Preparation method for loss-resistance water-based wood preservative

A wood preservative and anti-loss technology, which is applied in the direction of wood impregnation, impregnated wood, wood processing equipment, etc., can solve the problems of endangering aquatic organisms and the decline of anti-corrosion effect, and achieve improved anti-corrosion, increased density, and improved anti-loss performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

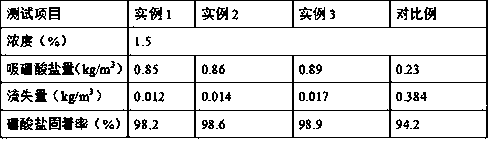

Examples

example 1

[0024] Put rosin, isopropanol and sodium hydroxide into a four-neck flask equipped with a thermometer, stirrer and reflux device at a mass ratio of 3:4:1, put it in a water bath, heat up to 60°C, and keep stirring for 20 minutes , then add epichlorohydrin equal to the quality of rosin and triethylamine with 70% of the mass of rosin to the four-neck flask, reflux at 75°C for 18 hours, and then distill and recover the unreacted epichlorohydrin and triethylamine to obtain the cation Thick rosin liquid, weigh the pomegranate peel and put it into a tissue grinder to grind for 20 minutes to obtain the crushed pomegranate peel, mix the crushed pomegranate peel and water at a mass ratio of 1:20 to obtain a mixed solution, and then add Sodium sulfite with 0.5% pomegranate peel mass, heated in an oil bath to 100°C for 3 hours, then filtered and separated to obtain the filtrate, which is the pomegranate peel extract. Soybeans, milk and 50% sodium chloride solution with a mass fraction of ...

example 2

[0026]Put rosin, isopropanol and sodium hydroxide into a four-neck flask equipped with a thermometer, agitator and reflux device according to the mass ratio of 3:4:1, put it in a water bath, heat up to 65°C, keep stirring for 25min , then add epichlorohydrin equal to the quality of rosin and triethylamine with 75% of the mass of rosin to the four-neck flask, reflux at 80°C for 19 hours, and then recover unreacted epichlorohydrin and triethylamine by distillation to obtain cations Thick rosin liquid, weigh the pomegranate peel and put it into a tissue grinder to crush for 25 minutes to obtain the crushed pomegranate peel, mix the crushed pomegranate peel and water at a mass ratio of 1:20 to obtain a mixed solution, and then add Sodium sulfite with 0.6% pomegranate peel mass, heated in an oil bath to 103°C for 4 hours, then filtered and separated to obtain the filtrate, which is the pomegranate peel extract. Soybeans, milk, and 50% sodium chloride solution with a mass fraction of...

example 3

[0028] Put rosin, isopropanol and sodium hydroxide into a four-necked flask equipped with a thermometer, stirrer and reflux device at a mass ratio of 3:4:1, put it in a water bath, heat up to 70°C, and keep stirring for 30 minutes , then add epichlorohydrin equal to the quality of rosin and triethylamine with 80% of the mass of rosin to the four-neck flask, reflux reaction at 85°C for 20h, and then recover the unreacted epichlorohydrin and triethylamine by distillation to obtain the cation Thick rosin liquid, weigh the pomegranate peel and put it into a tissue grinder to crush for 30 minutes to obtain the crushed pomegranate peel, mix the crushed pomegranate peel and water at a mass ratio of 1:20 to obtain a mixed solution, and then add Sodium sulfite with 0.8% pomegranate peel mass was heated in an oil bath to 105°C for 5 hours, and the filtrate was obtained by filtration and separation, which was the pomegranate peel extract. Soybeans, milk, and 50% sodium chloride solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com