Wood drying method and device for implementing same

A wood and cooling device technology, applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of core material moisture not evaporating, high drying cost, narrow application range, etc., to facilitate mass production , fast drying speed and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

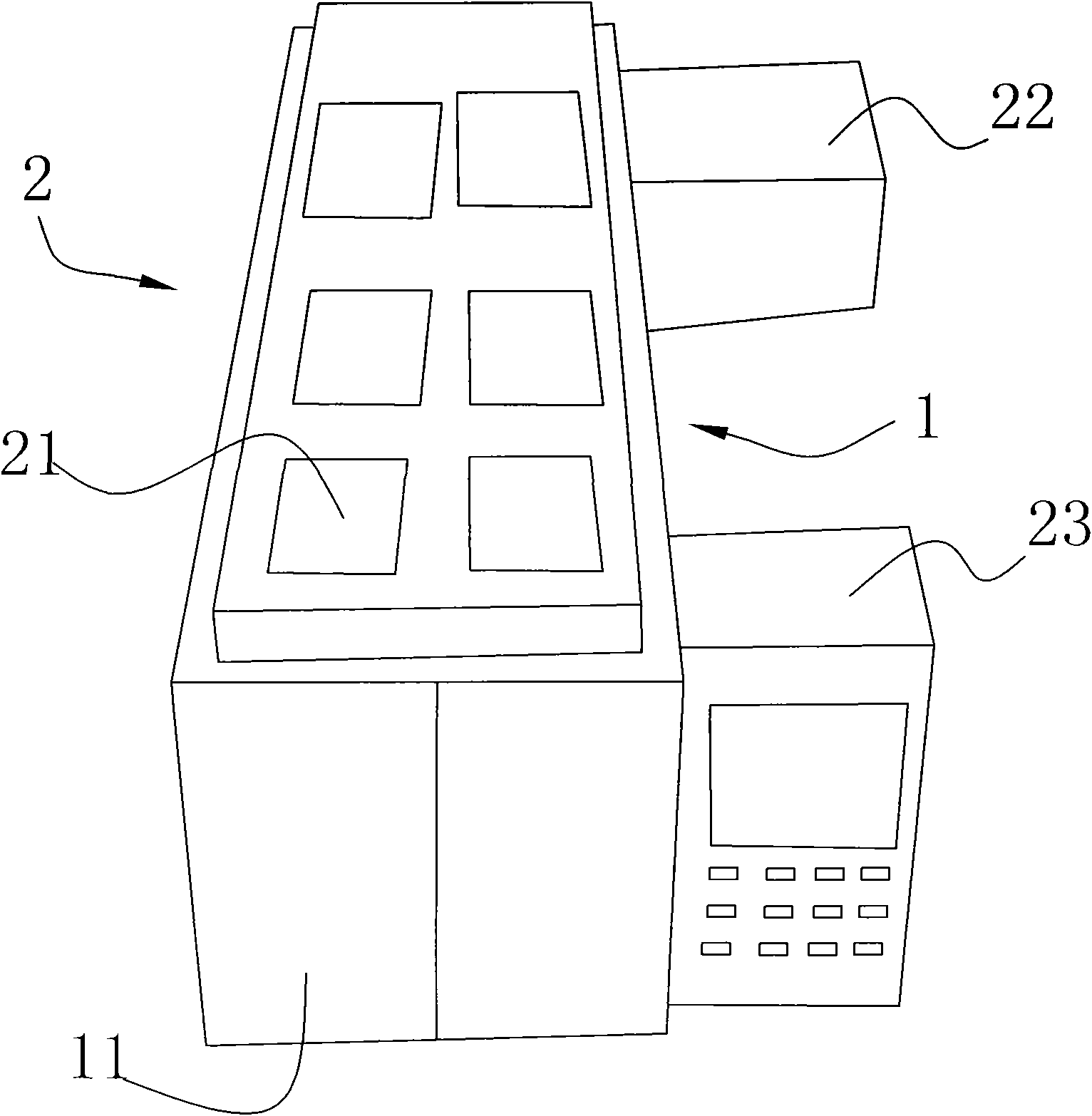

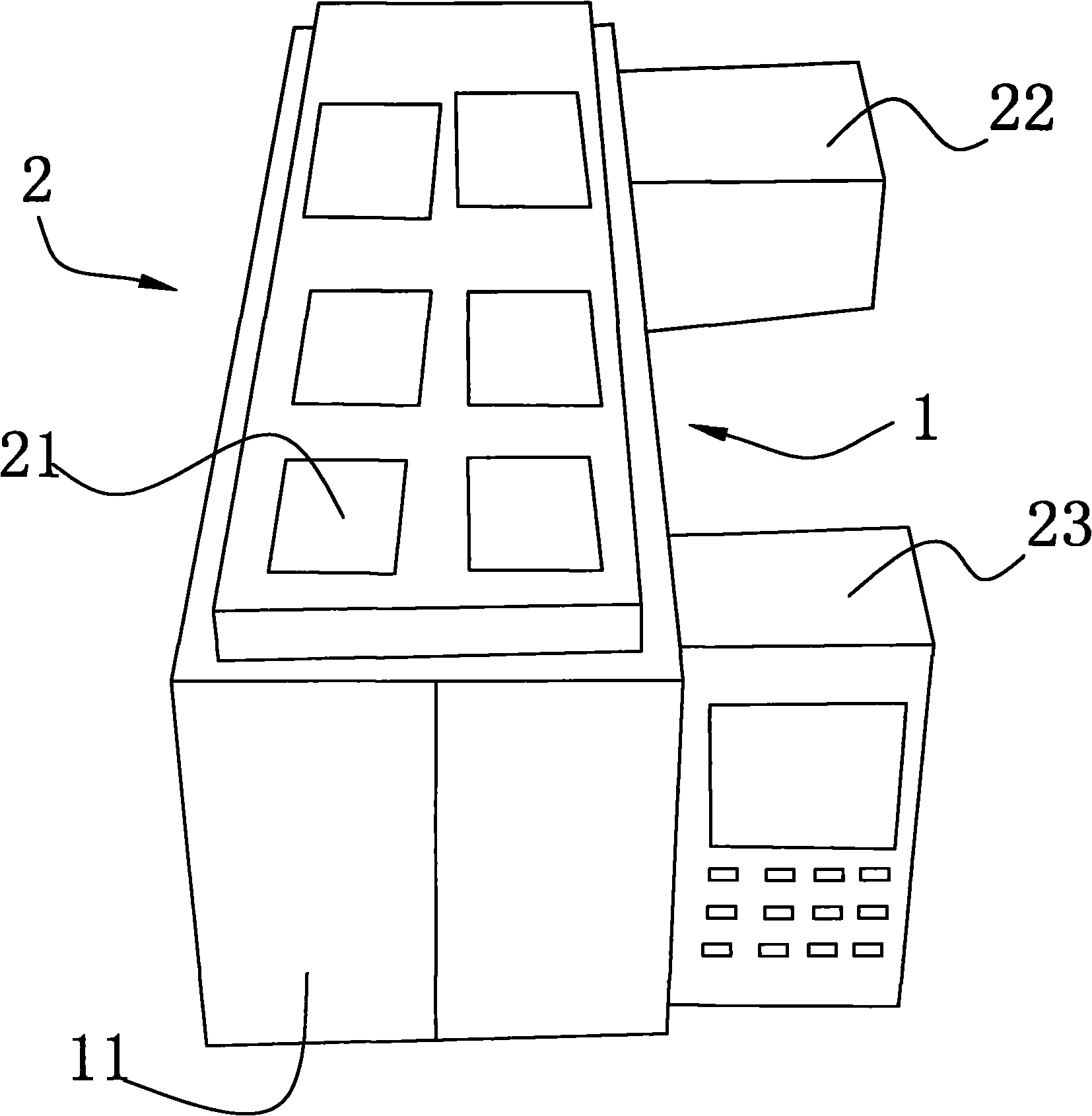

[0026] see figure 1 , a kind of wood drying method provided by the present embodiment, it comprises the following steps:

[0027] (1) Prepare a box body 1 that can accommodate multiple pieces of wood;

[0028] (2) A microwave drying system 2 is set up to generate a radiant microwave electromagnetic field that can penetrate the interior of the wood. The electromagnetic field interacts with the water molecules in the wood to generate heat, causing the wood moisture to evaporate rapidly and generate water vapor to achieve thorough drying. Effect. The method provided by the invention can carry out drying treatment on thick wood, and the process is simple, the processing cost is reduced, and it is beneficial to batch production;

[0029] Described step (1) specifically comprises the following steps:

[0030] (1.1) Cut out a plurality of strips of plank timber;

[0031] (1.2) A box door 11 is provided on the side wall of the box body 1;

[0032] (1.3) Open the box door 11, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com