Thin blockboard and manufacturing method thereof

A technology for blockboard and poplar veneer, which is applied in the direction of manufacturing tools, wood-layered products, wood processing appliances, etc. Shelf life, insect repellant effect lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

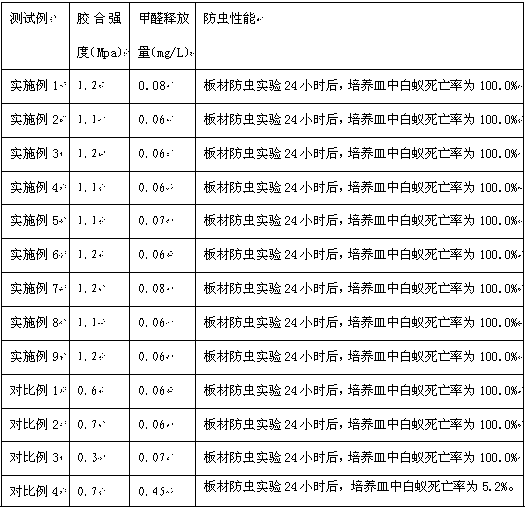

Examples

Embodiment 1

[0056] Modified soybean gum configuration: Add 3g of alkali and 100g of water into a three-neck round bottom flask, the alkali is sodium hydroxide, stir for 3 minutes to dissolve the sodium hydroxide, then add 0.5g of silicate, 0.5 g sulfite and 0.2g modifier, the silicate is sodium silicate, the modifier is urea, the sulfite is sodium sulfite, and stirred for 3 minutes, the temperature is 80-96 °C to obtain a preliminary mixed solution; then add 15 g of soybean derivatives to the preliminary mixed solution, the soybean derivatives are soybean protein isolate, stir for 10 minutes, and the temperature is 80 °C, so that the soybean protein isolate is fully dispersed in the solution, Obtain a mixed solution; then add 0.3 g of an aqueous solution of curing agent polyamide polyamine-epichlorohydrin (PAE) with a mass concentration of 12.5%, and stir for 10 minutes to obtain a solidified mixed solution; then add an acid, the acid being 0.1 The mass concentration of phosphoric acid wa...

Embodiment 2

[0059] With embodiment 1, difference is that described alkali is calcium hydroxide; Described silicate is potassium silicate; Described acid is oxalic acid; Described pyrethroid insect repellant is fenvalerate and permethrin; The filler is flour; the soybean derivative is soybean protein powder.

Embodiment 3

[0061] With embodiment 1, difference is that described alkali is calcium hydroxide; Described silicate is sodium silicate; Described acid is oxalic acid; Described pyrethroid insect repellant is fenvalerate, bifenthrin and phenthrin; the filler is diatomaceous earth bentonite; the soybean derivative is soybean protein powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com