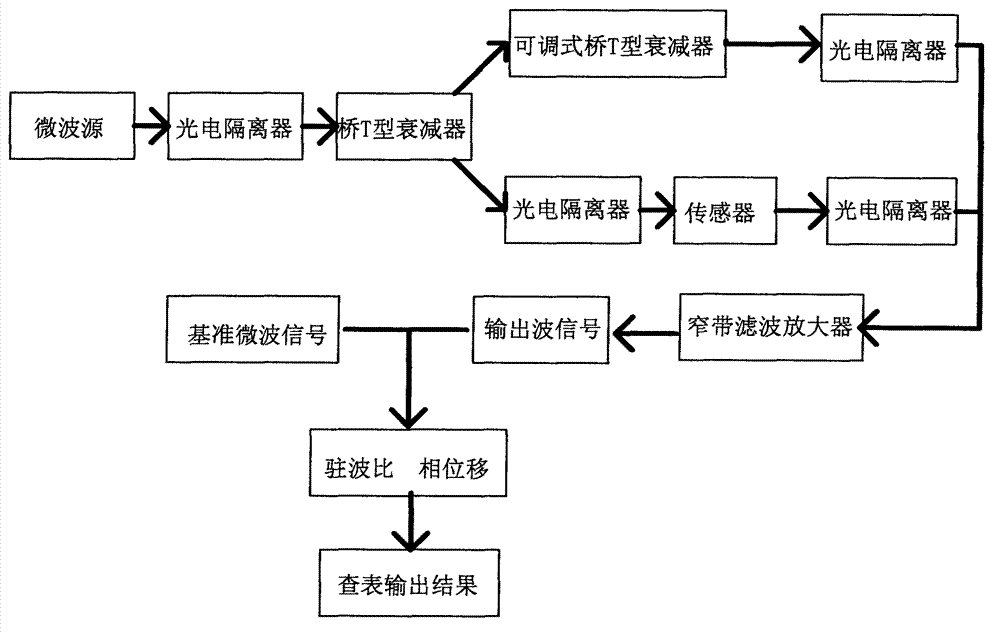

Designing of circuit for measurement of wood moisture content by using microwave technology

InactiveCN103207189AFast measuring methodHigh precisionMoisture content investigation using microwavesPhase shiftedEngineering

The invention relates to designing of a circuit for microwave measurement of wood moisture content and discloses a fast, non-contact, nondestructive and high-precision circuit for microwave measurement of wood moisture content, belonging to the technical field of electronic science. The circuit is designed based on xx principles and comprises a microwave signal generation circuit part, a sensor measurement circuit part, a modulation microwave signal circuit part and a narrow-band filtering and amplification circuit part. The invention has the following advantages: microwaves can penetrate wood, and microwave measurement results reflect moisture content in the wood and are free of influence by factors like the color and the structure of the wood; and a final measured value of the circuit is calculated according to a standing-wave ratio and phase shift obtained through narrow-band filtering and amplification of a deamplification signal of electromagnetic waves and a measurement signal of a sensor, so the process of measurement is fast and precision and a measurement scope can be adjusted according to actual conditions. With such advantages, the circuit is applicable to real-time rapid on-line measurement of wood moisture content.

Owner:毛世挺

Solid wood furniture plate type production process

InactiveCN109968485AReduce lossSimple processDecorative surface effectsWood working apparatusSolid woodPulp and paper industry

The invention provides a solid wood furniture plate type production process, and belongs to the technical field of furniture products. The solid wood furniture plate type production process comprisesthe following steps that a. the wood is selected for drying treatment, so that the wood moisture content is at 5-10%, and the wood is sawed into the required board; b. the board is polished to be flatand then planed; c. the water-borne sealed primer is brushed, polishing is conducted, the water-borne white primer is sprayed, re-polishing is conducted, and the water-borne white finish is sprayed;d. the assembling is conducted according to the drawing requirements, meanwhile, the pattern is carved on the surface of the board, and placing is conducted for 2-3 hours; e. overall dressing is conducted; f. paint spraying is conducted, and finally, the board is placed in a drying room for drying; and g. packaging and storage are conducted. The solid wood furniture plate type production process is simple in process, very little in material loss, and high in production efficiency, the mechanized mass production is facilitated, meanwhile, the quality of the produced product is stable, the produced product is not cracked and deformed, the performance is stable, and the service life is long.

Owner:江苏澳凡家具有限公司

Method for rapid pre-bleaching of wood

PendingCN108568876AUniform and stable colorThe color is fresh and beautifulWood treatment detailsWood impregnation detailsWood moistureProcessing cost

The present invention discloses a novel method for pre-bleaching and brightening of wood. The method comprises the following steps: (1) adjustment of wood moisture: subjecting fresh wood to natural drying at first and then to drying by rapid hot air; (2) introducing tap water into a pressure reaction tank, heating the tap water to 50 to 120 DEG C; and 3) successively injecting an aqueous solutionof an oxidizing agent, a buffering agent and a reducing agent into the pressure reaction tank, and carrying out stirring for a rapid reaction so as to achieve high whiteness and surface brightening effect of the wood. According to the invention, a novel catalytic system is used for pre-bleaching of the wood, so the color of the wood is brightened and whitened in a short period of time and looks fresh and agreeable, processing cost is greatly reduced, and a foundation is laid for later flaking, peeling, deep dyeing and other functional processing of the wood.

Owner:南京新莱尔材料科技有限公司

Method for wood drying treatment

InactiveCN107234693AIncrease temperatureWood treatment detailsThermal wood treatmentRoom temperaturePulp and paper industry

The invention discloses a wood drying treatment method. First, the humidity in the drying kiln is adjusted to 90-100%, and then the temperature is programmed to rise to 80-110°C, and then the temperature is raised to 80-110°C after releasing the steam in the kiln. 120-125°C, and at the same time, a wind speed of 1-3m / s is introduced into the kiln, and finally the wood is sampled, sawed into three layers from the outside to the inside, and the moisture content is measured separately with a wood moisture tester. When the moisture content reaches the required final moisture content of 8-15%, the drying is ended, and the wood is cooled at room temperature and removed from the wood drying kiln. The invention can improve the quality of the wood, achieve uniform drying effect, and prevent the cracking and deformation of the wood through the reasonable adjustment of programmed temperature rise and humidity.

Owner:朱贝康

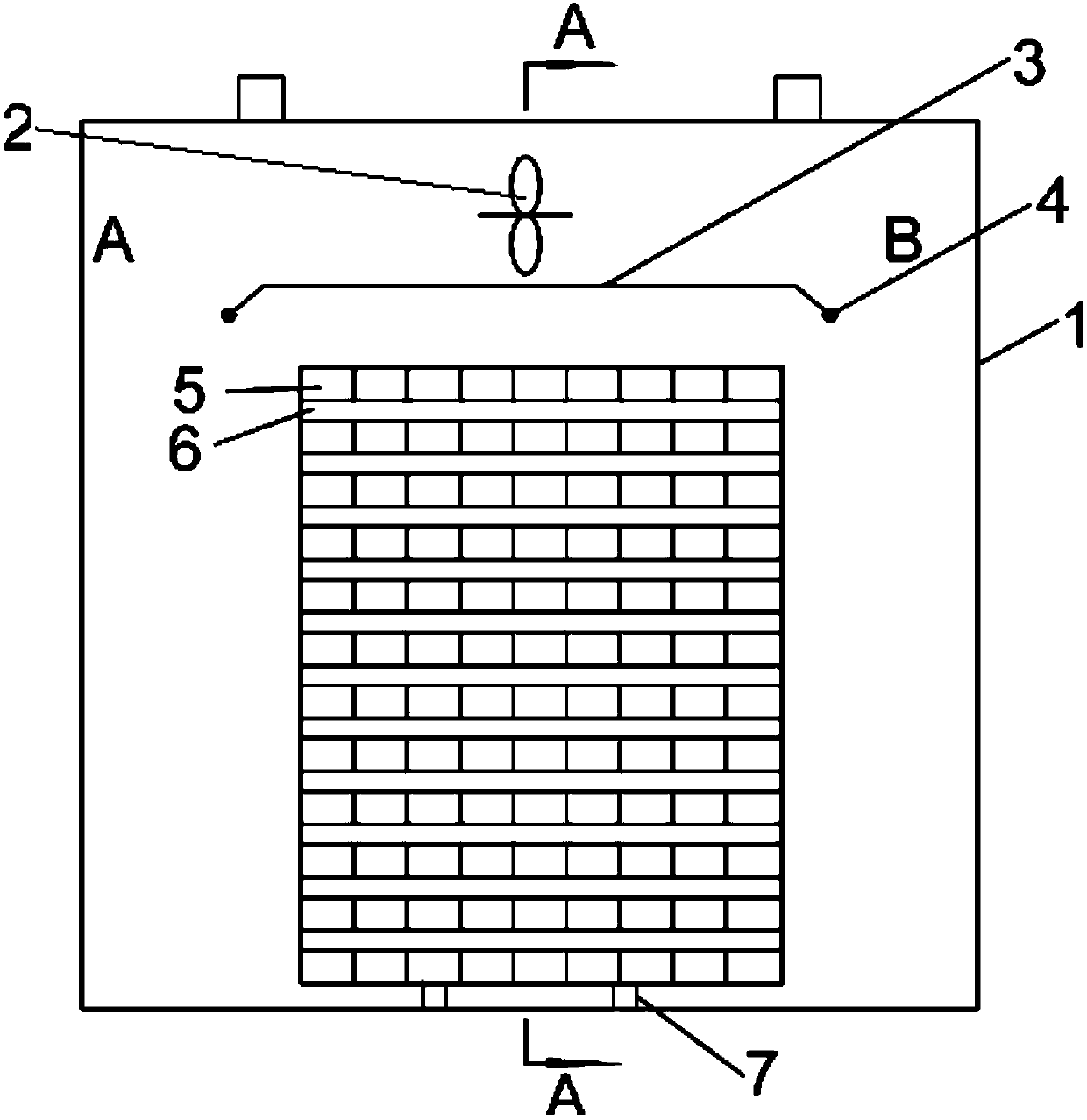

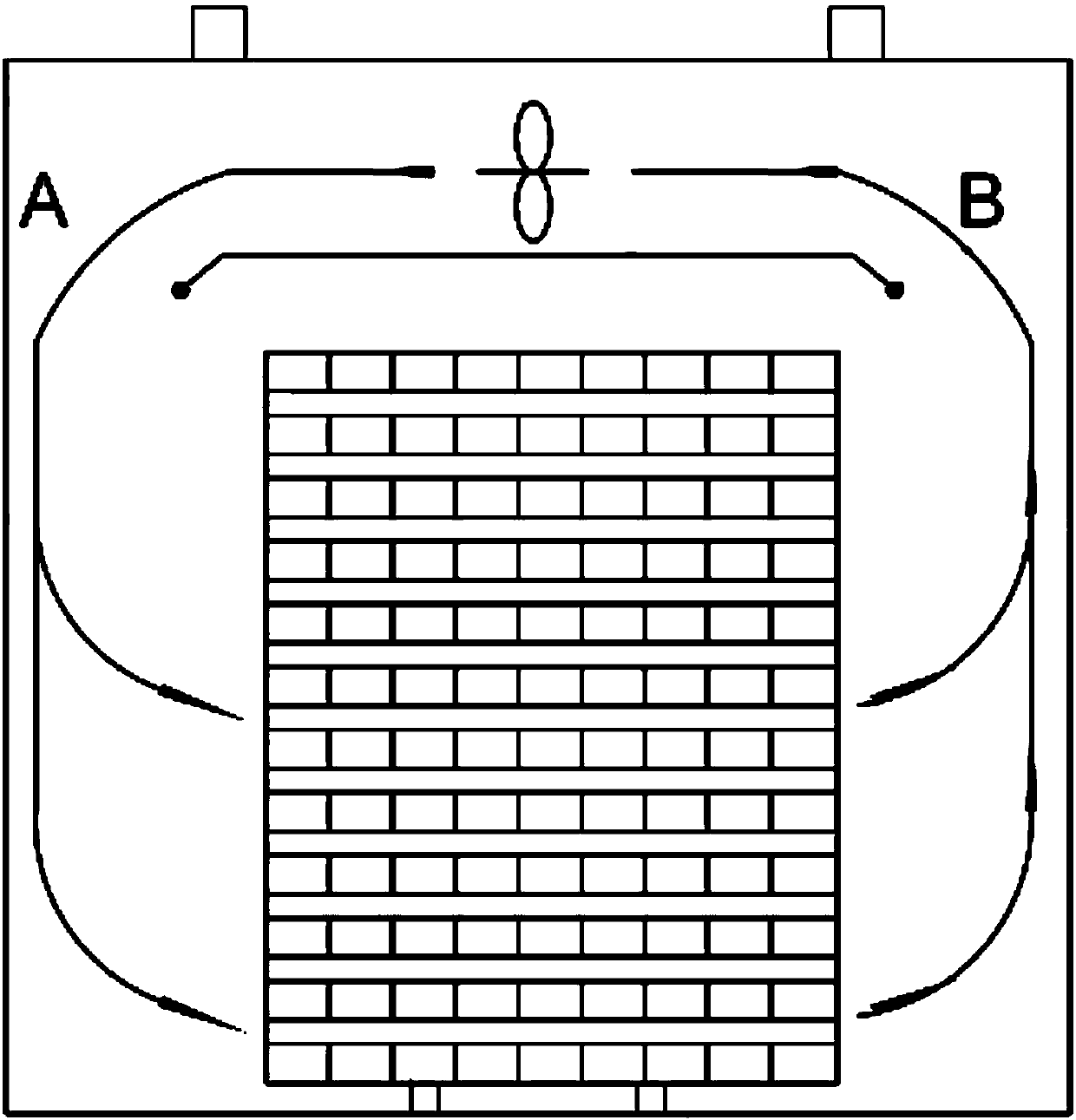

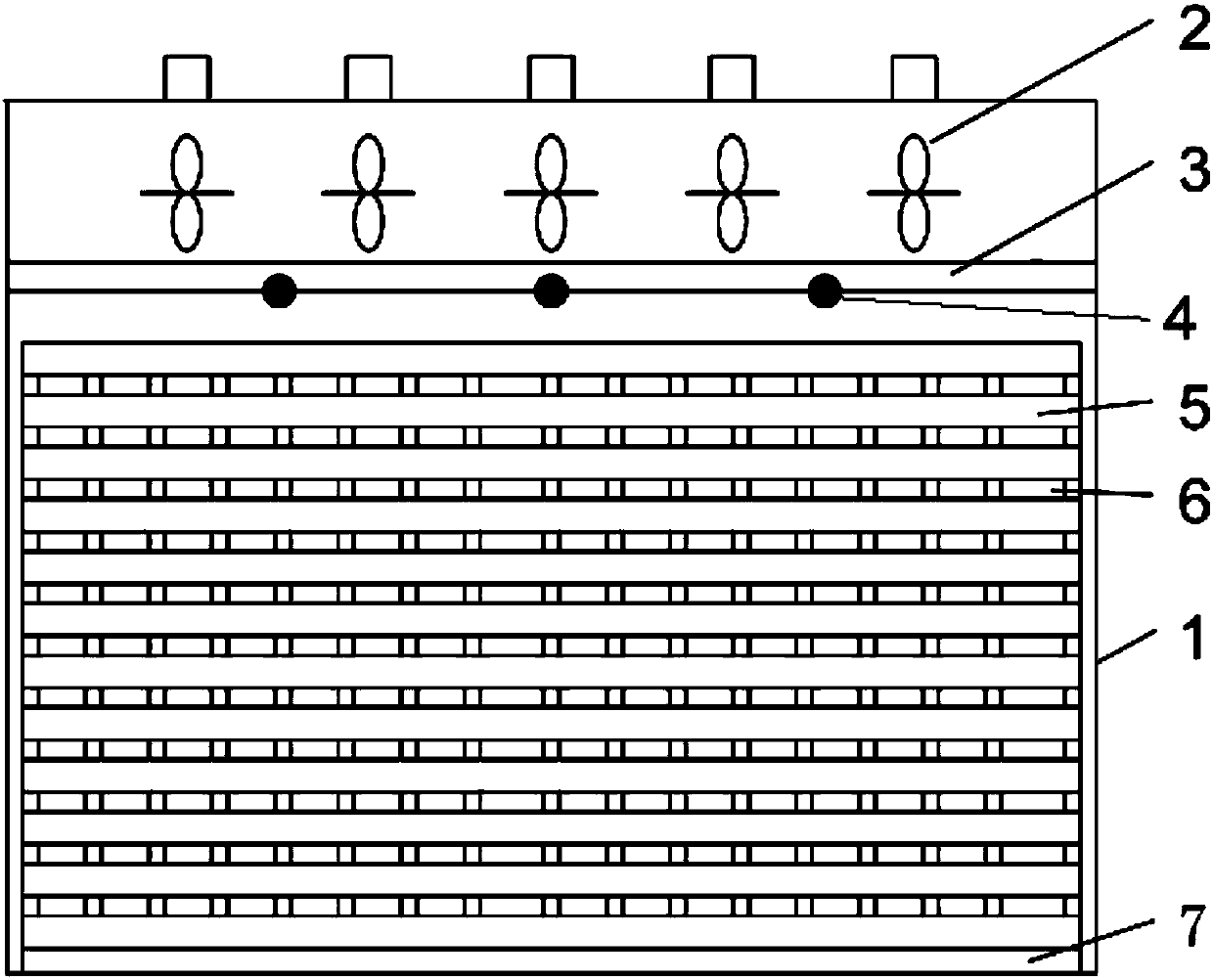

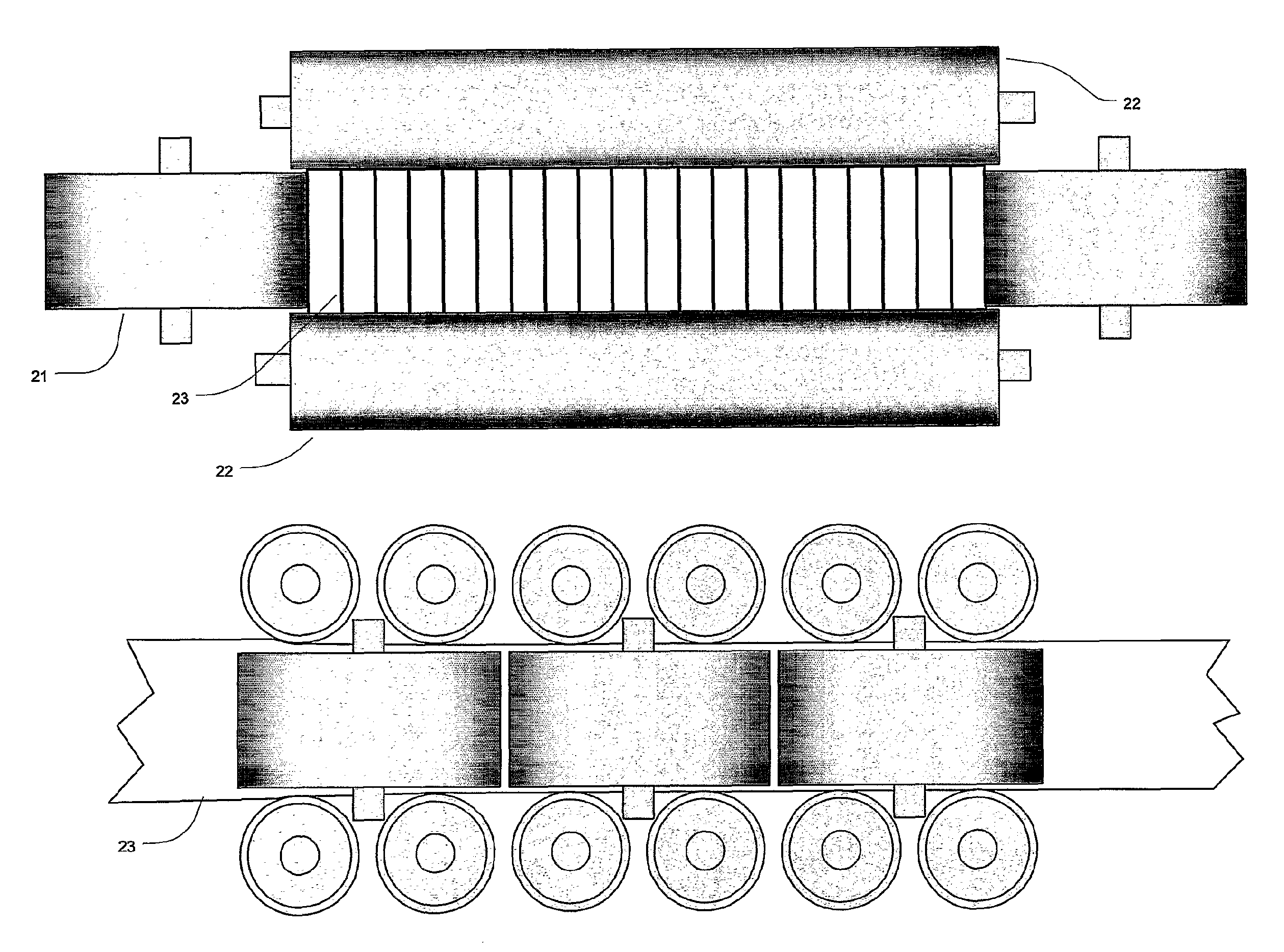

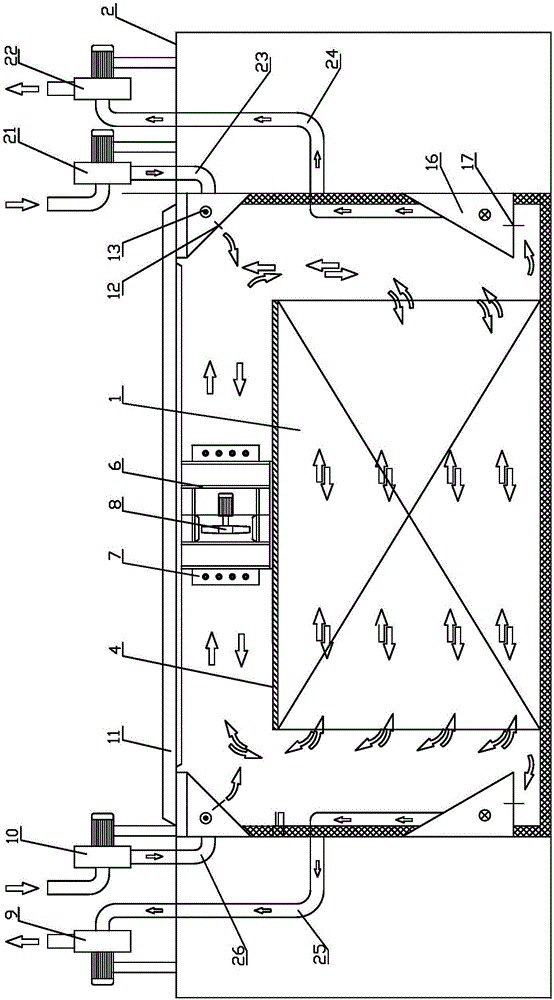

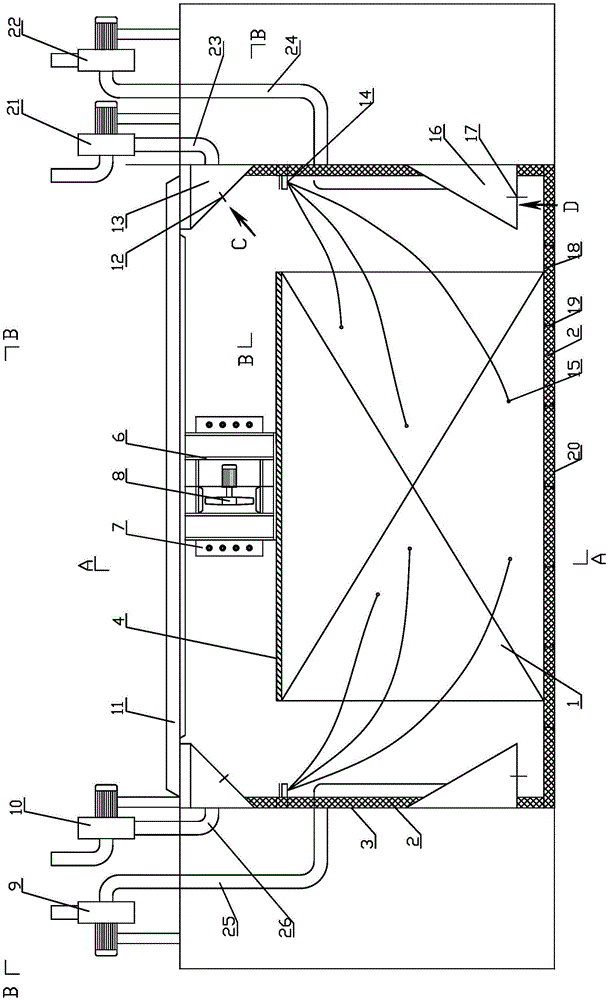

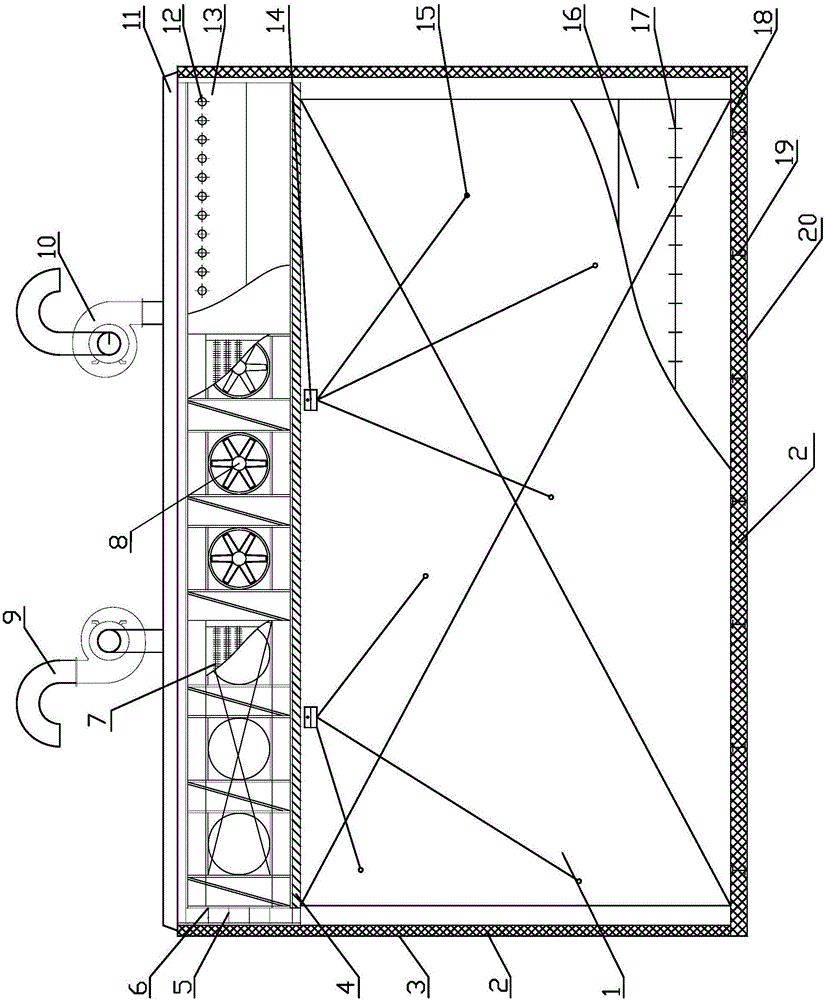

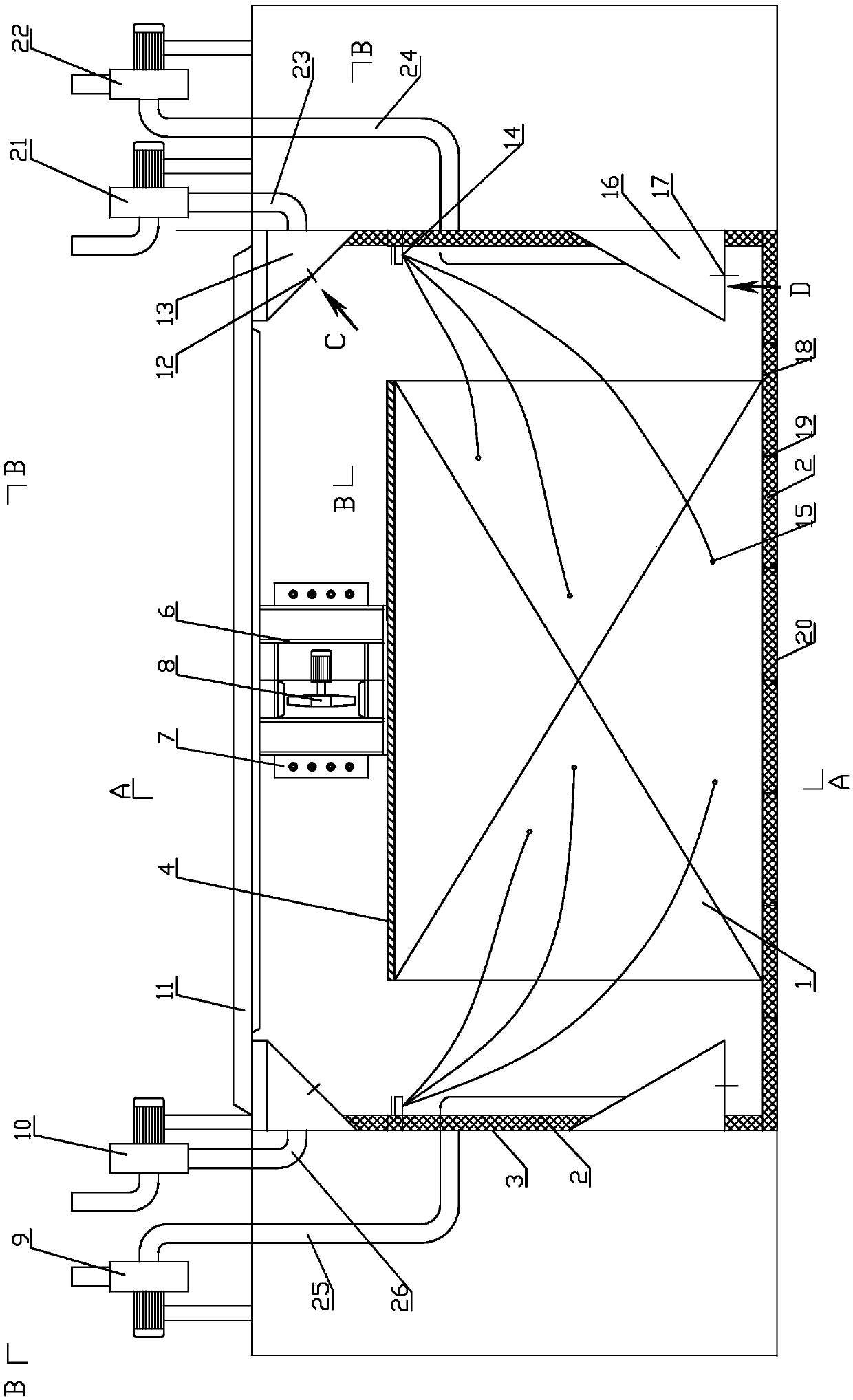

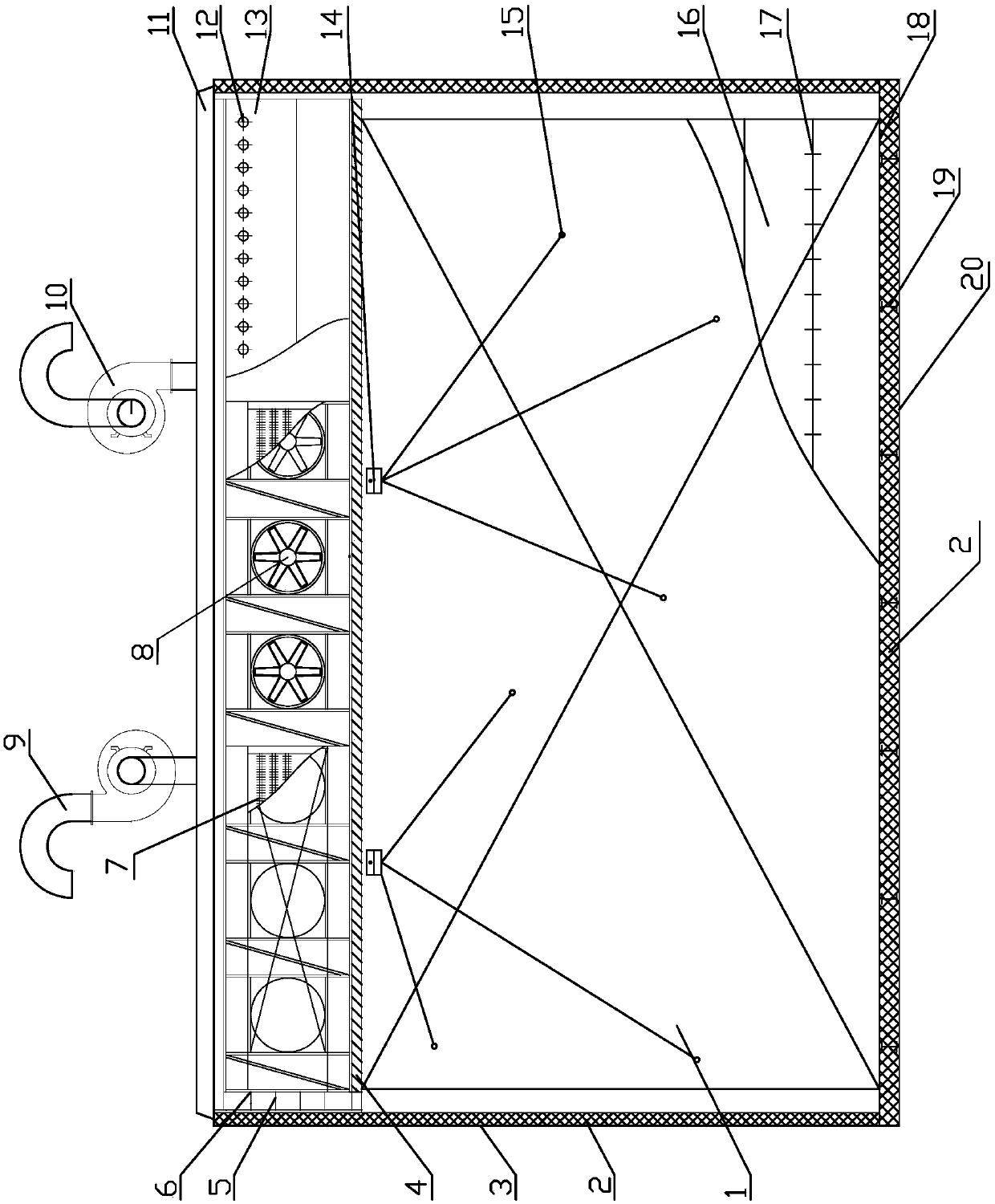

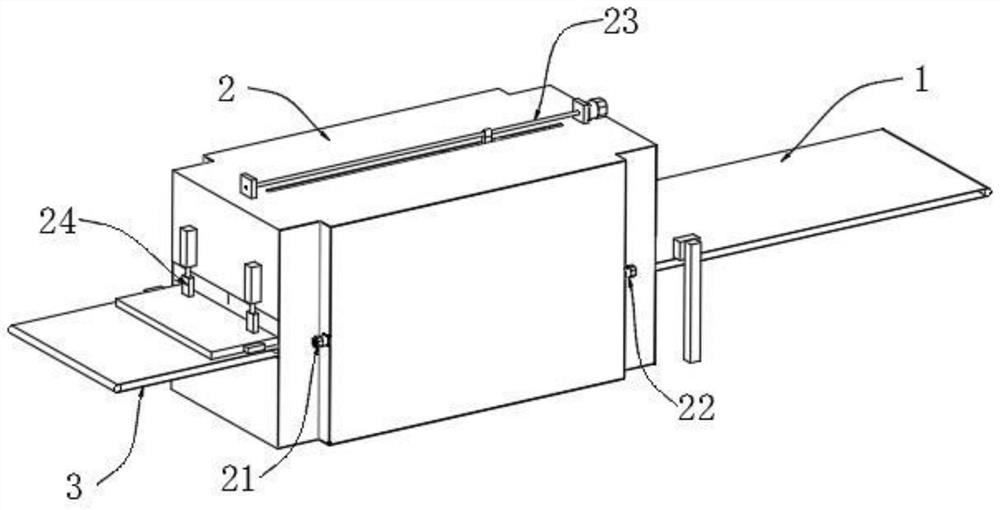

Winding machine type cabin wood drying device and drying method

ActiveCN106247762AShorten the timeReduce pollutionDrying solid materials with heatAuxillariesWinding machinePulp and paper industry

The invention provides a winding machine type cabin wood drying device and drying method, relates to a wood drying device and drying method, and aims at solving the problems that in an existing cabin wood drying device and drying method, energy is wasted, the environment is polluted, the wood producing and processing cycle is prolonged, and large quarantine and pest killing workload of imported wood is needed. The device comprises a cabin, a forced humidifying air changing system installed in the cabin, a detachable forced wood drying medium circulating system installed between a cabin cover and a wood pile, a heating system installed on the detachable forced wood drying medium circulating system and a drying medium state monitoring sensor system and a dried wood moisture content monitoring sensor system which are arranged in the cabin. The method comprises the steps that wood is loaded in the cabin, a drying medium circulating fan and the heating system are started, the wood moisture content and the drying medium state in the cabin are detected and controlled according to the predetermined process requirements, drying processing and pest killing processing on the wood loaded in the cabin drying device are achieved. The wood drying device and drying method are used for wood drying and pest killing processing.

Owner:BEIJING WUZHOUMU INT IND CO LTD

Wood drying method and device for implementing same

InactiveCN102032760ASimple processReduce processing costsDrying solid materials with heatDrying machines with local agitationWood dryingElectromagnetic field

The invention discloses a wood drying method, which comprises the following steps of: 1) preparing a box body capable of accommodating multiple wood slats; and 2) arranging a microwave drying system for generating a radiation microwave electromagnetic field capable of penetrating into the wood, wherein the electromagnetic field interacts with water molecules in the wood to generate heat, so that the water in the wood rapidly evaporates to generate water vapor and an effect of completely drying is achieved. The provided method can dry thick wood, has a simple process, reduces the processing cost, and is favorable for mass production. The provided device has a reasonable structure, convenience of use, high degree of automation, high drying speed and wide application range, is suitable for wood with the thickness of more than 10cm, and is favorable for popularization and application.

Owner:GUANGDONG HONGQI FURNITURE

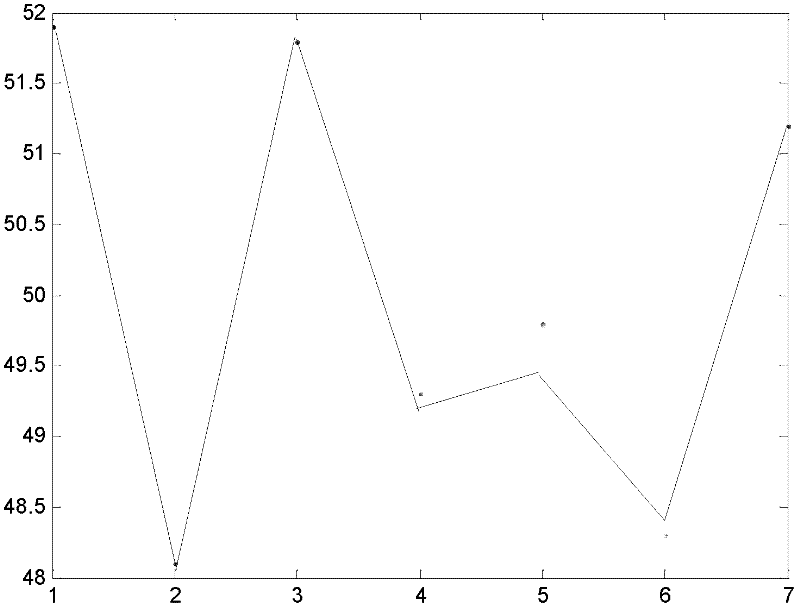

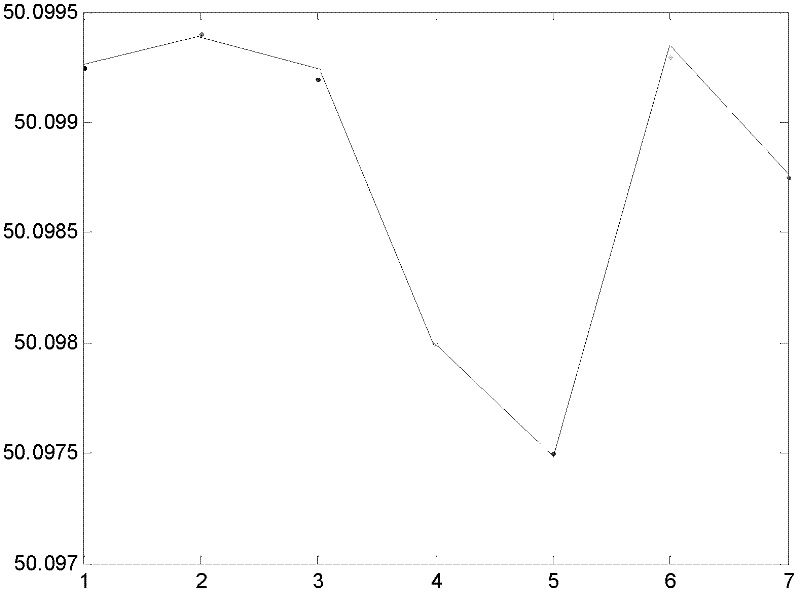

Temperature and humidity control method for wood drying system based on multi-sensor data fusion algorithm

InactiveCN102494532AReduce lossReduce redundancyDrying solid materialsSpecial data processing applicationsTemperature controlParameter control

The invention discloses a temperature and humidity control method for a wood drying system based on a multi-sensor data fusion algorithm and relates to a temperature and humidity control method for a wood drying system. The invention aims to apply the multi-sensor data fusion algorithm to control of the wood drying system so as to improve temperature and humidity control accuracy. The method comprises the following steps of: acquiring a temperature value and a humidity value in a wood drying chamber by using n temperature sensors and m wood moisture content sensor probes, and calculating the temperature value and the humidity value to obtain n temperature parameters and m humidity parameters according to a fuzzy entropy algorithm; and performing data integration according to a clustering ensemble algorithm, and obtaining temperature control parameters and humidity control parameters to control heaters and humidifiers in the wood drying system, so that the temperature and the humidity of the wood drying system are controlled. The temperature and humidity control method is suitable for controlling the temperature and the humidity of the wood drying system.

Owner:任洪娥

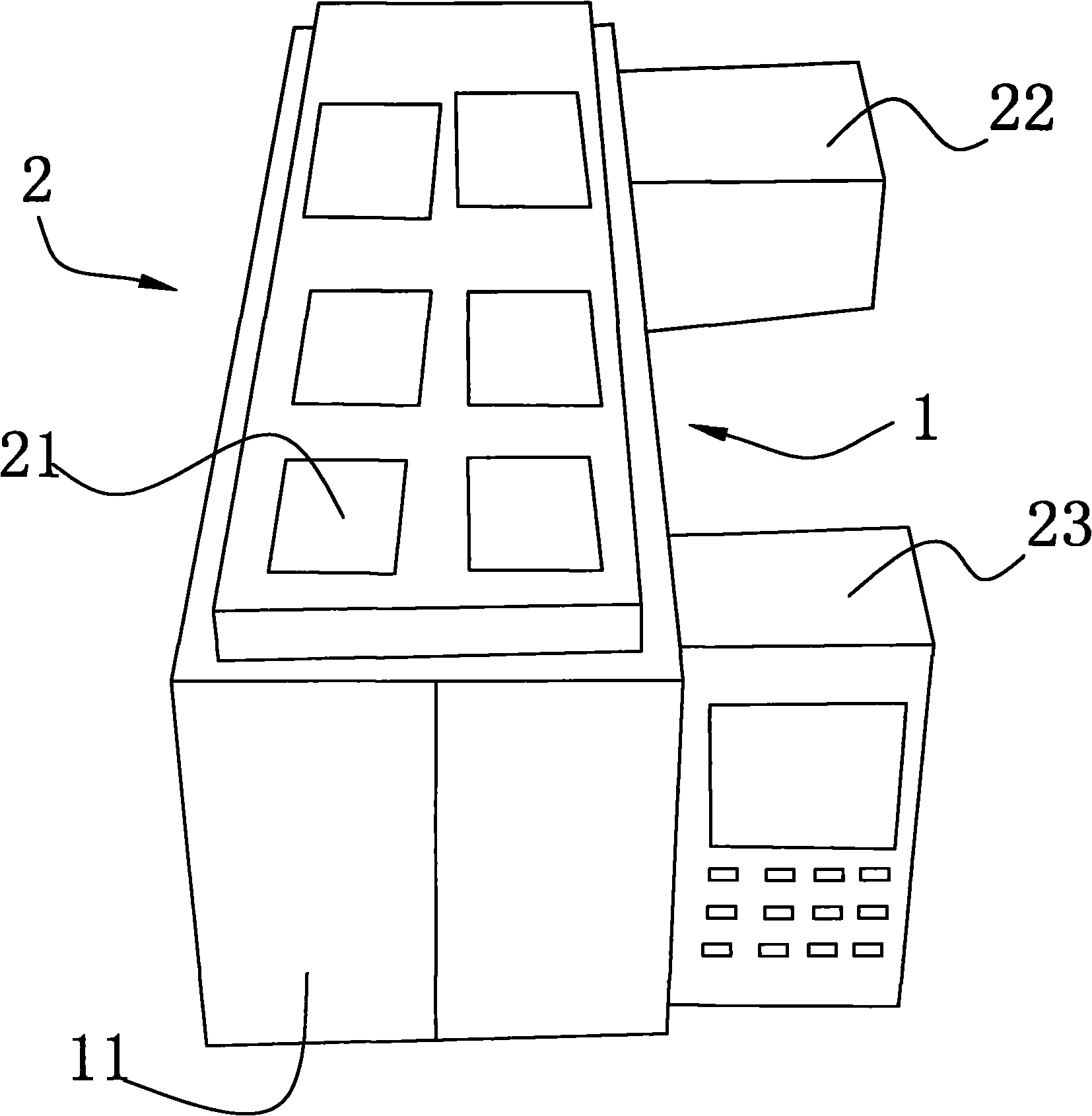

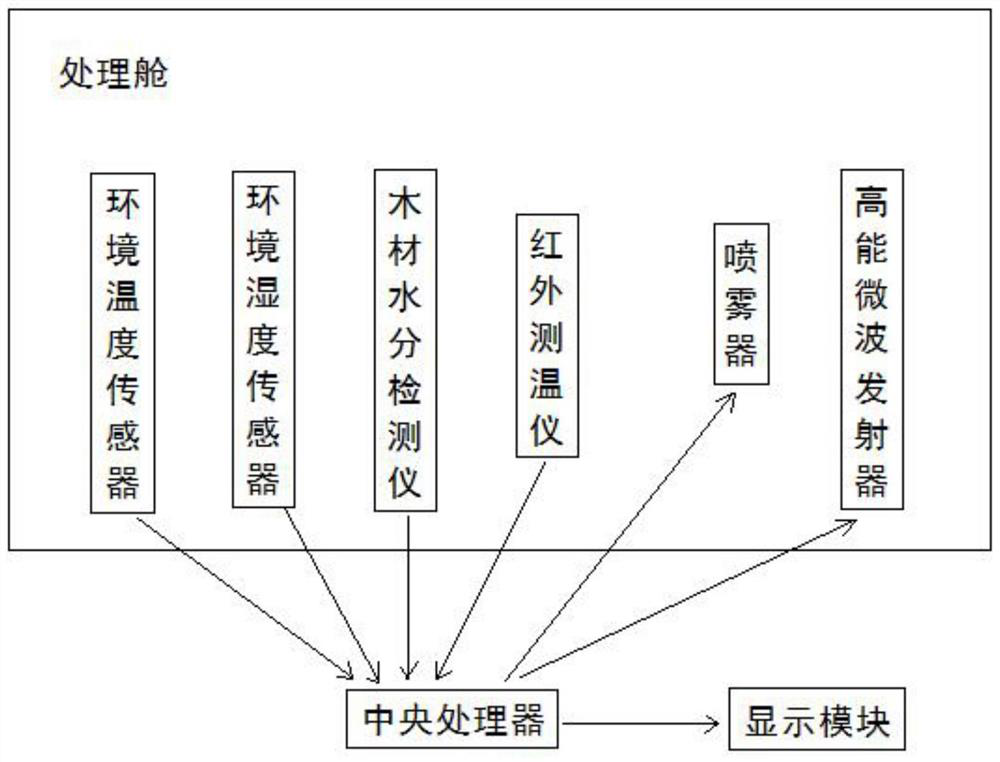

Pest removal system for wood packaging products

InactiveCN111844311AReduce distortionShort operating timeRadiation/waves wood treatmentWood treatment detailsSprayerAgricultural engineering

The invention discloses a pest removal system for wooden packaging products. The system comprises a processing cabin, a high-energy microwave emitter, an infrared thermometer, an environment temperature sensor, an environment humidity sensor, a wood moisture detector, a sprayer, a central processing unit and a display module, wherein the infrared thermometer, the environment temperature sensor, the environment humidity sensor and the wood moisture detector transmit detected data to the central processing unit, and the central processing unit adjusts the working parameters of the sprayer and the high-energy microwave emitter in real time according to the received data. The method has the advantages of being environmentally friendly, short in operation time, good in pest killing effect, small in deformation after wood treatment, free of scorching and carbonization, little in pollution and the like.

Owner:武汉市鹰达木质包装热处理有限公司

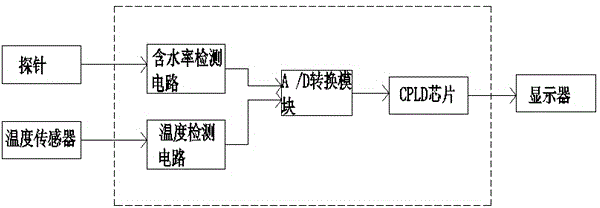

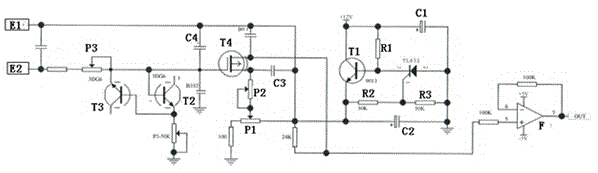

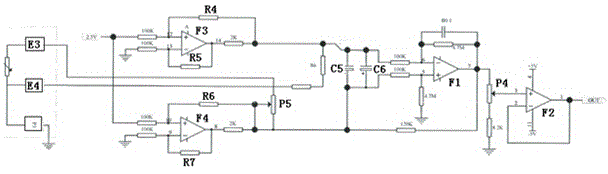

Wood moisture content detecting and verifying device

InactiveCN104483231ASmall fluctuationImprove protectionWeighing by removing componentMaterial resistanceCapacitanceComplex programmable logic device

The invention discloses a wood moisture content detecting and verifying device, relates to a moisture content detecting and verifying device, and solves problems that a conventional device cannot accurately detect the moisture content, cannot measure the wood moisture content of different trees at different temperatures and cannot verify the moisture content of wood with different moisture content at different temperatures. The device comprises a power supply, an induction part, a data processing part and a display screen, wherein the induction part comprises a probe and a temperature sensor; the data processing part comprises a moisture content detecting circuit, a temperature detecting circuit, an A / D (analog / digital) conversion module and a CPLD (complex programmable logic device) chip; the moisture content detecting circuit comprises a first detecting end, a second detecting end, a first triode, a second triode, a third triode, a field-effect tube, a first potentiometer, a second potentiometer, a third potentiometer, a voltage stabilizer, a first resistor, a second resistor, a third resistor, a first electrolytic capacitor, a second electrolytic capacitor, a first filter capacitor, a second filter capacitor and an operational amplifier. The device is simple in structure, and the detecting result is accurate.

Owner:黑龙江省木材科学研究所 +1

Wood single-plate microwave drying device and drying method

ActiveCN105276926AIndustrial Application BreakthroughSuitable for dryDrying solid materials with heatHearth type furnacesElectricityMicrowave

The invention provides a wood single-plate microwave drying device and drying method. The wood single-plate microwave drying device comprises a microwave heating device, a ventilation device controlling the ventilation quantity of the microwave heating device and a metering device metering the electricity consumption of the microwave heating device and is characterized in that the ventilation device is arranged on one side of the microwave heating device, and air in the microwave drying device enters the ventilation device through a ventilation opening in one side of the microwave heating device and is then discharged. In a work state, the metering device records the electricity consumption E of the microwave heating device when the wood water evaporation quantity is G so as to obtain a wood single-plate microwave drying water extracting rate eta. The numerical value of the wood single-plate microwave drying water extracting rate can be measured and calculated. Technical difficulties limiting the microwave wood drying technology for many years can be digitized, and a substantial breakthrough is made in the industrial application of the microwave wood drying technology.

Owner:山东千森木业集团有限公司

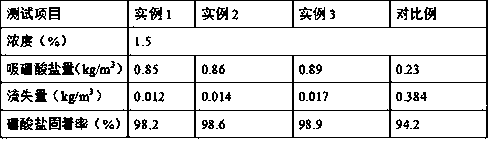

Preparation method for loss-resistance water-based wood preservative

InactiveCN107932668AThe effect of increasing densityAntisepticWood impregnation detailsWater basedAbsorption capacity

The invention relates to a preparation method for a loss-resistance water-based wood preservative, and belongs to the technical field of wood preservation. According to the preparation method, rosin thick liquid is prepared from rosin, an extracting solution rich in tannin and protein is obtained from pomegranate bark and soybean, the rosin thick liquid and the extracting solution are mixed to react with boric acid, and therefore the antiseptic and filling effects are achieved, and the wood corrosion resistance is improved; by means of ingredients including the tannin and the protein added into the water-based wood preservative, a polymer network can be built in wood, a borate compound is attached to the treated wood, and the loss-resistance of the preservative is improved; by means of therosin thick liquid with positive charges, the effect of protecting borate can be achieved, the rosin thick liquid has the hydrophobic property, and therefore the wood moisture absorption capacity canbe reduced; and the water content in wood cannot meet the water content condition needed by survival and multiplying of microorganisms like wood-destroying fungi, and therefore the wood corrosion resistance is improved, and the wide application prospect is achieved.

Owner:常州市瑞泰物资有限公司

Automatic measuring device for moisture content of wood

ActiveCN114460282AEasy to collectImprove environmental performanceWood testingWood splinterAgricultural engineering

The invention discloses an automatic wood moisture content measuring device, and relates to the technical field of wood moisture content measuring devices.The automatic wood moisture content measuring device comprises a measuring device body, a control module is fixedly installed on the outer surface of the measuring device body, conveying belts are arranged on the two sides of the measuring device body, and a first motor is fixedly connected to one side of each conveying belt; one end of one conveying belt is fixedly connected with a feeding end, one end of the other conveying belt is fixedly provided with a discharging end, and detection channels are formed in the two sides of the interior of the measuring device body. Through cooperation of the exhaust fan and the collection box, in the process that a drill bit drills wood, the output end of the exhaust fan sucks out wood chips in the drilling process into the collection box, it is guaranteed that the wood water content tester can stably detect the wood water content, and the problem that detection is affected by the wood chips generated in the testing process is solved; and the effects of removing the wood chips and protecting the wood water content tester are achieved.

Owner:赛德检测技术(浙江)有限公司

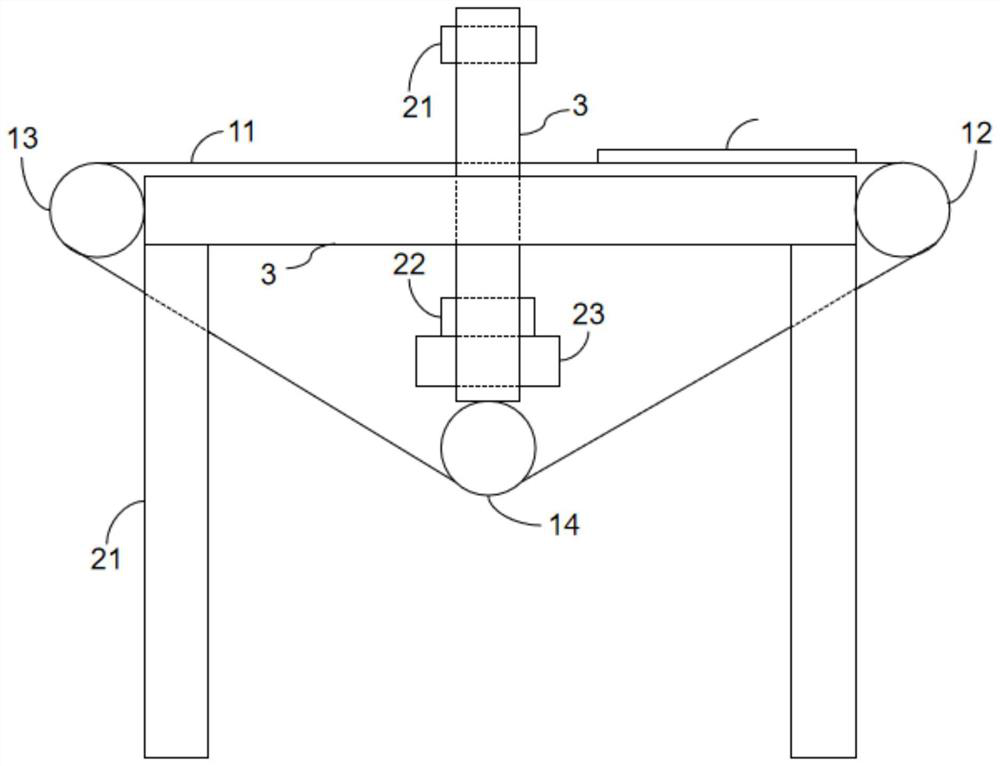

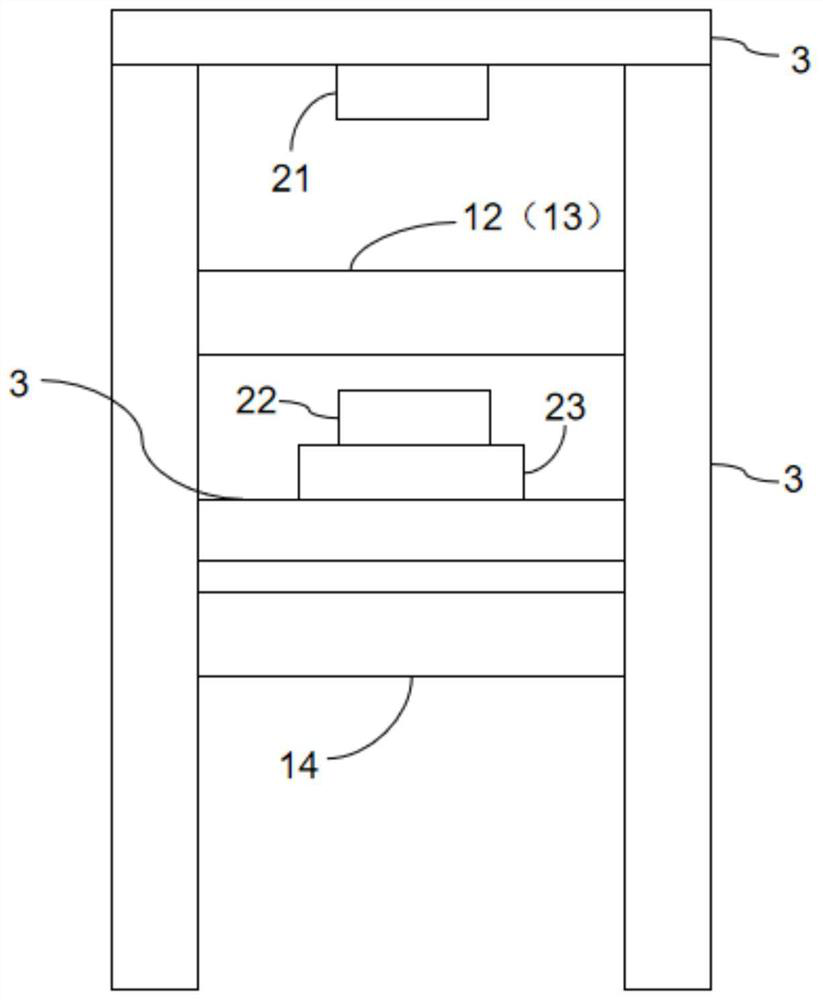

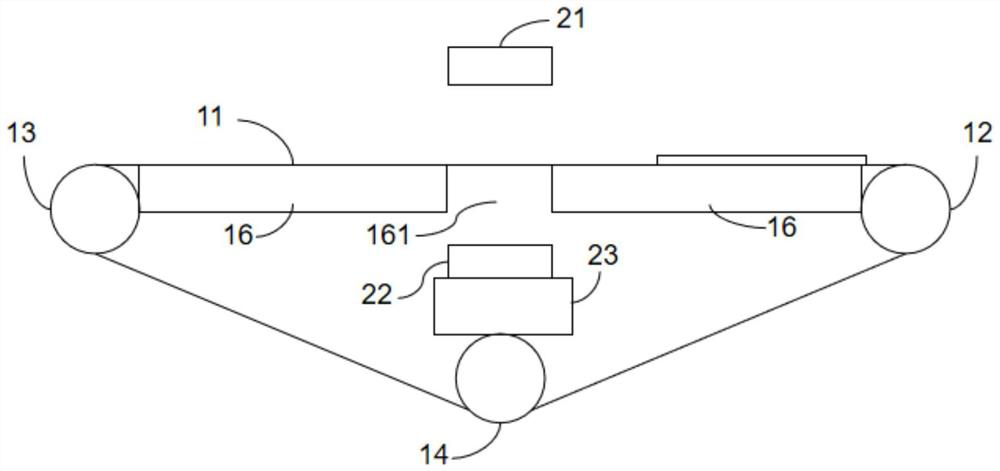

Wood moisture detection device and method

PendingCN113311007AImplement automatic detectionInstalledMoisture content investigation using microwavesFrequency spectrumElectric machine

The invention discloses a wood moisture detection device. The wood moisture detection device comprises a wood conveying mechanism, a moisture detection mechanism and a supporting mechanism. The wood conveying mechanism comprises a conveying belt, a first rotating shaft, a second rotating shaft, a third rotating shaft and a first driving motor; the first rotating shaft, the second rotating shaft, the third rotating shaft and the first driving motor are arranged on the supporting mechanism; the first rotating shaft and the second rotating shaft are arranged on the same horizontal plane; the third rotating shaft is arranged below the horizontal plane and is parallel to the first rotating shaft and the second rotating shaft; the conveying belt is used for connecting the first rotating shaft, the second rotating shaft and the third rotating shaft; and the moisture detection mechanism comprises a frequency spectrum transmitting probe, a frequency spectrum receiving probe and a frequency spectrum analyzer which are fixed on the supporting mechanism. The invention also provides a wood moisture detection method. According to the device and method of the invention, the moisture content of wood is automatically detected, and the measurement precision of the moisture content is improved.

Owner:ZHONGSHAN NATURE WOOD IND

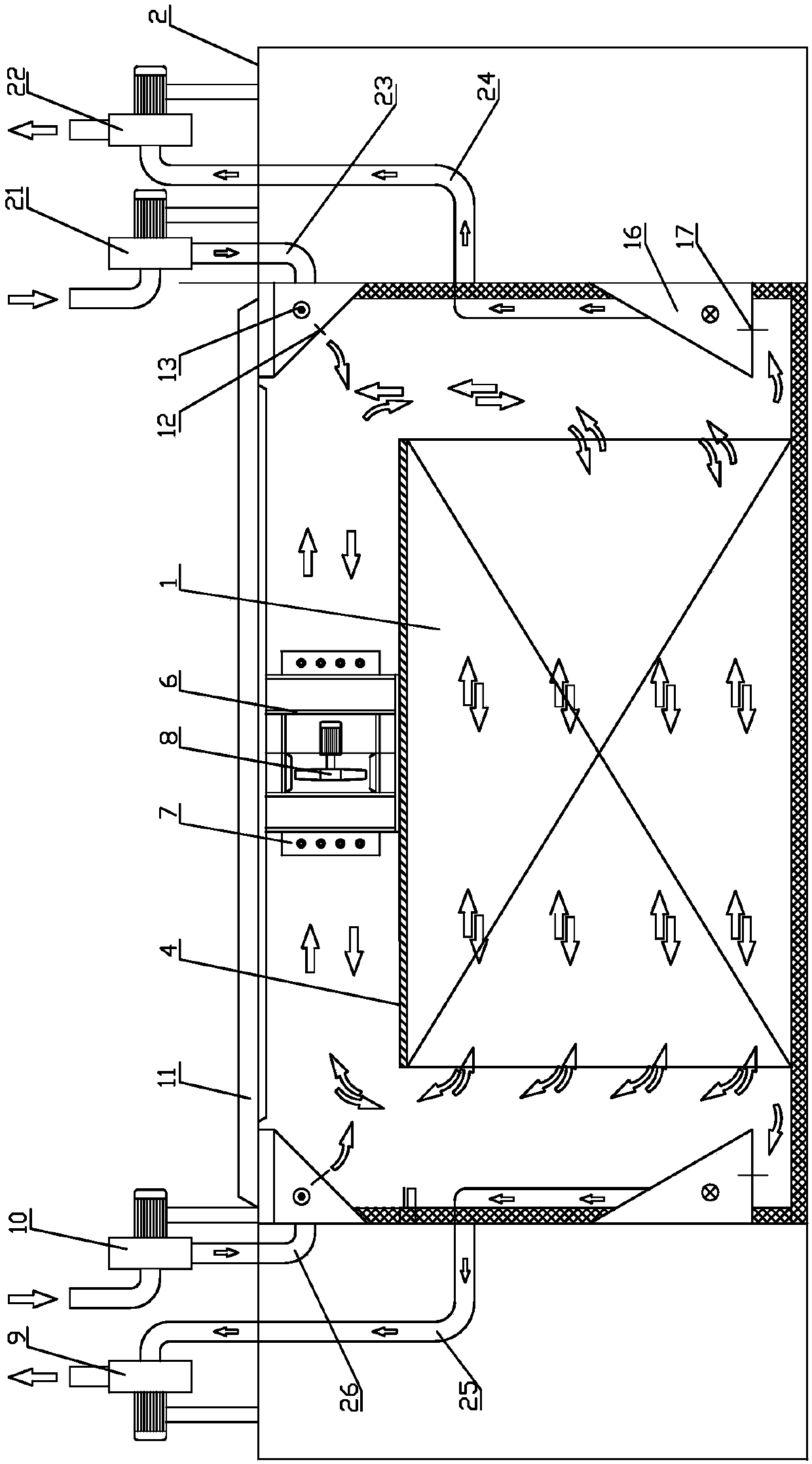

Wood drying device and drying method of a top fan type cabin

ActiveCN106247762BShorten the timeReduce pollutionDrying solid materials with heatAuxillariesPulp and paper industryForced-air

Disclosed are a ship cabin wood drying device and drying method of a top draught fan type. The drying device comprises: a ship cabin; a humidity-adjustment forced air-exchange system installed in the cabin; a detachable wood drying medium forced circulation system installed between a cabin cover (11) and a wood stack (1); a heating system installed on the detachable wood drying medium forced circulation system; a drying medium state monitoring sensor system and a dried wood moisture content monitoring sensor system which are arranged in the cabin. The drying method comprises: loading a cabin with wood; activating a drying medium circulation draught fan and a heating system; detecting and controlling, according to a pre-determined process requirement, the moisture content of wood in the cabin and a drying medium state so as to realize drying and a pest-killing treatment for wood loaded in a cabin drying device.

Owner:BEIJING WUZHOUMU INT IND CO LTD

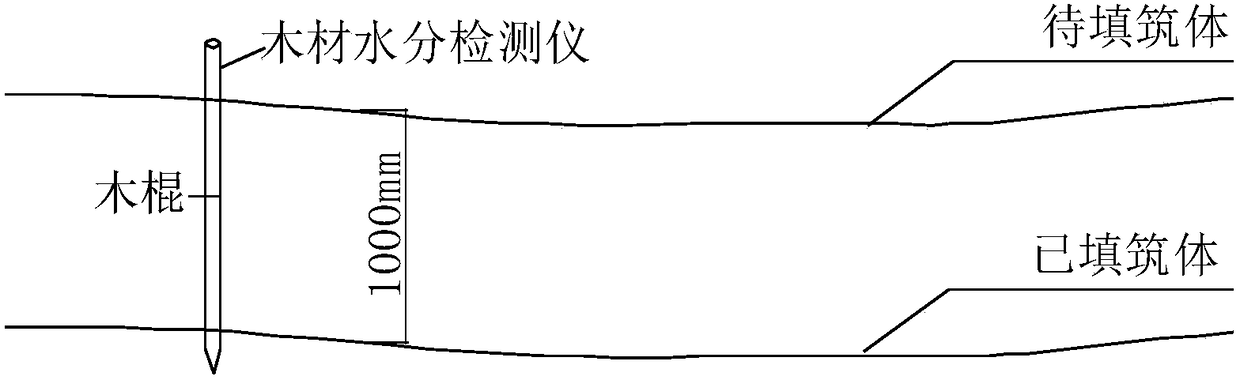

Method for rapidly and indirectly measuring moisture content in airport runway high-filled construction

The invention discloses a method for rapidly and indirectly measuring the moisture content in airport runway high-filled construction. The method comprises the steps that S1, in airport runway high-filled construction, a plurality of wood sticks are embedded into a filled body, and the top ends of the wood sticks are exposed above a body to be filled by a certain length; S2, filling body paving isperformed on the body to be filled, a wood moisture detector is arranged at the top end of each wood stick, and the moisture content value of wood is measured by the wood moisture detector; the soilmoisture content of the filled body is obtained through calculation; S3, the natural moisture content of various fillers in high-filled construction is measured, the finally-added water amount is calculated, and filled body construction reaches the best moisture rate; S4, according to the finally-added water amount obtained through calculation, the water adding or aeration mode is adopted for thefilled body, the soil moisture content is regulated, and the best moisture content is achieved; S5, the filled body is ground, the ground moisture content is measured, and it is ensured that the bestmoisture content is achieved. The method is convenient and rapid to implement, the construction period is shortened, and the construction quality of an airport runway is ensured.

Owner:CHINA FIRST METALLURGICAL GROUP

Wood moisture content detection method based on infrared difference spectrum technology

InactiveCN104390932BReduced measurement timeOvercoming the lack of high demandMaterial analysis by optical meansDifferential spectrumTrace Amounts

The invention discloses a method for detecting moisture content of wood on the basis of an infrared differential spectrum technology. The method is characterized by comprising the steps of selecting wood to be detected, preparing an absolutely-dry sample and balance samples of different relative humidity by utilizing the selected wood; measuring an infrared spectrogram I<o> of the absolutely-dry sample and an infrared spectrogram I<w> of each balance sample by utilizing an infrared spectrometer; subtracting the infrared spectrogram I<o> of the absolutely-dry sample from the infrared spectrogram I<w> of the balance sample to obtain an infrared differential spectrogram I<w-o>; solving an area A<w-o> in the range of 2900 to 3750 cm<-1> in the infrared differential spectrogram; determining the moisture content W of the wood samples of different relative humidity by utilizing a traditional drying method; linearly regressing the moisture content W and the area A<w-o> of each sample by utilizing a least square method to establish a model for detecting the moisture content of the wood by utilizing the infrared differential spectrum technology. The model can be used for the mass detection of the wood samples to be detected, each sample is detected only for one second, and the detection time of the wood moisture content is greatly shortened. The method has advantages of short period, rapidness in detection and micro scale and even trace amount of needed sample, is a nondestructive detection technique and can be applied to the field of the evaluation of wood.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

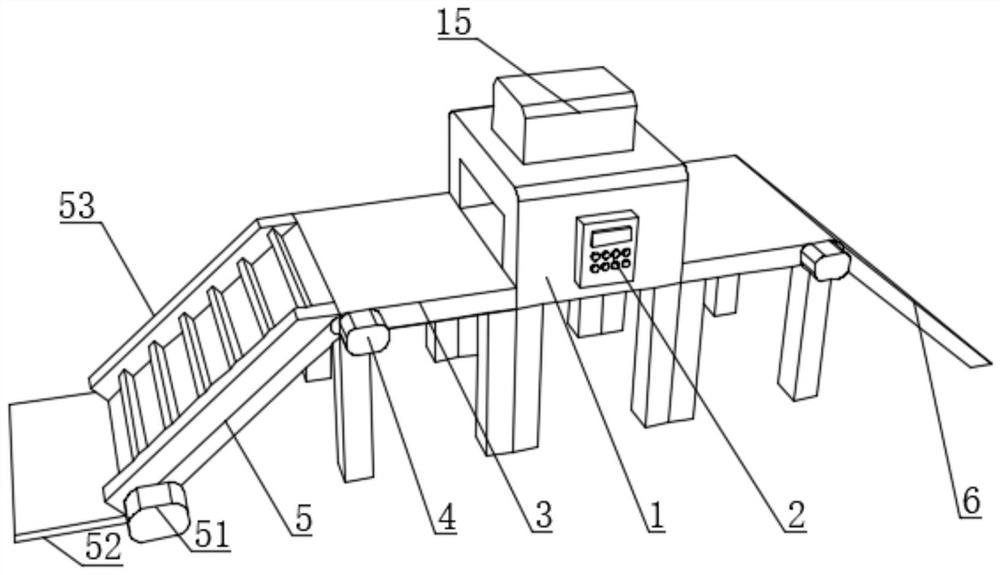

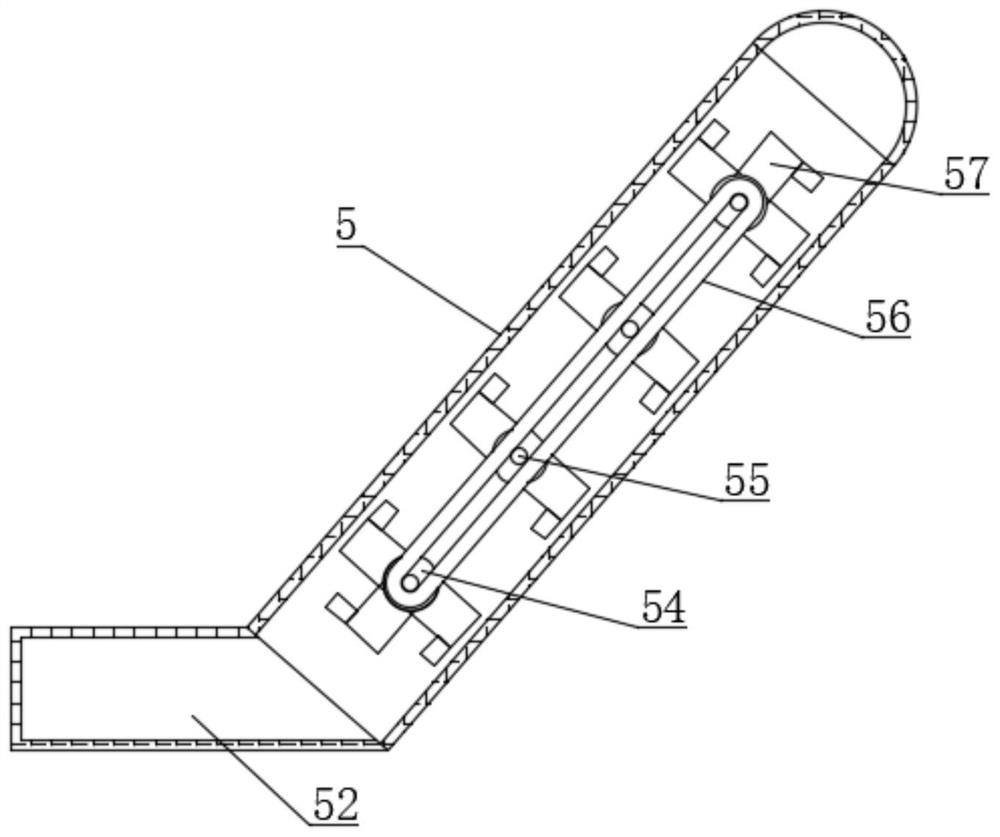

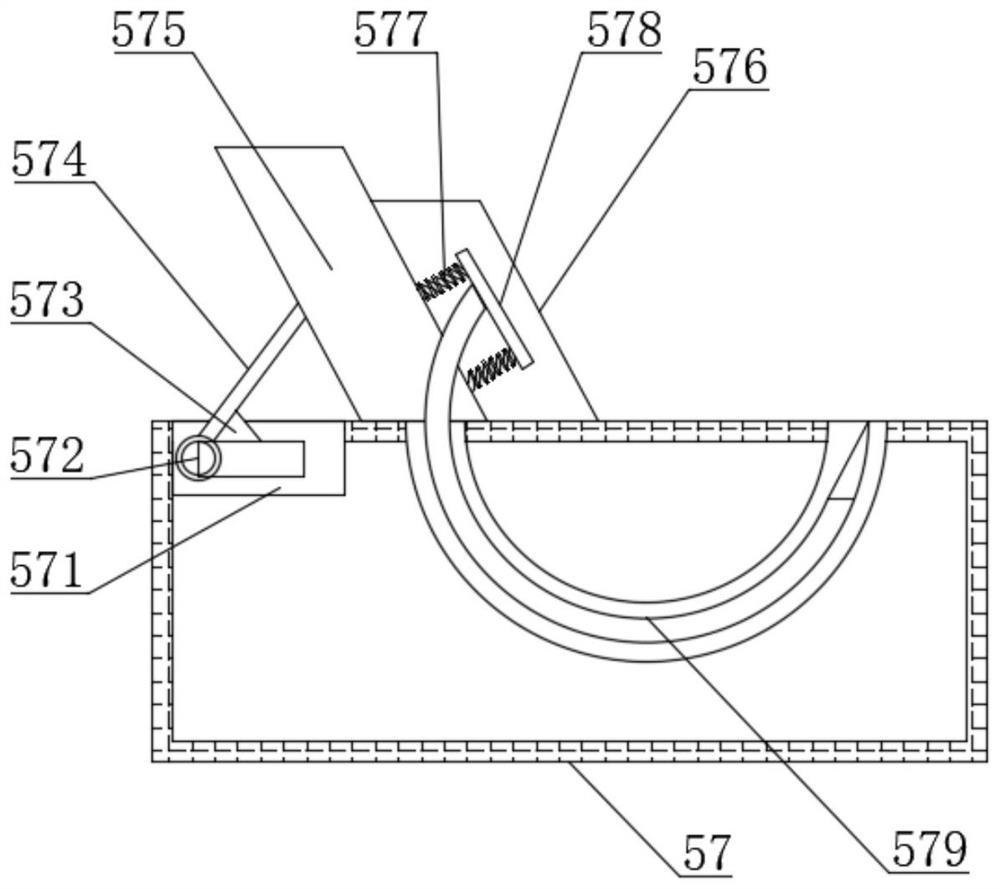

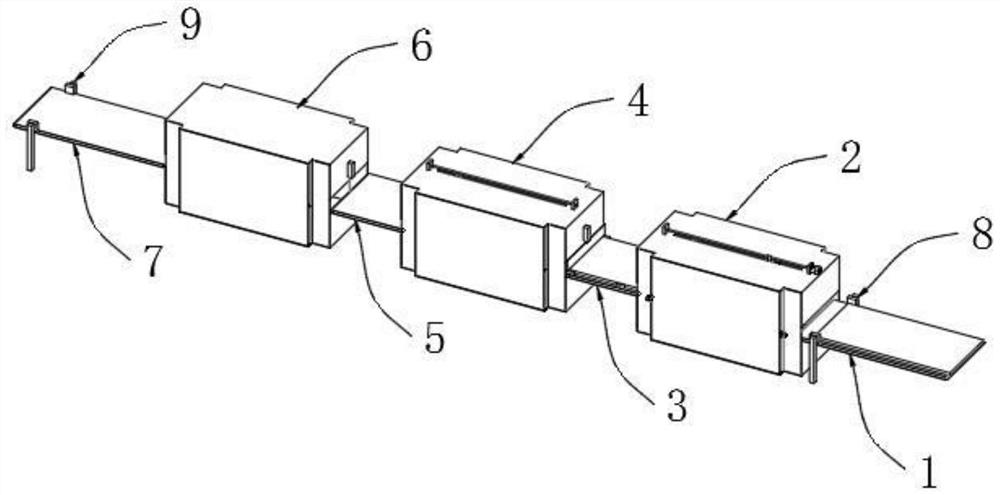

Electrostatic spraying equipment and process for wood door

ActiveCN112264234AImprove spraying effectLow costLiquid spraying plantsLiquid surface applicatorsStructural engineeringWood moisture

The invention provides electrostatic spraying equipment for a wood door. The electrostatic spraying equipment for the wood door comprises a first conveying belt, an infiltration box, a second conveying belt, a spraying box, a third conveying belt, a drying box and a fourth conveying belt, which are connected in sequence. The infiltration box comprises a first screw rod mechanism, a second screw rod mechanism, a third screw rod mechanism, a wood moisture detector and a roller bracket. First clamping blocks are slidably connected to the two sides, close to the first conveying belt, of the infiltration box, and second clamping blocks are slidably connected to the two sides, close to the second conveying belt, of the infiltration box. The top of the infiltration box is slidably connected withan atomization device. The wood moisture detector is arranged on the outer wall of the side, close to the second conveying belt, of the infiltration box. The roller bracket is arranged at the bottom of the infiltration box. The spraying box is used for carrying out electrostatic spraying operation on a first surface or a second surface of the wood door. The drying box is used for drying and curingthe first surface or the second surface of the wood door. By arranging the infiltration box, the spraying box and the drying box, electrostatic spraying operation on the wood door is achieved, the spraying effect is good, and the manufacturing cost is lower than that of imported equipment.

Owner:CHONGQING SHUAIZHIDUN DOOR IND

Microwave vacuum drying process of wood for solid wood ground heating flooring

InactiveCN108931108AImprove permeabilityImprove drying rateDrying solid materials with heatDrying solid materials without heatSolid woodPulp and paper industry

The invention discloses microwave vacuum drying process of wood for solid wood ground heating flooring. The microwave vacuum drying process comprises the following steps that a. the wood is placed into microwave processing equipment and the equipment is started; b, an accelerating drying stage is carried out, specifically, when the wood moisture content is more than 40-50%, first-time microwave radiation treatment is carried out on the wood, the radiation power is 1.3-1.6KW, the vacuum degree is adjusted to -0.065-(-0.07)Mpa, the radiation time is 4-6min, and the drying rate is maintained at 1.30-1.40% / min; c, a constant-speed drying stage is carried out, specifically, when the wood moisture content is between 45%-25%, second-time microwave radiation treatment is performed on the wood, theradiation power is 0.8-1.2KW, the vacuum degree is maintained at -0.055-(-0.065)Mpa, the radiation time is 18-25min, and the drying rate is maintained at 0.90-1% / min; d, a reduced drying stage is carried out, specifically, when the wood moisture content is less than 20-25%, the wood is subjected to third-time microwave radiation treatment, the radiation power is 0.4-0.7KW, the vacuum degree is maintained at -0.050-(-0.055)Mpa, the radiation time is 13-17min, and the drying rate is maintained at 0.5-0.6% / min; and e, a cooling stage is carried out, specifically, the wood is subjected to coolingto complete the microwave treatment process of the flooring.

Owner:JIUSHENG WOOD

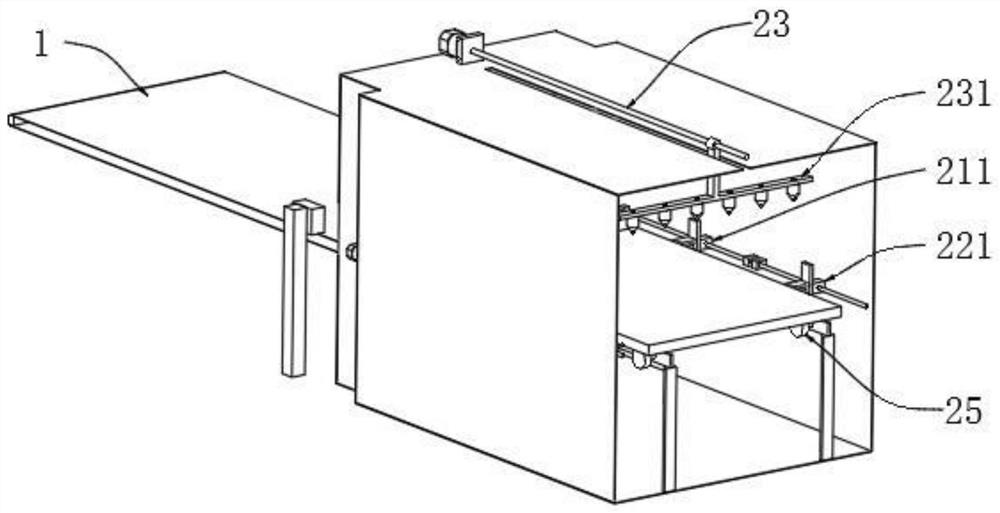

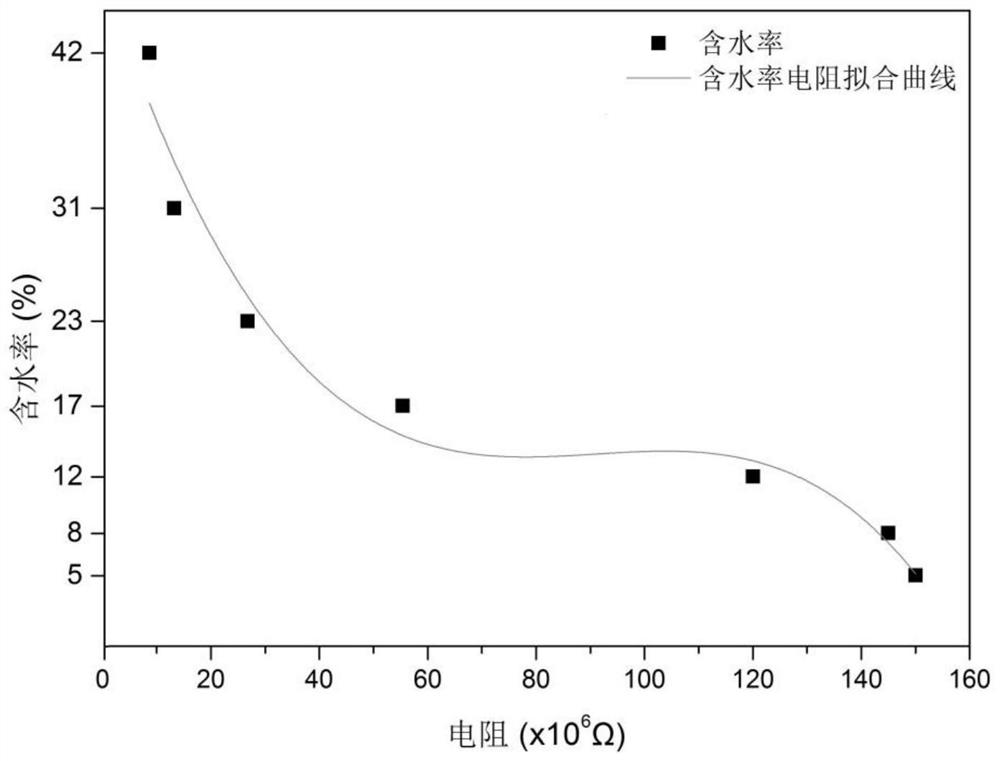

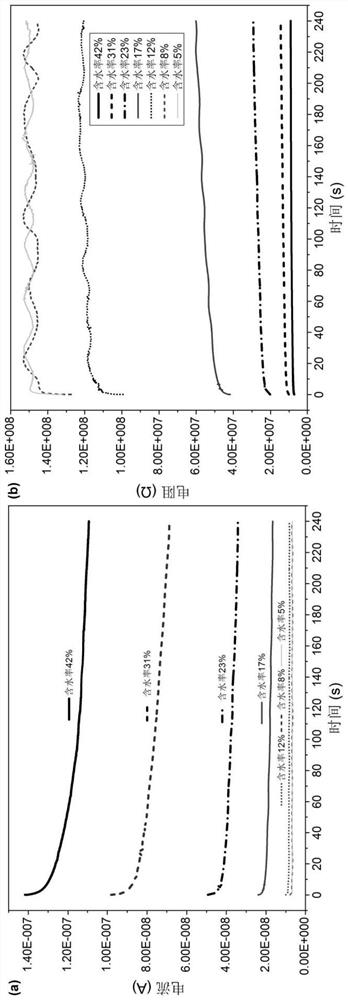

Online detection method and device for wood moisture content

PendingCN112378982ARealize online detectionImprove detection accuracyMaterial resistanceMaterial electrochemical variablesSoil scienceAgricultural engineering

The invention provides an online detection method and device for the wood moisture content. The online detection method for the wood moisture content comprises the following steps of connecting a to-be-detected sample to a probe of an electrochemical workstation to form a closed loop, measuring the current of the closed loop by using the electrochemical workstation, and obtaining the resistance ofthe to-be-measured sample, based on the resistance of the to-be-detected sample and according to the standard curve that the moisture content changes along with the resistance of the wood sample, acquiring the moisture content of the to-be-detected sample, wherein the density of the to-be-detected sample is approximately the same as that of the wood sample. According to the online detection method for the wood moisture content, online detection of all moisture content stages of the wood in the drying process can be achieved, and the detection precision is high.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Green mildew-proof treatment method for wood

ActiveCN106493812ALower structural groupGood long-term anti-mildew effectWood treatment detailsPressure impregnationWater vaporMildew

Belonging to the technical field of mildew proofing of wood, the invention relates to a green mildew-proof treatment method for wood. The mildew-proof treatment method is carried out according to the steps of: taking water vapor as the heating medium, introducing carbon dioxide at the same time, discharging air in a treatment tank to less than 5%, raising the temperature rapidly to 100-120DEG C, maintaining the pressure at 0.5-1MPa, and conducting heat preservation for 2-4h; further introducing water vapor, conducting air compressor pressurization, introducing carbon dioxide, performing heating to 120DEG C-150DEG C, maintaining the pressure at 1-3MPa, and conducting heat preservation for 4-8h; further introducing water vapor and carbon dioxide, maintaining the temperature at 120-150DEG C and the pressure at 1-2MPa, and performing drying to a water content of less than 5%; stopping introducing carbon dioxide, conducting spray cooling to less than 90DEG C, adjusting the humidity, and conducting natural cooling to obtain a wood moisture content of 4-8%. The method provided by the invention adopts synchronization of water vapor cooking and carbon dioxide extraction treatment, and has the advantages of green and environmental protection, safety and no harm, and good long-term mildew-proof effect, and can be used for preparing wooden toys for children, and home life articles for infants and children, etc.

Owner:云和县绿林幼教装备股份有限公司

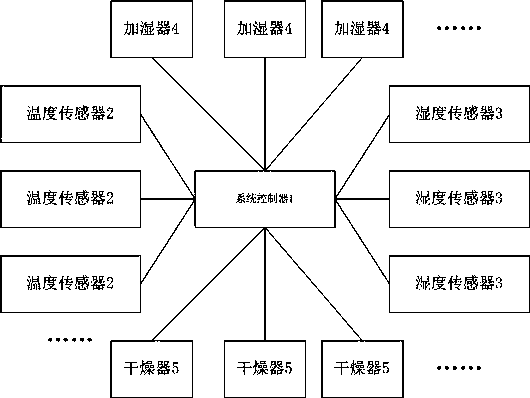

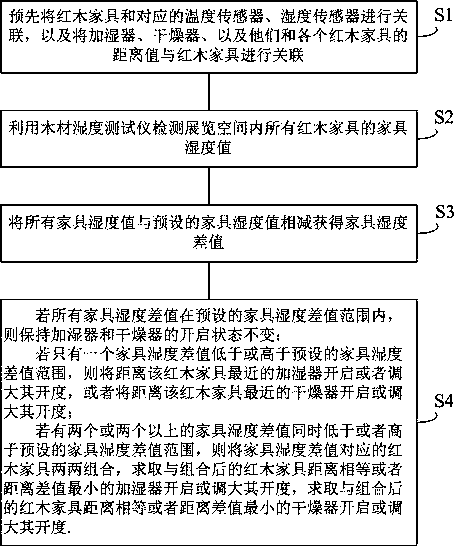

Mahogany furniture storage system with exhibition function and control method thereof

InactiveCN109085873AIntelligent daily maintenanceRealize daily maintenanceMeasurement devicesSimultaneous control of multiple variablesEngineeringWood moisture

The invention relates to a mahogany furniture storage system with an exhibition function and a control method thereof. The system is used in the exhibition space of mahogany furniture, which comprisesa wood moisture tester, a system controller, and a plurality of temperature sensors, a plurality of humidity sensors, and a plurality of humidifiers respectively connected to the system controller. The temperature sensors and the humidity sensors are respectively arranged within a certain range from the mahogany furniture, and each piece of mahogany furniture is provided with a temperature sensorand a humidity sensor; a plurality of humidifiers are arranged in the exhibition space to be linearly distributed from each mahogany furniture; and the system controller detects the humidity of the mahogany furniture through the wood moisture tester to obtain the humidity value of the mahogany furniture, acquires the detection data of the temperature sensors and the humidity sensors, and controlsone or more humidifiers to start or stop according to the acquired data. According to the mahogany furniture storage system with the exhibition function and the control method thereof, an intelligentdaily maintenance of the mahogany furniture can be realized.

Owner:深圳市红满庭红木文化有限公司

Eucalyptus veneer drying method

InactiveCN106996685AQuick removalAvoid deformationDrying gas arrangementsDrying machines with local agitationWood veneerEconomic benefits

The invention discloses a method for drying eucalyptus veneers, which comprises the following steps: (1) first stacking the eucalyptus veneers evenly on drying racks; (2) discharging the drying racks into a drying kiln, keeping the drying racks The gap is 30-60cm; (3) Heat the drying kiln by steam, raise the temperature to 45-85°C, and keep the constant temperature for 20-40h; (4) Finally cool down to 40°C, and use the moisture meter to detect the moisture content of the wood to reach the required moisture content After the rate is within, stop heating. A kind of eucalyptus veneer drying method of the present invention uses steam to heat the drying kiln to dry the eucalyptus veneer, not only can quickly remove the moisture of the eucalyptus veneer, but also avoid its large deformation, Help to improve product quality and economic benefits.

Owner:广西贵港市长雄干燥科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com