Swash plate of swash plate compressor

A compressor and swash plate technology, applied in the swash plate field of swash plate compressors, can solve the problems of surface treatment process, sticking between swash plate and sliding shoes, surface roughness and flatness of parts and other parameter accuracy Low problems, to achieve the effect of excellent lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

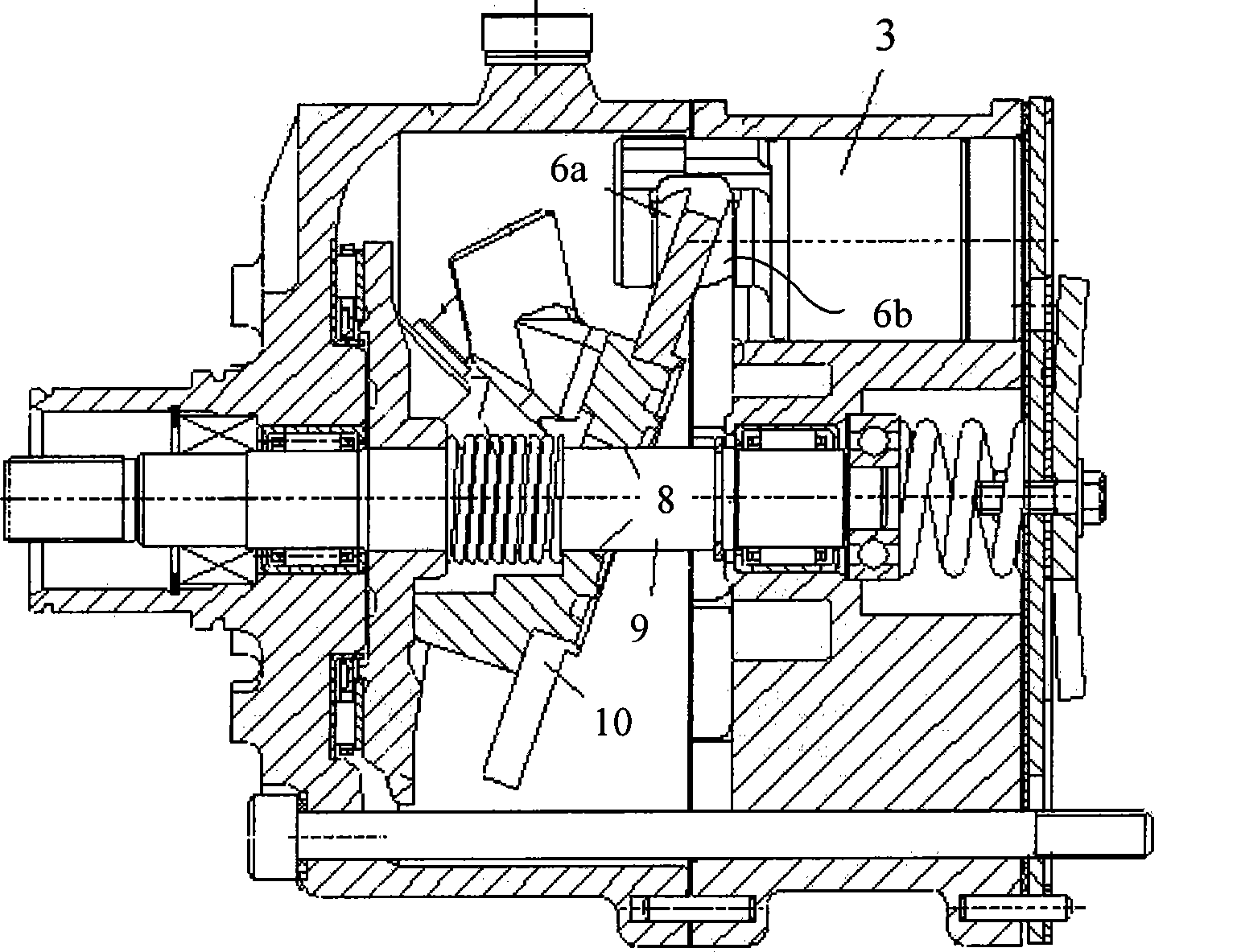

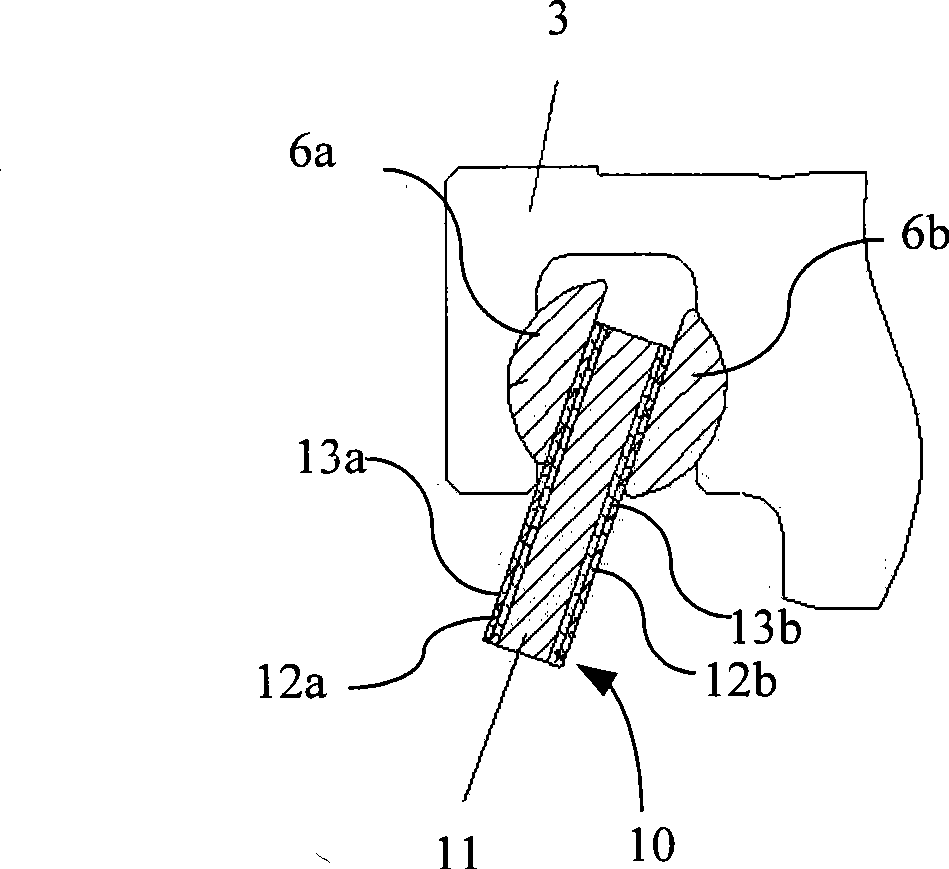

[0015] Please refer to figure 2 As shown, the swash plate 10 in this embodiment is a composite structure with a matrix 11 and two surface layers 12a, 12b. The material of the matrix 11 is, for example, 45# steel, and the material of the two surface layers 12a, 12b is copper alloy. The main components of the copper alloy are calculated by weight, including 78-82% of copper, 9-11% of lead and 9-11% of tin. This composite structure is made, for example, by powder metallurgy sintering technology, which has the characteristics of low cost and high performance, and the parts made have a certain porosity, and are often used in the manufacture of self-lubricating materials. The main process of powder metallurgy sintering technology includes sintering and pressing the powdered copper alloy on the substrate made of 45# steel by adopting the process of "pre-sintering → pre-pressing → deep-sintering → fine-pressing → final-sintering". The temperature of the deep sintering process reache...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com