Stable enhanced type solid wood profile and production method thereof

A production method and enhanced technology, applied in the direction of wood impregnation, impregnated wood, wood processing equipment, etc., can solve the problems of accelerating hemicellulose, cellulose degradation, reducing the mechanical properties of wood, and large residual stress of wood, so as to eliminate stress , Reduce drying defects, reduce surface polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

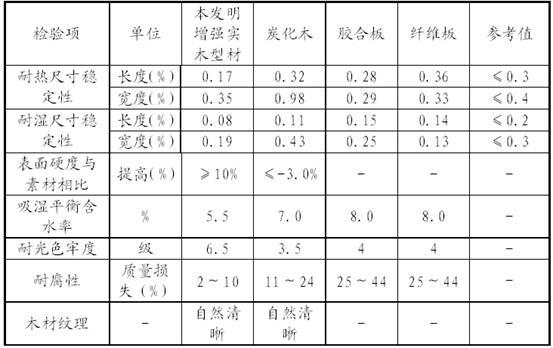

Image

Examples

Embodiment 1

[0042] a. Drying treatment: The southern pine boards with a specification of 4000×150×50mm are stacked in a drying kiln with glass walls on the east, west and south sides, with solar energy as the main heat source and hot gas from burning fuel As an auxiliary heat source, use sprinklers and ventilation holes to adjust the humidity, and use fans to cause forced circulation to achieve the purpose of drying, so that the moisture content of the wood is as low as 6.0%, the deviation of the moisture content in the thickness of the wood is less than 2.0%, and the internal residual stress of the wood is 2.0%. ;

[0043] b. Carbonization treatment: neatly stack the dried wood and press 1t / m on the top of the wood pile 2 The standard pressurized steel plate frame pours concrete briquettes, and then puts them into the wood carbonization equipment, heats up and humidifies rapidly, the temperature rises to 90°C, and the humidity is humidified to 80% relative humidity, keep for 4 hours, and...

Embodiment 2

[0049] a. Drying treatment: Pile poplar wood with a specification of 930×125×22mm in a drying kiln with glass walls on the east, west and south sides, use hot water or steam as the drying medium, and use water spray The humidity is adjusted by the device and ventilation holes, and the fan is used to cause forced circulation to achieve the purpose of drying, so that the moisture content of the wood is as low as 5.0%, the moisture content deviation of the wood thickness is 1.5%, and the internal residual stress of the wood is 1.8%;

[0050] b. Carbonization treatment: neatly stack the dried wood and press 1t / m on the top of the wood pile 2 The standard pressurized steel plate frame pours concrete briquettes, and then puts them into the wood carbonization equipment, heats up and humidifies rapidly, the temperature rises to 80°C, and the humidity is humidified to 70% relative humidity, keep for 2 hours, and then adopt the stepwise heating method according to Raise the temperature ...

Embodiment 3

[0057] a. Drying treatment: put the longan with a specification of 2000×200×32mm in a vacuum tank to heat and evacuate the wood, resulting in a water vapor pressure difference from the inside of the wood to the surface and from the surface to the outside; due to the water vapor pressure in the wood The boiling point of water is lowered under vacuum, and it is easy to gasify, so that the water is easily evaporated from the wood and extracted from the vacuum tank, so that the wood moisture content is as low as 8.0%, the moisture content deviation of the wood thickness is 1.0%, and the internal residual stress of the wood is 1.0% %;

[0058] b. Carbonization treatment: neatly stack the dried wood and press 1t / m on the top of the wood pile 2 The standard pressurized steel plate frame pours concrete briquettes, and then puts them into the wood carbonization equipment, heats up and humidifies rapidly, the temperature rises to 85°C, and the humidity is humidified to 75% relative humi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| release amount | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com